ʻAno E paipu kilahanaia e like meASTM A53a hana ʻia me ka hoʻohana ʻana i ka Electric-Resistance-Welding (ERW) kaʻina hana.

Hoʻohana mua ʻia kēia paipu no nā noi mīkini a me ke kaomi akā kūpono no ka hoʻohana ʻana ma ke ʻano he paipu maʻamau no ka lawe ʻana i ka mahu, ka wai, ke kinoea, a me ka ea.

Ka laula nui oʻO ASYM A53 ka DN 6-650.

Ka laula hana oʻO ke ʻano E ʻo DN 20-650 DN.

ʻO nā anawaena paipu ma lalo o DN 20 he liʻiliʻi loa no ka Type E. No nā kumu ʻenehana ʻaʻohe ala e hana ai iā lākou, no laila ʻo Type S, ʻo ia kahikaʻina hana maʻemaʻe, hoʻohana mau ʻia.

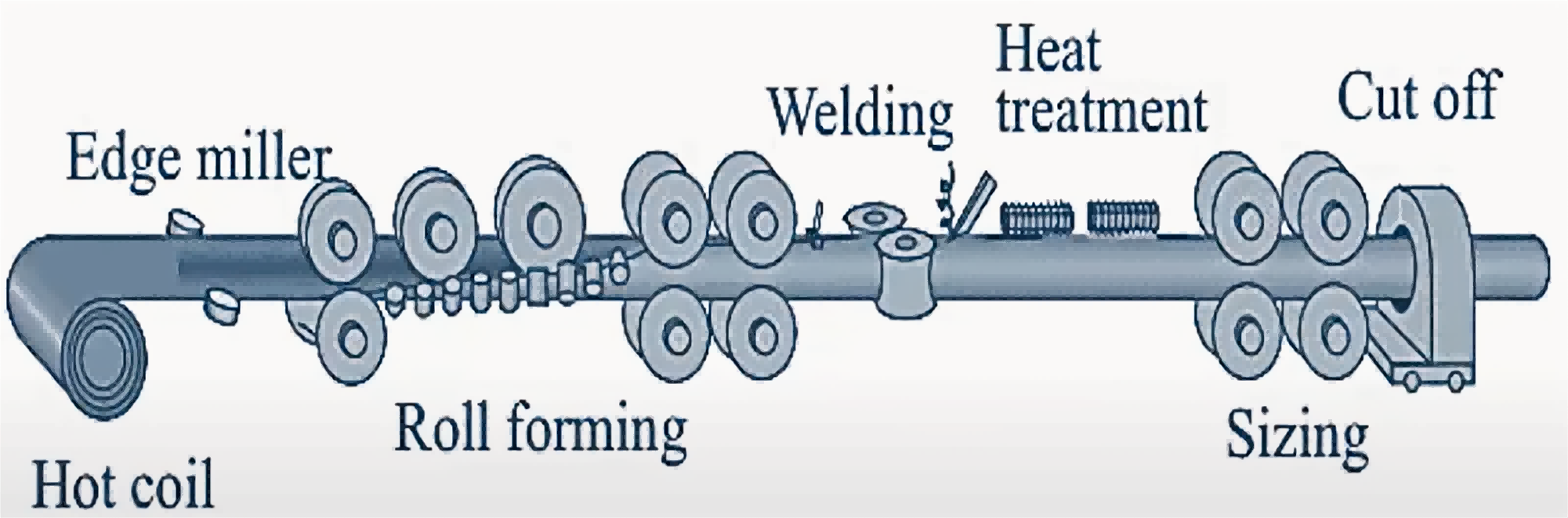

Kaʻina hana no ka ASTM A53 Type E

ʻO ke kaʻina hana e pili ana i ka hana ʻana i nā wili kila ma o nā ʻōwili, nā ʻaoʻao kuʻi ma ka hoʻomehana ʻana i ke kūpaʻa, ka deburring welds, a me ka nui a me ka hoʻopololei ʻana e hana i nā paipu.

Nā hiʻohiʻona o ASTM A53 Type E Steel Pipe

Loaʻa i ʻelua mau wiliwili lōʻihi ma loko a ma waho.Hoʻopiliʻia nāʻaoʻao o nā papa kila ma loko a ma waho o ka paipu i ka wā o ka hana hana e hōʻoia i ka ikaika a me ka sila.

ʻAʻole ʻike ʻia nā weld o loko a me waho.Hoʻomaʻemaʻe ʻia nā welds kūloko a me waho e like me ke kiʻekiʻe e like me ka ʻili o ka paipu i ka wā o ka hana ʻana, e kōkua ana i ka hiʻohiʻona holoʻokoʻa a me nā waiwai hydrodynamic hiki o ka paipu.

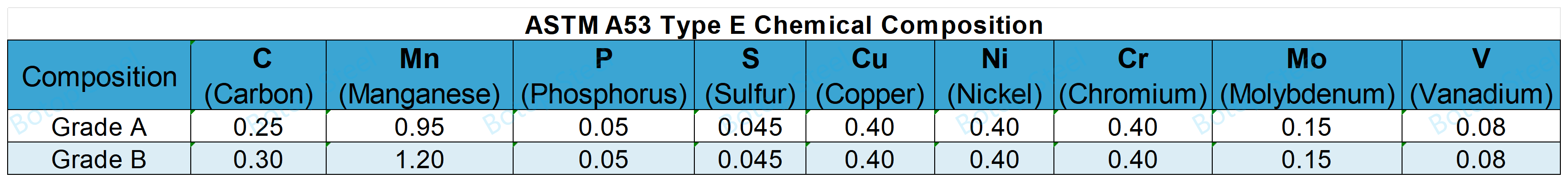

ʻO ASTM A53 ʻAno E Nā Mea Kemika

No kēlā me kēia ho'ēmi o 0.01 % ma lalo o ke kalapona kiʻekiʻe i ʻōlelo ʻia, e ʻae ʻia ka piʻi ʻana o 0.06 % o ka manganese ma luna o ka palena kiʻekiʻe a hiki i ka 1.65 %.

ʻO Cu, Ni, Cr, Mo, a me V, ʻo ia nā mea ʻelima i hui pū ʻia ʻaʻole ma mua o 1.00%.

ʻO ASTM A53 ʻAno E Mechanical Properties

Ho'āʻo Hoʻopaʻapaʻa

E ho'āʻo ʻia nā paipu welded kū'ē DN ≥ 200 me ka hoʻohana ʻana i ʻelua mau hiʻohiʻona transverse, hoʻokahi ma ka weld a ʻo kekahi e kū pono ana i ka weld.

| Papa inoa | hoʻolālikelike | Papa A | Papa B |

| Ka ikaika tensile, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ka ikaika hāʻawi, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation i loko o 50 mm (2 in) | Nānā | A, B | A, B |

Nānā A: E hoʻoholo ʻia ka elongation liʻiliʻi ma 2 in[50 mm] e ka hoohalike penei:

e = 625000 [1940] A0.2/U0.9

e = ka lōʻihi liʻiliʻi ma 2 i loko a i ʻole 50 mm i ka pākēneka, hoʻopuni ʻia i ka pākēneka kokoke loa

A = ka liʻiliʻi o 0.75 iniha2[500 mm2] a me ka wahi kea o ka ho'āʻo ho'āʻo hoʻopaʻapaʻa, i helu ʻia me ka hoʻohana ʻana i ke anawaena o waho o ka paipu, a i ʻole ka laula inoa o ka specimen hoʻāʻo hoʻopaʻapaʻa a me ka mānoanoa pā o ka paipu, me ka helu helu i hoʻopuni ʻia i ka 0.01 in kokoke loa.2 [1 mm2].

U = ka ikaika uʻi liʻiliʻi i ʻōlelo ʻia, psi [MPa].

Nānā B: E nānā i ka Papa X4.1 a i ʻole Papa X4.2, ʻo ia ka mea e pili ana, no nā koina elongation haʻahaʻa i koi ʻia no nā hui like ʻole o ka nui o ka hōʻike hoʻāʻo ʻana a me ka ikaika tensile haʻahaʻa i kuhikuhi ʻia.

Hoʻo Piʻo

No ka paipu, DN ≤50, hiki i ka lōʻihi o ka paipu ke kūlou i ke anuanu ma o 90 ° a puni kahi mandrel cylindrical, ʻo ke anawaena he ʻumikūmālua manawa o ke anawaena o waho o ka paipu, me ka hoʻomohala ʻole ʻana i nā māwae ma kekahi ʻāpana a me ka wehe ʻole ʻana i ka weld.

ʻAʻole pono e hoʻokō ʻia ka paipu pālua ʻoi aku ka ikaika ma luna o DN 32 i ka hoʻāʻo ʻana.

"Double-extra-strong", i kapa pinepine ʻia ʻo XXShe paipu me ka mānoanoa o ka paia i hoʻoikaika nui ʻia, i hoʻohana mau ʻia i nā ʻoihana ʻoihana e kū i nā koʻikoʻi kiʻekiʻe a me nā wahi ʻoi aku ka paʻakikī. ʻOi aku ka mānoanoa o ka pā o kēia paipu ma mua o ka paipu maʻamau, no laila hāʻawi ia i ka ikaika a ʻoi aku ka maikaʻi.

Ho'āʻo palahalaha

E hana ʻia ka hoʻāʻo palahalaha ma luna o ka paipu wili ʻia ma luna o DN 50 i ke kaumaha ʻoi aku ka ikaika (XS) a i ʻole ka māmā.

Pili ke kaʻina hana hoʻokolohua i ke ʻano E, Papa A a me B.

I ka wā paʻi paʻa, pono e hoʻonoho ʻia ka weld ma 0 ° a i ʻole 90 ° i ka laina o ke kuhikuhi ikaika, e pili ana i nā koi kikoʻī.

KaʻAnuʻu 1: E hoao i ka ductility o ka weld. ʻAʻohe māwae a haki paha i loko a i waho paha o ka weld a hiki i ka mamao ma waena o nā papa pālahalaha ma lalo o ʻelua hapakolu o ke anawaena o waho o ka paipu.

KaʻAnuʻu 2: E hoʻomau i ka paʻi palahalaha a hoʻāʻo no ka ductility ma kahi o waho o ka weld. ʻAʻole pono nā māwae a nahā paha ma ka ʻaoʻao o loko a i waho paha o ka paipu ma waho aʻe o ka weld a hiki i ka mamao ma waena o nā papa pālahalaha ma lalo o ka hapakolu o ke anawaena o waho o ka paipu, akā ʻaʻole e emi iho ma mua o ʻelima mau manawa o ka mānoanoa o ka pā paipu.

KaʻAnuʻu 3: E ho'āʻo i ka pono o ka mea ma ka hoʻomauʻana i ka paʻi palahalaha a hiki i ka wā e haki ai ka mea ho'āʻo a iʻole e pili nā paia paipu. Hoʻohana ʻia kēia no ka hoʻāʻo ʻana i ka mea no nā pilikia e like me nā ʻāpana ʻāhaʻi, maikaʻi ʻole, a i ʻole nā welds piha ʻole.

Hoʻāʻo Hydrostatic

E hoʻohana ʻia ka hoʻāʻo hydrostatic, me ka ʻole o ka leaka ma o ka weld seam a i ʻole ke kino paipu.

E ho'āʻo hydrostatically ka paipu pāpū i ke kaomi kūpono i hāʻawi ʻia ma ka Papa X2.2,

e ho'āʻo hydrostatically i ka paipu i hoʻopaʻa ʻia a hui ʻia i ke kaomi kūpono i hāʻawi ʻia ma ka Papa X2.3.

No nā paipu kila me DN ≤ 80,ʻaʻole eʻoi aku ke kaumaha o ka ho'āʻo ma mua o 17.2MPa;

No nā paipu kila me DN >80, ʻaʻole ʻoi aku ka nui o ke kaomi hoʻāʻo ma mua o 19.3MPa;

Hoao Uila Nondestructive

No nā paipu Type E a me Type F Class B DN ≥ 50, pono e hoʻokau ʻia nā welds i ka hoʻāʻo uila non-destructive.

E hana ʻia nā hoʻāʻo uila non-destructive e like me nā kikoʻī E213, E273, E309 a i ʻole E570.

Inā hana ʻia ka hoʻāʻo ʻana i ka uila non-destructive, e kaha ʻia ka paipu "NDE".

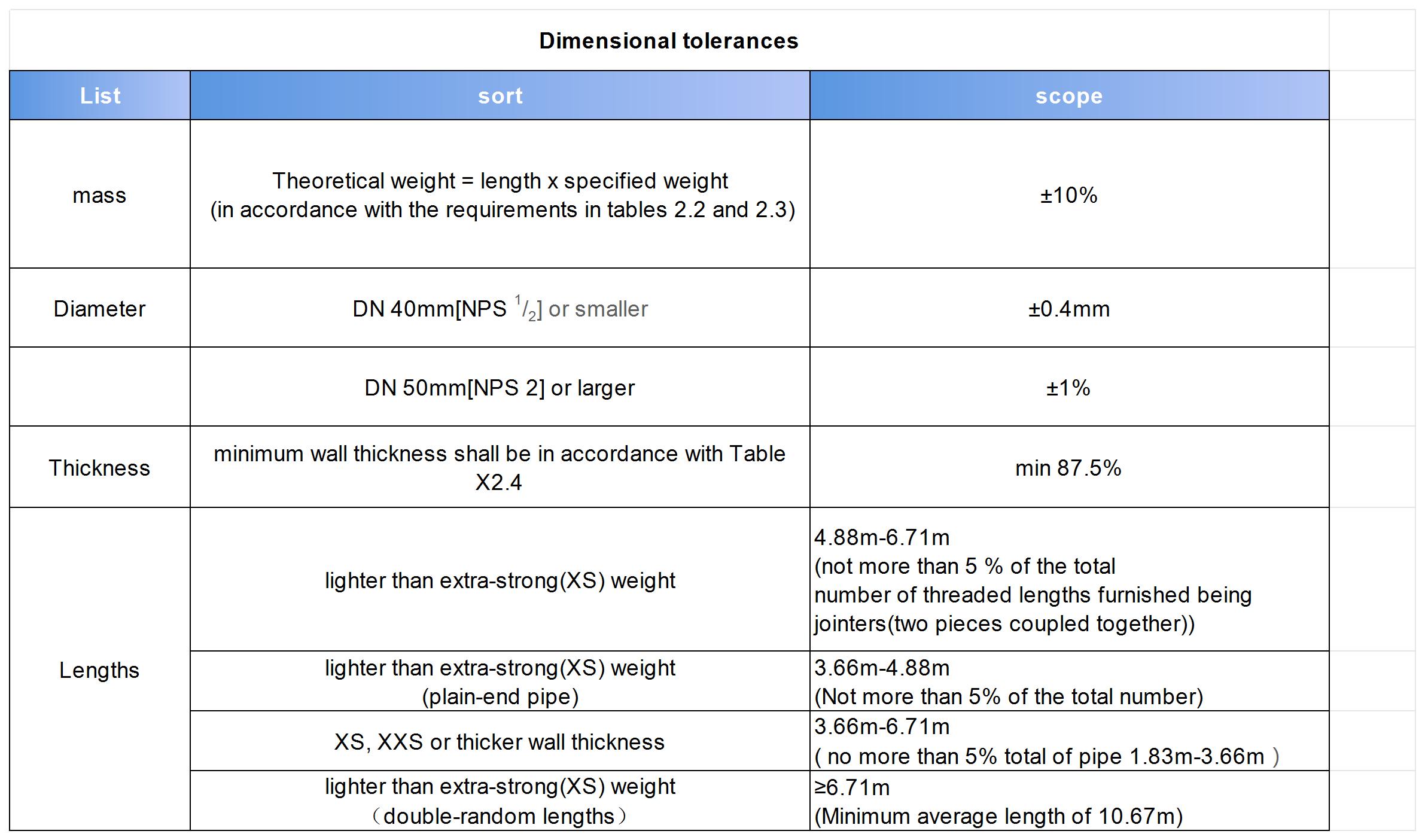

ʻO ka ASTM A53 Nā Manaʻo hoʻomanawanui

Nā Papa Kaumaha Paipu a me nā Papa Hana Paipu

ʻO nā pono o ka ASTM A53 Type E Pipe

ʻO ke kuʻi kūʻē kūʻē he ala haʻahaʻa haʻahaʻa haʻahaʻa, e hana ana i nā paipu Type E maʻalahi ke hana a kūpono no ka hana nui.

ʻO ke kaʻina hana welding resistance wikiwiki a hiki ke hana mau ʻia, e hoʻonui ai i ka huahana a hoʻemi i nā manawa alakaʻi.

Ma muli o kona mau ʻano mechanical maikaʻi a me ka pale ʻana i ka corrosion, hoʻohana nui ʻia kēia ʻano paipu i nā ʻano noi like ʻole no ka lawe ʻana i nā wai, e like me ka wai, ke kinoea, a me ka mahu.

Hiki ke ʻike ʻole ʻia nā welds ma o ka hoʻomaʻamaʻa maikaʻi ʻana i nā welds, ʻaʻole ia e hoʻomaikaʻi wale i ke ʻano o ka paipu akā hiki ke hōʻemi i ke kūʻē ʻana i ka kahe wai i hana ʻia e nā welds..

Nā noi o ASTM A53 Type E Steel Pipe

Hoʻohana hale: I ke kūkulu ʻia ʻana, hoʻohana ʻia ka paipu kila A53 Type E ma ke ʻano he mau mea hana e like me ke kākoʻo hale a me nā ʻōnaehana truss.

Paipu wai: Hoʻohana ʻia i nā ʻōnaehana wai no nā hale, me nā ʻōnaehana sprinkler ahi.

Pūnaehana mahu: Ma nā ʻoihana ʻoihana, hoʻohana pinepine ʻia kēia paipu kila i nā ʻōnaehana hoʻouna mahu, ʻoi aku hoʻi i nā noi haʻahaʻa haʻahaʻa.

Hoʻouna kinoea: Hoʻohana ʻia no ka lawe ʻana i nā kinoea kūlohelohe a i ʻole nā kinoea ʻē aʻe, ʻoi aku hoʻi i nā ʻōnaehana hoʻolako kinoea kūloko a me nā hale noho.

Mea kanu kemika: no ka lawe ana i ka mahu, ka wai, a me na mea kemika e ae.

Nā wili pepa a me ke kō: e lawe i nā mea maka a me nā huahana i hoʻopau ʻia, a me ka hoʻolei ʻana i nā ʻōpala hana.

Nā ʻōnaehana hoʻomehana a me ka hoʻoluʻu: Hoʻohana nui ʻia no ka paipu ʻana i nā ʻōnaehana hoʻomehana, ventilation, a me ka ea (HVAC).

Hoʻomaʻemaʻe wai ʻōpala: No ka lawe ʻana i ka wai ʻino a i ʻole ka wai i mālama ʻia.

Pūnaehana wai: Nā paipu wai i hoʻohana ʻia no ka hoʻoinu ʻana i ka ʻāina mahiʻai.

Ka mina: Hoʻohana ʻia no ka lawe ʻana i ka wai a me ke kinoea ma nā mines.

ʻO kā mākou huahana pili

Mai kona hoʻokumu ʻana i ka makahiki 2014, ua lilo ʻo Botop Steel i mea hoʻolako alakaʻi i ka paipu kila carbon ma Northern China, i ʻike ʻia no ka lawelawe maikaʻi loa, nā huahana kiʻekiʻe, a me nā hoʻonā piha.

Hāʻawi ka hui i nā ʻano paipu kila carbon a me nā huahana pili,

me ka seamless, ERW, LSAW, a me SSAW paipu kila, a me ka laina piha o na paipu paipu a me na flanges.

ʻO kāna mau huahana kūikawā pū kekahi me nā mea kila kiʻekiʻe a me nā kila stainless austenitic, i hoʻokō ʻia e hoʻokō i nā koi o nā papahana pipeline.

Tags: ASTM a53, ʻano e, papa a, papa b, erw.

Ka manawa hoʻouna: Mei-12-2024