ASTM A672bututun karfe ne da aka yi daga farantin ingancin jirgin ruwa,Wutar Lantarki-Fusion-Welded (EFW)don sabis na matsa lamba a matsakaicin zafi.

Maɓallan kewayawa

ASTM A672 Rarraba Grade

ASTM A672 Rarraba

ASTM A672 Size Range

Kariyar walda

Maganin zafi

Abubuwan sinadaran

Gwajin tashin hankali

Gwaje-gwajen Juyawa-Jagora-Weld-Lankwasa

Gwajin Matsi

Gwajin Radiyo

Juriyar girman girman ASTM A672

Bayanin ASTM A672

Lalacewa da Gyara

ASTM A672

Aikace-aikace na ASTM A672 Karfe bututu

Kayayyakinmu masu alaƙa

ASTM A672 Rarraba Grade

An rarraba bisa ga nau'in farantin da ake amfani da shi don kera bututun ƙarfe.

Maki daban-daban suna wakiltar nau'ikan sinadarai daban-daban da kaddarorin inji don matsi daban-daban da yanayin zafin jiki.

| Bututu Grade | Nau'in Karfe | Bayanin ASTM | |

| A'a. | Daraja | ||

| A 45 | carbon mai haske | A285 / A285M | A |

| A50 | carbon mai haske | A285 / A285M | B |

| A 55 | carbon mai haske | A285 / A285M | C |

| B 60 | carbon fili, ya mutu | A515/A515 | 60 |

| B 65 | carbon fili, ya mutu | A515/A515 | 65 |

| B 70 | carbon fili, ya mutu | A515/A515 | 70 |

| C 55 | carbon fili, kashe, lafiyayyen hatsi | A516/A516 | 55 |

| C 60 | carbon fili, kashe, lafiyayyen hatsi | A516/A516 | 60 |

| C 65 | carbon fili, kashe, lafiyayyen hatsi | A516/A516 | 65 |

| C 70 | carbon fili, kashe, lafiyayyen hatsi | A516/A516 | 70 |

| D 70 | manganese-silicon, al'ada | A537/A537M | 1 |

| D 80 | manganese-silicon, Q&TA | A537/A537M | 2 |

| H 75 | manganese-molybdenum, al'ada | Saukewa: A302M | A |

| H 80 | manganese-molybdenum, al'ada | Saukewa: A302M | B, C, ko D |

| J 80 | manganese-molybdenum, Q&TA | A533/A533 | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533/A533 | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533/A533 | Cl-3B |

| L 65 | molybdenum | A204/A204M | A |

| L 70 | molybdenum | A204/A204M | B |

| L 75 | molybdenum | A204/A204M | C |

| N75 | manganese - siliki | A299 / A299M | A |

AQ&T = kashewa da fushi.

ВAna iya samar da kowane daraja.

Za mu iya da farko ƙayyade nau'in bututun ƙarfe ta haruffa a cikin sa.

Maki da suka fara da haruffa A, B, da C yawanci suna nunawacarbon karfe bututu.

Makin da suka fara da haruffa D, H, J, L, da N suna nunagami karfe bututu.

ASTM A672 Rarraba

An rarraba bututun bisa ga nau'in maganin zafi da suke karɓa yayin aikin masana'antu da kuma ko an duba su ta hanyar rediyo da gwada matsa lamba.

| Class | Maganin zafi akan bututu | Radiyo, duba bayanin kula: | Gwajin matsin lamba, duba bayanin kula: |

| 10 | babu | babu | babu |

| 11 | babu | 9 | babu |

| 12 | babu | 9 | 8.3 |

| 13 | babu | babu | 8.3 |

| 20 | an kawar da damuwa, duba 5.3.1 | babu | babu |

| 21 | an kawar da damuwa, duba 5.3.1 | 9 | babu |

| 22 | an kawar da damuwa, duba 5.3.1 | 9 | 8.3 |

| 23 | an kawar da damuwa, duba 5.3.1 | babu | 8.3 |

| 30 | al'ada, duba 5.3.2 | babu | babu |

| 31 | al'ada, duba 5.3.2 | 9 | babu |

| 32 | al'ada, duba 5.3.2 | 9 | 8.3 |

| 33 | al'ada, duba 5.3.2 | babu | 8.3 |

| 40 | al'ada da fushi, duba 5.3.3 | babu | babu |

| 41 | al'ada da fushi, duba 5.3.3 | 9 | babu |

| 42 | al'ada da fushi, duba 5.3.3 | 9 | 8.3 |

| 43 | al'ada da fushi, duba 5.3.3 | babu | 8.3 |

| 50 | mai kashewa da fushi, duba 5.3.4 | babu | babu |

| 51 | mai kashewa da fushi, duba 5.3.4 | 9 | babu |

| 52 | mai kashewa da fushi, duba 5.3.4 | 9 | 8.3 |

| 53 | mai kashewa da fushi, duba 5.3.4 | babu | 8.3 |

Ya kamata a biya kulawa ta musamman ga zafin sabis da ake tsammanin lokacin zabar ajin kayan da ya dace.Koma zuwa takamaiman ASTM A20/A20M.

ASTM A672 Size Range

Girman girman da aka ba da shawarar:DN≥400mm[16 in] da WT≤75mm[3 in].

Don sauran girman bututu, idan har ya cika duk sauran buƙatun wannan ƙayyadaddun, ana iya amfani da shi.

Kariyar walda

Seams za a yi walda biyu, cikakken shigar da waldi.

Za a yi walda ko dai da hannu ko ta atomatik ta tsarin lantarki wanda ya haɗa da jigon ƙarfe na filler.

Ana iya bincika welds ta amfani da rediyo kuma ya kamata a bi tanadi a Sashe na VII UW-51 na ASME Boiler da Lambar Jirgin Ruwa.

Tsayin walda ba zai wuce mm 3 [1/8 in ba].

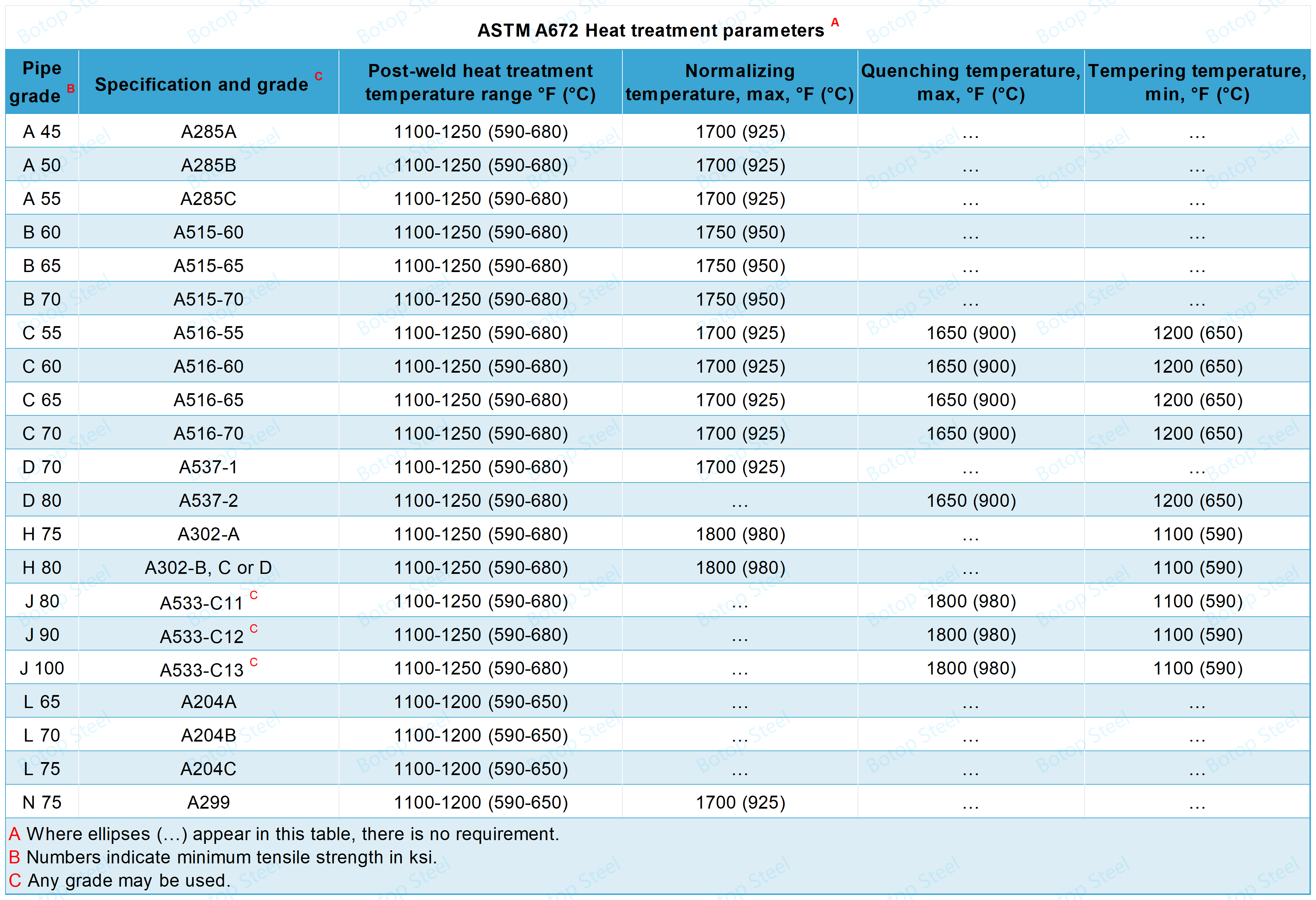

Maganin zafi

Duk azuzuwan ban da 10, 11, 12, da 13 za a kula da zafi a cikin tanderun da aka sarrafa zuwa ± 25 °F[± 15°C]:

Darasi na 20, 21, 22, da 23

Dole ne a yi zafi da bututu iri ɗaya a cikin kewayon zafin jiyya mai zafi bayan walda wanda aka nuna a cikin Tebu 2 don ƙarancin 1 h/in.[0.4 h/cm] na kauri ko na 1 h, duk wanda ya fi girma.

Darasi na 30, 31, 32, da 33

Za a yi zafi da bututu iri ɗaya zuwa zafin jiki a cikin kewayon austenitizing kuma kada ya wuce matsakaicin matsakaicin zafin jiki da aka nuna a cikin Tebu 2 kuma daga baya a sanyaya shi a cikin iska a zazzabi na ɗaki.

Darasi na 40, 41, 42, da 43

Za a daidaita bututun.

Za a sake mai da bututun zuwa zafin zafin da aka nuna a cikin Tebura 2 a matsayin mafi ƙanƙanta kuma a riƙe shi a zafin jiki mafi ƙarancin 0.5 h/in. [0.2 h/cm] na kauri ko don1/2h, duk wanda ya fi girma, kuma mai sanyaya iska.

Darasi na 50, 51, 52, da 53

Za a yi zafi da bututu iri ɗaya zuwa yanayin zafi a cikin kewayon austenitizing kuma kada ya wuce matsakaicin yanayin zafi da aka nuna a Tebur 2.

Daga baya, a kashe a cikin ruwa ko mai.Bayan quenching, bututu za a sake zafi zuwa mafi ƙarancin zafin jiki wanda aka nuna a cikin Tebu 2 kuma a riƙe shi a wancan.

zafin jiki mafi ƙanƙanta na 0.5 h/inch [0.2 h/cm] na kauri ko 0.5 h, duk wanda ya fi girma, da sanyaya iska.

Abubuwan sinadaran

Zai zama alhakin masana'anta don gwada nau'in sinadarai na farantin da walda don biyan buƙatun ƙayyadaddun farantin don kayan da aka ba da umarnin da tsarin walda don ajiyar ƙarfe na walda, bi da bi.

Gwajin tashin hankali

Mitar gwaji: samfuri ɗaya a kowace kuri'a.

Hanyar Gwaji: Za a yi samfurori na gwaji daidai da QW-150 a cikin Sashe na IX na ASME Boiler da Lambar Jirgin Ruwa.Za a gwada samfurori a zafin jiki daidai da Hanyoyin Gwaji da Ma'anar A370.

Bugu da kari ga Grades Dxx, Hxx, Jxx, da Nxx a cikin Classes 3x, 4x, da 5x transverse tensile Properties na gindin farantin, za a ƙayyade a kan samfurori da aka yanke daga bututun da aka yi wa zafi.

Abubuwan da ake bukata don sakamako: Abubuwan juzu'i masu jujjuyawar haɗin gwiwar welded za su hadu da mafi ƙarancin buƙatu don ƙarfin ƙarshe na ƙayyadaddun farantin kayan.

Gwaje-gwajen Juyawa-Jagora-Weld-Lankwasa

Yawan Gwaji: Mitar gwaji: sau ɗaya a kowane tsari, samfurori biyu

Hanyar gwaji: Abubuwan buƙatun gwaji na hanyoyin gwaji da ma'anar A370, sakin layi na A2.5.1.7 za a cika su.

Don kaurin bango ya wuce3/ 8in. [10mm] amma kasa da3/4in. [19 mm] Za a iya yin gwaje-gwajen gefe-lankwashe maimakon gwajin fuska da tushen lankwasa.

Don kaurin bango3/4in. [19 mm] kuma sama da duka samfuran duka za a yi gwajin gefen-lankwasa.

Abubuwan da ake bukata don sakamako: Gwajin lanƙwasawa za a karɓa idan babu fasa ko wasu lahani da suka wuce1/8in. [3 mm] a kowace hanya suna kasancewa a cikin ƙarfen walda ko tsakanin walda da ƙarfe na tushe bayan lanƙwasa.

Fashewar da ke tasowa tare da gefuna na samfurin yayin gwaji, kuma waɗanda ba su kai ba1/4in. [6 mm] da aka auna ta kowace hanya ba za a yi la'akari da shi ba.

Gwajin Matsi

Za a gwada bututun azuzuwan X2 da X3 daidai da ƙayyadaddun A530/A530M, Bukatun Gwajin Hydrostatic.

Gwajin Radiyo

Cikakken tsawon kowane weld na Azuzuwan X1 da X2 za a gwada su ta hanyar rediyo daidai da kuma biyan buƙatun ASME Boiler da Lambar Jirgin Ruwa, Sashe na VIII, Sakin layi na UW-51.

Ana iya yin gwajin rediyo kafin a yi maganin zafi.

Juriyar girman girman ASTM A672

| Wasanni | Darajar Haƙuri | Lura |

| Waje Diamita | ± 0.5% | Dangane da ma'aunin kewaye |

| Fita-da-Roundness | 1%. | Bambanci tsakanin manya da ƙananan diamita na waje |

| Daidaitawa | 1/8 in. [3 mm] | Yin amfani da madaidaicin gefen kafa 10 (m3) wanda aka sanya shi ta yadda iyakar biyu su kasance cikin hulɗa da bututu |

| Kauri | 0.01 in. [0.3mm] | Mafi ƙarancin kaurin bango ƙasa da ƙayyadadden kauri maras tushe |

| Tsawon tsayi | 0-+0.5in [0-+13mm] | ƙarewar da ba a sarrafa ba |

Bayanin ASTM A672

Bututun da aka gama ba zai zama mara lahani ba kuma ya kasance yana da ƙarewa kamar mai aiki.

Abubuwan buƙatu iri ɗaya kamar a cikin ƙayyadaddun ASTM A20/A20M don ƙare saman faranti na ƙarfe.

Lalacewa da Gyara

Ƙaddamar Ƙaddamarwa

Ma'auni na ASTM A672 baya ƙayyadaddun matakan da aka yarda da lahani da ƙayyadaddun ƙayyadaddun bututun bututu kuma yawanci yana nufin ƙa'idodin injiniya masu dacewa da ayyukan masana'antu.

Lalacewar ciki: Lalacewar ciki na iya haɗawa da porosity, slag, inclusions, da sauransu.

Lalacewar waje: Lalacewar waje na iya haɗawa da tsage-tsage, ƙulle-ƙulle, karce, da sauransu.

Cire ta Reriding

Ana iya cire lahani na saman ta hanyar niƙa ko injina tare da ragowar kauri wanda bai gaza 0.3 mm ƙasa da daidaitaccen kauri ba.

Ya kamata a haɗa baƙin ciki na regrind iri ɗaya zuwa saman kewaye.

Gyaran walda

Za a cire lahani ta hanyar ingantattun injiniyoyi ko yanke zafi ko hanyoyin dicing kuma a shirya don gyara kogon welded.

kuma an bincika ta hanyar rediyo daidai da ASME Boiler da Lambar Jirgin Ruwa, Sashe na VIII, Sakin layi na UW-51.

Cikakken tsawon bututun da aka gyara za a yi zafi da zafi bayan gyara daidai da ƙayyadaddun buƙatun bututun bututu.

ASTM A672

Alamar ta ƙunshi abubuwa masu zuwa:

Mai gano mai ƙira, kamar alamar kasuwanci ko tambari.

Ƙayyadaddun bututu (girman, kauri na bango, da dai sauransu).

Matsayin kayan abu ko nau'in bututu.Misali: C60-22 (taƙaice ga maki: C60 da aji 22).

Matsayin masana'anta na bututu shine ASTM A672.

Kwanan samarwa ko lambar adadin samarwa.

Aikace-aikace na ASTM A672 Karfe bututu

A cikin masana'antar wutar lantarki, ASTM A672 Electric Welded Karfe bututu ana yawan amfani dashi don isar da tururi a cikin tsarin tukunyar jirgi.

A cikin masana'antar sinadarai, ASTM A672 welded karfe bututu yawanci amfani dashi don jigilar sinadarai daban-daban, maganin acid, da alkali, da sauran kafofin watsa labarai.

A cikin masana'antar mai da iskar gas, ana amfani da bututun ƙarfe na ASTM A672 da aka yi wa walda don safarar ɗanyen mai, iskar gas, da sauran ruwa ko gas.

Mu ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun masana'anta ce kuma masu siyarwa daga China, har ila yau, ƙwararrun ƙwararrun bututun ƙarfe mara nauyi, suna ba ku nau'ikan mafita na bututun ƙarfe!

Tags: ASTM A672, efw, carbon karfe bututu, sa.

Lokacin aikawa: Afrilu-23-2024