ʻO ASTM A335 P9, ʻike ʻia hoʻi ʻo ASME SA335 P9, he paipu kila ferritic alloy ʻole no ka lawelawe wela kiʻekiʻe meUNS Helu K90941.

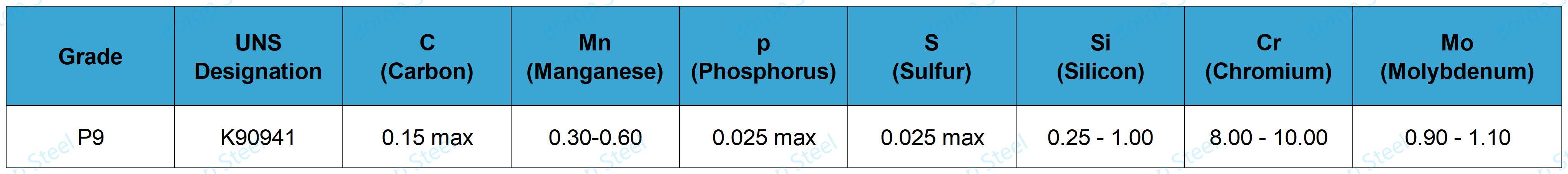

ʻO nā mea hoʻohui i ka chromium a me ka molybdenum. Aia ka chromium ma waena o 8.00 - 10.00%, aʻo ka molybdenum ma kahi o 0.90% - 1.10%.

P9loaʻa ka ikaika maikaʻi a me ke kūpaʻa corrosion maikaʻi i nā wahi wela kiʻekiʻe a hoʻohana nui ʻia i nā boilers, nā lako petrochemical, a me nā keʻena mana kahi e koi ʻia ai nā kaiapuni kiʻekiʻe a me ke kiʻekiʻe.

⇒ Mea: ASTM A335 P9 / ASME SA335 P9 paipu kila huila ʻole.

⇒Anawaena waho: 1/8"- 24".

⇒Mānoanoa pā: Nā koi ASME B36.10.

⇒Papa kuhikuhi: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 a me SCH160.

⇒ʻIkepili: STD (maʻamau), XS (kekahi-ikaika), a i ʻole XXS (pālua keu-ikaika).

⇒Ka lōʻihi: Nā lōʻihi kikoʻī a i ʻole ka lōʻihi.

⇒Hoʻopilikino: Non-standard waho anawaena, paia mānoanoa, lōʻihi, etc. e like me nā koi.

⇒Nā lako: Hiki iā mākou ke hāʻawi i nā mea like me nā piko, nā flanges stamping, a me nā huahana kākoʻo paipu kila.

⇒Palapala IBR: Hiki ke hāʻawi ʻia kahi palapala IBR inā pono.

⇒Hoʻopau: Ka welau maʻemaʻe, ka welau beveled, a i ʻole ka hopena paipu hui.

⇒Hoʻopili: pahu lāʻau, kāʻei kila a i ʻole ka hoʻopaʻa ʻana i ka uea kila, ka mea pale i ka hopena o ka paipu hao.

⇒Kaʻahele: ma ka moana a me ka mokulele.

ʻO ka paipu kila ASTM A335 pono ʻole.

ʻO ka paipu kila maʻemaʻe he paipu kila me ka ʻole o nā wili a puni.

No ka mea, ʻaʻohe wili i hoʻopaʻa ʻia i ka paipu kila maʻemaʻe, pale ia i nā pōʻino palekana e pili ana i nā pilikia maikaʻi. ʻO kēia hiʻohiʻona e hiki ai i ka paipu maʻemaʻe ke kū i nā kaomi kiʻekiʻe, a ʻo kona ʻano like ʻole i loko e hōʻoia hou i ka pono a me ka palekana o ka paipu ma nā wahi kiʻekiʻe.

Eia hou, ua hoʻonuiʻia ka hilinaʻi o ka ASTM A335 tubing e ka hoʻohuiʻana i nā mea hoʻohui kūikawā no nā kūlana kiʻekiʻe a me ke kiʻekiʻe.

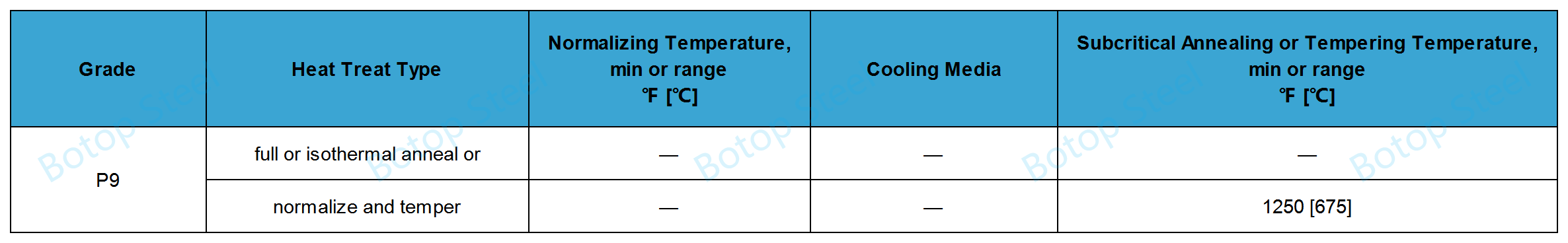

ʻO nā ʻano o ka hoʻomaʻamaʻa wela i loaʻa no ka mea P9 me ka hoʻopiha piha a i ʻole isothermal annealing, a me ka hoʻomaʻamaʻa ʻana a me ka hoʻoulu ʻana. ʻO ke kaʻina hana maʻamau a me ka hoʻoheheʻe ʻana he 1250°F [675°C].

ʻO nā mea hoʻohui nui o P9CraMo, he mau huila chromium-molybdenum.

Cr (Chromium): Ma keʻano he mea nui o ka'āpana, hāʻawiʻo Cr i ka ikaika wela kiʻekiʻe a me ke kū'ē i ka oxidation. Hoʻokumu ia i kahi kiʻiʻoniʻoni chromium oxide ma luna o ka ʻili o ke kila, e hoʻonui ana i ke kūpaʻa a me ke kūpaʻa corrosion o ka paipu i nā wela kiʻekiʻe.

Mo (Molybdenum): ʻO ka hoʻohui ʻana o Mo e hoʻomaikaʻi nui i ka ikaika a me ka paʻakikī o nā alloys, ʻoi aku hoʻi i nā wahi wela kiʻekiʻe. Kōkua pū ʻo Mo i ka hoʻomaikaʻi ʻana i ka ikaika kolo o ka mea, ʻo ia hoʻi ka hiki ke pale i ka deformation ma lalo o ka loaʻa ʻana o ka wela lōʻihi.

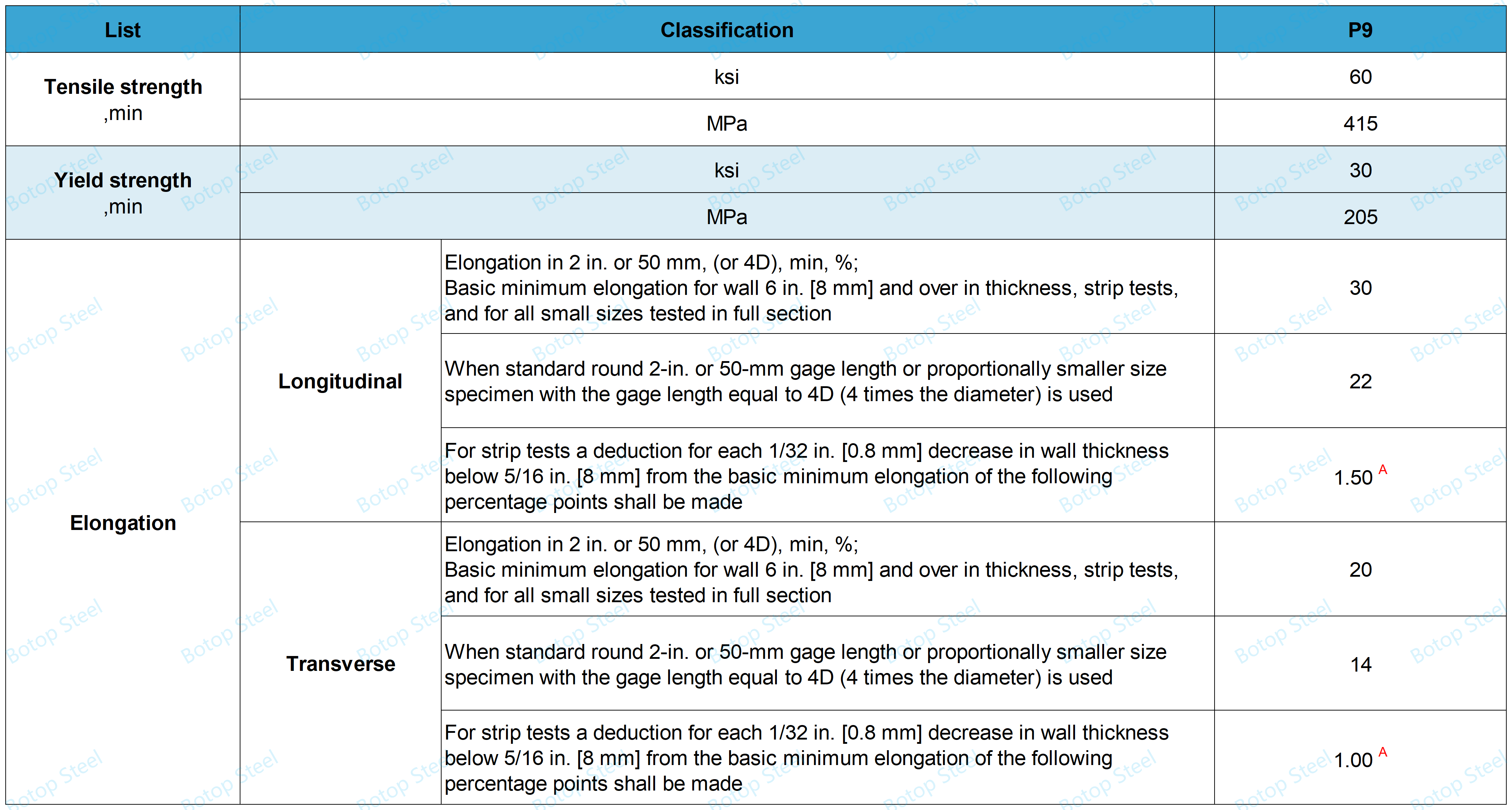

Na Waiwai Tensile

P5, P5b, P5c, P9,P11, P15, P21, a me P22: Ua like ka tensile a me ka ikaika hua.

P1, P2, P5, P5b, P5c,P9, P11, P12, P15, P21, a me P22: Ka elongation like.

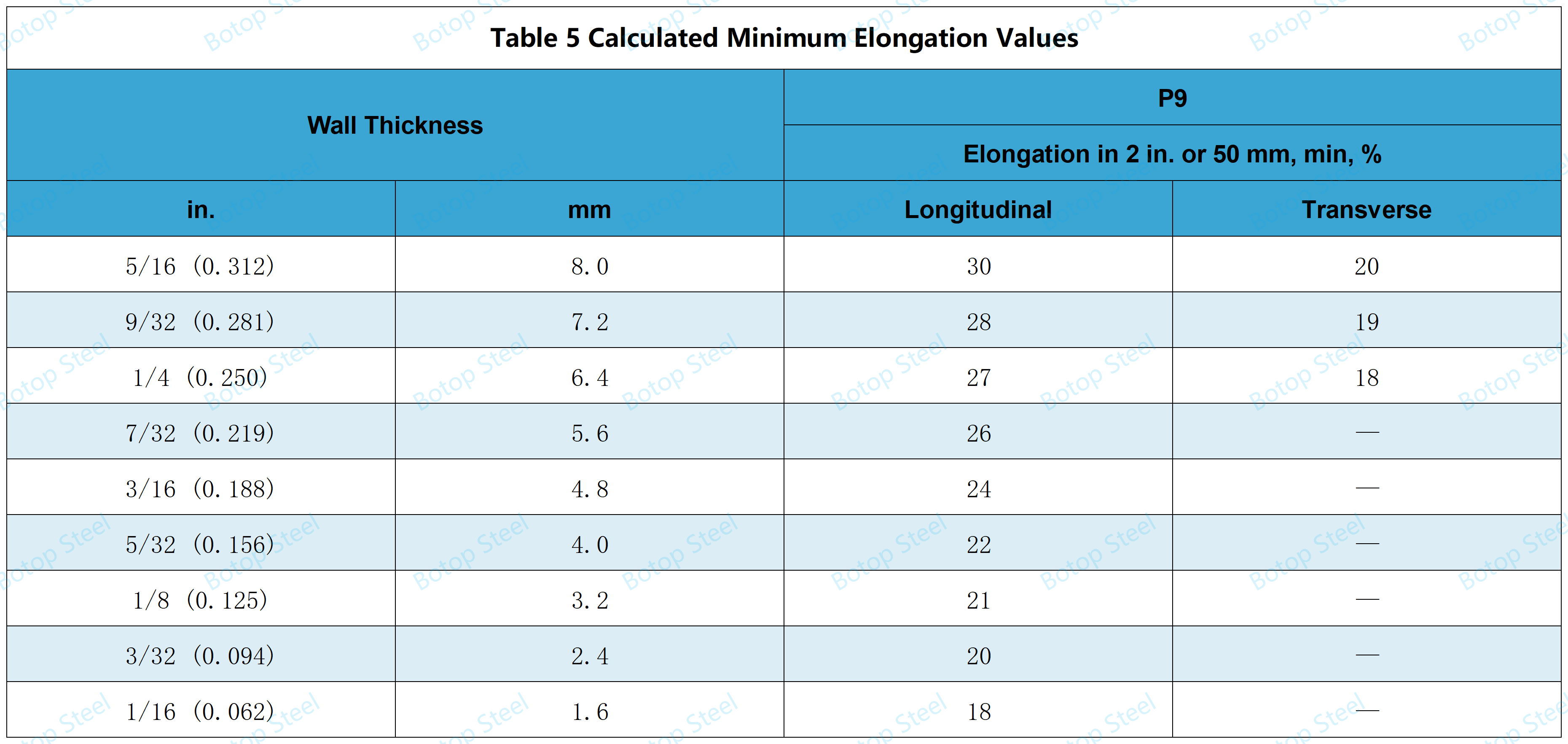

AHāʻawi ka papa 5 i nā kumu waiwai liʻiliʻi i helu ʻia.

Ma kahi e waiho ai ka mānoanoa o ka pā ma waena o nā waiwai ʻelua ma luna, ua hoʻoholo ʻia ka waiwai elongation liʻiliʻi e kēia ʻano:

Loihi, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

ʻApe, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

ma hea:

E = elongation i 2 in. a i ʻole 50 mm, %,

t = mānoanoa maoli o nā specimens, in. [mm].

ʻoʻoleʻa

ʻAʻole koi ʻo P9 i ka hoʻāʻo paʻakikī.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, a me P921: ʻAʻole pono ka hoʻāʻo paʻakikī.

Ke hoʻāʻo ʻia ke anawaena o waho ma mua o 10 in. [250 mm] a me ka mānoanoa o ka pā ≤ 0.75 in. [19 mm], e hoʻāʻo ʻia nā mea a pau i ka hydrostatically.

Hiki ke helu ʻia ke kaomi hoʻokolohua me ka hoʻohana ʻana i ka hoohalike.

P = 2St/D

P= pumi hoao hydrostatic ma psi [MPa];

S= ke kaumaha o ka paia paipu ma ka psi a i ʻole [MPa];

t= mānoanoa pā i ʻōlelo ʻia, mānoanoa pā i koho ʻia e like me ka helu ANSI i ʻōlelo ʻia a i ʻole 1.143 mau manawa o ka mānoanoa pā haʻahaʻa i ʻōlelo ʻia, in. [mm];

D= anawaena waho i hoakakaia, anawaena waho e like me ka nui paipu ANSI i hoakakaia, a i ole ke anawaena o waho i heluia ma ka hoonui ana i 2t (e like me ka mea i hoakakaia maluna) i ke anawaena o loko i hoakakaia, in. [mm].

Ka manawa hoʻāʻo: mālama ma ka liʻiliʻi he 5 mau hola, ʻaʻohe leakage.

Inā ʻaʻole e hoʻohāinu ʻia ka paipu, e hana ʻia kahi hoʻāʻo ʻole luku ma kēlā me kēia paipu e ʻike ai i nā hemahema.

Pono e hana ʻia ka hoʻāʻo ʻole luku ʻana i nā mea P9 e kekahi o nā ʻanoE213, E309 or E570.

E213: Hoʻomaʻamaʻa no ka hoʻāʻo ʻana i ke kani kani o ka paipu metala a me ka paipu;

E309: E hoʻomaʻamaʻa no ka nānā ʻana o Eddy i kēia manawa o nā huahana Tubular Steel me ka hoʻohana ʻana i ka Saturation Magnetic;

E570: E hoʻomaʻamaʻa no ka hoʻomaʻamaʻa Flux Leakage o nā huahana Ferromagnetic Steel Tubular;

ʻAe ʻia nā ʻokoʻa i ke anawaena

Hiki ke hoʻokaʻawale ʻia nā anawaena e like me 1. ma muli o ke anawaena o loko a i ʻole 2. ma muli o ke anawaena inoa a i ʻole ke anawaena o waho.

1. Anawaena o loko: ± 1%.

2. NPS [DN] a i ʻole ke anawaena o waho: Ua like kēia me nā ʻae ʻae ʻia ma ka papa ma lalo.

ʻAe ʻia nā ʻokoʻa o ka mānoanoa o ka pā

ʻAʻole ʻoi aku ka mānoanoa o ka pā paipu i kēlā me kēia wahi ma mua o ka ʻae ʻia.

Hōʻike ʻia ka mānoanoa liʻiliʻi o ka pā a me ke anawaena o waho no ka nānā ʻana no ka hoʻokō ʻana i kēia koi no ka paipu i kauoha ʻia e NPS [DN] a me ka helu hoʻonohonoho.ASME B36.10M.

Nā mea i loko o ka mākaʻikaʻi ʻana: Ka inoa a ka mea hana paha; helu maʻamau; papa; ka lōʻihi a me ka hōʻailona hou "S".

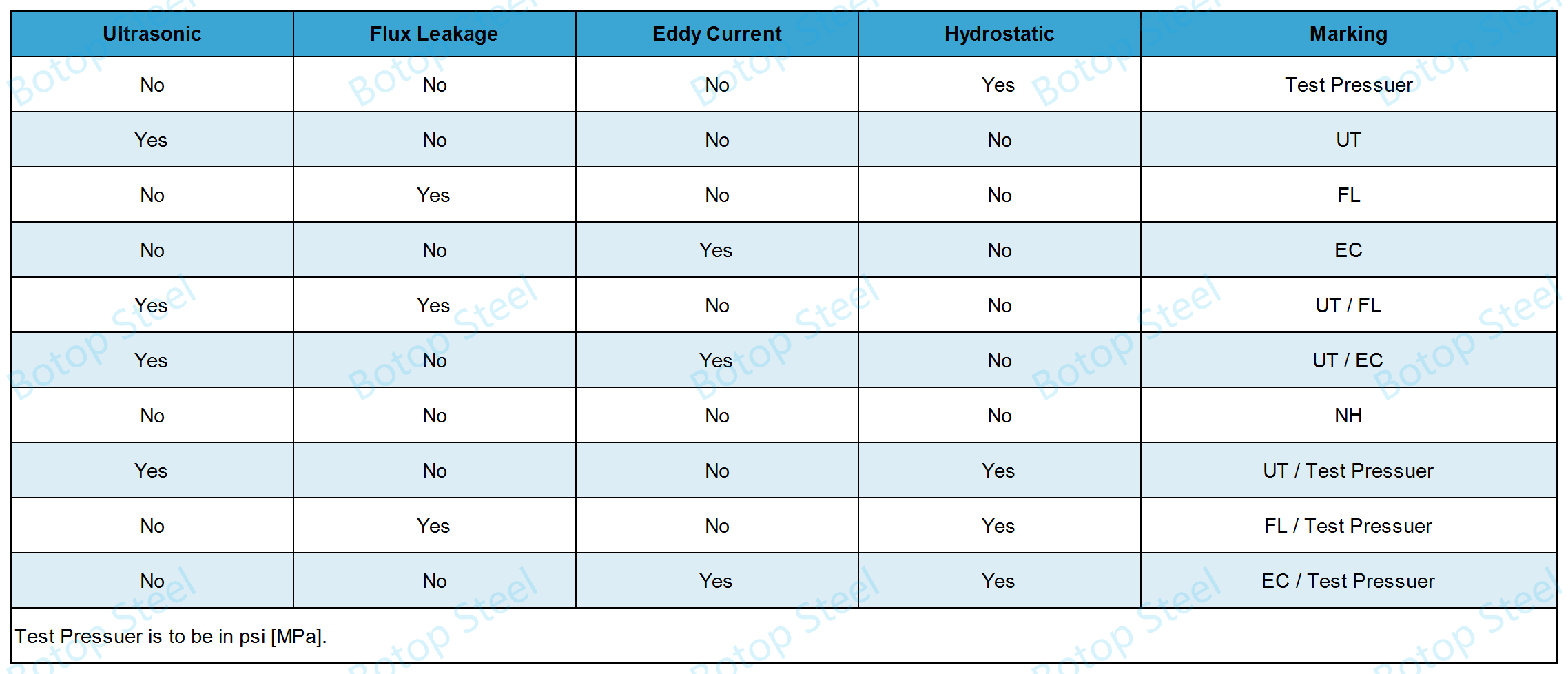

Pono e hoʻokomo pū ʻia nā hōʻailona no ke kaomi hydrostatic a me ka hoʻāʻo ʻole luku ʻia ma ka papa ma lalo.

Ka helu wahi: Pono e hoʻomaka ke kaha ʻana ma kahi o 12 iniha (300 mm) mai ka hopena o ka paipu.

No nā paipu a hiki i ka NPS 2 a i ʻole ka liʻiliʻi ma mua o 3 ft (1 m) ka lōʻihi, hiki ke hoʻopili ʻia ka hōʻailona ʻike i ka hōʻailona.

Hoʻohana nui ʻia ka paipu kila ASTM A335 P9 i nā boilers, nā lako mana petrochemical, a me nā mea ʻē aʻe, pono e kū i ke kiʻekiʻe kiʻekiʻe a me ke kaomi kiʻekiʻe ma muli o kona kiʻekiʻe kiʻekiʻe kiʻekiʻe a me ke kūpaʻa kiʻekiʻe.

ʻO nā paila: ʻOi loa i ka paipu mahu nui a me ka reheater paipu o nā paila supercritical a me ultra-supercritical no nā wela kiʻekiʻe loa a me nā kaomi.

Lako petrokimia: E like me nā paipu pahū a me nā paipu wela kiʻekiʻe, nāna e mālama i nā mahu a me nā mea kemika, pono nā mea me ka wela maikaʻi loa a me ka pale ʻana i ka corrosion.

Nā kikowaena uila: No ka paipu mahu nui a me ka pumehana kiʻekiʻe, a me ka paipu turbine kūloko e hoʻokō i nā manawa lōʻihi o ka wela kiʻekiʻe a me ke kaomi.

Loaʻa i nā mea P9 ko lākou mau māka maʻamau i nā ʻōnaehana maʻamau aupuni like ʻole.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

GOST 550: 12ChM;

Ma mua o ke koho ʻana i kekahi mea like, pono e hoʻokō ʻia nā hoʻohālikelike hana kikoʻī a me ka hoʻāʻo ʻana e hōʻoia i ka hoʻokō ʻana o nā mea ʻē aʻe i nā koi o ka hoʻolālā kumu.

Mai kona hoʻokumu ʻana i ka makahiki 2014,Ke kila Botopua lilo i mea hoʻolako alakaʻi o ka paipu kila kalapona ma Northern China, i ʻike ʻia no ka lawelawe maikaʻi loa, nā huahana kiʻekiʻe, a me nā hāʻina piha.

Hāʻawi ka hui i nā ʻano paipu kila kalapona a me nā huahana pili, me ka seamless, ERW, LSAW, a me ka paipu kila SSAW, a me ka laina piha o nā paipu paipu a me nā flanges. ʻO kāna mau huahana kūikawā pū kekahi me nā mea kila kiʻekiʻe a me nā austenitic stainless steel, i hana ʻia e hoʻokō i nā koi o nā papahana pipeline like ʻole.

E ʻoluʻolu e kelepona mai iā mākou inā he mau pono a nīnau paha e pili ana i ka paipu kila. Manaʻo mākou i ka loaʻa ʻana o kāu ʻike a ke kakali nei mākou i ke kōkua ʻana iā ʻoe.