ʻO API (American Petroleum Institute Standard) ʻo 5L ka pae honua no ka paipu kila i hoʻohana ʻia i nā ʻōnaehana halihali pipeline.

Hoʻopili ʻo API 5L i ka paipu kila no nā ʻano noi like ʻole no ka lawe ʻana i ke kinoea maoli, ka aila, a me nā wai ʻē aʻe.Ka lā kūpono o ka paʻi 46th: hoʻomaka i Nowemapa 1, 2018.

Inā makemake ʻoe e kiʻi i ka manaʻo nui o API 5L, e kaomiAPI 5L Pipe Hōʻike Manaʻo.

Nā pihi hoʻokele

He aha ka mea i hōʻano hou ʻia ma API 5L 46th

Ke kumu o ka API 5L PSL

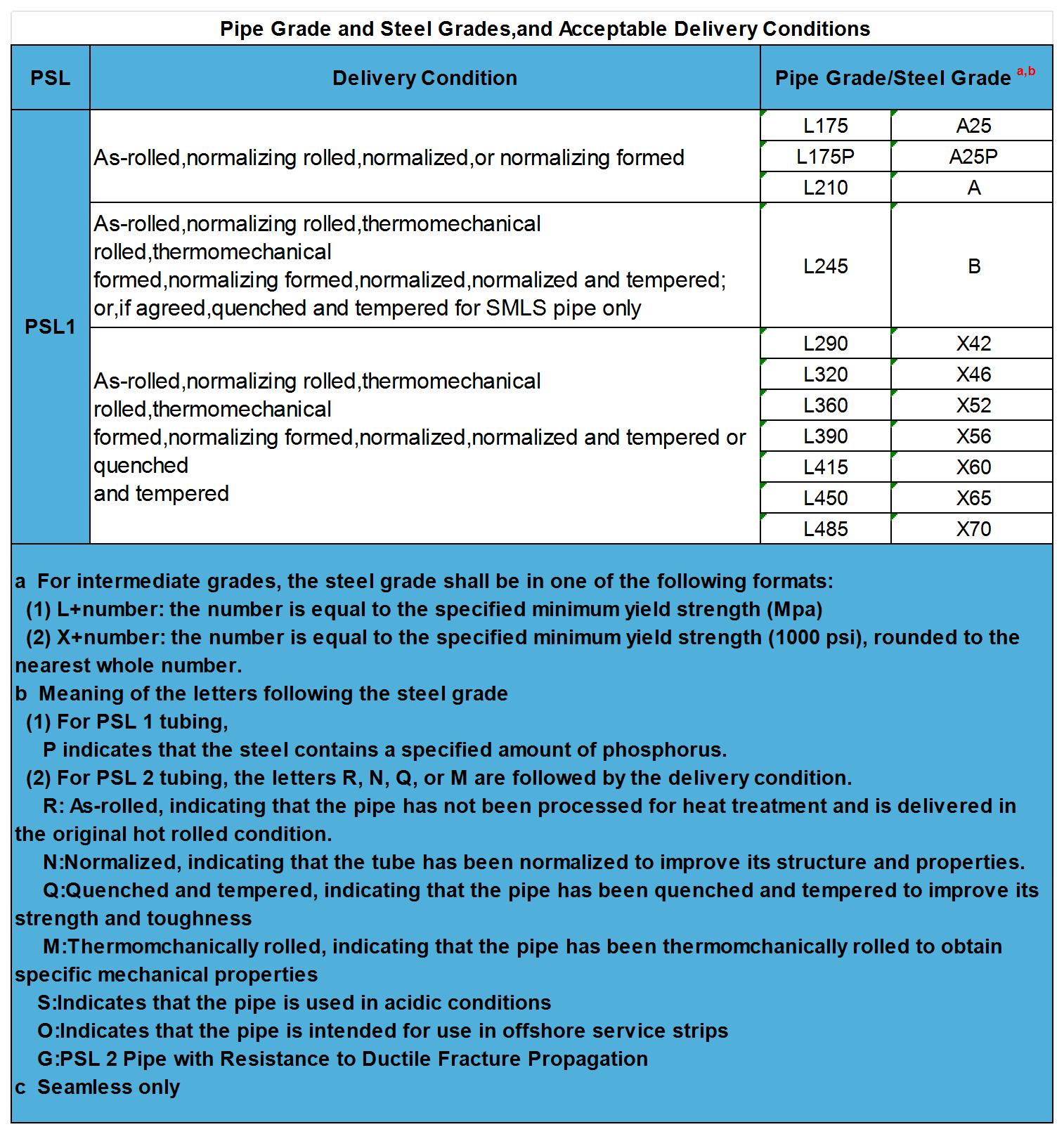

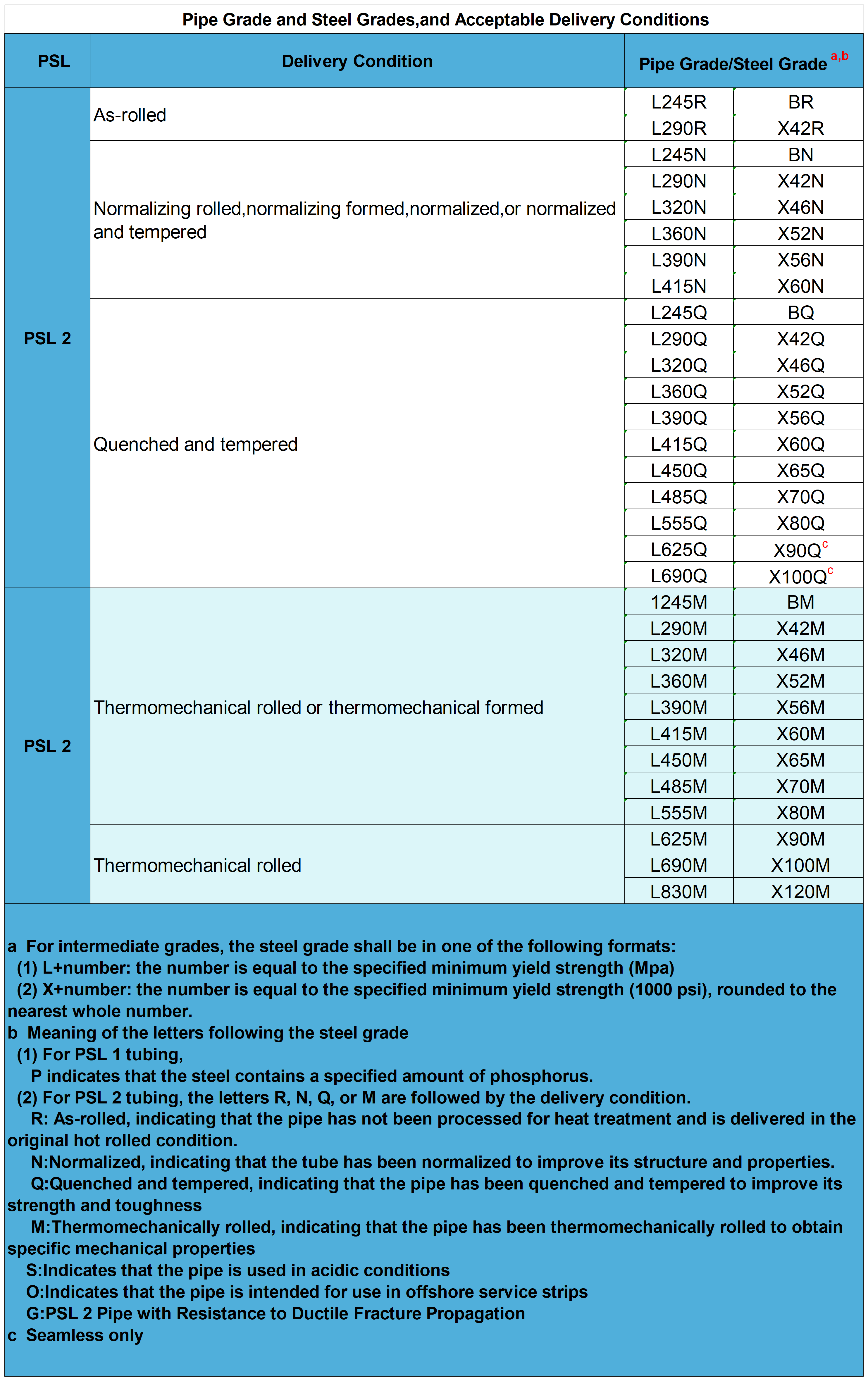

Hoʻokaʻawale ʻana i nā pae kila a me nā pae paipu

ʻAe ʻia nā moku hoʻouna

Na Mea Maka no na Paipu kila

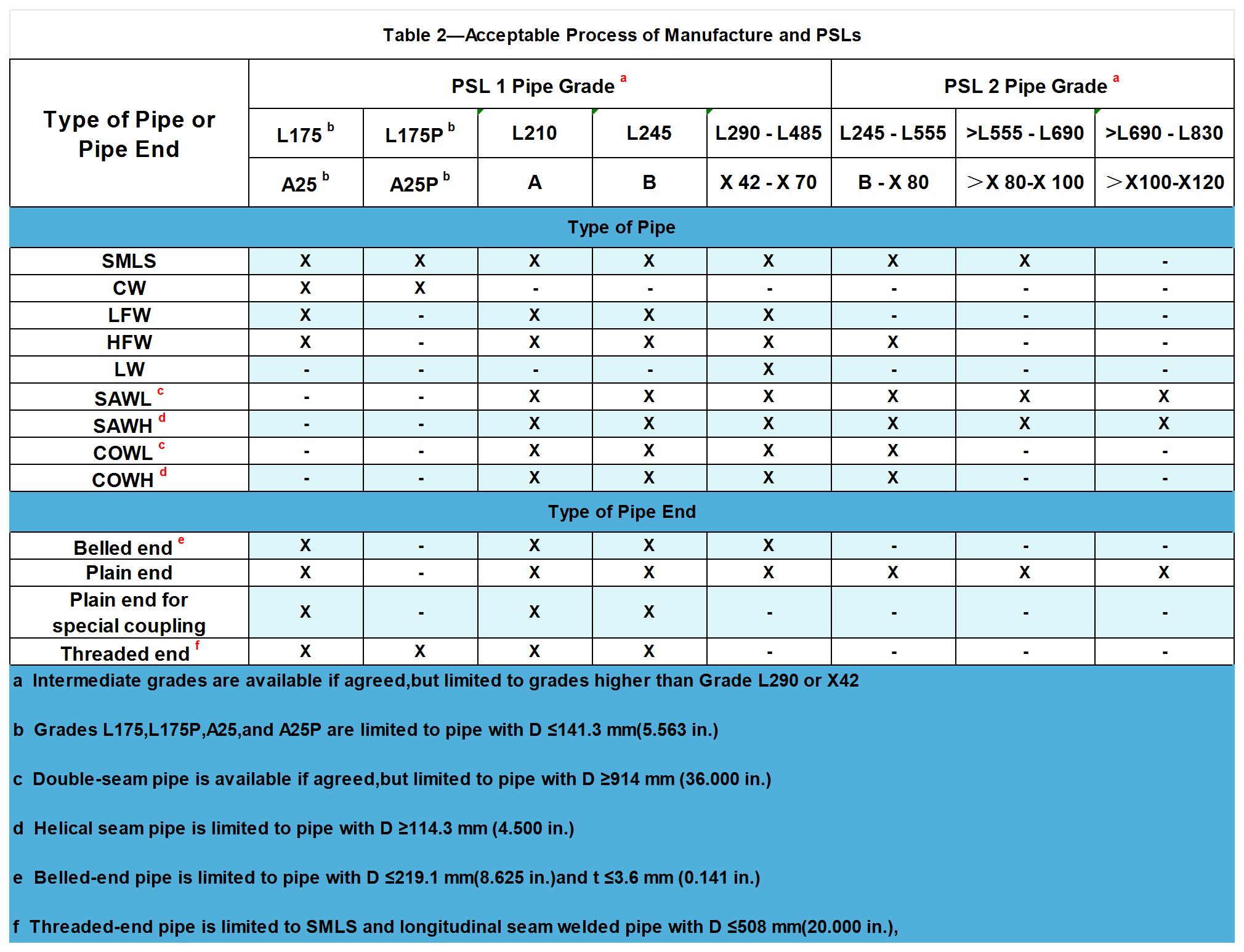

Nā ʻano o ka paipu kila a me nā welau i uhi ʻia e ka API 5L

ʻAe ʻia nā kaʻina hana no ka PSL2 Steel Tubing

Nānā hiʻona a me nā hemahema maʻamau o API 5L

Nānā Ana (Dimensional Deviation)

API 5L mea hoao

Hoailona Paipu a me kahi

Kūlana Kaulike

ʻO kā mākou huahana pili

He aha ka mea i hōʻano hou ʻia ma API 5L 46th

Nā mea hou

Hoʻonui a hoʻonui i nā koi no nā hui wili;

Nā koi hou no ka paipu hopena perpendicularity;

Nā koi hoʻāʻo paʻakikī hou no nā paipu API 5LPSL 2 no nā kaiapuni ʻawaʻawa a me nā paipu API 5L PSL 2 no nā kaiapuni waho;

Hou

API 5L PSL 2 paipu no nā noi e koi ana i ka hiki ke kānana plastic longitudinal.

Ke kumu o ka API 5L PSL

PSL: Pipeline Specification Level abbreviation ;

Māhele ʻia i: API 5L PSL 1 a me API 5L PSL 2.

Hoʻokaʻawale ʻana i nā pae kila a me nā pae paipu

L + helu(Huli ʻia ka leka L e ka ikaika hāʻawi liʻiliʻi i ʻōlelo ʻia ma MPa):

L175,L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485,L555,L625,L6890

X + helu(ʻo ka helu ma hope o ka leka X ke kuhikuhi nei i ka ikaika hāʻawi liʻiliʻi ma 1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

A me ka papa a me ka papa b.Papa A=L210 Papa B=L 2459

ʻAe ʻia nā mokuʻāina hoʻouna

Nānā: ʻAʻole pono e hoʻohana ʻia nā māka L415/X60 a i ʻole nā māka kiʻekiʻe ma kahi o L360/X52 a i ʻole nā māka haʻahaʻa me ka ʻole o ka ʻae ʻana o ka mea kūʻai.

Na Mea Maka no na Paipu kila

Ingot, billet, billet, strip (coil) or plate.

Nānā:

1. Ka mea maka noAPI 5L PSL2ʻO ka paipu kila he kila sedimented maikaʻi.

2. ʻAʻole loaʻa i ka paipu kila API 5L PSL2 a i ʻole ka pā i hoʻohana ʻia no ka hana ʻana i nā welds.

Nā ʻano o ka paipu kila a me nā welau i uhi ʻia e ka API 5L

Paipu kila welo

Paipu CW:ʻO ke kaʻina hana o ka hana ʻana i ka humuhumu ma ka hoʻomehana ʻana i ke kaula i loko o ka umu ahi a me ke kaomi ʻana me ka mīkini i ka ʻaoʻao i hana ʻia a hui pū ʻia, kahi i hui pū ʻia ai nā wili o ke kaula e hāʻawi i ke kahe mau ʻana o ke kaula no ka wili wili.

COWHPipe:ʻO ka huahana tubular me hoʻokahi hili helical i hana ʻia e ka hui ʻana o ke kinoea metala arc a me ka submerged arc weld, kahi i wehe ʻole ʻia ai ke kinoea arc arc weld bead e nā ala kuʻo kuʻo ʻana.

COWL Paipu:ʻO ka huahana tubular me hoʻokahi a ʻelua paha hili lōʻihi i hana ʻia e ka hui pū ʻana o ke kinoea metala arc a me ka submerged arc weld, kahi i wehe ʻole ʻia ai ke kinoea arc arc weld bead e nā ala kuʻi kuʻi ʻana i lalo.

Paipu EW:ʻO ka huahana tubular me hoʻokahi hili longitudinal i hana ʻia e ka wili uila haʻahaʻa a kiʻekiʻe paha.

Paipu HFW:Hana ʻia ʻo EWpipe me kahi alapine o kēia manawa e like me ka nui a i ʻole ma mua o 70 kHz.

Paipu LFW:Hana ʻia ka paipu EW me kahi alapine o kēia manawa ma lalo o 70 kHz.

Paipu LW:ʻO ka huahana tubular me hoʻokahi seam longitudinal i hana ʻia e ka welding laser.

Paipu SAWH:ʻO ka huahana tubular me hoʻokahi hili helical i hana ʻia e ke kaʻina hana kuʻikuʻi arc submerged.

SAWLPaipu:ʻO ka huahana tubular me hoʻokahi a ʻelua paha hili lōʻihi i hana ʻia e ka wiliwili arc i lalo.

Paipu kila ʻole

ʻO ka paipu SMLS:Hot rolled seamless steel paipu a me ke anu i olokaa seamless steel paipu, aia kekahi mau hana hana, e like me ke kii anu, ke kii anu, ka hana ana, etc.

API 5L PSL2 ʻano paipu no nā noi kūikawā

Kū'ē i ka hoʻolaha ʻana o ka haʻihaʻi ductile (G)

Pipa Kūlana Hana ʻawaʻawa (S)

Paipu Kūlana Kūlana Kūlana Kūʻē Kūʻē Kūʻē

Ke koi 'ana i ka paipu ho'opa'a 'ano lō'ihi

Nā ʻano hoʻopau paipu

Hope Hope, Hope Paʻa, Hoʻopaʻa Paʻa Kūikawā, Hope Uila.

Nānā:

1. ʻO nā ʻaoʻao kumu, nā ʻaoʻao o ka paipu no nā pipili kūikawā, a me nā ʻaoʻao o ka paipu wili no API 5L PSL1 wale nō.

2. L175 P/A25 P kila kila API 5L PSL1 paipu kila e machined me ka threaded welau, a API 5L PSL1 paipu kila o na kila kila e machined me ka palahalaha welau.

3. E hāʻawi ʻia nā paipu API 5L PSL 2 me nā wēlau palahalaha.

ʻAe ʻia nā kaʻina hana no ka PSL2 Steel Tubing

| Papa 3—Na Alanui Hana Pono no PSL 2 Pipe | ||||

| ʻAno Paipu | Materia hoʻomaka | Paipu | Wela Paipu Lapaʻau | Hāʻawi Kūlana |

| SMLS | Ingot, pua, a billet paha | As-rolled | — | R |

| Hoʻokumu maʻamau | — | N | ||

| Hoʻokumu wela | Hoʻoponopono maʻamau | N | ||

| Hoʻopiʻi a hoʻonā | Q | |||

| Hana wela a me ke anu hoopau ana | Hoʻoponopono maʻamau | N | ||

| Hoʻopiʻi a hoʻonā | Q | |||

| HFW | ʻO ka wili wili maʻamau | ʻO ke anuanu | Lapaʻau welaa o ka weld wahi wale no | N |

| Thermomechanical-rolled wiliwili | ʻO ke anuanu | Lapaʻau welaa o ka weld wahi wale no | M | |

| Lapaʻau welaa o ka weld wahi a me ka stress relieving o ka paipu holoʻokoʻa | M | |||

| As-rolled a i ʻole wili thermomechanical-rolled | ʻO ke anuanu | Hoʻoponopono maʻamau | N | |

| Ke kinai a hoʻohaunaele | Q | |||

| Hoʻokumu ʻia ke anu i ukali ʻia e ka wela hoemi ana malalo o ka hoomaluia wela ka hopena he kūlana maʻamau | — | N | ||

| Hoʻokumu anu i ukali ʻia e hana ʻana i ka thermomechanical o ka paipu | — | M | ||

| SAW a i ʻole BIPI | Hana maʻamau a maʻamau- ʻōwili ʻōwili a pā paha | ʻO ke anuanu | — | N |

| As-rolled thermomechanical-rolled normalizing-rolled, a i ʻole maʻamau | ʻO ke anuanu | Hoʻoponopono maʻamau | N | |

| Thermomechanical-rolled wili a pā paha | ʻO ke anuanu | — | M | |

| Hoʻopiʻi a huhū pā | ʻO ke anuanu | — | Q | |

| As-rolled thermomechanical-rolled normalizing-rolled, a i ʻole wili maʻamau a pā paha | ʻO ke anuanu | Ke kinai a hoʻohaunaele | Q | |

| As-rolled thermomechanical-rolled normalizing-rolled, or wili maʻamau a pā paha | Hoʻokumu maʻamau | — | N | |

| aE ʻike i ka ISO 5L 8.8 no ka hoʻoponopono wela | ||||

Nānā hiʻona a me nā hemahema maʻamau o API 5L

Nā hiʻohiʻona

ʻO ka ʻili o waho o ka paipu e maʻemaʻe a ʻaʻohe hemahema e pili ana i ka ikaika a me nā waiwai o ka paipu.

Nā hemahema nui

Nā ʻaoʻao i ʻoki ʻia:Hiki ke ʻike maikaʻi ʻia nā ʻaoʻao nibbled ma o ka nānā ʻana.

ʻAha ahi:E noʻonoʻo ʻia ke ahi ahi he hewa.

ʻO nā ahi ahi kekahi mau wahi kīnā i hoʻokumu ʻia e ka hoʻoheheʻe ʻana o ka ʻili metala i hoʻokumu ʻia e ke arc ma waena o ka electrode a i ʻole electrode grounding a me ka ʻili o ka paipu kila.

ʻO nā wahi hoʻopili he mau kiko kūwaho kokoke i ka laina weld o kahi paipu EW, ma muli o ka hoʻopili ʻana ma waena o ka electrode e hāʻawi ana i ke au wili a me ka ʻili o ka paipu.

ʻO ka wehe ʻana:ʻO ka delamination a i ʻole ka hoʻokomo ʻia ʻana ma luna o ka ʻili o ka paipu a i ʻole ka maka beveled a ʻoi aku ka lōʻihi o ka pōʻai ma kahi o ka 6.4 mm (0.250 in) ma ka nānā ʻike maka e manaʻo ʻia he kīnā.

Hoʻokaʻawale Geometric:ʻO kahi hoʻokaʻawale geometric (e laʻa, he poloka palahalaha a i ʻole pout, a me nā mea ʻē aʻe), ma waho o kahi lua kulu, i hana ʻia e ke kaʻina hana o ka paipu a i ʻole ka hana hana.ʻO ka mamao ma waena o ka lae ʻoi loa a me ka hoʻolōʻihi ʻia o ke kihi maʻamau o ka paipu, ʻo ia hoʻi, kahi hohonu i ʻoi aku ma mua o 3.2 mm (0.125 in), e manaʻo ʻia he kīnā.

ʻO ≤ 0.5 D nā lua hāʻule ma kekahi ʻaoʻao.

ʻoʻoleʻa: Ke hōʻike ʻia ka nānā ʻana i ka manaʻo paʻakikī, e hoʻohana ʻia kahi mea hoʻāʻo paʻakikī paʻa no ka hoʻāʻo ʻana i ka paʻakikī, a e noʻonoʻo ʻia kahi kuhi hoʻokahi me ka waiwai paʻakikī ma mua o 35 HRC, 345 HV10, a i ʻole 327 HBW e manaʻo ʻia he hemahema ke ka nui. ʻoi aku ka nui o ka indentation ma mua o 50 mm (2.0 in) ma kekahi ʻaoʻao.

Hoʻopaʻa hewa

E ʻoluʻolu e nānā i nā koi pili i ka API 5L Appendix C no ka lawelawe ʻana.

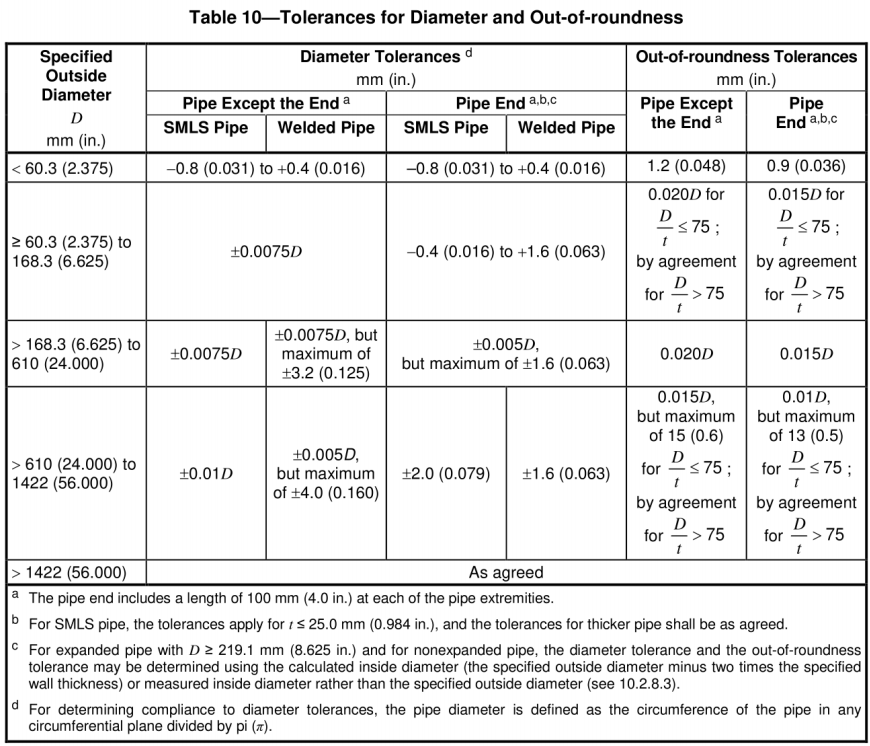

Nānā Ana (Dimensional Deviation)

Papa Kaumaha Paipu a me ka Wehe Paona

Kaumaha Kaumaha

M=(DT)×T×C

ʻO M ka nuipaʻa o kēlā me kēia ʻāpana lōʻihi;

ʻO D ka anawaena waho i ʻōlelo ʻia, i hōʻike ʻia ma nā millimeters (iniha);

ʻO T ka mānoanoa pā i kuhikuhi ʻia, i hōʻike ʻia ma nā millimeters (iniha);

ʻO C ka 0.02466 no ka helu ʻana i nā ʻāpana SI a me 10.69 no ka helu ʻana i nā ʻāpana USC.

PALAPALA PALAPALA A ME NA PALAPALA

Ua kuhikuhi ʻia nā papa kaumaha paipu ma API 5LISO 4200aASME B36.10M, e hāʻawi ana i nā waiwai maʻamau no ka paipu me ke anawaena o waho a me ka mānoanoa pā i kuhikuhi ʻia.

Papa 40 a Papa 80ua hoʻopili ʻia ma lalo, inā makemake ʻoe e ʻike i ka papa hana paipu piha,e kaomi maanei!

Wehe Wehe

ʻO ka maikaʻi o kēlā me kēia paipu e pili ana i ka manaʻo: ke kaumaha: 95% ≤ ke kaumaha ≤ 110;

ʻO ka hoʻokaʻawale ʻana a me nā paipu kikoʻī ʻoi aku ka lahilahi: 5% ≤ 110% o ke kaumaha theoretical;

L175, L175P, A25, a me A25P kila māka: 95% ≤ 110% o ka theoretical kaumaha.

Ka anawaena o waho a me ka mānoanoa o ka pā

| Papa 9—Ua ʻae ʻia ke anawaena o waho a me ka mānoanoa o ka pā | ||

| Hōʻike ʻia i waho ke anawaena D mm (in.) | Mānoanoa Pā i ʻōlelo ʻia t mm (in.) | |

| Nā Nui Māmā Kūikawāa | Nui mau | |

| ≥10.3 (0.405) a i<13.7 (0.540) | — | ≥1.7 (0.068) a i ≤2.4 (0.094) |

| ≥13.7 (0.540) a i<17.1 (0.675) | — | ≥2.2 (0.088) a i ka≤3.0 (0.118) |

| ≥17.1 (0.675) a i<21.3 (0.840) | — | ≥2.3 (0.091) a i ka≤3.2 (0.125 |

| ≥21.3 (0.840) a i<26.7 (1.050) | — | ≥2.1 (0.083) a i ka≤7.5(0.294) |

| ≥26.7(1.050) a i<33.4(1.315) | — | ≥2.1 (0.083) a i ≤7.8 (0.308) |

| ≥33.4(1311}5) a i<48.3 (1.900) | — | ≥2.1 (0.083) a i ka≤10.0 (0.394) |

| ≥48.3 (1.900) a i<60.3 (2.375) | — | ≥2.1 (0.083) a i ka≤12.5 (0.492) |

| ≥60.3 (2.375) a i<73.0 (2.875) | ≥2.1 (0.083) a i ka≤3.6 (0.141) | >3.6 (0.141)a ≤14.2 (0.559) |

| ≥73.0 (2.875) a i<88.9(3.500) | ≥2.1 (0.083) a i ka≤3.6 (0.141) | >3.6 (0.141) a i≤20.0 (0.787) |

| ≥88.9 (3.500) a i<101.6(4.000) | ≥2.1 (0.083) a i ka≤4.0 (0.156) | >4.0 (0.156) a i≤22.0 (0.866) |

| ≥101.6(4.000) a i<168.3 (6.625) | ≥2.1 (0.083) a i ka≤4.0 (0.156) | >4.0(0.156)a ≤25.0 (0.984) |

| ≥168.3 (6.625) a i<219.1 (8.625) | ≥2.1 (0.083) a i ka≤4.0 (0.156 | >4.0 (0.156) a i≤40.0(1.575) |

| ≥219.1 (8.625) a i<273.1 (10.750) | ≥3.2 (0.125) a i ka≤4.0 (0.156 | >4.0 (0.156) a i≤40.0 (1.575 |

| ≥273.1 (10.750) a i<323.9 (12.750) | ≥3.6 (0.141) a i ka≤5.2 (0.203) | >5.2 (0.203) a i≤45.0 (1.771) |

| ≥323.9(12.750) a i<355.6(14.000) | ≥4.0 (0.156) a i ka≤5.6 (0.219) | >5.6 (0.219) a i≤45.0(1.771 |

| ≥355.6(14.000) a i<457(18.000) | ≥4.5 (0.177) a i ≤7.1 (0.281) | >7.1 (0.281) a i≤45.0(1.771 |

| ≥457 (18.000) a i<559 (22.000) | ≥4.8 (0.188) a i ≤7.1 (0.281) | >7.1 (0.281) a i≤45.0(1.771) |

| ≥559 (22.000) a i<711(28.000) | ≥5.6 (0.219) a i ka≤7.1 (0.281) | >7.1 (0.281) a i≤45.0(1.771) |

| ≥711 (28.000) a i<864(34.000) | ≥5.6(0.219) a i ka≤7.1 (0.281) | >7.1 (0.281) a i≤52.0 (2.050) |

| ≥864 (34.000) a i<965(38.000) | — | ≥5.6 (0.219) a i ka≤52.0 (2.050) |

| ≥965(38.000) a i<1422 (56.000) | — | ≥6.4 (0.250) a i ≤52.0 (2.050) |

| ≥1422(56.000) a i<1829 (72.000) | — | ≥9.5 (0.375) a i ≤52.0 (2.050 |

| ≥1829(72.000) a i<2134(84.000) | — | ≥10.3 (0.406) a i ka≤52.0 (2.050) |

| aʻO ka paipu me ka hui pū ʻana o ke anawaena o waho a me ka mānoanoa o ka paia i wehewehe ʻia he paipu māmā nui;ʻO nā hui ʻē aʻe i hāʻawi ʻia ma kēia papa ʻaina i wehewehe ʻia he paipu nui maʻamau. | ||

Ke Anawaena a me ka Poepoe Wehewehe

Paʻa mānoanoa o ka pā

| Papa 11—Ka hoomanawanui no ka manoanoa o ka paia | |

| Mānoanoa Pā t mm (i.) | Hoʻomanawanuia mm (i.) |

| Paipu SMLSb | |

| ≤4.0 (0.157) | +0.6(0.024) -0.5 (0.020) |

| >4.0 (0.157) a i ka<25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146) a i ʻole+0.1t, ʻoi aku ka nui -3.0 (0.120) a i ʻole-0.1t, ʻoi aku ka nui |

| Paipu Weledcd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| >5.0 (0.197) a i ka<15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aInā ʻoi aku ka liʻiliʻi o ka mānoanoa o ka pā ma mua o ke kumu kūʻai i hāʻawi ʻia ma kēia pākaukau, e hoʻonui ʻia ka ʻae ʻana no ka mānoanoa o ka pā e ka nui e mālama ai i ka laulā kūpono. bNo ka paipu me D2 355.6 mm (14.000 in.) a me 1 2 25.0 mm (0.984 in.), hiki ke ʻoi aku ka mānoanoa o ka pā ma ka ʻāina ma mua o ka hoʻonui ʻana i ka mānoanoa o ka pā ma kahi 0.05t hou aku, ke hāʻawi ʻia ka hoʻohui ʻana no ka nui. 9.14) ʻaʻole i ʻoi aku ma mua. cʻAʻole pili ka ʻae ʻana i ka mānoanoa o ka pā i ka wahi weld. dE nānā i ka 9.13.2 no nā kapu hou. | |

Wehewehe lōʻihi

ʻO ka ʻae ʻana o ka paipu lōʻihi paʻa: 500 mm (20 iniha).

ʻO nā ʻae ʻana o ka paipu lōʻihi like ʻole:

| Papa 12—Ka hoomanawanui no ka paipu loihi | |||

| Ka lōʻihi like ʻole Koho m(ft) | Ka lōʻihi liʻiliʻi m (ft) | Ka lōʻihi maʻamau No kēlā me kēia mea kauoha m (ft) | Ka lōʻihi loa m (ft) |

| Paipu Uila-a-hui | |||

| 6(20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72(45.0 |

| Paipu Plain-end | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15(50) | 5.33 (17.5) | 13.35(43.8) | 16.76(55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34(70.0) | 25.91(85.0) |

Holoi pololei

ʻO ka hoʻokaʻawale ʻana mai kahi laina pololei ma luna o ka lōʻihi holoʻokoʻa o ka paipu he <0.2% o ka lōʻihi o ka paipu;

He <3.2 mm (0.125 in) ka mamao mai ka laina pololei ma luna o 1.5 m (5.0 ft) ka lōʻihi o kēlā me kēia hopena paipu.

ʻO kaʻeʻe kihi Bevel

ʻO ka paipu me ka t > 3.2 mm (0.125 in) nā wēlau palahalaha e mīkini ʻia me ka weld bevel me kahi kihi bevel o 30°-35°.

Laulā o ka ʻili aʻa i kūkulu ʻia

1.6 mm (0.063 in) me ka ʻae ʻana o ±0.8 mm (0.031 in).

Ka laula o ka Inner Cone Angle (no ka paipu kila ʻole wale nō)

| Papa 13—Ka kihi kiʻekiʻe o ka liʻiliʻi o loko no ka paipu SMLS | |

| Mānoanoa Pā i ʻōlelo ʻia t mm (in.) | ʻO ke kihi kiʻekiʻe o ka lipi degere |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413) a i<14.0 (0.551) | 9.5 |

| 14.0 (0.551) a i<17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

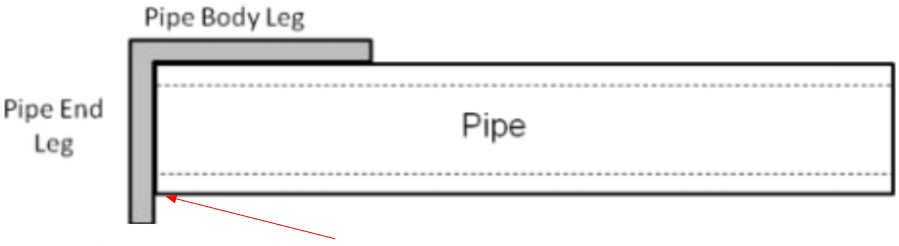

Pahu Pipe End Squareness (out-of-squareness)

Ua ana ʻia ka ʻokoʻa ma ke ʻano he ʻokoʻa ma waena o ka hopena o ka paipu a me ka wāwae hope o ka paipu, ʻo ia ka 1.6 mm (0.063 in.).

Welding Seam Deviation

Hoʻopololei ʻole ka ʻāʻī/pepa:

No ka paipu electro-welded (EW) a me ka laser-welded (LW), ʻaʻole pono ka misalignment i ke koena o ka mānoanoa o ka pā ma ka weld i emi iho ma mua o ka mānoanoa o ka pā i ʻae ʻia.

No ka paipu Submerged Arc Welded (SAW) a me Combination Welded (COW), ʻaʻole pono ke kuhi hewa ʻana ma mua o nā koina i hāʻawi ʻia ma ka Papa 14 o API 5L.

Burrs ( mau paipu electro-welded (EW) a me laser-welded (LW) :

E hoʻoneʻe ʻia nā burrs o waho i kahi kūlana flush nui (me ka mea kumu).

ʻAʻole e hoʻolōʻihi ʻia nā burrs o loko i ka 1.5 mm (0.060 in) ma waho aʻe o ke ʻano o ka paipu, a ʻo ka mānoanoa o ka paia ma kahi o ka wehe ʻia ʻana o ka burr ʻaʻole e emi iho ma mua o ka mānoanoa o ka pā i ʻae ʻia.

Weld Kiʻekiʻe( Hoʻohaʻahaʻa Arc Welding (SAW) a me Combination Welding (COW) Pipe):

Wehe i ke kiʻekiʻe i koe o ka weld kūloko ma loko o ka liʻiliʻi o 100 mm (4.0 in) o ka hopena paipu ma kēlā me kēia kihi o ka paipu, a wili i ka weld i ʻole e piʻi aʻe ma mua o 0.5 mm (0.020 in) ma luna o ka ʻili. o ka paipu pili.

API 5L mea hoao

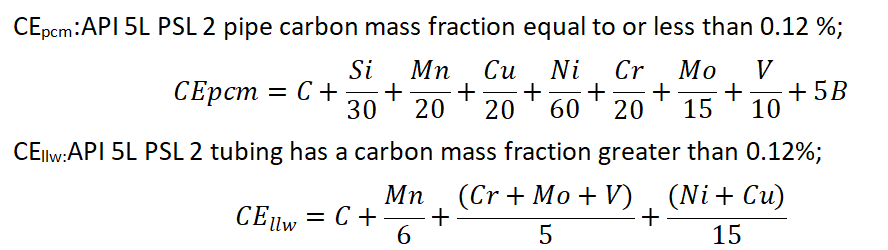

Hoʻohui Kimia

ʻAno hoʻāʻo: E nānā i ka ISO 9769 a i ʻole ASTM A751.

E hoʻoholo ʻia ka hui kemika o API 5L PSL1 a me API 5L PSL2 paipu kila t > 25.0 mm (0.984 in) ma ke kūkākūkā ʻana ma muli o nā haku mele ma nā papa e pili ana.

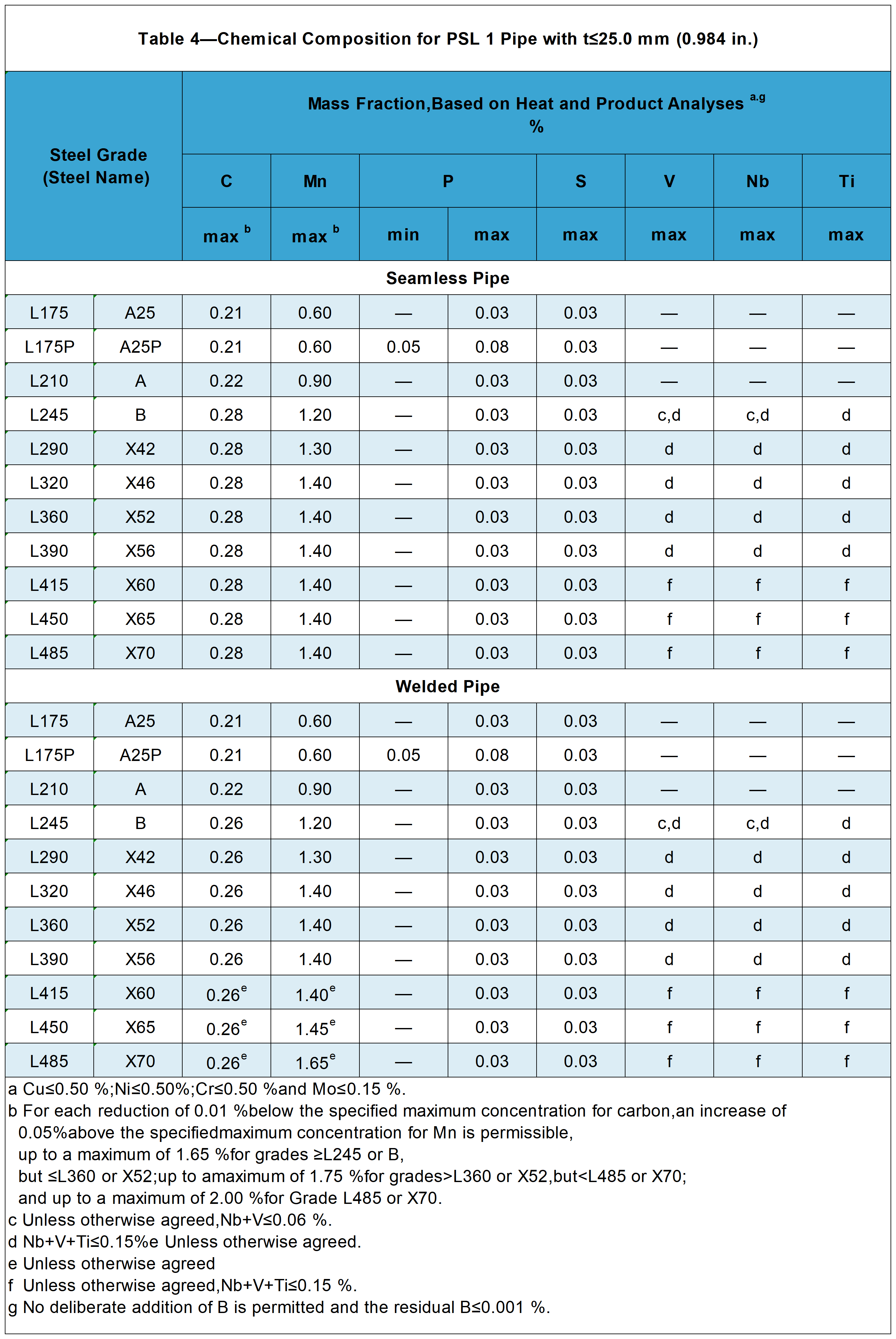

Hoʻohui Kimia no PSL 1 Paipu me ka t≤25.0 mm (0.984 iniha)

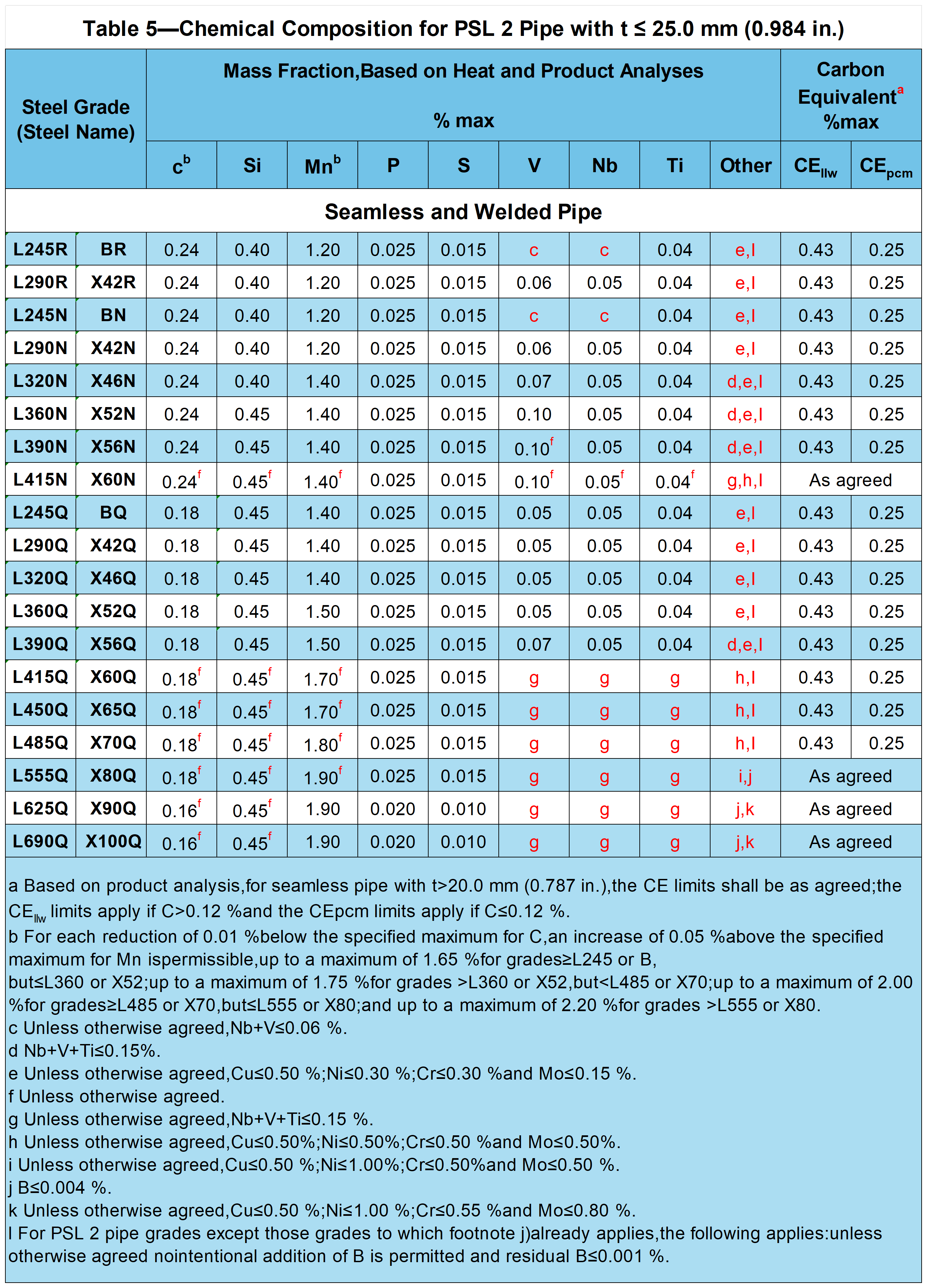

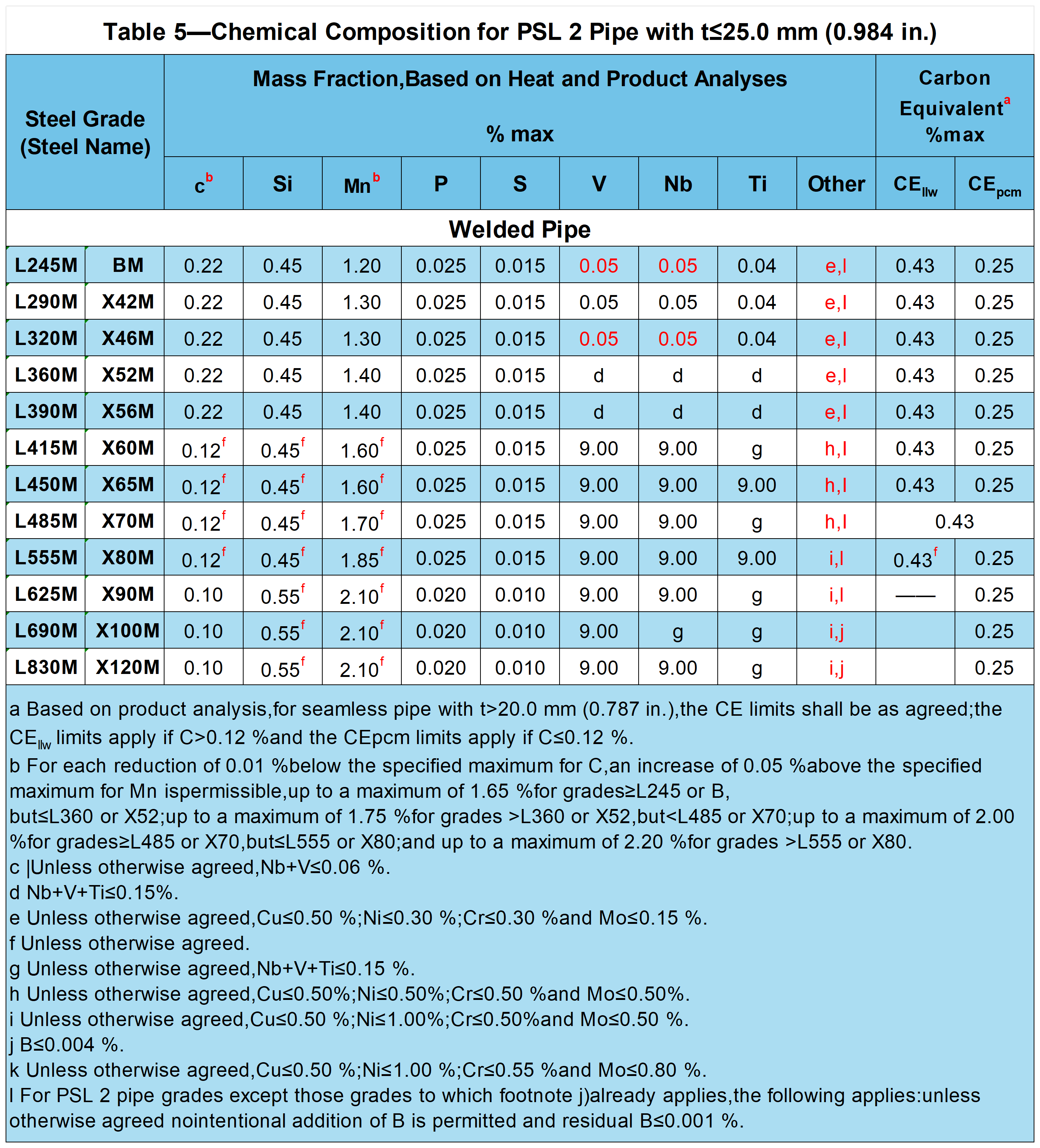

Hoʻohui Kimia no PSL 2 Paipu me ka t≤25.0 mm (0.984 in.)

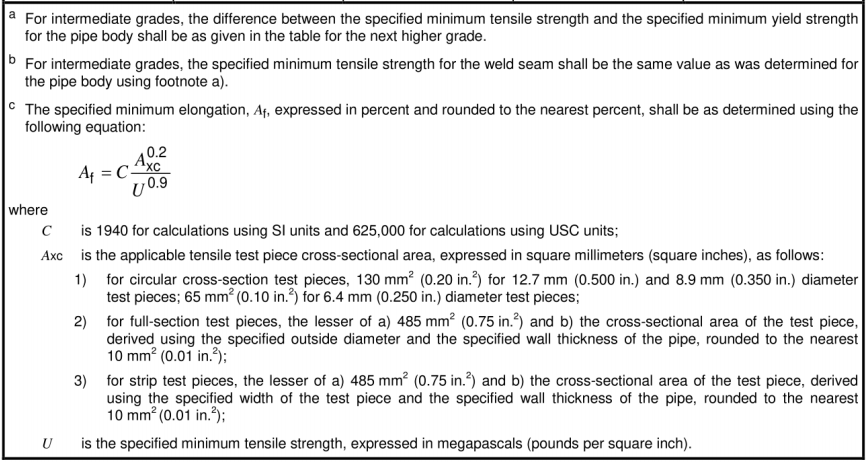

Na Waiwai Tensile

Nā Hana Hoʻāʻo: E hana ʻia e like me ISO 6892-1 a i ʻole ASTM A370.

ʻO nā koi no nā hopena o nā ho'āʻo tensile no ka paipu PSL 1

| Papa 6—Koi no ka hopena o na hoao ana no ka paipu PSL 1 | ||||

| Papa Paipu | Kino Paipu o ka Paipu Holoʻole a Weled | Weld Seam o EW, LW, SAW, a me COW Paipu | ||

| Hua ikaikaa Ri.5 MPa(psi) | Ikaika U'ia Rm MPa(psi) | ʻO ka elongation (ma ka 50 mm a i ʻole 2 in.) Af % | Ikaika U'ib Rm MPa(psi) | |

| min | min | min | min | |

| L175 a i ʻole A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| L175P a i ʻole A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 a i ʻole A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 a i ʻole B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 a i ʻole X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 a i ʻole X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 a i ʻole X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 a i ʻole X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 a i ʻole X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 a i ʻole X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 a i ʻole X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

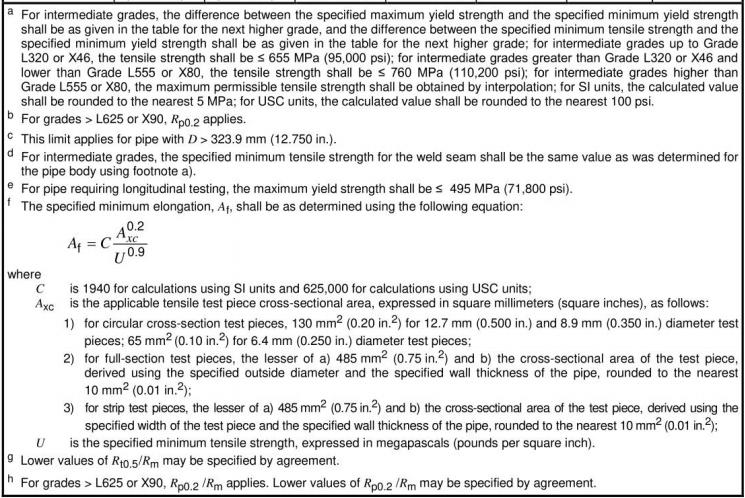

ʻO nā koi no nā hopena o nā ho'āʻo tensile no ka paipu PSL 2

| Papa 7—Koi no ka hopena o na hoao ana no ka paipu PSL 2 | |||||||

| Papa Paipu | Kino Paipu o ka Paipu Holoʻole a Weled | Weld Seam o HFW SAW a Paipu CoW | |||||

| Hua ikaikaa Rto.5 MPa(psi) | Ikaika U'ia Rm MPa (psi) | Lakiac Rt0.5/Rm | ʻO ka elongation (ma ka 50 mm a i ʻole 2 in.) Af % | Kuʻi Ka ikaikad Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R a i ʻole BR L245N a i ʻole BN L245Q a i ʻole BQ L245M a i ʻole BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R a i ʻole X42R L290N a i ʻole X42N L290Q a i ʻole X42Q L290M a i ʻole X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N a i ʻole X46N L320Q a i ʻole X46Q L320M a i ʻole X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N a i ʻole X52N L360Q a i ʻole X52Q L360M a i ʻole X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N a i ʻole X56N L390Q a i ʻole X56Q L390M a i ʻole X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N a i ʻole X56N L390Q a i ʻole X56Q L390M a i ʻole X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N a i ʻole X60N L415Q a i ʻole X60Q L415M a i ʻole X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q a i ʻole X65Q L450M a i ʻole X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q a i ʻole X70Q L485M a i ʻole X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q a i ʻole X80Q L555M a i ʻole X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M a i ʻole X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q a i ʻole X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | — |

| L690M a i ʻole X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q a i ʻole X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | — |

| L830M a i ʻole X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

E hōʻike ʻia ka pākēneka elongation i ka wā hoʻomaha no nā specimens me kahi anana lōʻihi o 50 mm (2 in).

No nā hiʻohiʻona me ka lōʻihi ana ma lalo o 50 mm (2 in), e hoʻololi ʻia ka elongation i ka wā haki i ka elongation ma 50 mm (2 in) e like me ISO 2566-1 a i ʻole ASTM A370.

ʻO ka hoʻāʻo ʻana i ke kaomi Hydrostatic

ʻAno hoʻāʻo: API 5L 10.2.6.

ʻO nā nui a pau o ka paipu seamless (SMLS) a me ka paipu welded me D ≤ 457 mm (18.000 in) e loaʻa i ka manawa hoʻomaha ʻaʻole i emi iho ma mua o 5 kekona.ʻO ka paipu welded me D > 457 mm (18.000 in) e loaʻa i ka manawa hoʻopaʻa ʻaʻole i emi iho ma mua o 10 kekona.

Ho'āʻo Bend

Nā ʻano hoʻāʻo: E hoʻokō ka hōʻike kulou i nā koi o ISO 8491 a i ʻole ASTM A370.

ʻAʻohe wahi o ka specimen e nahā a ʻaʻole nahā ka weld.

ʻO ka papa L175P/A25P he kila i hoʻonui ʻia i ka phosphorus e hāʻawi ana i ka hana threading ʻoi aku ka maikaʻi ma mua o ke kila L175/A25 akā ʻoi aku ka paʻakikī o ka piko.

Ho'āʻo palahalaha

Nā ʻano hoʻāʻo: E hoʻokō ka hoʻāʻo ʻana i nā koi o ISO 8492 a i ʻole ASTM A370.

ʻO ka mamao ma waena o nā papa ʻelua e like me ka hiki ʻole o ka pohā o ka weld a hiki i ka mamao i ʻōlelo ʻia.

Ho'āʻo Kūlou alakaʻi

Nā ʻano hoʻāʻo: E kūlike ka hoʻāʻo ʻana i ke alakaʻi ʻana i nā koi o ISO 5173 a i ʻole ASTM A370.

Ho'āʻo Paʻakikī

Ke ala hoʻāʻo: Hoʻāʻo paʻakikī e like me ISO 6506, ISO 6507, ISO 6508, a i ʻole ASTM A370.

Ke ʻike ʻia nā puʻupuʻu paʻakikī kānalua i ka nānā ʻana, pono e hoʻohana ʻia kahi mea hoʻāʻo paʻakikī paʻakikī no ka hoʻāʻo ʻana i ka paʻakikī.

ʻO ka hoʻāʻo ʻana i ka hopena CVN no ka API 5L PSL2 Pipe kila

Nā ʻano hoʻāʻo: E hoʻokō ka hōʻike hopena charpy i nā koi o ASTM A370.

Ho'āʻo DWT no API 5L PSL2 Pipe Welded

Ke ala ho'āʻo: Pono ka ho'āʻo DWT e like me ka API5L3.

Ho'āʻo Macro-Inspection a me Metallographic

E nānā ʻia nā ʻokoʻa kuʻekuʻe kuʻekuʻe o loko a me waho o ke arc welded (SAW) a me ka paipu hui pū (COW) e ka nānā ʻana macroscopic.

No nā paipu e koi ana i ka lāʻau wela weld, e hana ʻia kahi hoʻokolohua metallurgical e hōʻoia i ka mālama pono ʻana o ka HAZ holoʻokoʻa i ka ʻaoʻao mānoanoa o ka pā.

No nā paipu i koi ʻole i ka mālama wela weld, e hana ʻia kahi hoʻokolokolo metallographic e hōʻoia ʻaʻohe koena martensite i hoʻopaʻa ʻole ʻia.

ʻO ka hoʻāʻo hoʻopau ʻole (no ʻekolu paipu API 5L PSL2 kumu kūikawā wale nō)

ʻAno hoʻāʻo: API 5L Annex E.

Hoailona Paipu a me kahi

Nā mea hōʻailona maʻamau no nā paipu kila:

ʻO ka inoa o ka mea hana paipu a hōʻailona paha;

E kaha ana i ka "API Spec 5L".(Hoʻopau maʻamau i ka API 5L.) Hiki ke kaha ʻia nā huahana e like me nā maʻamau kūpono ʻoi aku ma mua o hoʻokahi me ka inoa o kēlā me kēia maʻamau.

Hōʻike ʻia i waho ke anawaena

ʻO ka mānoanoa pā i kuhikuhi ʻia

Papa paipu (inoa kila)

ʻAno paipu

Ka lōʻihi (ka lōʻihi o ka paipu ma ka m a hiki i ka 0.01 m kokoke loa (ma ka ft a i ka hapaʻumi kokoke loa o ka wāwae))

Kahi o nā kaha paipu kila

D ≤ 48.3 mm (1.900 in) paipu kila: ʻO nā papa i hana mau ʻia ma ka lōʻihi o ka paipu kila a i ʻole hiki ke hoʻopaʻa ʻia i ka pūʻolo paipu kila.

Paipu me D > 48.3 mm (1.900 in):

Ma waho o ka ʻili: E hoʻomaka ana ma kahi kiko ma ka ʻili waho o ka paipu ma waena o 450 mm a me 760 mm (1.5 ft a me 2.5 ft) mai kekahi kihi o ka paipu.

Ili o loko: E hoʻomaka e kaha ma ka ʻili o loko o ka paipu ma kahi o 150 mm (6.0 in) mai kekahi kihi o ka paipu.

Kūlana Kaulike

ʻO nā kūlana paipu a me nā paipu o ka honua a me ka āpana no ka API 5L ka mea like a i ʻole, i kekahi mau kūlana, he koho ʻē aʻe, a me kekahi mau kūlana kikoʻī noiʻi:

Nā kūlana honua a me nā pae'āina

1. ISO 3183 - He kūlana paipu honua no ka ʻoihana ʻaila a me ke kinoea i paʻi ʻia e ka International Organization for Standardization a pili pono i ka API 5L.

2. EN 10208 - European Standard no nā paipu kila no ka lawe ʻana i nā kinoea a me nā wai.

3. GB / T 9711 - ka pae aupuni Kina no nā ʻōnaehana kaʻa pipeline i ka ʻoihana aila a me ke kinoea.

4. CSA Z245.1 - Canadian Standard uhi laina paipu no ka lawe 'ana i ka aila a me ke kinoea.

5. GOST 20295 - Russian Standard no ka paipu laina kila no ka laweʻana i kaʻaila a me kaʻaila.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards no ka paipu laina no kaʻoihanaʻaila a me ke kinoea.

7. JIS G3454, G3455, G3456 - Nā Kūlana ʻOihana Kepani no nā paipu hoʻouna o nā papa kaomi like ʻole.

8. DIN EN ISO 3183 - German Industrial Standard ma muli o ISO 3183 no ka paipu laina.

9. AS 2885 - Australian Standard no nā ʻōnaehana paipu laina no ka lawe ʻana i ka aila a me ke kinoea.

Nā Kūlana Kūikawā Noi

1. API 5CT - American Petroleum Institute maʻamau no ka aila pahu pahu a me ka paipu, ka mea, oiai ma mua i hoʻohana 'ia i loko o ka aila luawai, he mea nui no hoi i ka aila a me ke kinoea oihana.

2. ASTM A106 - American Society for Testing and Materials standard for seamless and welded carbon steel pipe for high-temperature service.

3. ASTM A53 - National Institute for Testing and Materials standard for seamless and welded carbon steel pipe, maʻamau i hoʻohana ʻia no ka lawe ʻana i ka wai ma ka lumi wela a i ʻole ka haʻahaʻa haʻahaʻa.

4. ISO 3834 - International Organization for Standardization standard no nā koi o ka maikaʻi, e kālele ana i nā ʻōnaehana hōʻoia maikaʻi no nā metala welded.

5. dnv-os-f101 - Norewai classification society standard for submarine pipelines for the offshore oil and gas transmission pipelines.

6. MSS SP-75 - Manufacturers Standards Society maʻamau e kālele ana i ka ikaika kiʻekiʻe, nui anawaena pōʻai welded kila paipu.

Nā Kūlana Kūlana Kūikawā a me nā Kūlana Kūikawā

1. NACE MR0175/ISO 15156 - Nā koi no nā mea i hoʻohana ʻia i ka ʻaila a me ka ʻili kinoea i loko o ka sulfur-containing hydrocarbon environments, ʻoiai e pili nui ana i ke koho ʻana i nā mea, he mea nui ia no ka hōʻoia ʻana i ke kūpaʻa corrosion o nā mea i hoʻohana ʻia i ka ʻoihana ʻaila a me ke kinoea.

ʻO kā mākou huahana pili

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Welded Paipu

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Paipu hao hao

API 5L GR.B Paʻa kaumaha mānoanoa o ka paipu kila maʻemaʻe no ka hana ʻana i nā mīkini

API 5L Gr.X52N PSL 2 Paipu kila maʻemaʻe ʻole ACC.To IPS-M-PI-190(3) & NACE MR-01-75 no ka lawelawe ʻawaʻawa.

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 ʻAila a me ka ʻea kinoea ʻaʻohe hao hao ʻole.

API 5L GR.B Paipu laina laina ʻole no ke kaomi a me ke kūkulu ʻana

API 5L/ASTM A106/ASTM A53 Gr.B paipu hao kalapona ʻole.

ʻO BotopSteel kahi loea KinaWelded Carbon Steel Pipes Manufacturers & SuppliersʻOi aku ma mua o 16 mau makahiki me 8000+ Tons o Seamless Linepipe ma ke kumukūʻai i kēlā me kēia mahina.Mākaukau mākou e pane aku iā ʻoe i loko o 24 mau hola ma hope koke o ka loaʻa ʻana o hoʻokahi noi a e hoʻomohala pū i nā pono palena ʻole a me ka hoʻonohonoho ʻana e pili ana i ka hiki.

nā hōʻailona: API 56 46th, Hoʻokaʻawale Ana, PSL1, PSL2,nā mea hoʻolako, nā mea hana, nā hale hana, nā mea kūʻai, nā hui, kūʻai nui, kūʻai, kumu kūʻai, ʻōlelo, nui, no ke kūʻai aku, kumukūʻai.

Ka manawa hoʻouna: Mar-22-2024