ʻO API 5L X70 kahi papa waiwai API 5L no ka paipu laina me ka ikaika haʻahaʻa haʻahaʻa o 70,000 psi.Hoʻohana mua ia no ka lawe ʻana i ke kinoea maoli, ka aila, a me ka wai.

No ka ʻike hou aku e pili ana i ka API 5L-46th, hiki iā ʻoekaomi maanei!

API 5L X70 Hiʻona

ʻO ka ikaika hua kiʻekiʻe: ʻO ka ikaika hua liʻiliʻi o 70,000 psi (ma kahi o 485 MPa), kūpono no nā kaomi kūloko kiʻekiʻe.

ʻO ka paʻakikī maikaʻi: mālama i ka hana ma nā mahana haʻahaʻa no nā wahi anu a me nā noi kai hohonu.

ʻOi aku ka maikaʻi o ka weldability: ʻO ka ikaika kiʻekiʻe i ka mālama ʻana i ka weldability maikaʻi, me nā welds e pili ana i nā waiwai o ka metala kumu.

ʻO ke kūpaʻa ʻino: hiki ke hoʻonui ʻia e ka hoʻomalu ʻana i ka haku mele a me ka mālama ʻana ma hope (e laʻa me ka uhi ʻana), kūpono no nā kaiapuni waho a me ka corrosive.

Kūpono kaiapuni: Hiki ke hoʻolālā ʻia no ka hoʻohana ʻana i ka ʻāina maʻamau, waho, a me nā kaiapuni lawelawe waika.

Hoʻomau: Hoʻemi ʻia ka hopena o ke kaiapuni a me ka hoʻomaikaʻi ʻana i ka pono o ka hoʻouna ʻana ma ke ʻano he mea hiki ke hana hou ʻia.

API 5L X70 Hoʻohui

ʻAno Pipe: Welded a Seamless Steel Pipe

Papa kiko'ī huahana: API 5L X70 PSL1 a me API 5L X70 PSL2

Kaʻina hana paipu: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

ʻAno hopena paipu: ʻO ka hope bele, ʻO ka hopena maʻamau

Mea Maka

ʻO nā ingots, billets, billets, strips (coils), a i ʻole nā papa i mea maka no ka hana ʻana i nā paipu kila.

ʻO ka mea maka no ka paipu kila PSL2 he kila sedimented maikaʻi.

Eia kekahi, ʻaʻole loaʻa i ke kaula kila (coil) a i ʻole ka pā i hoʻohana ʻia no ka hana ʻana i ka paipu kila PSL2.

API 5L X70 Paipu Kaʻina Hana Hana

| ʻAno Paipu | SMLS | LFW | HFW | LW | SAWLc | SAWHd | COWLc | COWHd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | — | X | — | X | X | X | X |

cLoaʻa ka paipu humu lua inā ʻae ʻia, akā kaupalena i ka paipu me D ≥ 914 mm.

dUa kaupalena ʻia ka paipu seam Helical i ka paipu me D ≥ 114.3 mm.

Nā ʻano hoʻopau paipu no API 5L X70

| Hopena Paipu | Hopena belee | ʻO ka hopena maʻamau |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | — | X |

eHoʻopili ʻia ka paipu Belled-end i ka paipu me D ≤219.1 mm a me t≤ 3.6 mm.

Kūlana hoʻouna hope

API 5L X70 moku'āina hāʻawi hope loa (ka wela wela hope o ka pau kila paipu) hiki ke maheleia i: olokaa, normalizing rolling, thermo-mechanical rolling, thermo-mechanical forming, normalizing forming, normalizing, normalizing and tempering or quenching and tempering.

| PSL | Kūlana Hoʻouna | Papa Paipu/Papa kila | |

| PSL1 | As-rolled, normalizing rolled, thermomechanical rolled, thermomechanical hana ʻia, hana maʻamau i hoʻokumu ʻia, maʻamau, maʻamau a hoʻonāukiuki a kinai paha a huhu | X70 | L485 |

| PSL 2 | Hoʻopiʻi a huhū | X70Q | L485Q |

| Hoʻokumu ʻia ka thermomechanical a i ʻole ka thermomechanical | X70M | L485M | |

ʻO kēia mau mokuʻāina hoʻopuka e hōʻoia i ka hana maikaʻi ʻana o ka paipu API 5L X70 i nā ʻano noi like ʻole, e like me ka hoʻohana ʻana i nā kaiapuni kiʻekiʻe, haʻahaʻa haʻahaʻa, a i ʻole corrosive.

Hoʻohui Kimia

API 5L X70 PSL1 Hoʻohui Kimia

ʻO ka hui kemika o API 5L X70 PSL1 paipu kila he kalapona haʻahaʻa, ka nui o ka manganese, a me ka liʻiliʻi o ka phosphorus, sulfur, a me ke silika.Eia kekahi, hoʻohui ʻia nā mea hoʻohui e like me ka chromium, nickel a me ke keleawe e hoʻonui ai i ka ikaika a me ka pale ʻana i ka corrosion.ʻO nā mea micro-alloying e like me ka vanadium, molybdenum a me ka titanium e hoʻomaikaʻi hou aku i ka lōʻihi a me nā waiwai hua, e hōʻoiaʻiʻo ana i ka hana i nā kaiapuni paʻakikī.

| Hoʻohui Kimia no PSL 1 Paipu me ka t≤25.0 mm (0.984 iniha) | |||||||||

| Papa kila (Inoa hao) | ʻO ka hapa nui, e pili ana i ka wela a me nā kānana huahanaag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | min | max | max | max | max | max | ||

| Paipu Seamless | |||||||||

| L485 | X70 | 0.28 | 1.40 | — | 0.03 | 0.03 | f | f | f |

| Paipu Weled | |||||||||

| L485 | X70 | 0.26e | 1.65e | — | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50 %a me Mo≤0.15 %. b No kēlā me kēia hōʻemi o 0.01 % ma lalo o ka manaʻo kiʻekiʻe loa no ke kalapona, he hoʻonui o ʻAe ʻia ka 0.05% ma luna o ka manaʻo nui loa no Mn, a hiki i ka 1.65 % kiʻekiʻe no nā māka ≥L245 a i ʻole B, akā ≤L360 a i ʻole X52;a hiki i ka 1.75 % kiʻekiʻe no nā māka> L360 a i ʻole X52, akā a hiki i ka 2.00 % kiʻekiʻe no ka Papa L485 a i ʻole X70. e Inā ʻaʻole i ʻae ʻia f Inā ʻaʻole i ʻae ʻia, Nb+V+Ti≤0.15 %. g ʻAʻole ʻae ʻia ka hoʻohui ʻana o B a me ke koena B≤0.001 %. | |||||||||

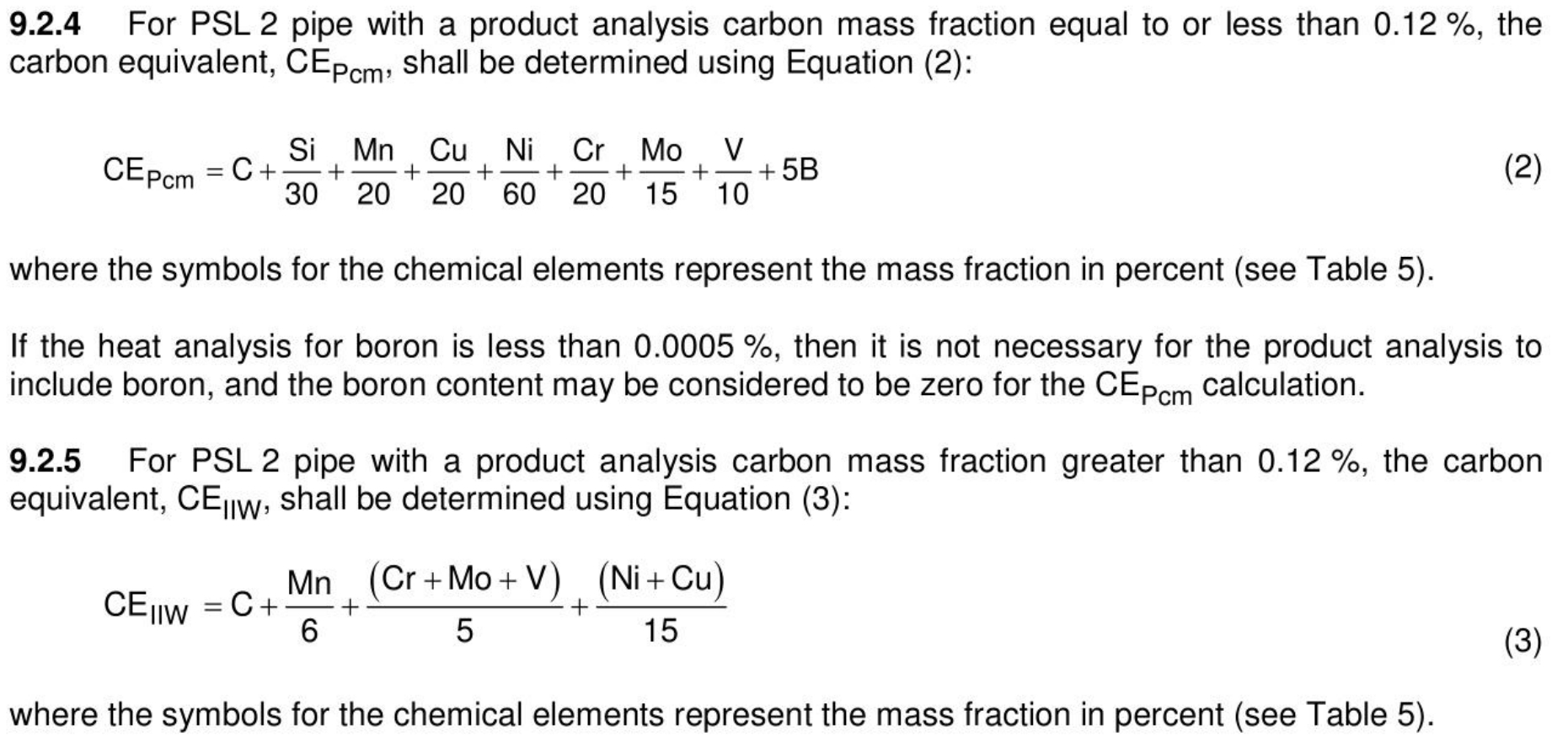

API 5L X70 PSL2 Hoʻohui Kimia

ʻO ka hui kemika o API 5L X70 PSL2 e pili ana i ke kalapona i hoʻomalu pono ʻia, manganese, sulfur, a me ka phosphorus, a me ka ʻāpana kūpono o ke silicon, chromium, nickel, a me ke keleawe.ʻAʻole hoʻonui ka mana elemental koʻikoʻi i ka ikaika a me ka paʻakikī o ka paipu akā hoʻomaikaʻi pū kekahi i ka pale ʻana i ka corrosion ma lalo o nā kūlana koʻikoʻi.Eia kekahi, ua hoʻololi ʻia nā mea trace e like me ka vanadium, molybdenum, a me ka titanium e hoʻomaikaʻi hou i ka hana, e hana ana i ka X70 PSL2 kūpono no ka hoʻoponopono ʻana i nā kaiapuni kiʻekiʻe.

| Hoʻohui Kemika no PSL 2 Paipu me ka t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| Papa kila (Inoa hao) | ʻO ka hapa nui, e pili ana i ka wela a me nā kānana huahana % ka nui | Kalapona Kaulikea %max | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | 'ē aʻe | CEllw | CEpcm | ||

| Paipu hili ʻole a me ka wili | ||||||||||||

| L485Q | X70Q | 0.18f | 0.45 f | 1.80f | 0.025 | 0.015 | g | g | g | Hui | 0.43 | 0.25 |

| Paipu Weled | ||||||||||||

| L485M | X70M | 0.12 f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | Hui | 0.43 | |

| a Ma muli o ka loiloi huahana, no ka paipu seamless me ka t>20.0 mm (0.787 in.), e like me ka ʻae ʻana o nā palena CE;pili nā palena CEllw inā C>0.12 %, a pili nā palena CEpcm inā C≤0.12 %. b No kēlā me kēia hōʻemi o 0.01 % ma lalo o ka palena kiʻekiʻe loa no C, he piʻi o 0.05 % ma luna o ka palena kiʻekiʻe i ʻae ʻia no Mn hiki ʻole ke ʻae ʻia, a hiki i ka palena kiʻekiʻe o 1.65 % no nā māka≥L245 a i ʻole B, but≤L360 a i ʻole X52;a hiki i ka 1.75 % kiʻekiʻe no nā māka > L360 a i ʻole X52, akāL555 a i ʻole X80. c Inā ʻaʻole i ʻae ʻia, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Inā ʻaʻole i ʻae ʻia, Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 %a me Mo≤0.15 %. f Ke ole i ae like. g Inā ʻaʻole i ʻae ʻia, Nb+V+Ti≤0.15 %. h Inā ʻaʻole i ʻae ʻia, Cu≤0.50%;Ni≤0.50%;Cr≤0.50 %a me Mo≤0.50%. i Inā ʻaʻole i ʻae ʻia, Cu≤0.50 %; Ni≤1.00%; Cr≤0.50% a me Mo≤0.50 %. j B≤0.004 %. k Inā ʻae ʻole ʻia, Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 %a me Mo≤0.80 %. l No nā māka paipu PSL 2 koe naʻe nā māka i pili i ka footnote j) e pili ana kēia: ke ʻae ʻole ʻia ka hoʻohui ʻole ʻana o B a me ke koena B≤0.001 %. | ||||||||||||

Hoʻohui Kimia no nā Kūlana lawelawe ʻawaʻawa API 5L X70 PSL2

ʻO nā kūlana lawelawe ʻawaʻawa e pili nui ana i ka hoʻohana ʻana i nā paipu i nā kaiapuni i loaʻa ka hydrogen sulfide (H₂S), hiki ke alakaʻi i ka hydrogen sulfide stress corrosion cracking (HIC) a me ka sulfide stress corrosion cracking (SSCC).

Hoʻololi i ka haku mele: Ma lalo o kēia mau ʻano, pono e hoʻoponopono pono ʻia ka hui kemika o nā kila pipeline e hoʻomaikaʻi i ko lākou kūpaʻa ʻana.ʻO ka mea maʻamau, pili kēia i ka hōʻemi ʻana i ka ʻona kalapona o ka mea a me ka hoʻohui ʻana i nā mea hoʻohui e like me ka molybdenum (Mo) a me ka nickel (Ni), e hoʻonui ai i ka pale ʻana a me ka paʻakikī o ka mea.

| Papa H.1—Hui Kemika no ka Paipu me ka t≤25.0 mm (0.984 in.) | |||||||||||

| Papa kila | ʻO ka hapa nui ma muli o ka wela a me ka hoʻomāhuahua ʻana i nā huahana% max | Kalapona Kaulikea % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | 'ē aʻec,d | CEllw | CEpcm | |

| ʻO SMLS a me ka Paipu Welded | |||||||||||

| L485QS a i ʻole X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.003e | 0.09 | 0.05 | 0.06 | g, I, k | 0.42 | 0.22h |

| Paipu Weled | |||||||||||

| L485MS a i ʻole X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002e | 0.10 | 0.08 | 0.06 | g, I, j | — | 0.22 |

Hiki ke loaʻa ka ʻike kikoʻī ma API 5L Appendix H.

Hoʻohui Kimia o API 5L X70 PSL2 no nā Kūlana lawelawe o waho

ʻO nā kūlana lawelawe ma waho e pili ana i ke kaiapuni moana, me ka ʻike ʻana i ka wai paʻakai a me nā kūlana ʻino loa.Pono kēia mau kūlana i nā paipu me ke kūpaʻa ʻino kiʻekiʻe a me ka paʻakikī e pale aku i ka ʻino wai paʻakai a me nā hopena haʻahaʻa haʻahaʻa.

Hoʻololi i ka haku mele: No ka lawelawe ʻana i waho, hoʻonui pinepine ʻia ka huila o ka paipu i ka chromium (Cr), nickel (Ni) a me ka molybdenum (Mo) e hoʻonui ai i kona kūʻē ʻana i ka wai kai.Hiki ke hoʻololi ʻia ka nui o nā mea micro-alloying e like me ka vanadium (V) a me ka niobium (Nb) e hoʻopaʻa i ka paʻakikī i nā wela haʻahaʻa.

| Papa J.1—Ka Hui Kemika no ka Paipu me ka t≤25.0 mm (0.984 in.) | ||||||||||||

| Papa kila | ʻO ka hapa nui ma muli o ka wela a me ka hoʻomāhuahua ʻana i nā huahana max % | Kalapona Kaulike max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | 'ē aʻec | CEllw | CEPcm | ||

| ʻO SMLS a me ka Paipu Welded | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | e, h | 0.42 | 0.23g |

| Paipu Weled | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | e, h | — | 0.22 |

Hiki ke loaʻa ka ʻike kikoʻī ma API 5L Appendix J.

Hoʻohui ʻia, ʻo ka hui kemika o ka paipu kila no nā kūlana lawelawe o waho ma API 5L X70 PSL2 e like me nā koi no ka paipu no nā noi e koi ana i ka hiki ke hoʻopaʻa ʻia i ka plastic longitudinal.Hiki i nā poʻe makemake ke nānā i ka API 5L Appendix N.

Na Waiwai Mechanical

API 5L X70 PSL1 Mea Mechanical

| Papa 6—Koi no ka hopena o na hoao ana no ka paipu PSL 1 | ||||

| Papa Paipu | Kino Paipu o ka Paipu Holoʻole a Weled | Weld Seam o EW, LW, SAW, a me COW Paipu | ||

| Hua ikaikaa Ri.5 MPa(psi) | Ikaika U'ia Rm MPa(psi) | ʻO ka elongation (ma ka 50 mm a i ʻole 2 in.) Af % | Ikaika U'ib Rm MPa(psi) | |

| min | min | min | min | |

| L485 a i ʻole X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Hiki ke nānā ʻia nā ʻāpana kikoʻī ma API 5L Papa 6.

API 5L X70 PSL2 waiwai mechanical

Hoʻoponopono nui ʻia nā paipu PSL2 no nā noi kūikawā no ka haku mele, akā like nā koi no nā waiwai mechanical.

| Papa 7—Koi no ka hopena o na hoao ana no ka paipu PSL 2 | |||||||

| Papa Paipu | Kino Paipu o ka Paipu Holoʻole a Weled | Weld Seam o HFW SAW a Paipu CoW | |||||

| Hua ikaikaa Ri.5 MPa(psi) | Ikaika U'ia Rm MPa (psi) | Lakiac Rt0.5/Rm | ʻO ka elongation (ma ka 50 mm a i ʻole 2 in.) Af % | Kuʻi Ka ikaikad Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L485Q a i ʻole X70Q L485M a i ʻole X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

Hiki ke ʻike ʻia nā ʻāpana kikoʻī ma API 5L Papa 7.

Nā ʻano hoʻokolohua

| Māhele hoʻāʻo | ʻAno hoʻāʻo |

| Hoʻohui Kimia | ISO 9769 a i ʻole ASTM A751 |

| Na Waiwai Mechanical | ISO 6892-1 a i ʻole ASTM A370 |

| Hoʻāʻo Hydrostatic | API 5L 10.2.6 |

| ʻO ka nānā ʻole ʻana | API 5L Pākuʻi E |

| Ho'āʻo Kulou | ISO 8491 a i ʻole ASTM A370 |

| Ho'āʻo Bend alakaʻi | ISO 5173 a i ʻole ASTM A370 |

| Ho'āʻo palahalaha | ISO 8492 a i ʻole ASTM A370 |

| ʻO ka hoʻāʻo ʻana i ka hopena CVN (PLS2) | ASTM A370 |

| Nā ho'āʻo DWT(PSL2) | API 5L3 |

Nā noi no API 5L X70

ʻO nā paipu aila: hoʻohana ʻia no ka lawe ʻana i ka aila ʻaila a i ʻole nā huahana i hoʻomaʻemaʻe ʻia, ʻoi aku ka lōʻihi o ka halihali ʻana ma nā wahi ʻāina a i ʻole lalo o ka wai.

ʻO nā paipu kinoea: no ka hōʻiliʻili ʻana a me ka hāʻawi ʻana i ke kinoea maoli, e komo pū ana me ka lawe ʻana i kahi mamao mamao a me nā wahi kiʻekiʻe.

Nā noi hoʻolālā: Hoʻohana pū ʻia ka paipu kila API 5L X70 i nā papahana kūikawā e like me nā kahua o waho a i ʻole nā hale kākoʻo ikaika kiʻekiʻe.

Nā noi ʻenehana: ʻO nā ʻōnaehana kaʻa wai i nā mea kanu kemika, nā mea hoʻomaʻemaʻe, etc.

Kaiapuni hoʻohana kūikawā: ʻO ke kūpaʻa ʻana o ka paipu kila API 5L X70 e kūpono ia no ka hoʻohana ʻana i nā ʻano kaiapuni kūikawā, ʻoi loa i nā kūlana corrosive acidic a me waho.

ʻO kā mākou huahana pili

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Paipu hao hao

Hoʻopau Pipe

ʻOki paipu

ʻO nā pale anti-corrosion: galvanized, pena, 3PE, FBE, etc.

ʻO mākou kekahi o nā mea hoʻolaha kiʻekiʻe kiʻekiʻe kiʻekiʻe a me nā mea kūʻai mai Kina, me ka nui o nā paipu kila kila kiʻekiʻe, ua paʻa mākou i ka hāʻawiʻana iāʻoe i ka piha piha o nā paipu paipu.No nā kikoʻī huahana hou aku, e ʻoluʻolu e kelepona mai iā mākou, ke kakali nei mākou i ke kōkua ʻana iā ʻoe e ʻike i nā koho paipu kila maikaʻi loa no kāu mau pono!

Tags: X70, API 5l x70, ai 5l, nā mea hoʻolako, nā mea hana, nā hale hana, nā mea kūʻai, nā hui, kūʻai nui, kūʻai, kumukūʻai, ʻōlelo, nui, no ke kūʻai aku, kumukūʻai.

Ka manawa hoʻouna: Apr-14-2024