API 5L Qib Bsteel yeeb nkab yog tsim nyob rau hauv raws li cov kev cai ntawmAPI 5Lthiab yog dav siv nyob rau hauv pipeline tsheb thauj mus los hauv kev lag luam roj thiab roj.

Qib Bkuj tseem hu ual245 ua. Cov yam ntxwv yog tias qhov tsawg kawg nkaus tawm lub zog ntawm cov yeeb nkab steel yog245 MPa rau.

API 5L kab yeeb nkab muaj nyob rau hauv ob qib khoom specification:PSL1feem ntau yog siv rau hauv cov txheej txheem kev thauj mus los, thaumPSL2yog tsim nyog rau cov mob hnyav dua nrog cov neeg kho tshuab siab dua thiab cov qauv ntsuas nruj dua.

Cov txheej txheem tsim khoom tuaj yeem ua seamless (SMLS), hluav taws xob kuj welded (ERW), los yog submerged arc welded (SAW) kom haum rau qhov sib txawv installation thiab kev ua haujlwm xav tau.

Botop Steelyog ib lub chaw tsim khoom ntawm tuab-walled loj-inch ob-sided submerged arc LSAW steel yeeb nkab nyob rau hauv Suav teb.

Qhov chaw: Cangzhou City, Hebei Province, Suav teb;

Kev nqis peev tag nrho: 500 lab RMB;

Factory cheeb tsam: 60,000 square meters;

Muaj peev xwm tsim tau txhua xyoo: 200,000 tons ntawm JCOE LSAW steel kav;

Khoom siv: Advanced ntau lawm thiab cov khoom siv kuaj;

Tshwj xeeb: LSAW steel yeeb nkab ntau lawm;

Daim ntawv pov thawj: API 5L tau ntawv pov thawj.

API 5L Qib B Classification

Nws tau muab faib ua ntau hom sib txawv raws li cov khoom sib txawv (PSL) nrog rau kev xa khoom.

Qhov categorization no ua rau kev xaiv ntawm txoj kab txoj kab yeeb nkab muaj feem cuam tshuam rau cov kev xav tau ntawm ib qhov project tshwj xeeb thiab cov kev xav tau ntawm qhov chaw ua haujlwm.

PSL1: B.

PSL2: BR;BN;BQ;BM.

Ob peb qhov tshwj xeeb PSL 2 steel hlab yog siv rau qhov chaw pabcuam tshwj xeeb.

Cov kev pabcuam qaub: BNS; BQS; BMS.

Offshore kev pab cuam ib puag ncig: BNO; BQO; BMO.

Cov ntawv thov uas yuav tsum tau muaj peev xwm ua tau ntev ntev: BNP; BQP; BMP.

Kev Xa Khoom

| PSL | Kev Xa Khoom | Qib Qib / Hlau Qib | |

| PSL1 | Raws li-dov, normalizing dov, thermomechanical dov, thermomechanical tsim, normalizing tsim, normalized, normalized thiab tempered; los yog, yogpom zoo, quenched thiab tempered rau SMLS yeeb nkab xwb | B | l245 ua |

| PSL 2 | Raws li dov | BR | L245R |

| Normalizing dov, normalizing tsim, normalized, los yog normalized thiab tempered | BN | L245 N | |

| Quenched thiab tempered | BQ | l245 qw | |

| Thermomechanical dov los yog thermomechanical tsim | BM | L245 M | |

Kev xa khoom ntawm cov yeeb nkab steel feem ntau yog hais txog kev kho cua sov lossis lwm yam kev kho mob ua tiav thaum kawg ntawm kev tsim cov yeeb nkab steel, thiab cov kev kho mob no muaj kev cuam tshuam tseem ceeb rau cov khoom siv kho tshuab, kev tiv thaiv corrosion, thiab kev ruaj ntseg ntawm cov yeeb nkab steel.

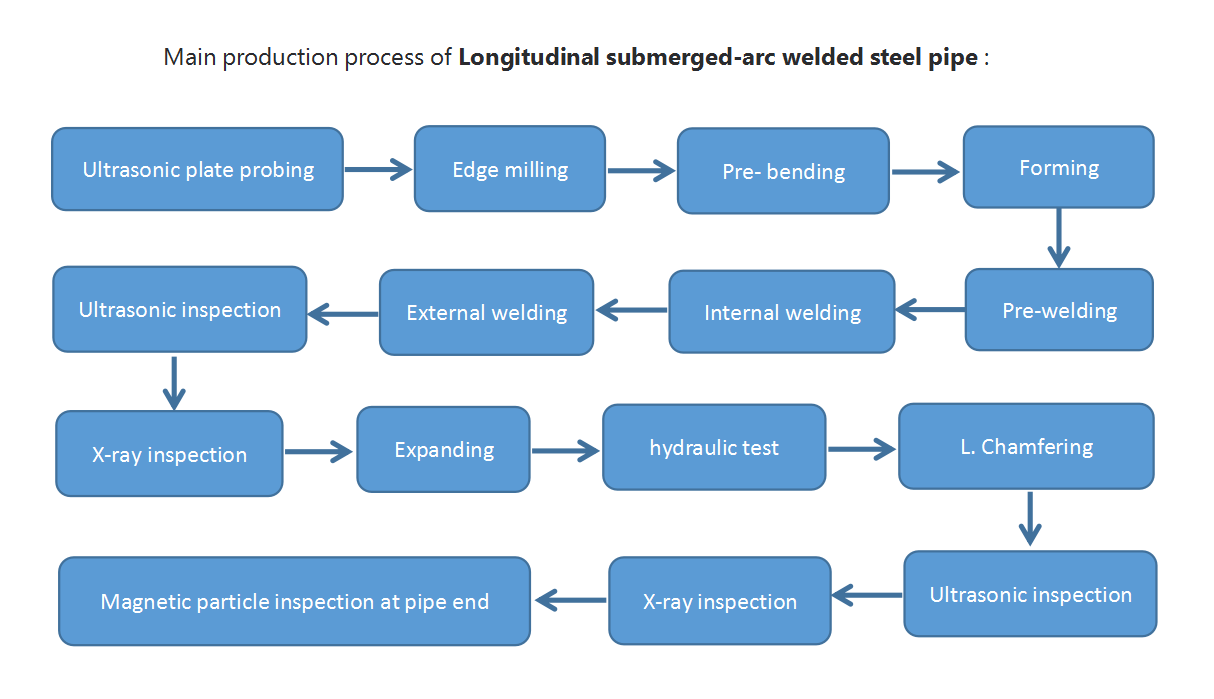

API 5L GR.B Steel Pipe Manufacturing Txheej txheem

Hauv API 5L tus qauv Qib B yeeb nkab tuaj yeem tsim tau siv ib qho ntawm cov txheej txheem ntau lawm hauv cov lus hauv qab no.

| API 5L PSL1 Qib B | SMLS | LFW | HFW | SAWL | SAWH | COWL | COV |

| API 5L PSL2 Qib B | SMLS | — | HFW | SAWL | SAWH | COWL | COV |

Txhawm rau kom paub ntau ntxiv txog lub ntsiab lus ntawm lub ntsiab lus Manufacturing Process,nias ntawm no.

LSAWyog qhov kev daws teeb meem zoo tshaj plaws rau cov kav dej loj, tuab-walled steel kav.

Qhov txawv feature nyob rau hauv tsos yog lub xub ntiag ntawm ib tug weld nyob rau hauv lub longitudinal kev taw qhia ntawm cov yeeb nkab.

Pipe End Hom

API 5L Qib B steel yeeb nkab kawg hom yuav txawv hauv PSL1 thiab PSL2.

PSL 1 steel yeeb nkab kawg

Belled kawg; Plain kawg;Plain kawg rau tshwj xeeb coupling; Xov kawg.

Belled kawg: txwv rau cov raj nrog D ≤ 219.1 hli (8.625 hauv) thiab t ≤ 3.6 hli (0.141 hauv) ntawm lub qhov (socket) kawg.

Threaded kawg: Threaded-kawg yeeb nkab yog txwv rau SMLS thiab longitudinal seam welded yeeb nkab nrog D <508 mm (20 in).

PSL 2 steel yeeb nkab kawg

Plain kawg.

Rau cov kav dej tiaj tiaj yuav tsum tau ua raws li cov cai hauv qab no:

Lub ntsej muag kawg ntawm t ≤ 3.2 hli (0.125 hauv) cov yeeb nkab kawg yuav tsum yog square txiav.

Plain-kawg raj nrog t> 3.2 hli (0.125 nyob rau hauv) yuav tsum tau beveled rau vuam. Lub kaum sab xis yuav tsum yog 30-35 ° thiab qhov dav ntawm lub hauv paus ntsej muag ntawm bevel yuav tsum yog 0.8 - 2.4 hli (0.031 - 0.093 nyob rau hauv).

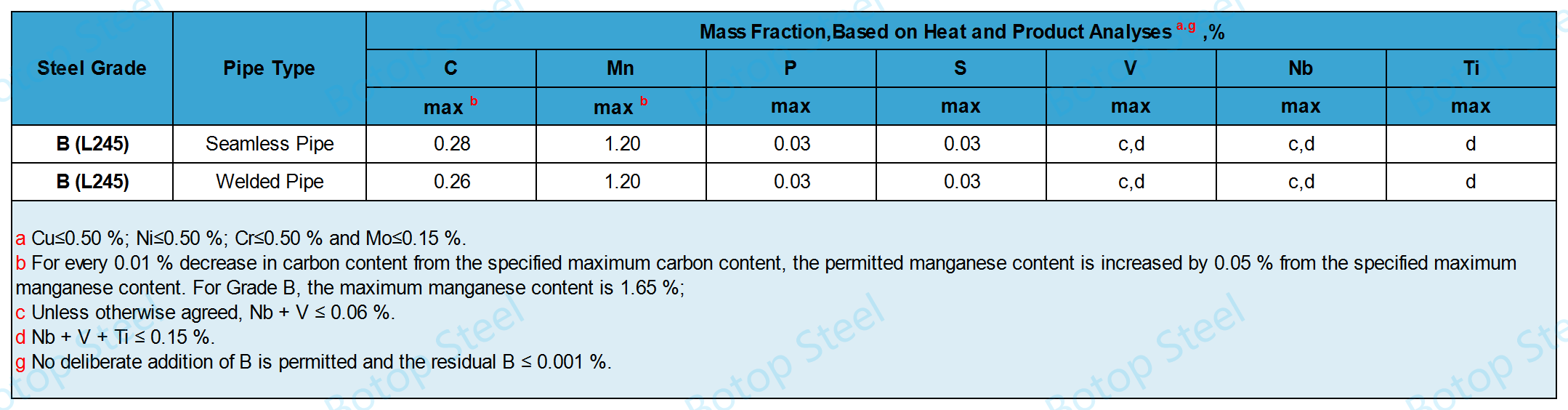

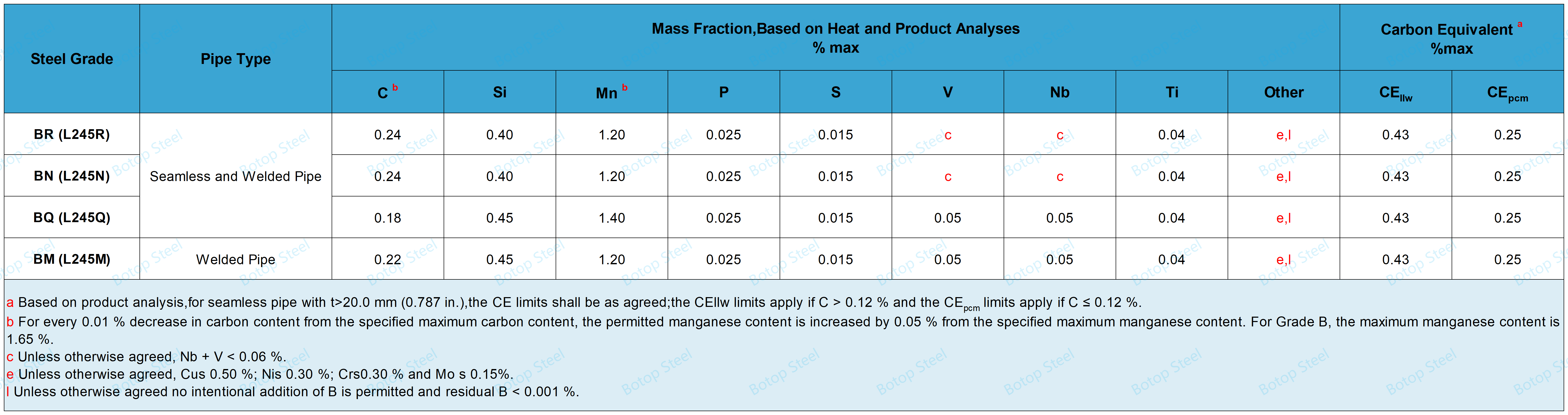

API 5L Qib B Chemical Composition

Cov tshuaj muaj pes tsawg leeg ntawm PSL1 thiab PSL2 steel yeeb nkab t> 25.0 hli (0.984 hauv) yuav tsum txiav txim siab los ntawm kev pom zoo.

Chemical Composition rau PSL 1 Pipe nrog t ≤ 25.0 mm (0.984 in.)

Chemical Composition rau PSL 2 Pipe nrog t ≤ 25.0 mm (0.984 in.)

Rau PSL2 steel yeeb nkab khoom soj ntsuam nrog acarbon cov ntsiab lus ≤0.12%, carbon sib npaug CEpcm uatuaj yeem suav nrog cov qauv hauv qab no:

CEpcm ua= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

Rau PSL2 steel yeeb nkab khoom soj ntsuam nrog aCov ntsiab lus carbon> 0.12%, carbon sib npaug CElwjtuaj yeem suav nrog cov qauv hauv qab no:

CElwj= C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

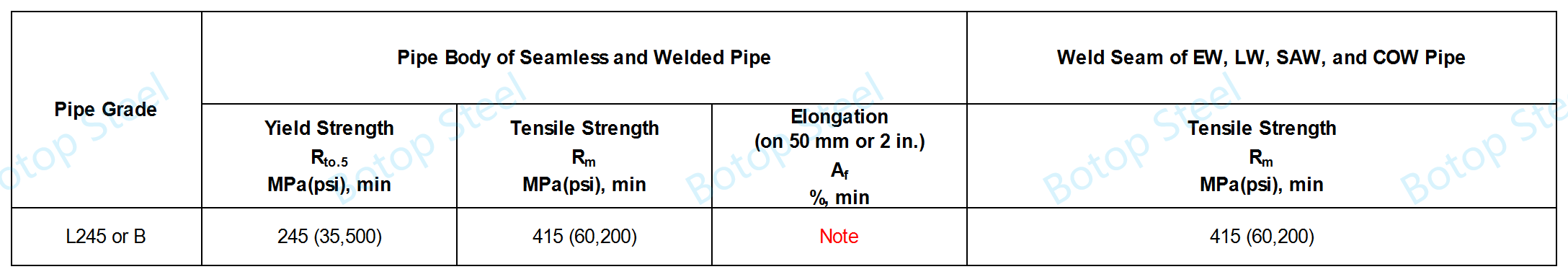

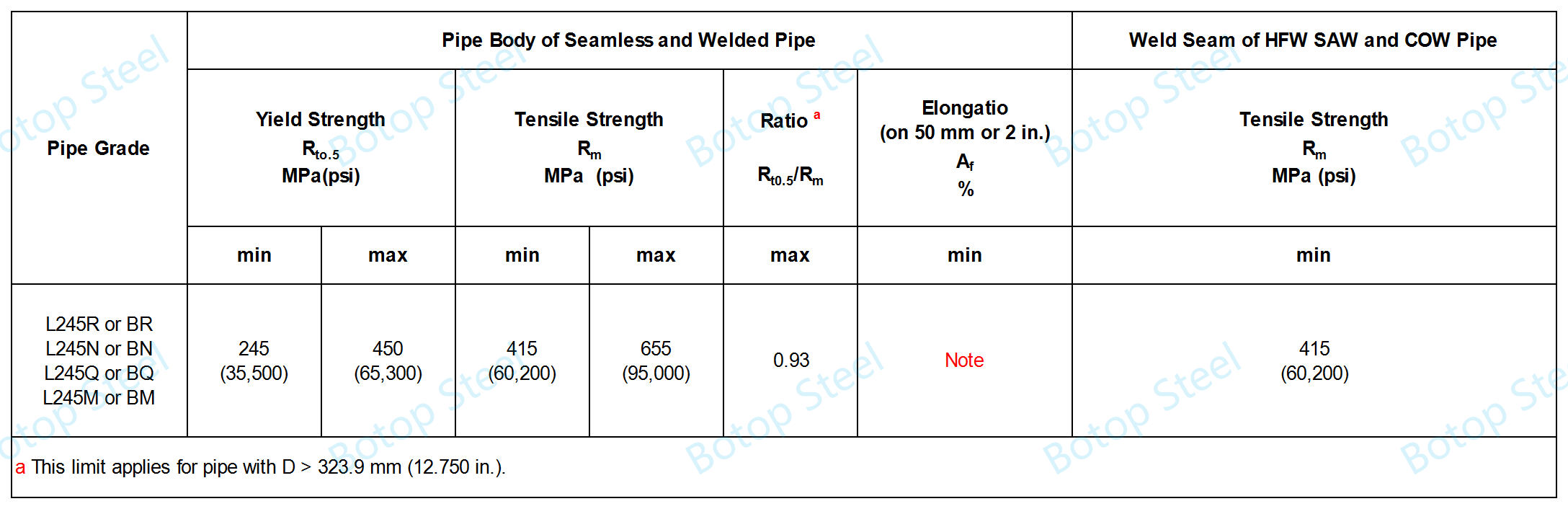

API 5L Qib B Mechanical Property

Tensile Khoom

PSL1 GR.B Tensile Properties

PSL2 GR.B Tensile Properties

Nco tseg: Yam tsawg kawg nkaus elongation, Afyuav tsum tau txiav txim siab siv cov kab zauv hauv qab no:

Af= C × (Axc0.2/U0.9)

Cyog 1940 rau kev suav siv SI units thiab 625,000 rau kev suav nrog USC units;

Axc yog qhov siv tau tensile xeem piece cross-sectional cheeb tsam, qhia nyob rau hauv square millimeters (square inches), raws li nram no:

1) rau kev sib tw hla ntu, 130 mm2(0.20 hli.2) rau 12.7 hli (0.500 nyob rau hauv.) thiab 8.9 hli (0.350 nyob rau hauv.) txoj kab uas hla xeem daim; 65mm ib2(0.10 hli.2) rau 6.4 hli (0.250 nyob rau hauv.) txoj kab uas hla xeem daim;

2) rau tag nrho-section xeem daim, qhov tsawg dua ntawm a) 485 mm2(0.75 hli.2) thiab b) thaj tsam ntawm qhov kev sib tw ntawm daim ntawv xeem, T tau muab los ntawm kev siv cov txheej txheem sab nraud thiab cov phab ntsa tuab ntawm cov yeeb nkab, sib npaug mus rau qhov ze tshaj 10 hli2(0.01 hli.2);

3) rau strip test pieces, qhov tsawg dua ntawm a) 485 mm2(0.75 hli.2) thiab b) thaj tsam ntawm qhov kev sib tw ntawm daim ntawv xeem, muab tau los ntawm qhov dav dav ntawm daim ntawv xeem thiab cov txheej txheem phab ntsa thickness ntawm cov yeeb nkab, sib npaug mus rau qhov ze tshaj 10 hli.2(0.01 hli.2);

Uyog qhov tsawg kawg nkaus tensile lub zog, qhia nyob rau hauv megapascals (phaus ib square inch).

Khoov Test

Tsis muaj ib feem ntawm cov qauv yuav tsum tawg thiab lub vuam yuav tsis tawg.

Flattening Test

Tsis siv rau LSAW steel yeeb nkab.

Haum rauEW, LW, thiabCWmanufacturing hom raj.

Guided-bend Test

Tshaj tawm cov kab nrib pleb lossis ruptures nyob rau hauv lub vuam hlau ntev tshaj 3.2 hli (0.125 hauv), tsis hais qhov tob.

Qhia tawm cov kab nrib pleb lossis ruptures nyob rau hauv niam txiv hlau, HAZ, los yog fusion kab ntev tshaj 3.2 hli (0.125 nyob rau hauv) los yog tob tshaj 12.5% ntawm cov phab ntsa thickness.

CVN Impact Test rau PSL 2 Pipe

CVN (Charpy V-Notch) Impact test, tus qauv xeem txoj hauv kev los ntsuas qhov tawv ntawm cov ntaub ntawv thaum raug cuam tshuam rau cov loads ceev.

Cov kev cai hauv qab no siv rau qib ≤ X60 lossis L415.

| CVN Absorbed zog yuav tsum tau rau cov yeeb nkab lub cev ntawm PSL 2 yeeb nkab | |

| Specified Sab Nraud Diameter D mm (hauv.) | Tag Nrho Loj CVN Absorbed Zog min Kv J (ft.lbf) |

| ≤762 (30) | 27 (20) |

| 762 (30) rau 2134 (84) | 40 (30) |

DWT Test rau PSL 2 Welded Yeeb Nkab

Qhov nruab nrab shear cheeb tsam ib qho kev xeem yuav tsum yog ≥ 85% ntawm 0 ° C (32 ° F) ntsuas kub.

Rau cov raj nrog phab ntsa tuab> 25.4 hli (1 nyob rau hauv.), qhov kev lees paub rau DWT xeem yuav tsum tau sib tham.

Hydrostatic Test

Lub Sijhawm Xeem

Txhua qhov ntau thiab tsawg ntawm seamless thiab welded steel hlab nrog D ≤ 457 mm (18 in.):xeem lub sij hawm ≥ 5s;

Welded steel yeeb nkab D> 457 mm (18 nyob rau hauv.):xeem lub sij hawm ≥ 10s.

Xeem zaus

Txhua cov yeeb nkab steel.

Kev sim siab

Kev ntsuas hydrostatic siab P ntawm aplain-end steel yeeb nkabtuaj yeem suav tau los ntawm kev siv cov mis.

P = 2st/D

Syog lub hoop stress. tus nqi yog sib npaug rau qhov tsawg kawg nkaus tawm lub zog ntawm cov yeeb nkab steel xa feem pua, hauv MPa (psi);

Rau API 5L Qib B, cov feem pua yog 60% rau cov qauv ntsuas siab thiab 70% rau qhov kev xaiv ntsuas siab.

Rau D <88.9 mm (3.500 in.), nws tsis yog qhov tsim nyog uas qhov ntsuas siab tshaj 17.0 MPa (2470 psi);

Rau D> 88.9 mm (3.500 in.), nws tsis tsim nyog tias qhov ntsuas siab tshaj 19.0 MPa (2760 psi).

tyog lub thickness ntawm phab ntsa, qhia nyob rau hauv millimeters (inch);

Dyog qhov teev sab nraud txoj kab uas hla, qhia hauv millimeters (inch).

Kev tshuaj xyuas tsis zoo

Rau SAW tubes, ob txoj kev,UT(ultrasonic testing) los yogRT(radiographic kuaj), feem ntau yog siv.

ET(electromagnetic testing) tsis siv rau SAW raj.

Welded seams ntawm welded kav ntawm qib ≥ L210 / A thiab txoj kab uas hla ≥ 60.3 mm (2.375 hauv) yuav tsum tsis txhob raug tshuaj xyuas kom tag nrho tuab thiab ntev (100%) raws li tau teev tseg.

UT cov kev xeem tsis muaj kev puas tsuaj

RT kev kuaj xyuas tsis muaj kev puas tsuaj

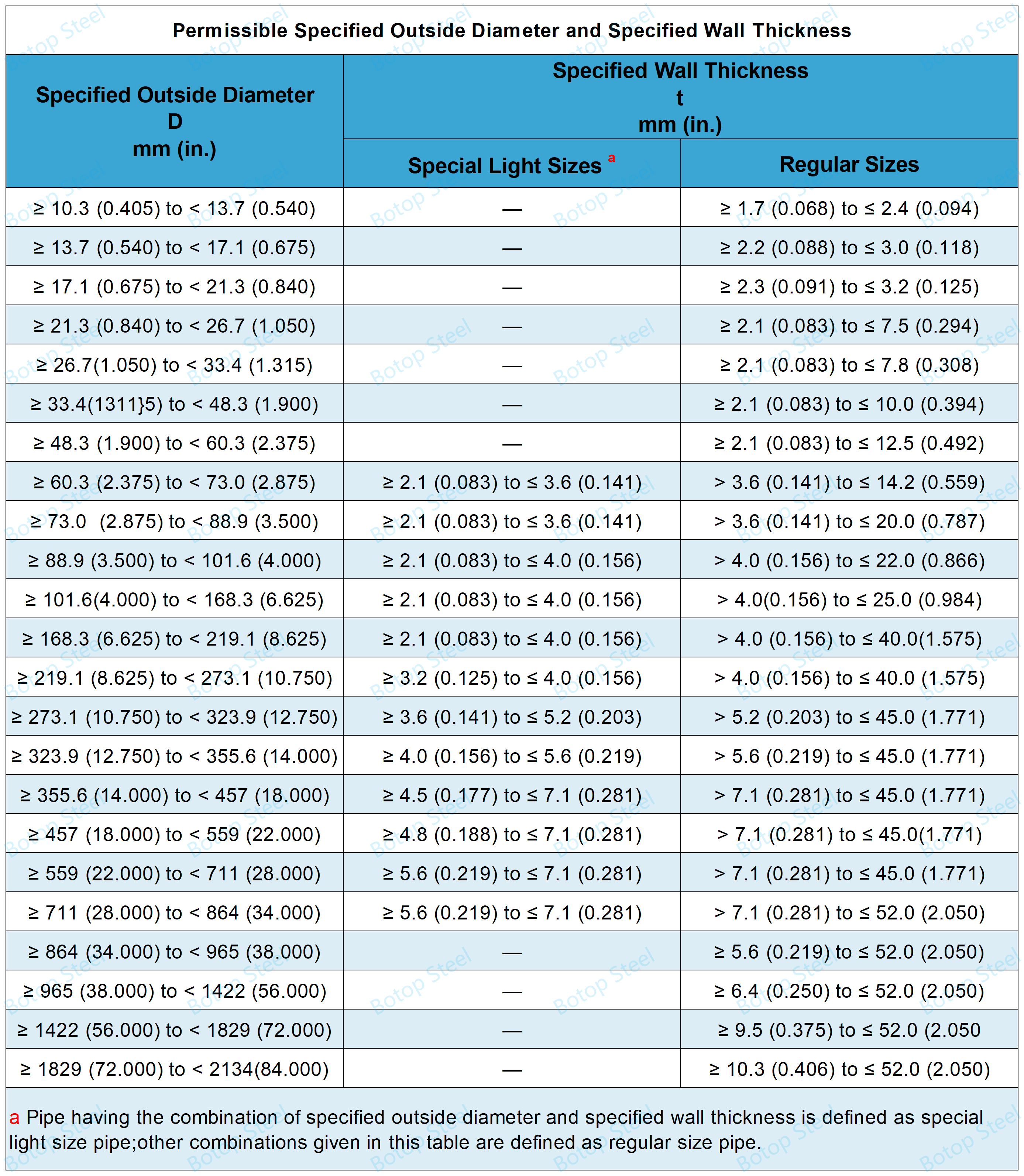

Qhia tawm sab nraud thiab phab ntsa Thickness

Cov nqi tsim nyog rau kev teev sab nraud diameters thiab teev cov phab ntsa thicknesses ntawm cov yeeb nkab steel yog muab rau hauvISO 4200 UASthiabASME B36.10M.

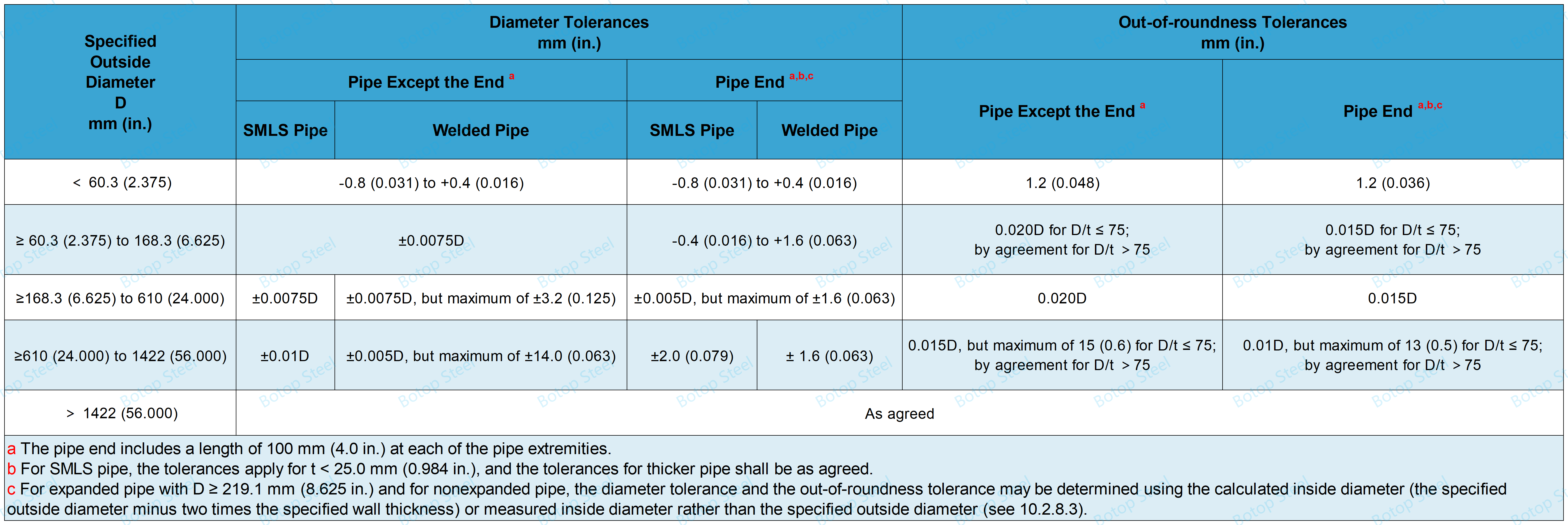

Dimensional Tolerances

Tolerances rau txoj kab uas hla thiab Out-of-roundness

Txoj kab uas hla ntawm cov yeeb nkab steel yog txhais raws li qhov ncig ntawm cov yeeb nkab nyob rau hauv ib lub dav hlau circumferential faib los ntawm π.

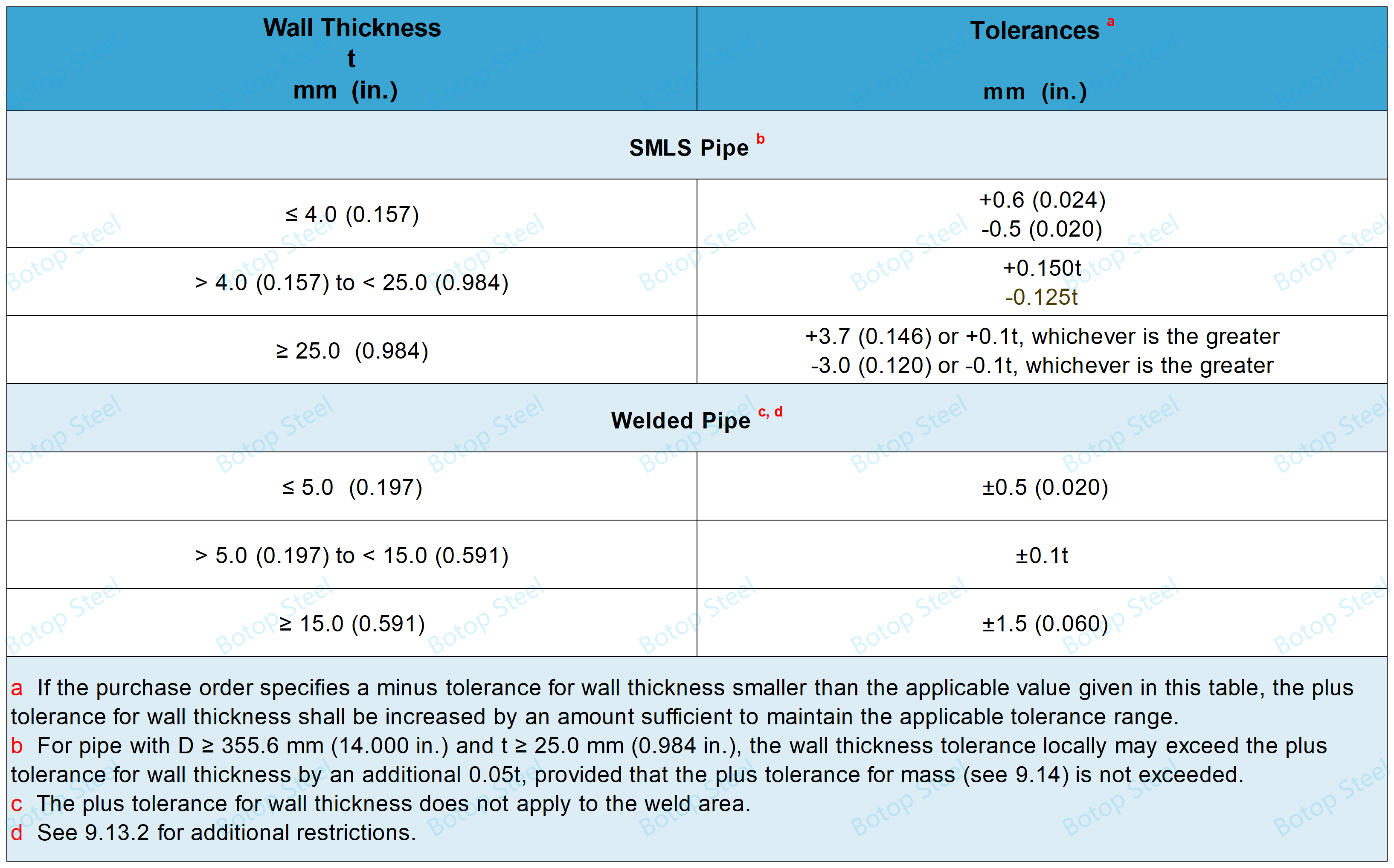

Tolerances rau phab ntsa Thickness

Tolerance rau Ntev

Kwv yees qhov ntevyuav tsum tau xa nyob rau hauv ib tug kam rau ua ntawm ± 500 hli (20 nyob rau hauv.).

Tolerances raurandom ntev

| Random Length Designation m (ft) | Yam tsawg kawg nkaus m (ft) | Yam tsawg kawg nruab nrab ntev rau txhua yam khoom xaj m (ft) | Qhov siab tshaj plaws m (ft) |

| Threaded-thiab-coupled Pipe | |||

| 6 (20) | 4.88 (16.0) Nws. | 5.33 (17.5) Nws. | 6.86 (22.5 hli) |

| 9 (30) | 4.11 (13.5) Nws. | 8.00 (26.2 Nws) | 10.29 (33.8) Nws. |

| 12 (40) | 6.71 (22.0) Nws. | 10.67 (35.0) Nws. | 13.72 (45.0) Nws. |

| Plain-end Pipe | |||

| 6 (20) | 2.74 (9.0) Nws. | 5.33 (17.5) Nws. | 6.86 (22.5 hli) |

| 9 (30) | 4.11 (13.5) Nws. | 8.00 (26.2 Nws) | 10.29 (33.8) Nws. |

| 12 (40) | 4.27 (14.0) Nws. | 10.67 (35.0) Nws. | 13.72 (45.0) Nws. |

| 15 (50) | 5.33 (17.5) Nws. | 13.35 (43.8) Nws. | 16.76 (55.0) Nws. |

| 18 (60) | 6.40 (21.00 Nws. | 16.00 (52.5 Nws.) | 19.81 (65.0) Nws. |

| 24 (80) | 8.53 (28.0) Nws. | 21.34 (70.0) Nws. | 25.91 (85.0) Nws. |

Tolerance rau Ncaj

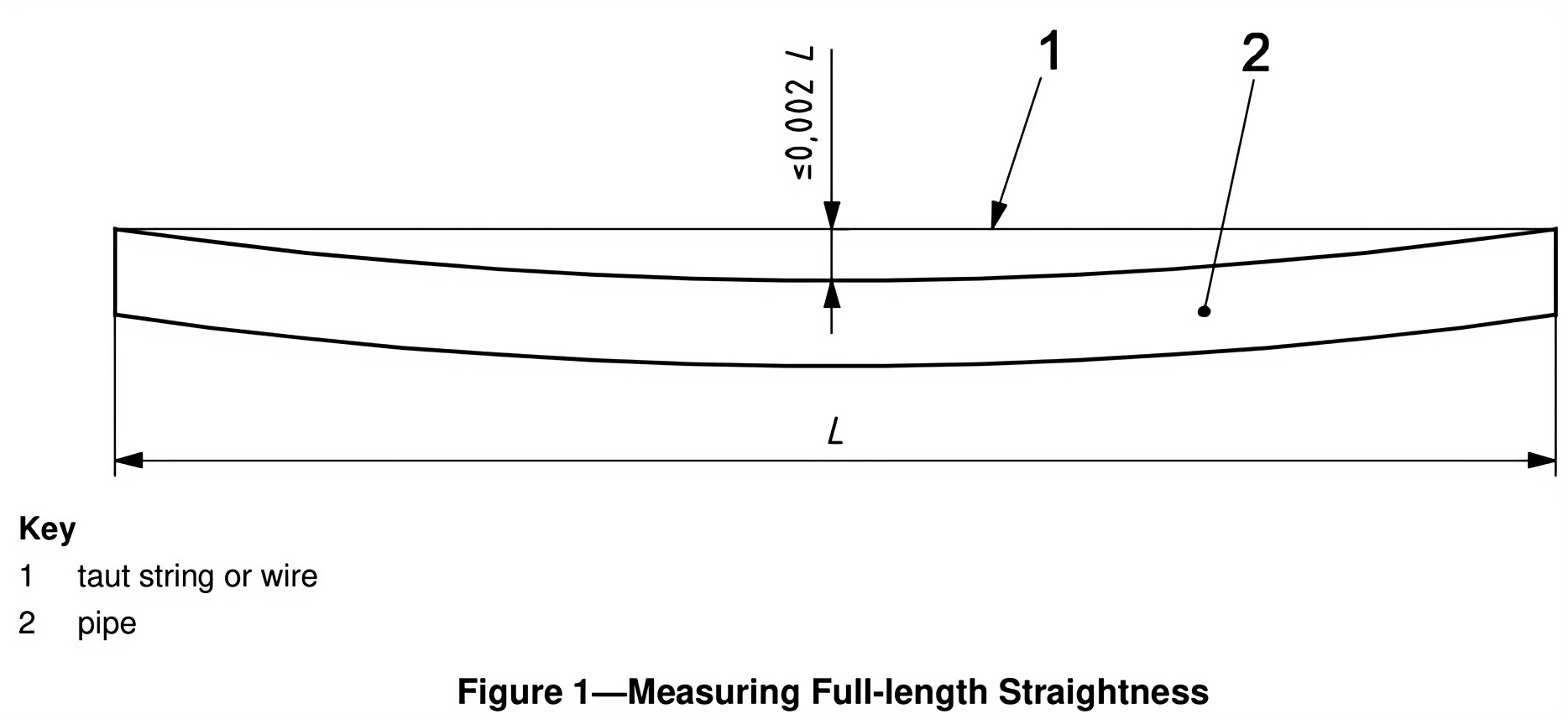

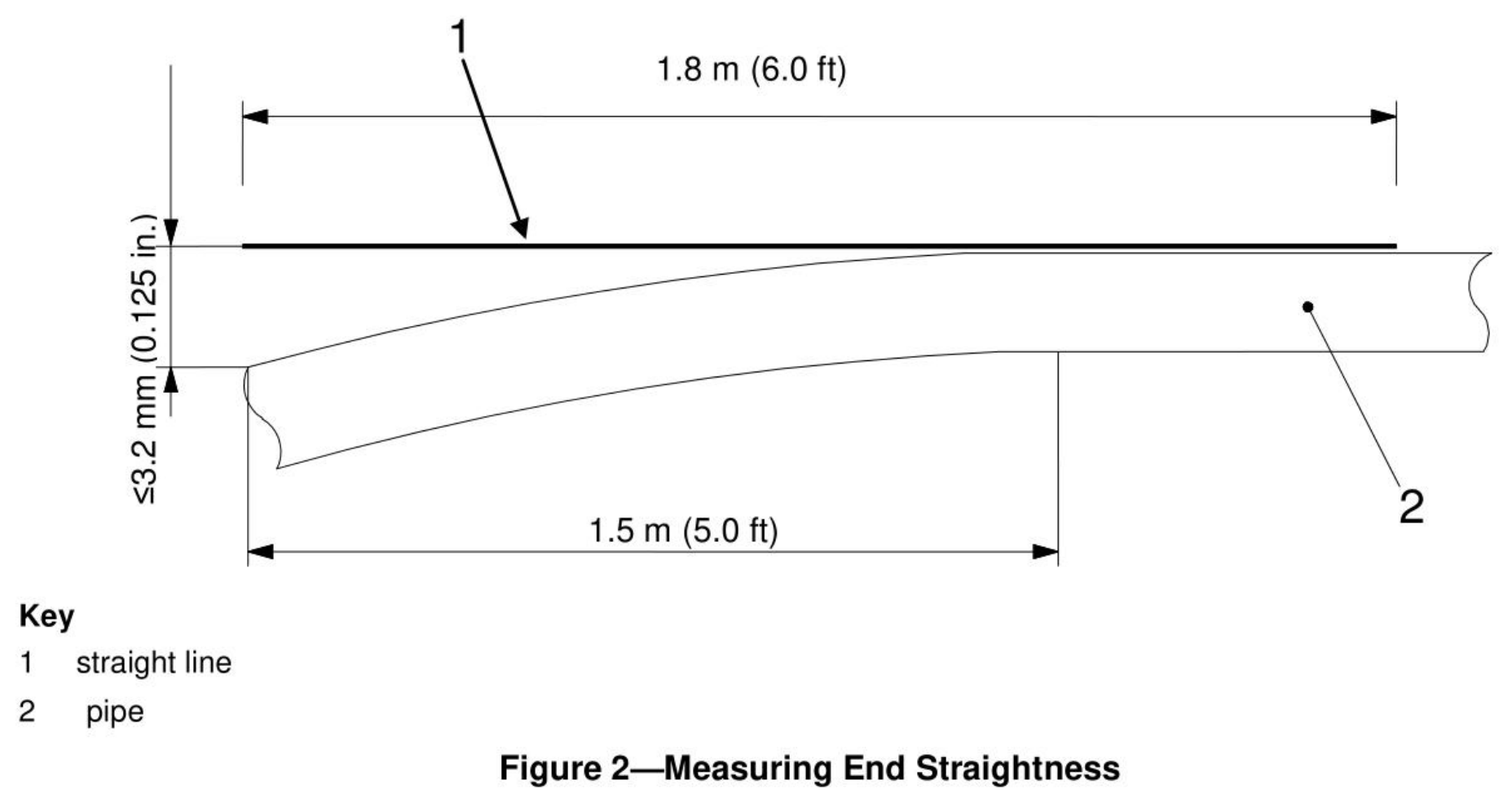

Straightness sib txawv ntawm qhovtag nrho ntev ntawm lub raj: ≤ 0.200 L;

Straightness sib txawv ntawm1.5 m (5.0 ft) yeeb nkab kawg ntawm cov yeeb nkab steel: ≤ 3.2mm (0.125 nti).

Tolerance rau Ncaj

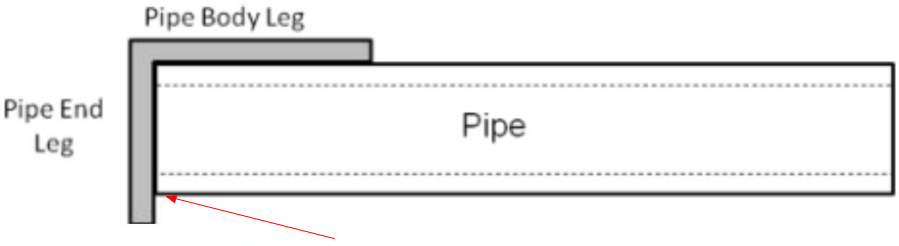

End squareness txhais tau tias yog square mus rau qhov kawg ntawm cov yeeb nkab.

Qhov tawm ntawm-squareness yuav tsum <1.6 mm (0.063 in.). Qhov tawm-ntawm-squareness yog ntsuas raws li qhov sib txawv ntawm qhov kawg ntawm cov yeeb nkab thiab cov yeeb nkab kawg ceg.

Tolerances rau Weld Seam

Tshaj Tawm Tshaj Tawm Radial Offsetrau SAW thiab COW Pipe.

| Specified Phab ntsa Thickness t mm (hauv.) | Tshaj Tawm Tshaj Tawm Radial Offsetamm (hauv.) |

| ≤ 15.0 (0.590) | 1.5 (0.060) |

| > 15.0 (0.590) txog 25.0 (0.984) | 0,1t :ua |

| > 25.0 (0.984) | 2.5 (0.098 hli) |

| aCov kev txwv no tseem siv tau rau sawb / phaj kawg welds | |

Maximum Permissible Weld Bead Qhov siabrau SAW thiab COW Pipe (Tshwj tsis yog ntawm Cov Yeeb Nkab Kawg).

| Specified Phab ntsa Thickness mm (hauv.) | Weld Bead Qhov siab mm (hauv.) maxim | |

| Sab hauv Bead | Sab nraud Bead | |

| ≤ 13.0 (0.512) | 3.5 (0.138 hli) | 3.5 (0.138 hli) |

| > 13.0 (0.512) | 3.5 (0.138 hli) | 4.5 (0.177 hli) |

Lub vuam yuav tsum muaj kev hloov pauv mus rau qhov chaw ntawm cov yeeb nkab steel uas nyob ib sab.

Cov yeeb nkab kawg welds yuav tsum tau muab tso rau hauv qhov ntev ntawm 100 hli (4.0 nyob rau hauv.) nrog qhov seem weld qhov siab ntawm ≤ 0.5 hli (0.020 hauv.).

Tolerances rau Mass

Txhua lub yeeb nkab steel:

a) rau qhov tshwj xeeb lub teeb loj yeeb nkab: -5.0% - +10.0%;

b) rau cov yeeb nkab hauv Qib L175, L175P, A25, thiab A25P: -5.0% - +10.0%;

c) rau tag nrho lwm cov kav dej: -3.5% - +10.0%.

Pipe rau ntau(≥ 18 tons (20 tons) rau kev txiav txim ntau):

a) rau qib L175, L175P, A25, thiab A25P: -3.5%;

b) rau tag nrho lwm cov qib: -1.75%.

API 5L GR.B Daim ntawv thov

API 5L Qib B steel yeeb nkab yog ib hom kab yeeb nkab, feem ntau yog siv los thauj cov dej xws li roj, roj, thiab dej, thiab yog ib qho ntawm cov khoom siv feem ntau siv hauv kev lag luam roj thiab roj.

Roj thiab roj kis systems: API 5L Qib B steel yeeb nkab feem ntau yog siv rau hauv cov roj thiab roj av extraction thiab cov chaw ua haujlwm thauj cov roj crude thiab cov nkev roj mus rau kev sib sau ua ke lossis cov chaw ua haujlwm.

Cov kav dej: Cov kev kho deg ntxiv, xws li cov coatings lossis cladding, tuaj yeem siv los txhim kho lawv cov kev tiv thaiv corrosion rau kev siv hauv kev xa dej, suav nrog cov khoom siv dej thiab cov kav dej.

Refineries: Nyob rau hauv refineries, API 5L Qib B steel yeeb nkab yog siv los thauj ntau yam chemicals thiab intermediates muab tau los ntawm cov fractional distillation ntawm cov roj crude.

Kev tsim kho thiab infrastructure: Hauv kev tsim kho kev lag luam, rau kev tsim cov choj, kev txhawb nqa cov qauv, lossis lwm yam tseem ceeb hauv kev tsim kho vaj tse, tshwj xeeb tshaj yog qhov yuav tsum tau muaj kev thauj mus los ntev.

API 5L Qib B sib npaug

ASTM A106 Qib B: Seamless carbon steel tubing feem ntau yog siv rau cov kev pabcuam kub kub, nrog cov tshuaj lom neeg muaj pes tsawg leeg thiab cov khoom siv kho tshuab zoo ib yam li API 5L Qib B. ASTM A106 Qib B feem ntau siv rau kev thauj cov dej kub kub, tshuaj lom neeg, thiab roj av.

ASTM A53 Qib B: Qhov no yog lwm hom carbon steel yeeb nkab, uas tuaj yeem welded los yog seamless, thiab yog siv dav hauv kev siv tshuab, kev tsim kho, thiab lwm yam kev siv engineering. Txawm hais tias nws feem ntau yog siv rau kev siv qis thiab kub, qee qhov ntawm nws cov cuab yeej cuab tam tsis zoo ib yam li API 5L Qib B.

EN 10208-2 L245NB: Siv rau kev tsim cov kav dej rau kev thauj cov pa taws thiab lwm yam kua. L245NB (1.0457) yog cov kav dej nruab nrab muaj zog nrog cov khoom siv kho tshuab zoo ib yam li API 5L Qib B.

TS EN ISO 3183 L245: Siv nyob rau hauv pipeline tsheb thauj mus los systems nyob rau hauv cov roj thiab roj kev lag luam.L245 nyob rau hauv ISO 3183 yog ze heev nyob rau hauv cov khoom rau API 5L Qib B thiab feem ntau yuav siv interchangeably.

Cov kev pabcuam ntxiv peb tuaj yeem muab tau

Botop SteelTsis tsuas yog muab cov yeeb nkab zoo API 5L Qib B steel yeeb nkab, tab sis kuj tseem muab cov kev pabcuam txhawb nqa rau koj, suav nrog ntau yam kev xaiv txheej txheej tiv thaiv, kev ntim khoom tus kheej, thiab kev pabcuam kev thauj mus los kom ntseeg tau tias peb tuaj yeem ua tau raws li koj xav tau ntau yam.

Peb tau cog lus los tsim ib qho chaw nres tsheb uas tso cai rau koj kom yooj yim nkag mus rau txhua yam khoom thiab cov kev pabcuam koj xav tau. Nrog peb cov kev pabcuam tshaj lij thiab txhim khu kev qha, koj tuaj yeem ua tiav txhua kauj ruam ntawm koj qhov project kom zoo thiab tsis muaj teeb meem, ua kom zoo thiab ua tiav. Peb lub hom phiaj yog los ua koj tus khub uas ntseeg siab tshaj plaws.

Anti-corrosion Txheej

Botop Steelmuaj ntau yam kev tiv thaiv corrosion txheej xaiv, suav nrogpleev xim rau, galvanized,3 LPE (HDPE), 3 PIB,FBE, thiab cementitious counterweights, kom tau raws li ntau yam kev xav tau ntawm koj qhov project.

ntim

Peb muab ntau yam kev xaiv ntim, nrog rau cov bales, tarps, crates, thiab cov kaus mom yeeb nkab, uas tuaj yeem ua raws li koj cov kev xav tau tshwj xeeb.

Kev pab txhawb nqa

Peb lub tuam txhab tau cog lus tias yuav muab cov kev pabcuam kev txhawb nqa dav dav rau txhua theem ntawm qhov project. Los ntawm kev npaj ua ntej qhov kev sib tw mus rau nruab nrab ntawm qhov project procurement thiab kev thauj mus los, mus rau tom qab qhov project tu thiab daws teeb meem, peb pab neeg tshaj lij tuaj yeem muab cov lus qhia thiab kev txhawb nqa rau koj.

Peb lub hom phiaj yog los pab koj yuav cov khoom lag luam zoo thiab pheej yig hauv Suav teb, kom ntseeg tau tias koj txoj haujlwm ua haujlwm tau zoo thiab muaj txiaj ntsig zoo. Peb tos ntsoov yuav ua haujlwm nrog koj los tsim kom muaj kev yeej-yeej yav tom ntej.