ASTM A178ʻO nā paipu kila he mau paipu hoʻopaʻa uila i wiliwili ʻia (RW) okalapona a me carbon-manganese kilahoʻohana ʻia e like me nā paipu boiler, nā ʻauheʻe paila, nā ʻauheʻe superheater, a me nā hopena palekana.

He kūpono ia no nā paipu kila me ke anawaena o waho o 12.7-127mm a me ka mānoanoa o ka pā ma waena o 0.9-9.1mm.

Ua kūpono nā paipu ASTM A178 no nā paipu welded kū'ē menā anawaena waho ma waena o 1/2 - 5 in [12.7 - 127 mm] a me ka mānoanoa o ka paia ma waena o 0.035 - 0.360 in [0.9 - 9.1 mm], ʻoiai aia nā ʻano nui ʻē aʻe e like me ka mea e pono ai, inā e hoʻokō kēia mau paipu i nā koi ʻē aʻe a pau o kēia kikoʻī.

ʻEkolu mau māka no ka hoʻokō ʻana i nā kaiapuni hoʻohana like ʻole.

Papa A, Papa C, a me Papa D.

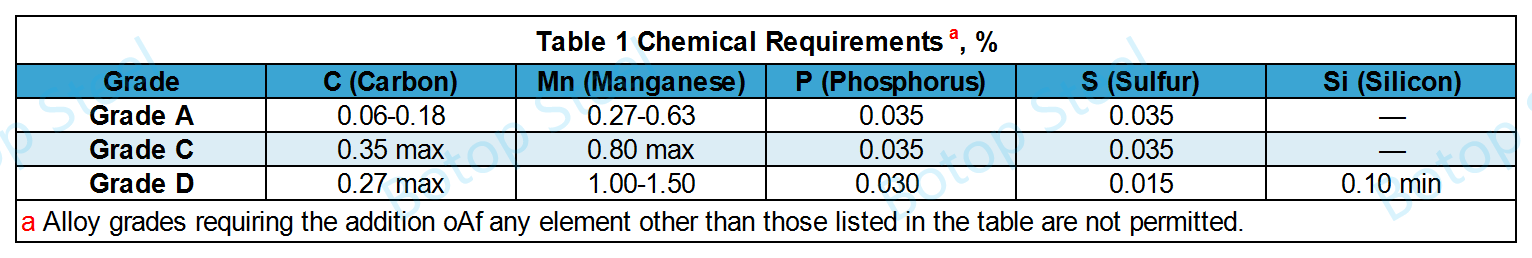

| Papa | ʻAno ʻano hao kalapona |

| Papa A | Haʻahaʻa-Carbon Steel |

| Papa C | Medium-Carbon Steel |

| Papa D | ʻO ka hao hao-mangane |

Pono nā mea i hoʻolako ʻia ma lalo o kēia kikoʻī i nā koi kūpono o ka paʻi o kēia manawa o ka Specification A450/A450M. ke ole i hoakakaia maanei.

Papa AaPapa Cmai kuhikuhi i kahi kila kūikawā; koho i ka mea maka e pono ai.

ʻO ke kila noPapa De pepehiia.

Hana ʻia ke kila pepehi ʻia ma ka hoʻohui ʻana i nā deoxidizers (eg, silicon, aluminika, manganese, etc.) i ke kila hoʻoheheʻe ʻia i ka wā o ke kaʻina hana kila, a laila e hōʻemi a hoʻopau paha i ka ʻike oxygen o ke kila.

Hoʻomaikaʻi kēia hoʻomaʻamaʻa i ka homogeneity a me ka paʻa o ke kila, hoʻomaikaʻi i kona ʻano mechanical, a hoʻomaikaʻi i ka pale ʻana i ka corrosion.

No laila, hoʻohana nuiʻia nā kila i pepehiʻia i nā noi kahi e koiʻia ai kahi kiʻekiʻe o ka homogeneity a me nā mea mechanical maikaʻi loa, e like me ka hanaʻana i nā ipu kaomi, nā paila, a me nā mea hana nui.

Hana ʻia nā paipu kila me ka hoʻohana ʻana i kaERWhana hana.

ERW (Uila Kū'ē Uila)he kaʻina hana kūpono no ka hana ʻana i ka paipu kila kalapona.

Me nā mea maikaʻi o ka ikaika welding kiʻekiʻe, nā ʻili o loko a me waho, ka wikiwiki hana wikiwiki, a me ke kumu kūʻai haʻahaʻa, hoʻohana nui ʻia ia i nā ʻoihana ʻoihana a me nā kahua kūkulu.

ASTM A178paipu kilapono e mālama i ka welai ka wā hana hana. Hoʻohana ʻia ia e hoʻomaikaʻi i nā ʻano mechanical a me ke kūpaʻa o ka paipu, a me ka hoʻopau ʻana i nā koʻikoʻi i hoʻokomo ʻia i ka wā o ke kaʻina hana.

Ma hope o ka wili ʻana, e mālama ʻia nā paipu a pau ma kahi mahana o 1650°F [900°C] a ʻoi aʻe paha a hahai ʻia e ka hoʻolili ʻana i ka ea a i ʻole i loko o ke keʻena hoʻoluʻu o ka umu hoʻomalulewa.

ʻO nā paipu anuue mālama ʻia ka wela ma hope o ke kaʻa ʻana o ka huki anu ma kahi mahana o 1200°F [650°C] a i ʻole.

Ke hoʻokō ʻia ka loiloi huahana, ʻike ʻia ka pinepine o ka nānā ʻana e like me kēia.

| Hoʻokaʻawale | Ka pinepine nana |

| ʻO ke anawaena waho ≤ 3in [76.2mm] | 250 pcs / manawa |

| Anawaena waho > 3in [76.2mm] | 100 pcs / manawa |

| E hoʻokaʻawale i ka helu wela o ka paipu | No ka helu wela |

ʻAʻole pili nā koi waiwai mīkini i nā paipu liʻiliʻi ma mua o 1/8 iniha [3.2 mm] ke anawaena o loko a i ʻole 0.015 iniha [0.4 mm] ka mānoanoa.

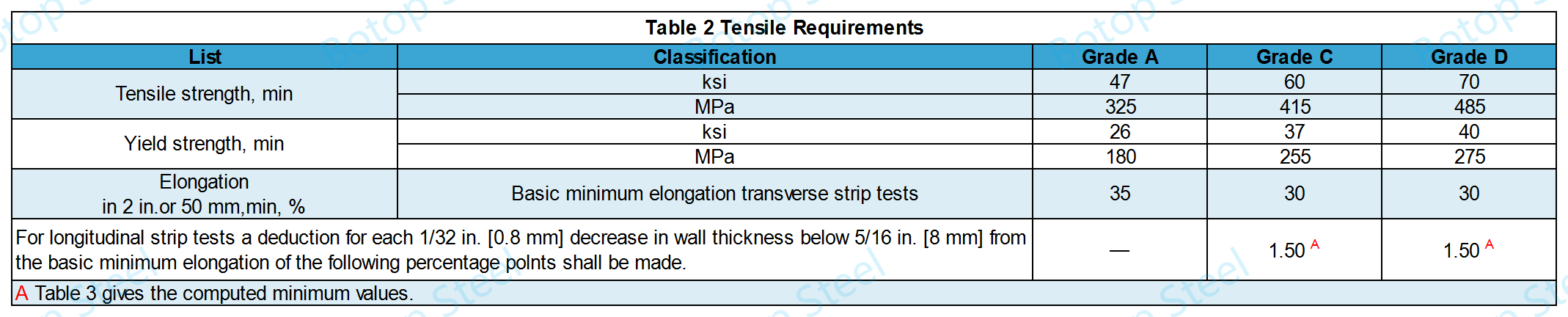

1. Waiwai Tensile

No nā papa C a me D, e hana ʻia kahi hoʻāʻo tensile ma nā paipu ʻelua i kēlā me kēia ʻāpana.

No ka paipu Papa A, ʻaʻole koi ʻia ka hoʻāʻo tensile. Ma muli o ka hoʻohana mua ʻia ʻana o ka paipu Grade A no nā noi haʻahaʻa haʻahaʻa a me ka wela haʻahaʻa.

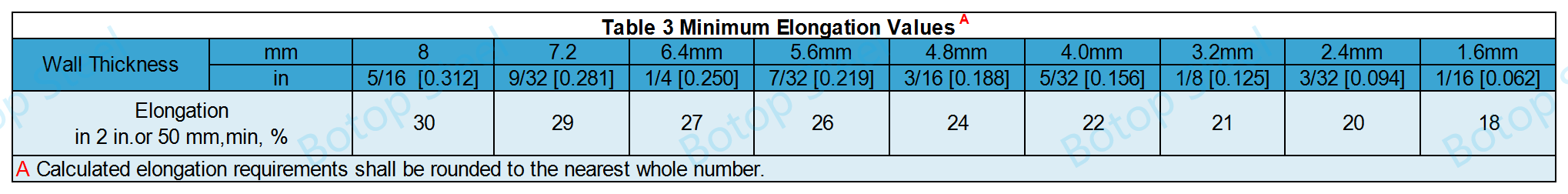

Hāʻawi ka Papa 3 i nā helu elongation liʻiliʻi i helu ʻia no kēlā me kēia 1/32 in. [0.8 mm] emi i ka mānoanoa pā.

Inā ʻaʻole ʻo ka mānoanoa o ka pā o ka paipu kila kekahi o kēia mau mānoanoa o ka pā, hiki ke helu ʻia ma ke ʻano.

ʻĀpana ʻīniha: E = 48t + 15.00a i ʻoleHuina ISI: E = 1.87t + 15.00

E = elongation i 2 in. a i ʻole 50 mm, %,

t= mānoanoa kikoʻī maoli, in. [mm].

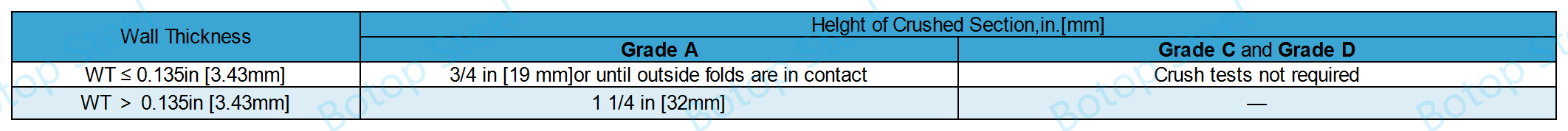

2. Crush Test

Hana ʻia nā hoʻāʻo extrusion ma nā ʻāpana paipu 2 1/2 iniha [63 mm] ka lōʻihi e kū pono ai i ka extrudinal longitudinal me ka ʻole o ka māhā, ʻokiʻoki, a i ʻole ma ka welds.

No ka paipu i emi iho malalo o 1 iniha [25.4 mm] ke anawaena o waho, he 2 1/2 ka loihi o ke anawaena o waho o ka paipu. ʻAʻole kumu no ka hōʻole ʻana i ka nānā ʻana i ka ʻili.

3. Ho'āʻo palahalaha

Kūlike ke ʻano hoʻokolohua i nā koi kūpono o ASTM A450 Pauku 19.

4. Ho'āʻo Flange

Kūlike ke ʻano hoʻokolohua i nā koi kūpono o ASTM A450 Pauku 22.

5. Ho'āʻo hoʻopololei hoʻohuli

Kūlike ke ʻano hoʻokolohua i nā koi kūpono o ASTM A450, Māhele 20.

Hana ʻia ka hoʻāʻo hydrostatic a i ʻole ka hoʻāʻo ʻana i ka uila ma kēlā me kēia paipu kila.

Pono nā koi me ka ASTM A450, Pauku 24 a i ʻole 26.

Loaʻa ka ʻikepili aʻe mai ka ASTM A450 a hoʻokō i nā koi kūpono no ka paipu kila welded wale nō.

Wehe Wehe

0 - +10%.

Paʻa mānoanoa o ka pā

0 - +18%.

Kaʻe anawaena o waho

| Anawaena waho | ʻAe ʻia nā ʻano like ʻole | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1<OD ≤1½ | 25.4<OD ≤38.4 | ±0.006 | ±0.15 |

| 1½<OD<2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD<2½ | 50.8≤ OD<63.5 | ±0.010 | ±0.25 |

| 2½≤ OD<3 | 63.5≤ OD<76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Ma hope o ka hoʻokomo ʻia ʻana i loko o ka paila, hiki i ka paipu ke kūpaʻa i ka hoʻonui ʻana a me ke kūlou ʻana me ka ʻole o ka haki ʻana i nā hemahema a i ʻole ka haki ʻana i nā welds.

Hiki i ka paipu superheater ke pale aku i na hana ku'i, ku'i, a me ke ku'o pono 'ole.

Hoʻohana nui ʻia i nā paipu boiler, nā ʻauwaʻa boiler, nā ʻauwaha superheater, a me nā hopena palekana.

ASTM A178 Papa AʻO ka haʻahaʻa kalapona haʻahaʻa o ka paipu e hāʻawi iā ia i ka weldability maikaʻi a me ka paʻakikī kiʻekiʻe no nā noi ʻaʻole i kau ʻia i nā kaomi kiʻekiʻe.

Hoʻohana mua ʻia ia no nā noi haʻahaʻa haʻahaʻa a me ka wela waena e like me nā paila haʻahaʻa haʻahaʻa (e laʻa, nā boilers home, hale keʻena liʻiliʻi, s a i ʻole nā boilers hale hana) a me nā mea hoʻololi wela ʻē aʻe ma nā wahi wela haʻahaʻa.

ASTM A178 Papa CLoaʻa iā ia ka ʻike kalapona a me ka manganese e hāʻawi ana i kēia paipu i ka ikaika a me ke kūpaʻa wela no nā kūlana hana ʻoi aku ka koi.

He kūpono no ke kaomi maʻamau a me ka hoʻohana ʻana i ka mahana wela e like me ka ʻoihana ʻenehana a me nā paila wai wela, ka mea maʻamau e koi i nā ʻoi aku ka kiʻekiʻe a me nā mahana ma mua o nā boilers home.

ASTM A178 Papa DLoaʻa i nā paipu ka manaʻo manganese kiʻekiʻe a me ka ʻike silika kūpono e hāʻawi i ka ikaika maikaʻi a me ka pale ʻana i ka wela, e hoʻokūpaʻa iā lākou i nā kaiapuni kiʻekiʻe a me ke kaomi kiʻekiʻe a kūpono no ke kū ʻana i nā kūlana hana koʻikoʻi.

Hoʻohana maʻamau i nā kaiapuni kiʻekiʻe a me ka wela kiʻekiʻe, e like me nā boiler hale mana a me nā superheater ʻoihana.

1. ASTM A179 / ASME SA179: Mea hoʻololi wela kila māmā a me nā paipu condenser no ka lawelawe cryogenic. Hoʻohana mua ʻia i nā kaiapuni haʻahaʻa haʻahaʻa, ua like ia me nā mea kemika a me nā waiwai me ka ASTM A178.

2. ASTM A192 / ASME SA192: ʻO nā paipu paila kalapona kila ʻole i ka lawelawe puʻe kiʻekiʻe. Hoʻohana mua ʻia i ka hana ʻana i nā paia wai, economizers a me nā ʻāpana kaomi ʻē aʻe no nā boilers ultra-high pressure.

3. ASTM A210 / ASME SA210: E uhi ana i ka paila kalapona kalapona a me ka paila kila a me na paipu wela nui no ka wela wela a me ka pumehana maalea.

4. DIN 17175: ʻO nā paipu kila maʻemaʻe ʻole a me nā paipu no ka hoʻohana ʻana i ke kaomi kiʻekiʻe a me nā wahi wela kiʻekiʻe. Hoʻohana nui ʻia i ka hana ʻana i nā paipu mahu no nā paila a me nā moku kaomi.

5. EN 10216-2: Ke kuhikuhi nei i nā kūlana ʻenehana no nā paipu liʻiliʻi a me nā paipu o nā kila non-alloy a me nā kila kila me nā waiwai wela kiʻekiʻe no nā noi ma lalo o ke kaomi.

6. JIS G3461: Uhi i na paipu kila kalapona no na paila a me na mea hoololi wela. He kūpono ia no nā kūlana hoʻololi wela haʻahaʻa a me waena.

ʻO mākou kahi mea hana kiʻekiʻe kiʻekiʻe welded carbon steel paipu a me ka mea hoʻolako mai Kina, a me kahi mea hoʻoheheʻe paipu kila maʻemaʻe, hāʻawi iā ʻoe i kahi ākea o nā paipu kila!

No nā nīnau a i ʻole e aʻo hou aʻe e pili ana i kā mākou hāʻawi, mai hoʻokaʻulua e hoʻokaʻaʻike mai iā mākou. ʻO kāu mau hoʻonā paipu kila maikaʻi he memo wale nō!