ASTM A53 ERWpaipu kilaʻAno Ei ka A53 kiko'ī, i hanaʻia e ke kaʻina hana kuʻikuʻi kū'ē, a loaʻa iā ia ma nā papa A me ka Papa B.

He mea kūpono ia no nā noi mechanical a me ke kaomi a hoʻohana pinepine ʻia ma ke ʻano he kumu maʻamau no ka lawe ʻana i ka mahu, ka wai, ke kinoea, a me ka ea.

ʻO nā pono o ka paipu kila ERW, e like mekumu kūʻai haʻahaʻaakiʻekiʻe huahana, e hoʻolilo iā ia i mea koho no nā noi ʻoihana he nui.

Ke kila Botophe mea hana kiʻekiʻe kiʻekiʻe welded carbon kila paipu a me ka mea hoʻolako mai Kina, a me ka seamless steel pipe stockist, e hāʻawi iā ʻoe i ka laulā o nā paipu kila!

Hoʻopili maikaʻi ʻia kā mākou waihona waiwai a hiki iā mākou ke hoʻokō i ka noi wikiwiki o kā mākou mea kūʻai aku no ka nui o ka nui a me ka nui.

Loaʻa iā ASTM A53/A53M nā ʻano a me nā māka:

ʻAno E: Uila-kue-weled, Papa A me B.

ʻAno S: Holomua, Papa A me B.

ʻAno F: Uhi-pu-weled, wili mau ʻia ʻo Papa A me B.

ʻAno EaʻAno Sʻelua ʻano paipu i hoʻohana nui ʻia. He ʻokoʻa,ʻAno Fhoʻohana maʻamau no nā paipu anawaena liʻiliʻi. Ma muli o ka holomua o ka ʻenehana welding, hoʻohana pinepine ʻia kēia ʻano hana hana.

Anawaena inoa inoa: DN 6 - 650 [NPS 1/8 - 26];

Anawaena waho: 10.3 - 660 mm [0.405 - 26 iniha];

ʻO ka mānoanoa o ka pā a me nā palapala kaumaha paipu kila:

Ua ʻae ʻo ASTM A53 i ka hoʻolako ʻana i ka paipu me nā ʻāpana ʻē aʻe inā hoʻokō ka paipu i nā koi ʻē aʻe a pau o kēia kikoʻī.

ERWhoʻohana nui ʻia no ka hana ʻana i ke kalapona a puni, square, rectangular a me nā paipu hao hao haʻahaʻa.

ʻO ka hana ma lalo nei ke kaʻina hana no ka hana ʻanapaipu kila ERW poepoe:

a) Hoʻomākaukau waiwai: ʻO ka mea mua he mau wili kila wela. Hoʻopili mua ʻia kēia mau ʻōwili a ʻako ʻia i ka laulā i makemake ʻia.

b) Hoʻokumu: Ma muli o ke ʻano o nā ʻōwili, hoʻokumu ʻia ke kaula i loko o kahi ʻano tubular pōʻai ākea. I loko o kēia kaʻina hana, hoʻopili mālie ʻia nā kihi o ke kaula i mea e hoʻomākaukau ai no ka wili.

c) wiliwili: Ma hope o ka hoʻokumu ʻana i ke ʻano tubular, hoʻomehana ʻia nā ʻaoʻao o ka ʻili kila e ke kūpaʻa uila i ka ʻāpana kuʻi. Hoʻohana ʻia kahi ʻano alapine kiʻekiʻe ma o ka mea, a hoʻohana ʻia ka wela i hana ʻia e ke kūpaʻa e wela i nā ʻaoʻao a hiki i ko lākou helu heheʻe, a laila hoʻopili ʻia lākou e ke kaomi.

d) Hoʻopau ʻana: Ma hope o ka wili ʻana, hoʻoneʻe ʻia nā burrs weld (metala keu aʻe mai ka wili ʻana) mai loko a ma waho o ka paipu e hōʻoia i ka maʻalahi o ka ʻili i loko o ka paipu.

e) Ka hoʻonohonoho ʻana a me ka lōʻihi: Ma hope o ka pau ʻana o ka wili a me ka deburring, ua hele ʻia nā paipu ma kahi mīkini nui no ka hoʻoponopono ʻana i ka dimensional e hōʻoia i ka hoʻokō ʻana i nā koi kūpono a me ka pōʻai. A laila ʻoki ʻia nā paipu i nā lōʻihi i koho mua ʻia.

f) Nānā a hoʻāʻo: E ho'āʻo a nānā ponoʻia ka paipu kila, me ka ho'āʻo ultrasonic, hydrostatic testing, a me nā mea'ē aʻe, e hōʻoia i ka maikaʻi o ka paipu kila i nā kūlana a me nā kiko'ī.

g) Lapaʻau ʻili: ʻO ka hope, hiki ke kau ʻia ka paipu kila i nā hana hou e like me ka hot dip galvanizing, pena kiʻi, a i ʻole nā mea lapaʻau ʻē aʻe e hāʻawi i ka pale ʻino a me ka nani.

Nā welds ma ke ʻano E a i ʻole ke ʻano F Papa Be mālama ʻia ka paipu i ka wela a i ʻole e mālama ʻia ma hope o ka wili ʻana i ʻole e loaʻa ka martensite untempered.

ʻO ka mahana hoʻomaʻamaʻa wela ma ka liʻiliʻi loa1000°F [540°C].

Ke hoʻonui ʻia ke anu, ʻaʻole e ʻoi aku ka hoʻonui1.5%o ke anawaena o waho o ka paipu.

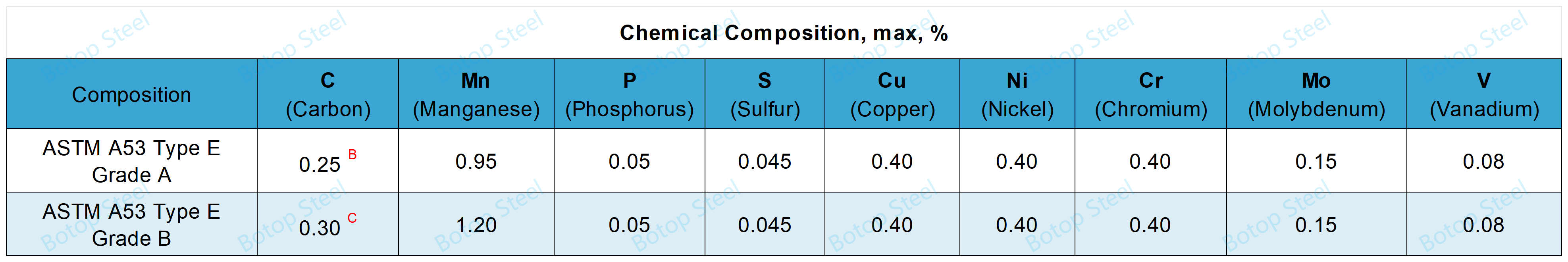

AʻO nā mea ʻelimaCu, Ni, Cr, Mo, aVʻAʻole pono e hui pū ʻia ma mua o 1.00%.

BNo kēlā me kēia hōʻemi o 0.01 % ma lalo o ke kalapona i ʻōlelo ʻia, e ʻae ʻia ka piʻi ʻana o 0.06 % o ka manganese ma luna o ka palena kiʻekiʻe a hiki i ka 1.35 %.

CNo kēlā me kēia ho'ēmi o 0.01 % ma lalo o ke kalapona kiʻekiʻe i ʻōlelo ʻia, e ʻae ʻia ka piʻi ʻana o 0.06 % o ka manganese ma luna o ka palena kiʻekiʻe a hiki i ka 1.65 %.

Waiwai Tensile

| Papa inoa | Hoʻokaʻawale | Papa A | Papa B |

| Ka ikaika tensile, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ka ikaika hāʻawi, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation ma 50 mm [2 in.] | Nānā | A,B | A,B |

Nānā A: E hoʻoholo ʻia ka elongation liʻiliʻi ma 2 in[50 mm] e ka hoohalike penei:

e = 625,000 [1940] A0.2/U0.9

e = ka lōʻihi liʻiliʻi ma 2 i loko a i ʻole 50 mm i ka pākēneka, hoʻopuni ʻia i ka pākēneka kokoke loa

A = ka liʻiliʻi o 0.75 iniha2[500 mm2] a me ka wahi kea o ka ho'āʻo ho'āʻo hoʻopaʻapaʻa, i helu ʻia me ka hoʻohana ʻana i ke anawaena o waho o ka paipu, a i ʻole ka laula inoa o ka specimen hoʻāʻo hoʻopaʻapaʻa a me ka mānoanoa pā o ka paipu, me ka helu helu i hoʻopuni ʻia i ka 0.01 in kokoke loa.2 [1 mm2].

U = ka ikaika uʻi liʻiliʻi i ʻōlelo ʻia, psi [MPa].

Nānā B: E nānā i ka Papa X4.1 a i ʻole Papa X4.2, ʻo ia ka mea e pili ana, no nā koina elongation haʻahaʻa i koi ʻia no nā hui like ʻole o ka nui o ka hōʻike hoʻāʻo ʻana a me ka ikaika tensile haʻahaʻa i kuhikuhi ʻia.

Hoʻo Piʻo

No ka paipu DN ≤ 50 [NPS ≤ 2], hiki i ka lōʻihi o ka paipu ke kūlou i ke anuanu ma o 90° a puni kahi mandrel cylindrical, ʻo ke anawaena he ʻumikūmālua manawa o ke anawaena o waho o ka paipu, me ka hoʻomohala ʻole ʻana i nā māwae ma kekahi ʻāpana a me ka wehe ʻole ʻana i ka weld.

Pālua-ʻoi-ikaika(papa kaumaha:XXS) paipu ma luna o DN 32 [NPS 1 1/4] ʻaʻole pono e hoʻokō ʻia i ka hoʻāʻo ʻana.

Ho'āʻo palahalaha

E hana ʻia ka hoʻāʻo palahalaha ma luna o ka paipu wili ʻia ma luna o DN 50 i ke kaumaha ʻoi aku ka ikaika (XS) a i ʻole ka māmā.

He kūpono no ke ʻano E, Papa A a me B; a me Type F, pae B.

ʻAʻole pono e hoʻāʻo ʻia nā paipu kila ʻole.

Manawa Hoao

No nā nui a pau o Type S, Type E, a me Type F Grade B paipu, e mālama ʻia ke kaomi hoʻokolohua no ka liʻiliʻi o 5s.

E hoʻohana ʻia ka hoʻāʻo hydrostatic, me ka ʻole o ka leaka ma o ka weld seam a i ʻole ke kino paipu.

Ho'āʻo Paʻi

Plain-end pipee hoʻāʻo hydrostatically i ke kaomi pili i hāʻawi ʻia i lokoPapa X2.2,

Paipu kaula-a-huie hoʻāʻo hydrostatically i ke kaomi pili i hāʻawi ʻia i lokoPapa X2.3.

No nā paipu kila me DN ≤ 80 [NPS ≤ 80],ʻaʻole eʻoi aku ke kaumaha o ka ho'āʻo ma mua o 17.2MPa;

No nā paipu kila me DN >80 [NPS >80], ʻaʻole e oi aku ke kaomi hoʻāʻo ma mua o 19.3MPa;

Hiki ke koho ʻia nā kaomi hoʻokolohua kiʻekiʻe inā loaʻa nā koi ʻenehana kūikawā, akā pono kēia i ke kūkākūkā ma waena o ka mea hana a me ka mea kūʻai aku.

Hoailona

Inā hoʻāʻo ʻia ka paipu hydrostatically, pono e hōʻailona ʻia kakaomi hoʻāʻo.

E pili ana kēia mau koi i ka Pipe Type E a me Type F Grade B.

Loaʻa nā koi ʻē aʻe i ka paipu seamless ʻaʻole i kūkākūkā ʻia ma kēia palapala.

Nā ʻano hoʻāʻo

ʻO nā paipu i hana ʻia e nā mīkini hoʻonui ʻole wela a me nā mīkini ʻoki: DN ≥ 50 [NPS ≥ 2], kawiliwilii kēlā me kēia ʻāpana o ka paipu pono e hele i kahi hoʻāʻo uila non-destructive, a pono ke ʻano hoʻāʻo e like me kaE213, E273, E309 a i ʻole E570maʻamau.

ʻO nā paipu ERW i hana ʻia e ka mīkini hoʻēmi wela wela: DN ≥ 50 [NPS ≥ 2]ʻO kēlā me kēia māheleo ka paipu e nana piha loa ia e ka hoao ana i ka uwila ole, e like me kaE213, E309, a i ʻoleE570nā kūlana.

'Ōlelo Aʻo: ʻO ka Hot Stretch Expansion Diameter Machine he mīkini e hoʻopololei mau ana i nā paipu kila e nā wili i nā wela kiʻekiʻe e hoʻoponopono i ko lākou mau anawaena a me ka mānoanoa o ka paia.

Hoailona

Inā ua hoʻokau ʻia ka paipu i ka hoʻokolokolo non-destructive, pono e hōʻikeNDEma ka hoailona ana.

Mass

± 10%.

Pipe DN ≤ 100 [NPS ≤ 4], i kaupaona ʻia ma ke ʻano he pūʻulu.

Paipu DN > 100 [NPS > 4], kaupaona ʻia ma nā ʻāpana hoʻokahi.

Anawaena

No ka paipu DN ≤40 [NPS≤ 1 1/2], ʻaʻole e oi aku ka hoʻololi OD ma mua o ±0.4 mm [1/64 in.].

No ka paipu DN ≥50 [NPS>2], ʻaʻole ʻoi aku ka hoʻololi o OD ma mua o ±1%.

Nā mānoanoa

ʻAʻole emi ka mānoanoa liʻiliʻi o ka pā87.5%o ka mānoanoa pā i kuhikuhi ʻia.

ʻoi aku ka māmā ma mua o ke kaumaha keu aku (XS).:

a) paipu maʻamau: 3.66 - 4.88m [12 - 16 ft], ʻAʻole ʻoi aku ma mua o 5% o ka huina helu.

b) ka lōʻihi kaulua: ≥ 6.71 m [22 ft], 10.67m [35 ft] ka lōʻihi.

c) ka lōʻihi like ʻole: 4.88 -6.71m [16 - 22 ft], ʻaʻole ʻoi aku ma mua o 5 % o ka huina o nā lōʻihi wili i hoʻolako ʻia he mea hui (ʻelua ʻāpana i hui pū ʻia).

Ke kaumaha a ʻoi aku ka ikaika (XS).: 3.66-6.71 m [12 - 22 ft], ʻaʻole i oi aku ma mua o 5% ka nui o ka paipu 1.83 - 3.66 m [6 - 12 ft].

No ka ASTM A53 paipu kila i loaʻa i ka ʻeleʻele a i ʻole galvanized.

ʻeleʻele: ʻO nā paipu kila me ka ʻole o ka mālama ʻana i ka ʻili, kūʻai maʻamau ma hope o ke kaʻina hana, no kēlā mau noi i koi ʻole ʻia ke kūpaʻa corrosion hou.

Pono nā paipu Galvanized i nā koi kūpono.

Kaʻina hana

E uhi ʻia ka zinc ma loko a ma waho e ka hana wela.

Mea Maka

ʻO ka zinc i hoʻohana ʻia no ka uhi ʻana he ʻano o ka zinc e like me nā koi o ke kikoʻīASTM B6.

Ka nana aku

ʻAʻohe wahi i uhi ʻole ʻia ka paipu galvanized, nā ʻōhū ea, nā waiho kahe, a me nā hoʻokomo ʻia ʻana o ka pala. ʻAʻole ʻae ʻia nā puʻupuʻu, puʻupuʻu, globules, a i ʻole ka nui o nā waihona zinc e hoʻopilikia i ka hoʻohana ʻana i ka mea.

Kaumaha Uila Uila

E hoʻoholo ʻia e ka hoʻāʻo ʻili e like me ke ʻano hōʻike ASTM A90.

ʻAʻole pono ke kaumaha o ka uhi ʻana ma lalo o 0.55 kg/m² [1.8 oz/ft²].

ASTM A53 ERW paipu kilahoʻohana maʻamau ʻia i nā noi haʻahaʻa haʻahaʻa e like me ka ʻenekinia municipal, ke kūkulu ʻana, a me ka paipu hana mechanical. ʻO nā hiʻohiʻona maʻamau ka lawe ʻana i ka wai, ka mahu, ka ea, a me nā wai haʻahaʻa haʻahaʻa.

Me ka weldability maikaʻi, ua kūpono lākou no ka hana ʻana i nā hana e pili ana i ka coiling, bending, a me ka flanging.