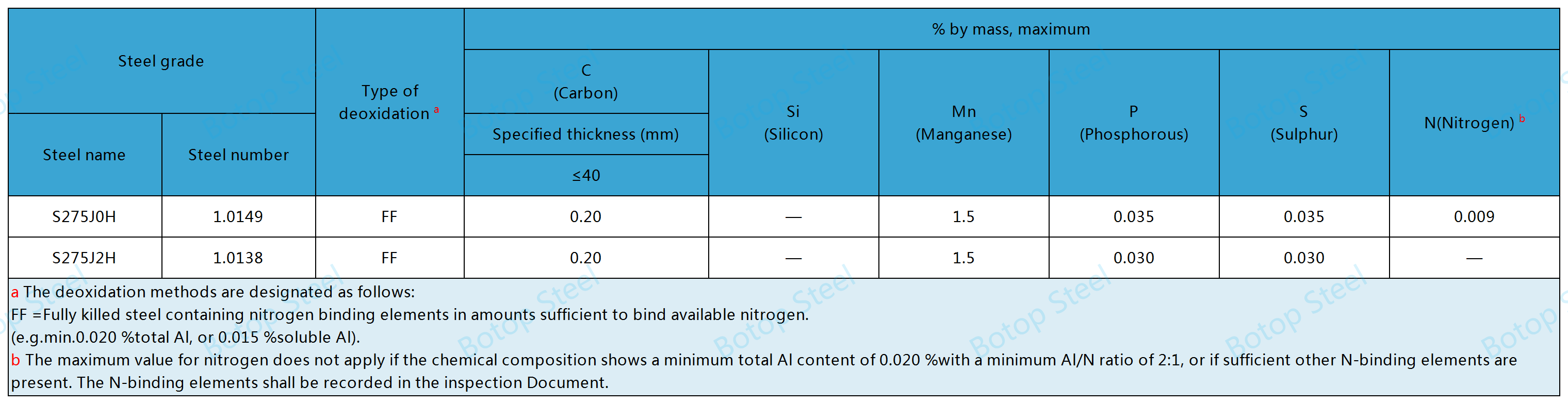

EN 10219 S275J0H a me S275J2Hhe mau ʻāpana hollow welded welded i hana ʻia me ke kila non-alloyed e like me EN 10219.

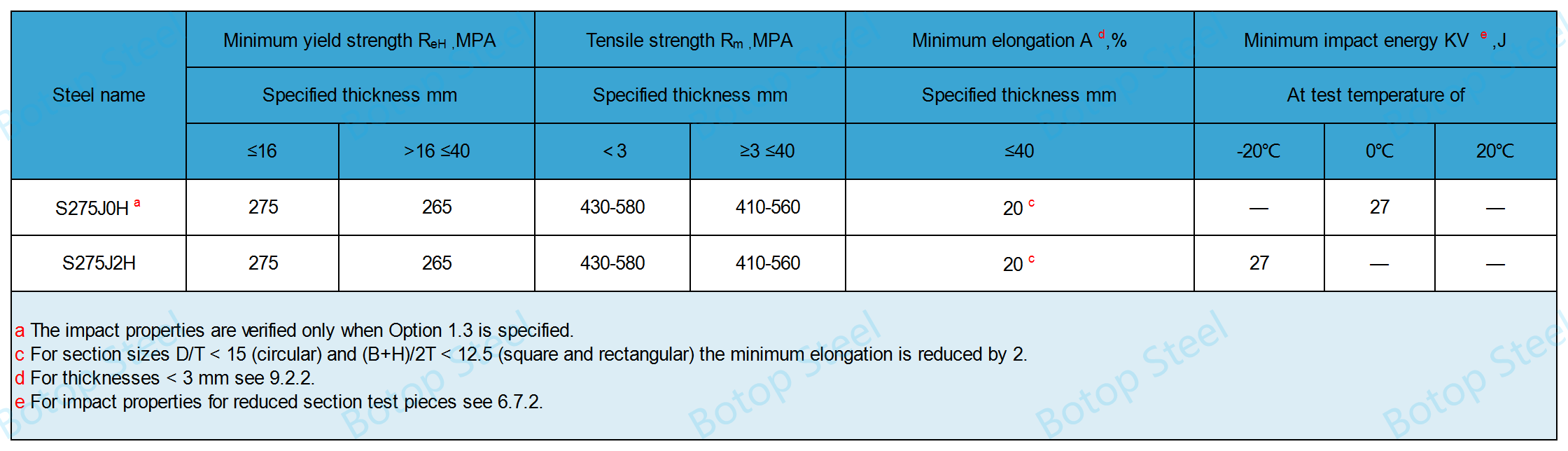

Loaʻa iā lāua ʻelua ka ikaika haʻahaʻa haʻahaʻa o 275MPa (ka mānoanoa o ka paia ≤16mm). ʻO ka ʻokoʻa nui ma nā waiwai hopena: S275J0H ka liʻiliʻi o ka ikehu hopena o 27 J ma 0 ° C, aʻo S275J2H ka liʻiliʻi o ka ikehu hopena o 27 J ma -20 ° C.

He kūpono no ka hoʻohana ʻana i nā hale a me nā hale ʻenekinia e pili ana i nā ukana māmā.

ʻO BS EN 10219 ka European Standard EN 10219 i hāpai ʻia e UK.

ʻO ka mānoanoa pā ≤40mm, Ke anawaena o waho ≤2500mm.

ʻO CFCHS kahi pōkole no Cold-Formed Circular Hollow Section.

Hoʻopili ka maʻamau EN 10219 i kahi ākea o nā ʻano kila hollow, me ka poepoe, square, rectangular, a me oval, e kūpono i nā koi hoʻohana like ʻole.

Ke kila Botopkūikawā i ka hāʻawi ʻana i nā paipu kila ʻāpana poʻo i nā ʻano nui a me nā kaʻina hana e kūpono i ka nui o nā noi ʻoihana, e hōʻoia ana e hiki ke hoʻokō ʻia nā pono kikoʻī o kā mākou mea kūʻai.

Mai kona hoʻokumu ʻana i ka makahiki 2014,Ke kila Botopua lilo i mea hoʻolako alakaʻi o ka paipu kila kalapona ma Northern China, i ʻike ʻia no ka lawelawe maikaʻi loa, nā huahana kiʻekiʻe, a me nā hāʻina piha.

Hāʻawi ka hui i nā ʻano paipu kila carbon a me nā huahana e pili ana, meSMLS, ERW, LSAW, aSSAWpaipu kila, a me ka laina piha o nā paipu paipu a me nā flanges. ʻO kāna mau huahana kūikawā pū kekahi me nā mea kila kiʻekiʻe a me nā austenitic stainless steel, i hana ʻia e hoʻokō i nā koi o nā papahana pipeline like ʻole.

Manaʻo mākou i ka hoʻokumu ʻana i kahi pilina pili me ʻoe a me ka hoʻokumu ʻana i kahi lanakila-lanakila e hiki mai ana.

ʻO ke kila kila no ka hana ʻana i nā ʻāpana hollow i hoʻoheheʻe ʻia i ke anuanu, ua deoxidized a pono e hoʻokō i nā kūlana hoʻopuka kikoʻī.

ʻO nā koi kūpono no S275J0H a me S275J2HFF(Ke kila make piha i loaʻa nā mea hoʻopaʻa naikokene i nā nui e hiki ai ke hoʻopaʻa i ka nitrogen i loaʻa (e laʻa me min.0,020 % ka huina Al a i ʻole 0,015 % soluble Al)).

ʻO ke kūlana hoʻouna: ʻōwili ʻia a i ʻole i hoʻololi ʻia / ʻōwili maʻamau (N) no nā kila JR, J0, J2, a me K2.

Hiki ke hana ʻia nā paipu kila a EN 10219 e nā mea ʻeluaERW( electro resistance welding ) aSAW( wiliwili arc submerged ) hana hana.

ʻO ka hana ʻana oNā paipu ERWLoaʻa ka maikaʻi o ka wikiwiki a me ke kumukūʻai kūpono a koho pinepine ʻia no nā papahana e koi ana i ka hana nui a me ke kumukūʻai kiʻekiʻe.

ERWhoʻohana mau ʻia nā paipu e hana i nā anawaena liʻiliʻi a me nā mānoanoa pā lahilahi, ʻoiaiSAWʻoi aku ka maikaʻi o nā paipu no nā anawaena nui a me nā paia mānoanoa. E ʻoluʻolu e koho i ke ʻano o ka paipu kila kūpono no kāu papahana.

ʻO nā paipu ERW i hana ʻia e like me ka EN 10219 ʻaʻole pono e ʻoki i ka weld i loko.

ʻO kēia no ka mea ua hoʻohana nui ʻia nā paipu EN 10219 i nā noi hoʻolālā, e like me ke kūkulu ʻana a me ka ʻenekinia mechanical, kahi i emi iki ai nā koi no ke ʻano weld ma mua o nā moku kaomi a i ʻole nā pipeline kiʻekiʻe. No laila, e like me ka ikaika a me ka pono o ka weld e hoʻokō i nā koi o ka maʻamau, hiki ke hoʻohana ʻia nā welds i loko me ka ʻole o ka ʻoki ʻana.

ʻAʻole hana ʻia ka hoʻomaʻamaʻa wela ma hope aku, koe wale nō ke ʻano o ka weld i loko o kahi kūlana welded a wela paha.

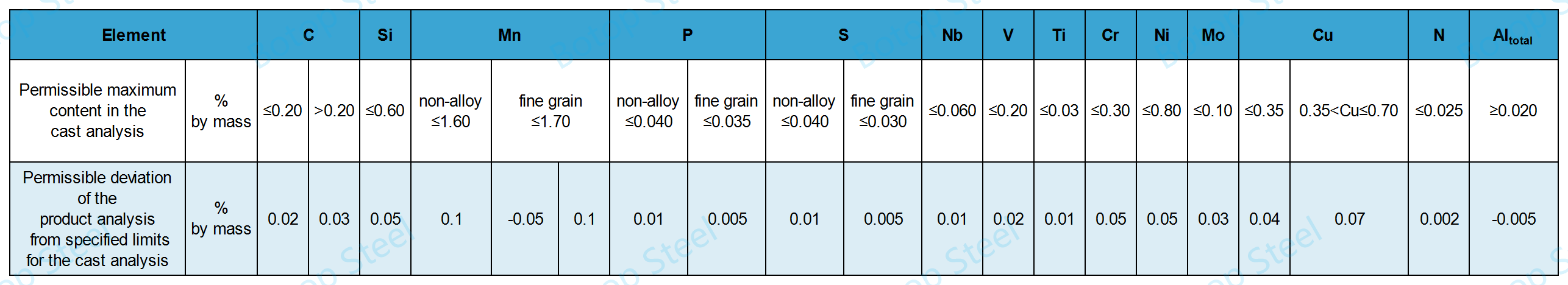

Ka Noʻonoʻo Hoʻolei (Hui Kemika o nā Mea Maka)

Loaʻa iā S275J0H a me S275J2H ka waiwai like kalapona (CEV) o 0.40%.

ʻO S725J0H a me S275J2H me ka CEV kiʻekiʻe o 0.4% e hōʻike ana i ka maikaʻi o ka weldability me ka liʻiliʻi o ka paʻakikī a me ka haki ʻana i ka wā wili.

Hiki ke helu ʻia me ka hoʻohana ʻana i ke ʻano hoʻohālike:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

Nānā Huahana (Hui Kemika o nā Huahana Hoʻopau)

I ka wā o ka hana ʻana i ke kila, hiki ke hoʻololi ke ʻano kemika no nā kumu he nui, a hiki i kēia mau hoʻololi ke hoʻololi i nā waiwai a me ka maikaʻi o ke kila.

Pono e hoʻokō ka hui kemika o ka paipu kila hope loa i ka haku mele ʻana a me kona ʻae ʻia ʻana.

ʻO nā ʻāpana waiwai mechanical e pili ana i ka ikaika hua, ka ikaika tensile, elongation, a me ka ikaika hopena.

ʻO ka hoʻoluhi hoʻoluhi ʻana i ke kaumaha ma mua o 580 ℃ a i ʻole hoʻokahi hola ke alakaʻi i ka pōʻino o nā waiwai mechanical.

Nā memo:

ʻAʻole koi ʻia ka hoʻāʻo ʻana i ka hopena inā he <6mm ka mānoanoa i ʻōlelo ʻia.

ʻAʻole hōʻoia ʻia nā waiwai hopena o nā paipu maikaʻi JR a me J0 ke ʻole i kuhikuhi ʻia.

EN 10219 Welds i nā paipu kila ERW hiki ke hoʻāʻo ʻia ma ke koho ʻana i kekahi o kēia.

EN 10246-3 i ka pae ʻae E4, koe naʻe ʻaʻole ʻae ʻia ke ʻano o ka ʻenehana rotating tube/pancake coil;

EN 10246-5 i ka pae ʻae F5;

EN 10246-8 i ka pae ʻae U5.

ʻO ka helu ʻana o ke kaumaha kumu o nā paipu EN 10219 hiki ke hoʻokumu ʻia ma ka puʻupuʻu puʻupuʻu o 7.85 kg/dm³.

M=(DT)×T×0.02466

ʻO M ka nuipaʻa o kēlā me kēia ʻāpana lōʻihi;

ʻO D ka anawaena waho i ʻōlelo ʻia, nā ʻāpana i mm;

ʻO T ka mānoanoa pā i ʻōlelo ʻia, nā ʻāpana i mm.

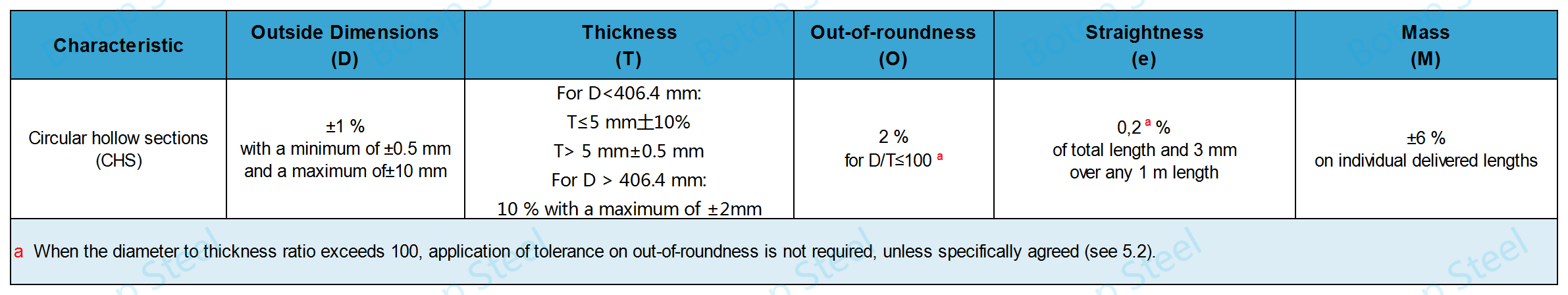

ʻO ka hoʻomanawanui ma ke ʻano, ka pololei a me ka nui

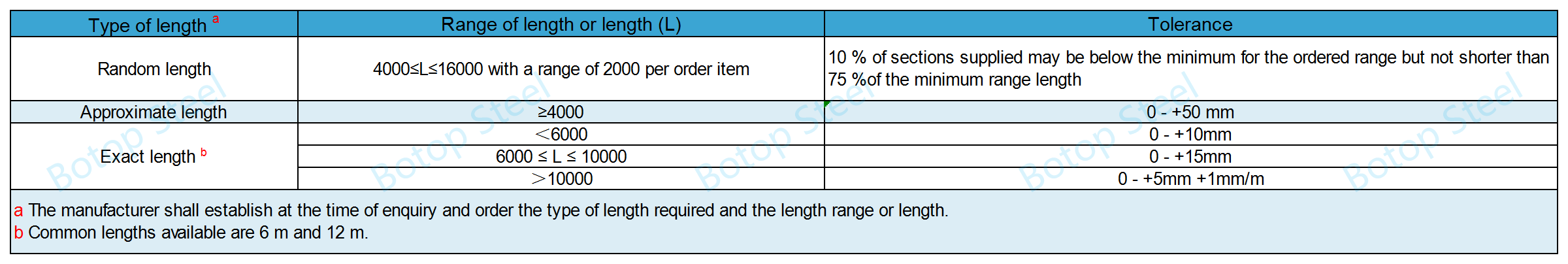

Ka lōʻihi o ka hoʻomanawanui

Hiki ke weldable nā ʻāpana ʻāpana hollow i hana ʻia e like me EN 10219.

I ka wā e wili ai, ʻo ka hāhā anu i ka weld zone ka pilikia nui e like me ka mānoanoa, ka pae ikaika, a me ka CEV o ka huahana. Ma muli o ka hui pū ʻana o kekahi mau kumu:

kiʻekiʻe o ka diffusible hydrogen i loko o ka weld metala;

he hale palupalu i loko o ka ʻāpana wela;

koʻikoʻi koʻikoʻi koʻikoʻi i loko o ka hui welded.

Pono ka ʻili o ka paipu kila a maʻemaʻe a ʻaʻohe hemahema e hoʻopilikia i ka hana o ka huahana, e like me nā māwae, nā lua, nā ʻōpala, a i ʻole ka ʻino.

Hiki ke ʻae ʻia nā ʻōpala, nā ʻūhā, a i ʻole nā ʻūhā longitudinal pāpaʻu i hana ʻia e ke kaʻina hana ʻoiai ʻo ke koena o ka mānoanoa o ka pā i loko o ka hoʻomanawanui, hiki ke wehe ʻia ka hemahema ma ka wili ʻana, a ʻo ka mānoanoa o ka pā i hoʻoponopono ʻia e kūpono i nā koi mānoanoa liʻiliʻi.

Ke kila Botopʻaʻole wale e hāʻawi i nā paipu kila kiʻekiʻe e like me EN 10219, hāʻawi pū ia i kahi ākea o nā koho no ka uhi ʻana i ka ʻili o nā paipu kila e kūpono i nā pono kikoʻī o kāna mau mea kūʻai aku i nā papahana ʻenehana like ʻole. Hoʻolālā ʻia kēia mau uhi no ka hoʻonui ʻana i ke kūpaʻa corrosion o nā paipu a hoʻohui i ka pale hou, no laila e hoʻolōʻihi i ko lākou ola lawelawe.

Hoʻopaʻa wela wela

3LPE (HDPE) ka uhi

Ka uhi FBE

Kāhili Varnish

Pena Pena

ʻO ka uhi ʻana i ke kaumaha sima

Nā mea alahaka: nā hale halihali ukana ʻole i hoʻohana ʻia i nā alahaka, e like me nā ala hao a me nā pale.

Nā kia hoʻolālā: nā kolamu kākoʻo a me nā kaola i hoʻohana ʻia i ka hale a me ka ʻenekinia kīwila.

Pūnaehana paipu: paipu no ka lawe ʻana i nā wai a me nā kinoea, ʻoi loa i nā noi e koi ana i kahi degere o ka maʻalahi a me ka pale ʻana i ka corrosion.

Nā hale kūʻokoʻa: nā kākoʻo manawaleʻa a me nā papa kūpono no ke kūkulu ʻana a me nā kahua ʻenekinia.

Hoʻohana kēia mau noi i nā waiwai mechanical maikaʻi loa a me ka weldability o S275J0H a me S275J2H e hoʻokō i nā pono o nā hale māmā akā paʻa.

ASTM A500:Hōʻike maʻamau no ka Cold-Formed Welded and Seamless Carbon Steel Structural Tubing ma nā pōʻai a me nā ʻano.

ASTM A501: Hōʻike maʻamau no ka Welded Welded a me ka Seamless Carbon Steel Structural Tubing.

EN 10210: ʻO nā ʻāpana hollow kūkulu wela wela o nā kila palaoa maikaʻi ʻole.

EN 10219: ʻO nā ʻāpana ʻāwīwī i hoʻoheheʻe ʻia i ke anuanu o nā kila palaoa maikaʻi ʻole.

JIS G 3466: Ke kila kila huinaha a me na paipu huinahalike no ka hana ma'amau.

AS/NZS 1163: Nā ʻāpana puʻu kila kila i hana ʻia anu.

Hoʻohana nui ʻia kēia mau maʻamau a puni ka honua, a kōkua lākou e hōʻoia i ka hoʻokō ʻana o nā paipu kila i nā koina hana i manaʻo ʻia i nā noi ʻenehana like ʻole. Ke koho ʻana i kahi maʻamau paipu kila, he mea nui e noʻonoʻo i kāna pono noi kikoʻī, nā hoʻoponopono kūloko, a me nā koi hana.

ASTM A252 GR.3 Kūlana LSAW(JCOE) Paipu kila kabone

BS EN10210 S275J0H LSAW(JCOE) Paipu kila

ASTM A671/A671M LSAW Paipu kila

ASTM A672 B60/B70/C60/C65/C70 LSAW Paipu Kinohi

API 5L X65 PSL1/PSL 2 LSAW Paipu kila Carbon / API 5L Papa X70 LSAW Paipu kila

EN10219 S355J0H Kūlana LSAW(JCOE) Paipu kila