ASTM A671 he paipu kila i hana ʻia mai ka pā maikaʻi o ka ipu kaomi,Uila-Fusion-Welded (EFW)no nā kaiapuni kiʻekiʻe ma nā wela a me nā haʻahaʻa haʻahaʻa.

He kūpono ia no nā noi e koi ana i ka paʻa paʻa kiʻekiʻe a me nā waiwai haʻahaʻa haʻahaʻa.

ASTM A671 Nui Nui

Manaʻo ʻia: nā paipu kila me DN ≥ 400 mm [16 in] a me WT ≥ 6 mm [1/4].

Hiki ke hoʻohana ʻia no nā nui ʻē aʻe o ka paipu, ke hoʻokō nei i nā koi ʻē aʻe a pau o kēia kikoʻī.

ASTM A671 hōʻailona

I mea e hoʻomaopopo maikaʻi ai i ka ASTM A671, e hoʻomaopopo mua kākou i kāna ʻike mākaʻikaʻi. Kōkua kēia i ka wehewehe ʻana i ke ʻano o ka noi a me nā ʻano o kēia maʻamau.

Ka Laʻana o ka hoʻopā ʻana:

BOTOP EFW ASTM A671 CC60 -22 16"×SCH80 HEAT NO.4589716

BOTOP: Ka inoa o ka mea hana.

EFW: Ke kaʻina hana ʻana o ka paipu kila.

ASTM A671: Kūlana Hoʻokō no ka Paipu kila.

CC60-22: Nā pōkole no ka papa:cc60 a me ka papa 22.

16" x SCH80: Anawaena a me ka manoanoa o ka paia.

HEAT NO. 4589716: Wela no. no ka hana ana i na paipu kila.

ʻO kēia ke ʻano maʻamau o ka ASTM A671 spray labeling.

ʻAʻole paʻakikī ka loaʻa ʻana o ka ASTM A671 i ka papa a me ka papa ʻelua, a laila hōʻike kēia mau papa ʻelua i ke ʻano.

Papa helu

Hoʻokaʻawale ʻia e like me ke ʻano o ka pā i hoʻohana ʻia no ka hana ʻana i nā paipu kila.

Hōʻike nā māka ʻokoʻa i nā haku mele like ʻole a me nā waiwai mechanical no nā ʻano paʻi a me nā kūlana wela.

No ka laʻana, he mau kila kalapona maʻemaʻe kekahi mau māka, a ʻo nā mea ʻē aʻe he kila me nā mea hoʻohui i hoʻohui ʻia, e like me nā kila nickel.

| Papa Paipu | ʻAno kila | Hōʻike hōʻike ASTM | |

| ʻAʻole. | Papa/papa/ʻano | ||

| CA 55 | kalapona maʻemaʻe | A285/A285M | Gr C |

| CB 60 | kalapona maʻemaʻe, pepehi ʻia | A515/A515M | Gr 60 |

| CB 65 | kalapona maʻemaʻe, pepehi ʻia | A515/A515M | Gr 65 |

| CB 70 | kalapona maʻemaʻe, pepehi ʻia | A515/A515M | Gr 70 |

| CC 60 | kalapona maʻemaʻe, pepehi ʻia, palaoa maikaʻi | A516/A516M | Gr 60 |

| CC 65 | kalapona maʻemaʻe, pepehi ʻia, palaoa maikaʻi | A516/A516M | Gr 65 |

| CC 70 | kalapona maʻemaʻe, pepehi ʻia, palaoa maikaʻi | A516/A516M | Gr 70 |

| CD 70 | manganese-silicon, maʻamau | A537/A537M | Cl 1 |

| CD 80 | manganese-silikona, kinai a me ka huhu | A537/A537M | Cl 2 |

| CFA 65 | kila nikela | A203/A203M | Gr A |

| CFB 70 | kila nikela | A203/A203M | Gr B |

| CFD 65 | kila nikela | A203/A203M | ʻO Gr D |

| CFE 70 | kila nikela | A203/A203M | Gr E |

| CG 100 | 9% nikela | A353/A353M | |

| CH 115 | 9% nikela | A553/A553M | ʻAno 1 |

| CJA 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr A |

| CJB 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr B |

| CJE 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr E |

| CJF 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr F |

| CJH 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr H |

| CJP 115 | kila kila, kinai ʻia a hoʻonāwaliwali | A517/A517M | Gr P |

| CK 75 | kalapona-manganese-silikona | A299/A299M | Gr A |

| CP 85 | kila kila, hoʻopaʻakikī makahiki, kinai ʻia a mālama ʻia ka ua | A736/A736M | Gr A, Papa 3 |

Papa Papa

Hoʻokaʻawale ʻia nā paipu e like me ke ʻano o ka mālama wela i loaʻa iā lākou i ka wā o ke kaʻina hana a inā paha i nānā ʻia a ʻaʻole i nānā ʻia a hoʻāʻo ʻia ke kaomi.

Hōʻike nā ʻāpana like ʻole i nā kikoʻī lapaʻau wela like ʻole no nā paipu.

ʻO nā hiʻohiʻona e like me ka normalizing, ka hoʻomaha hoʻoluhi, ke kinai ʻana, a me ka huhū.

| Papa | Hana wela ma ka paipu | Radiography, ʻike i ka leka: | ho'āʻo paʻi, ʻike i ka leka: |

| 10 | ʻaʻohe | ʻaʻohe | ʻaʻohe |

| 11 | ʻaʻohe | 9 | ʻaʻohe |

| 12 | ʻaʻohe | 9 | 8.3 |

| 13 | ʻaʻohe | ʻaʻohe | 8.3 |

| 20 | hoʻomaha ʻia ke kaumaha, e ʻike i ka 5.3.1 | ʻaʻohe | ʻaʻohe |

| 21 | hoʻomaha ʻia ke kaumaha, e ʻike i ka 5.3.1 | 9 | ʻaʻohe |

| 22 | hoʻomaha ʻia ke kaumaha, e ʻike i ka 5.3.1 | 9 | 8.3 |

| 23 | hoʻomaha ʻia ke kaumaha, e ʻike i ka 5.3.1 | ʻaʻohe | 8.3 |

| 30 | maʻamau, e nānā i ka 5.3.2 | ʻaʻohe | ʻaʻohe |

| 31 | maʻamau, e nānā i ka 5.3.2 | 9 | ʻaʻohe |

| 32 | maʻamau, e nānā i ka 5.3.2 | 9 | 8.3 |

| 33 | maʻamau, e nānā i ka 5.3.2 | ʻaʻohe | 8.3 |

| 40 | maʻamau a me ka huhū, e nānā i ka 5.3.3 | ʻaʻohe | ʻaʻohe |

| 41 | maʻamau a me ka huhū, e nānā i ka 5.3.3 | 9 | ʻaʻohe |

| 42 | maʻamau a me ka huhū, e nānā i ka 5.3.3 | 9 | 8.3 |

| 43 | maʻamau a me ka huhū, e nānā i ka 5.3.3 | ʻaʻohe | 8.3 |

| 50 | kinai a huhu, nana 5.3.4 | ʻaʻohe | ʻaʻohe |

| 51 | kinai a huhu, nana 5.3.4 | 9 | ʻaʻohe |

| 52 | kinai a huhu, nana 5.3.4 | 9 | 8.3 |

| 53 | kinai a huhu, nana 5.3.4 | ʻaʻohe | 8.3 |

| 70 | hoʻopiʻi ʻia a mālama ʻia ka ua | ʻaʻohe | ʻaʻohe |

| 71 | hoʻopiʻi ʻia a mālama ʻia ka ua | 9 | ʻaʻohe |

| 72 | hoʻopiʻi ʻia a mālama ʻia ka ua | 9 | 8.3 |

| 73 | hoʻopiʻi ʻia a mālama ʻia ka ua | ʻaʻohe | 8.3 |

Pono e ʻike ʻia ka mahana o ka hoʻohana ʻana i ke koho ʻana i nā mea. Hiki ke kuhikuhi ʻia i ka kikoʻī ASTM A20/A20M.

Mea Maka

Hiki ke loaʻa nā papa kiʻekiʻe no nā moku kaomi, nā kikoʻī o nā ʻano, a me nā kūlana hoʻokō ma ka papa maPapa helumaluna.

Nā Lae Kūlohelohe

Welding: E hoʻopaʻa ʻia nā kuʻina, e hoʻopili piha ʻia.

E hana ʻia ka welding e like me nā kaʻina hana i kuhikuhi ʻia ma ka Pauku IX o ka ASME Boiler and Pressure Vessel Code.

E hana ʻia nā welds me ka lima a i ʻole ma ke kaʻina hana uila e pili ana i ka waiho ʻana o ka metala filler.

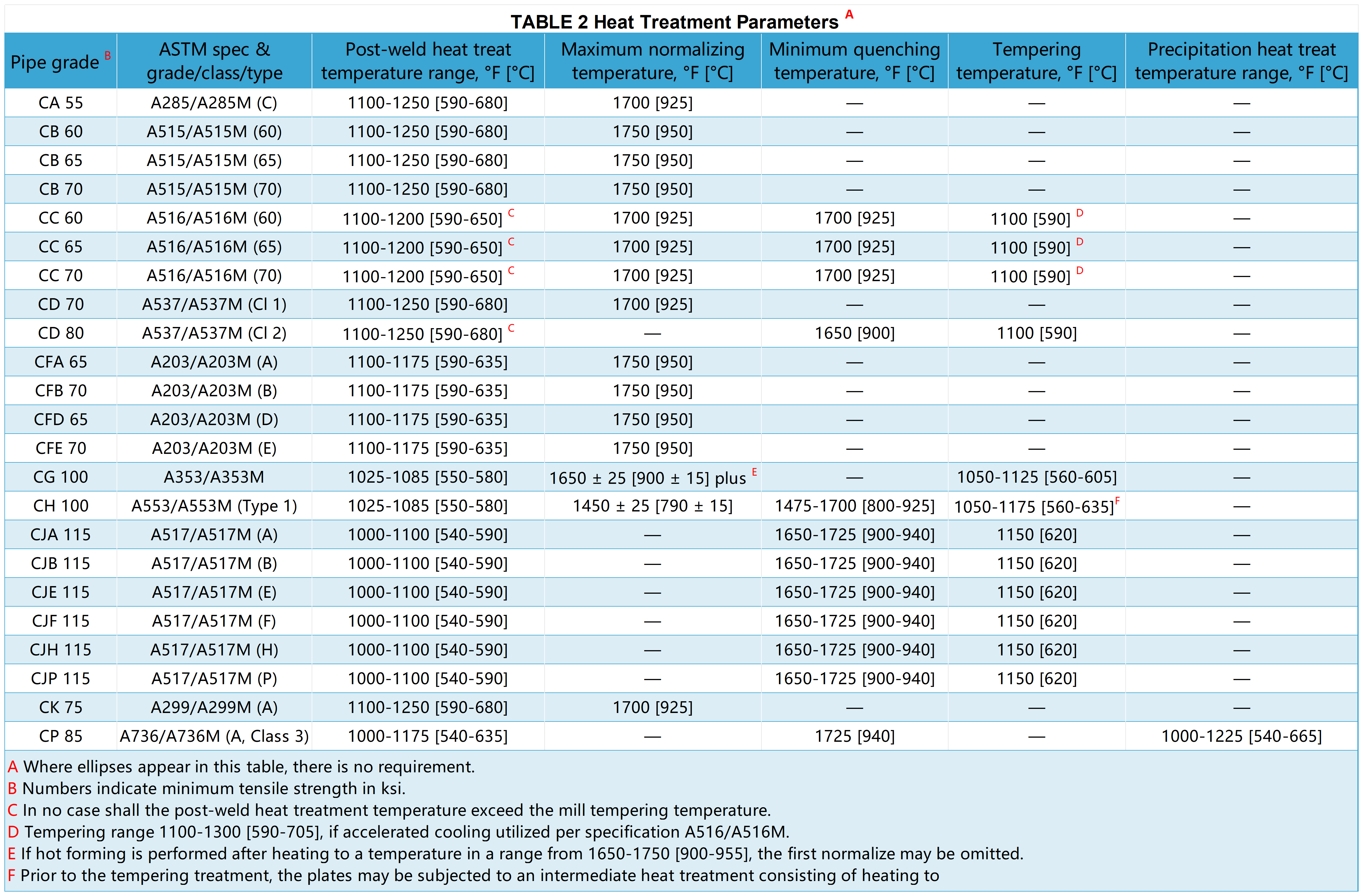

Lapaau Wela no na Papa like ole

ʻO nā papa ʻē aʻe ma mua o 10, 11, 12, a me 13 e mālama ʻia i ka wela i loko o kahi umu i hoʻomalu ʻia i ± 25 °F[± 15°C].

Nā papa 20, 21, 22, a me 23

E hoʻomaʻamaʻa like ʻia i loko o ka pae wela o ka mālama ʻana i ka wela ma hope o ka weld i hōʻike ʻia ma ka Papa 2 no ka liʻiliʻi o 1 h/in. [0.4 h/cm] o ka mānoanoa a i ʻole no 1 hola, ʻo ia ka mea i ʻoi aku ka nui.

Nā papa 30, 31, 32, a me 33

E hoʻomaʻamaʻa like ʻia a hiki i kahi wela o ka austenitizing range a ʻaʻole i ʻoi aku ma mua o ka wela maʻamau maʻamau i hōʻike ʻia ma ka Papa 2 a ma hope iho e hoʻomaloʻo ʻia i ka lewa ma ka wela lumi.

Nā papa 40, 41, 42, a me 43

E hoʻomaʻamaʻa ʻia ka paipu.

E hoʻomaʻamaʻa hou ʻia ka paipu i ka wela wela i hōʻike ʻia ma ka Papa 2 ma ke ʻano he haʻahaʻa a mālama ʻia ma kahi wela no ka liʻiliʻi o 0.5 h/in.[0.2 h/cm] o ka mānoanoa a i ʻole no 0.5 h, ʻo ia ka mea i ʻoi aku ka nui, a hoʻoluʻu ea.

Nā papa 50, 51, 52, a me 53

E hoʻomāhana like ʻia ka paipu i nā mahana i loko o ka pae austenitizing a ʻaʻole i ʻoi aku ma mua o ka wela hoʻopau kiʻekiʻe i hōʻike ʻia ma ka Papa 2.

A laila e kinai i ka wai a i ʻole ka aila. Ma hope o ke kinai ʻana, e hoʻomaʻamaʻa hou ʻia ka paipu i ka wela haʻahaʻa haʻahaʻa i hōʻike ʻia ma ka Papa 2 a paʻa i kēlā.

ka mahana no ka liʻiliʻi o 0.5 h/ʻīniha [0.2 h/cm] o ka mānoanoa a i ʻole 0.5 h, ʻo ia ka mea i ʻoi aku ka nui, a hoʻoluʻu ea.

Nā papa 70, 71, 72, a me 73

Na paipue hoʻomaʻamaʻa like ʻia i kahi wela ma ka laula austenitizing, ʻaʻole i ʻoi aku ma mua o ka wela hoʻopiʻi kiʻekiʻe i hōʻike ʻia ma ka Papa 2, a laila kinai ʻia i ka wai a i ʻole ka aila.

Ma hope o ke kinai ʻana, e hoʻomaʻamaʻa hou ʻia ka paipu i loko o ka pae mālama wela i hōʻike ʻia ma ka Papa 2 no kahi manawa e hoʻoholo ʻia e ka mea hana.

Nā papahana hoʻokolohua ASTM A671

Hoʻohui Kimia

E like me nā koi kūpono o nā kūlana hoʻokō o nā mea maka, ka nānā ʻana i ka haku mele, nā hopena o ka hoʻokolohua e hoʻokō i nā koi maʻamau.

Ho'āʻo Hoʻopaʻapaʻa

ʻO nā paipu welded a pau i hana ʻia e like me kēia kikoʻī pono e loaʻa i kahi hoʻāʻo cross-weld tensile ma hope o ka hoʻomaʻamaʻa ʻana i ka wela, a pono e kūlike nā hopena i nā koi kumu kumu no ka ikaika tensile hope o ka mea pā i kuhikuhi ʻia.

Hoʻohui hou, e loaʻa i nā Papa CD XX a me CJ XXX, inā ʻo kēia o ka Papa 3x, 4x, a i ʻole 5x, a me ka Papa CP o 6x a me 7x e loaʻa i kahi hoʻāʻo tensile base metal tensile i hana ʻia ma nā specimen i ʻoki ʻia mai ka paipu paʻa. ʻO nā hopena o kēia mau hoʻāʻo e hoʻokō i nā koi hoʻāʻo mechanical haʻahaʻa loa o ka kikoʻī pā.

Ho'āʻo Weld Bend Alakaʻi Transverse

E ʻae ʻia ka hoʻāʻo piʻo inā ʻaʻohe māwae a i ʻole nā hemahema ʻē aʻe1/8i. [3 mm] ma kekahi ʻaoʻao aia i loko o ka weld metala a i ʻole ma waena o ka weld a me ka metala kumu ma hope o ke kulou ʻana.

ʻO nā māwae i puka mai ma nā ʻaoʻao o ka hōʻailona i ka wā o ka hoʻāʻo ʻana, a ʻoi aku ka liʻiliʻi ma mua1/4in. [6 mm] i ana ma kekahi aoao aole e noonooia.

Ho'āʻo Paʻi

E hoʻāʻo ʻia nā papa X2 a me X3 paipu e like me ka Specification A530/A530M, Hydrostatic Test Requirements.

ʻO ka hōʻike radiographic

E nānā ʻia ka lōʻihi piha o kēlā me kēia weld o nā Papa X1 a me X2 e like me nā koi o ka ASME Boiler and Pressure Vessel Code, Section VIII, Paragraph UW-51.

Hiki ke hana ʻia ka hoʻokolohua radiographic ma mua o ka mālama ʻana i ka wela.

ASTM A671 Nānā

ʻO ka paipu i hoʻopau ʻia ʻaʻole ia me nā pōʻino ʻino a loaʻa ka hopena e like me ka hana.

ʻAe ʻia ka ʻae ʻana i ka nui

| Haʻuki | Waiwai hoʻomanawanui | Nānā |

| Anawaena waho | ±0.5% | Ma muli o ke ana puni |

| Poe-waho | 1%. | ʻO ka ʻokoʻa ma waena o nā anawaena nui a me ka liʻiliʻi ma waho |

| Hoʻopololei | 1/8 in [3 mm] | E hoʻohana ana i kahi ʻaoʻao pololei 10 kapuaʻi [3 m] i hoʻopili ʻia nā welau ʻelua me ka paipu |

| mānoanoa | 0.01 in [0.3 mm] | ʻOi aku ka mānoanoa o ka paia liʻiliʻi ma mua o ka mānoanoa nominal i kuhikuhi ʻia |

| Nā lōʻihi | 0 - +0.5in [0 - +13mm] | nā hopena ʻole |

Nā noi no ka ASTM A671 Steel Tubing

ʻoihana ikehu

Hoʻohana ʻia no ka lawe ʻana i nā wai cryogenic i nā mea kanu mālama kinoea maoli, nā refineries, a me nā mea hana kemika.

Nā Pūnaehana Hoʻolulu ʻOihana

No ka hoʻohana ʻana i ka ʻāpana cryogenic o ka refrigeration a me nā ʻōnaehana ea e hōʻoia i ka paʻa o ka ʻōnaehana a me ka palekana.

Nā pono hana

No ka waiho ʻana a me ka lawe ʻana i nā kinoea wai.

Hale a me ka hana

Hoʻohana ʻia i nā hana ʻenehana i nā haʻahaʻa haʻahaʻa a i ʻole nā kūlana kaiapuni koʻikoʻi, e like me ke kūkulu hale mālama anu.

ʻO mākou kekahi o nā mea hoʻolaha kiʻekiʻe kiʻekiʻe kiʻekiʻe a me nā mea kūʻai mai Kina, me ka nui o nā paipu kila kila kiʻekiʻe, ua paʻa mākou i ka hāʻawiʻana iāʻoe i ka piha piha o nā paipu paipu. No nā kikoʻī huahana hou aku, e ʻoluʻolu e kelepona mai iā mākou, ke kakali nei mākou i ke kōkua ʻana iā ʻoe e ʻike i nā koho paipu kila maikaʻi loa no kāu mau pono!

Tags: ASTM a671, efw, cc 60, papa 22, nā mea hoʻolako, nā mea hana, nā hale hana, nā mea kūʻai aku, nā hui, kūʻai nui, kūʻai, kumukūʻai, ʻōlelo, nui, no ke kūʻai aku, kumu kūʻai.

Ka manawa hoʻouna: Apr-19-2024