| Khoom npe | Carbon Steel Yeeb Nkab / Boiler Steel Yeeb Nkab |

| Khoom siv | A53 GrB, A36, ST52, ST35, ST42, ST45, X42, X46, X52, X60, X65, X70 |

| Txuj | API 5L, ASTM A106 Gr.B, ASTM A53 Gr.B, ASTM A179/A192, ASTM A335 P9, ASTM A210, ASTM A333 |

| Daim ntawv pov thawj | API 5L, ISO9001, SGS, BV, CCIC |

| Sab nraud | 13.7mm-762 hli |

| Phab ntsa Thickness | SCH 10 SCH 20 SCH 30 TSI SCH 40 SCH 60 SCH 80 SCH 100 SCH 120 SCH 160 XS XXS |

| Ntev | 1m, 4m, 6m, 8m, 12m raws li tus neeg yuav khoom thov |

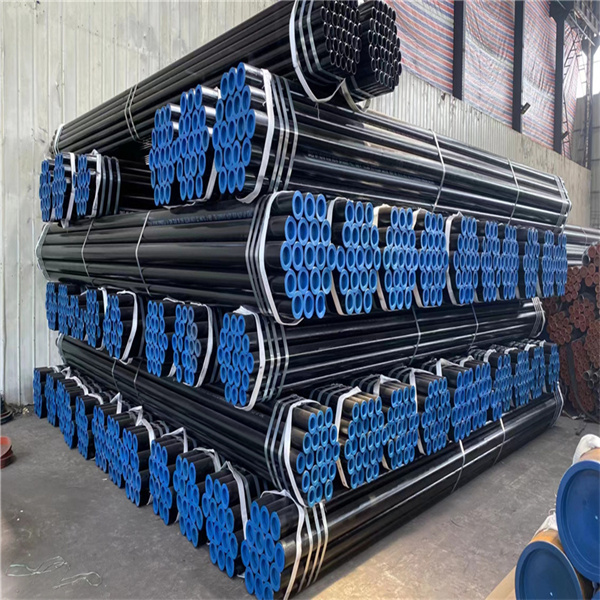

| Kev kho saum npoo | xim dub, kua roj vanish, roj, galvanized, anti-corrosion coated |

| Kos npe | Cov cim cim, lossis raws li koj qhov kev thov.Kev kos npe: Txau xim dawb |

| Kev kho mob kawg | Plain End / Beveled End / Grooved End / Threaded End With Plastic Caps |

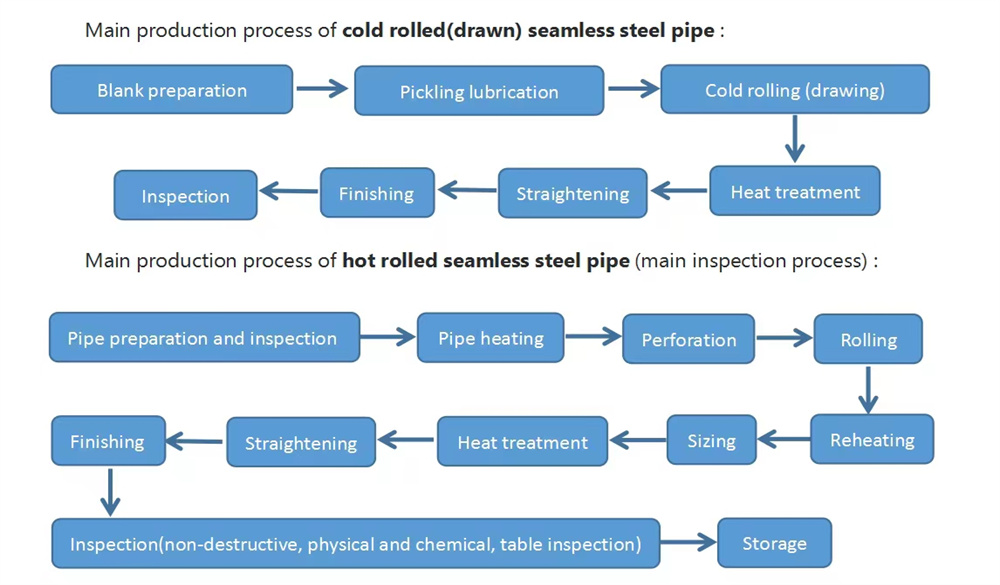

| Cov txheej txheem | Kub Rolled lossis Cold Rolled ERW |

| Pob | Cov pob xoob; Ntim hauv pob khoom (2Ton Max); cov kav dej nrog cov hlua ntawm ob qho kawgkom yooj yim thauj khoom thiab tso tawm; ntoocov ntaub ntawv; waterproof woven hnab |

| Kuaj | Chemical Component Analysis, Mechanical Properties, Technical Properties, Sab nrauv Loj Kev tshuaj xyuas, kuaj hydraulic, X-ray Test |

| Daim ntawv thov | Kev xa khoom ua kua, cov yeeb nkab, kev tsim kho, roj av tawg, cov yeeb nkab roj, cov yeeb nkab roj |

API 5L X42-X80, PSL1 & PSL2 Roj thiab RojCarbon Seamless Steel Yeeb Nkabyog siv rau conveying roj, dej, thiab roj av ntawm ob qho tib si roj thiab natural gas industries.

API 5L X42-X80, PSL1 & PSL2 Roj thiab Roj Carbon Seamless Steel Yeeb Nkab yog tsim los ntawm txias-draw lossis kub dov, raws li cov neeg siv khoom xav tau.

API 5L X52 PSL1 & PSL2 Roj thiab Roj Carbon Seamless Steel Yeeb Nkab yog tsim los ntawm txias-draw los yog kub dov, feem ntau me me los ntawm txias-kos thiab loj loj los ntawm kub dov.

Qib thiab tshuaj muaj pes tsawg leeg (%)Rau API 5L PSL1

| Txuj |

Qib | Tshuaj muaj pes tsawg leeg(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤ 0.28 | ≤ 1.30 | ≤ 0.030 | ≤ 0.030 |

| X46, X52, X56 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

| 60,x 65 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

| X 70 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

| X52 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | |

Qib thiab tshuaj muaj pes tsawg leeg (%)Rau API 5L PSL2

| Txuj |

Qib | Tshuaj muaj pes tsawg leeg(%) | |||

| C | Mn | P | S | ||

| API 5L | X42 | ≤ 0.24 | ≤ 1.30 | ≤ 0.025 | ≤ 0.015 |

| X46, X52, X56 | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | |

| 60,x 65 | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | |

| 70x80, ua | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | |

| X52 | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | |

Mechanical Properties ntawm API 5L GR.B X42-X80 /X52(PSL1):

| Qib | Yield zog(MPa) | Tensile zog(MPa) | Elongation A% | ||

|

| psi | MPa | psi | MPa | Elongation (Min) |

| X42 | 42,000 ib | 290 | 60,000 | 414 ib | 21-27 : kuv |

| X46 | 46,000 ib | 317 | 63,000 ib | 434 ib | 20-26 : kuv |

| X52 | 52,000 ib | 359 ib | 66,000 ib | 455 | 20-24 : kuv |

| X56 | 56,000 ib | ib 386 | 71,000 ib | 490 ib |

|

| X 60 | 60,000 | 414 ib | 75,000 ib | 517 ib |

|

| X 65 | 65,000 ib | 448 ib | 77,000 ib | 531 ib |

|

| X 70 | 70,000 | 483 ib | 82,000 ib | 565 ib |

|

| X52 | 52,000 ib | 359 ib | 66,000 ib | 455 | 20-24 : kuv |

Mechanical Properties ntawm API 5L /X52GR.B Seamless Kab Yeeb (PSL2):

| Qib | Yield zog(MPa) | Tensile zog(MPa) | Elongation A% | Kev cuam tshuam (J) | ||

|

| psi | MPa | psi | MPa | Elongation (Min) | Min |

| X42 | 290 | 496 ib | 414 ib | 758 ib | 21-27 : kuv | 41(27) |

| X46 | 317 | 524 ib | 434 ib | 758 ib | 20-26 : kuv | 41(27) |

| X52 | 359 ib | 531 ib | 455 | 758 ib | 20-24 : kuv | 41(27) |

| X56 | ib 386 | 544 ib | 490 ib | 758 ib |

|

|

| X 60 | 414 ib | 565 ib | 517 ib | 758 ib |

|

|

| X 65 | 448 ib | 600 | 531 ib | 758 ib |

|

|

| X 70 | 483 ib | 621 ib | 565 ib | 758 ib |

|

|

| X80 | 552 ib | 690 ib | 621 ib | 827 ib |

| |

| X52 | 359 ib | 531 ib | 455 | 758 ib | 20-24 : kuv | 41(27) |

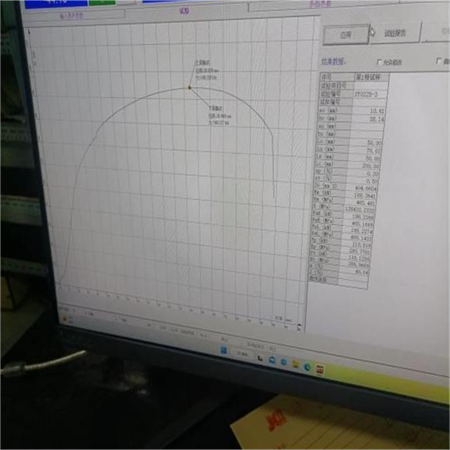

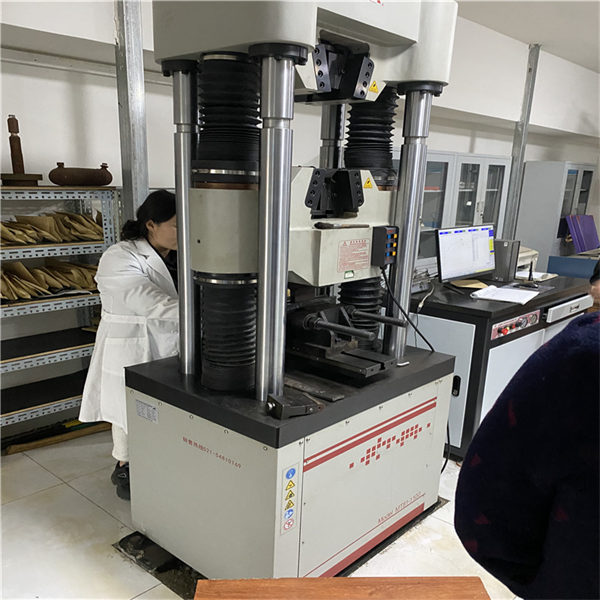

Mechanical Testing

Kev Xeem Hardness

Khoov Kev Xeem

Tensile testing ntawm lub cev yeeb nkab-Kev ntsuas tensile yuav tsum tau ua raws li ISO6892 lossis ASTM A370.Longitudinal kuaj yuav tsum tau siv.Ob zaug ib chav ntsuas ntawm cov yeeb nkab nrog tib qhov txias-expansion piv abd

flattening Test—Ib qho kev sim flattening yuav tsum tau ua ntawm cov qauv ntawm txhua qhov kawg ntawm ob lub raj xaiv los ntawm txhua qhov ntau

CVN cuam tshuam kev xeem-Kev xeem Charpy yuav tsum tau ua raws li ASTM A370. Ob zaug ib chav ntsuas tsis ntau tshaj 100 qhov ntev ntawm cov yeeb nkab nrog tib qhov txias-expansion piv abd

Hardness Test-Thaum xav tias qhov chaw nyuaj raug kuaj pom los ntawm kev tshuaj xyuas qhov muag, kev ntsuam xyuas qhov tawv yuav tsum ua raws li ISO 6506, ISO 6507, ISO 6508 lossis ASTM A 370 siv cov khoom siv tawv tawv thiab cov txheej txheem ua raws li ASTM A 956, ASTM A 1038 lossis ASTM E 1.

Hydro-static Test-Txhua lub raj yuav tsum raug kuaj los ntawm hydro-static siab

Bending Test - qhov ntev txaus ntawm cov yeeb nkab yuav tsum sawv ntsug ntawm qhov kub ntawm 90 ° nyob ib ncig ntawm lub cylindrical mandrel.

100% X-ray kuaj rau vuam seam

Kev kuaj ultrasonic

Kev ntsuam xyuas tam sim no

Bare yeeb nkab lossis Dub / Varnish txheej (raws li cov neeg siv khoom xav tau);

6 "thiab hauv qab hauv pob nrog ob lub paj rwb slings;

Ob qhov xaus nrog qhov kawg tiv thaiv;

Plain kawg, bevel kawg (2 "thiab saum toj no nrog bevel xaus, degree: 30 ~ 35 °), threaded thiab coupling;

Kos npe.

| Loj | Tolerance (nrog respect to teev sab nraudtxoj kab uas hla) |

| <2 3/8 | 0.016 "- 0.031" (+ 0.41 hli, - 0.79 hli) |

| > 2 3/8 thiab ≤4 1/2, nruam welded | ± 1.00% |

| > 2 3/8 thiab <20 | ± 0.75% |

| > 20. seamless | ± 1.00% |

| > 20 thiab <36, welded | 0.75% -0.25% |

| > 36, welded | 1/4 "- 1/8" (+ 6.35mm, -3.20mm) |

Nyob rau hauv cov ntaub ntawv ntawm cov yeeb nkab hydro-statically ntsuam xyuas rau pressures nyob rau hauv ntau tshaj ntawm standard test pressures, lwm yam kam rau ua tej zaum yuav pom zoo raws li cov chaw tsim tshuaj paus thiab cov neeg yuav khoom.

| Out-of-Roundness | |||||

| Loj | Minus kam rau ua | Ntxiv Tolerance | End-to-End Tolerance | Txoj kab uas hla, Axis kam rau ua (Percent ntawm OD) | Qhov sib txawv ntawm qhov tsawg kawg nkaus thiab qhov siab tshaj plaws (tsuas yog siv rau cov yeeb nkab nrog D / t≤75) |

| ≤10 3/4 l&V4 | 1/64 (0.40 hli) | 1/16 (1.59mm) | — | — | |

| > 10 3/4 thiab ≤20 | 1/32 (0.79 hli) | 3/32 (2.38 hli) | — | — | — |

| > 20 thiab ≤ 42 | 1/32 (0.79 hli) | 3/32 (2.38 hli) | b | ± 1% | <0.500 nyob rau hauv. (12.7mm) |

| > 42 | 1/32 (0.79 hli) | 3/32 (2.38 hli) | b | ± 1% | £ Q625 nyob rau hauv. (15.9 mm) |

Out-of-roundness kam rau ua siv rau qhov siab tshaj plaws thiab qhov tsawg kawg nkaus diameters raws li ntsuas nrog lub ntsuas ntsuas, caliper, lossis cov cuab yeej ntsuas qhov siab tshaj plaws thiab qhov tsawg kawg nkaus.

Qhov nruab nrab txoj kab uas hla (raws li ntsuas nrog ib txoj kab uas hla) ntawm ib kawg ntawm cov yeeb nkab yuav tsum tsis txhob sib txawv los ntawm ntau tshaj 3/32 nyob rau hauv. (2.38 mm) ntawm qhov kawg ntawm qhov kawg.

| Loj | Hom yeeb nkab | Tolerance1 (Pib feem ntawm cov Phab Ntsa Thickness) | |

| Qib B lossis qis dua | Qib X42 lossis siab dua | ||

| <2 7/8 | Tag nrho | +20.- 12.5 Nws | + 15.0.-12.5 |

| > 2 7/8 thiab <20 | Tag nrho | + 15,0,-12.5 | + 15-I2.5 |

| > 20 | Welded | + 17.5.-12.5 | + 19.5.-8.0.0 Nws |

| > 20 | Seamless | + 15.0.-12.5 | + 17.5.-10.0 Nws |

Yog tias qhov kev zam tsis zoo me dua li cov npe teev tseg los ntawm tus neeg yuav khoom, qhov kev zam zoo yuav tsum tau nce ntxiv rau qhov siv tau tag nrho cov kev kam rau siab nyob rau hauv feem pua tsawg dua phab ntsa thickness tsis kam rau siab.

| Ntau | Tokev ua siab ntev (feem pua) |

| Ib qhov ntev, tshwj xeeb cov yeeb nkab kawg lossis A25 yeeb nkabIb leeg ntev, lwm cov yeeb nkabCarloads.GradeA25,40,000lb (18 144kg) lossis ntau duaCarloads, uas tsis yog Qib A25,40.0001b (18 144 kg) lossis ntau duaCarloads, tag nrho cov qib qis dua 40000 lb (18 144 kg) Order khoom. Qib A25. 40,000 lb (18 144 kg) lossis ntau dua Cov khoom xaj, uas tsis yog Qib A25,40,000 lb (18 144 kg) lossis ntau dua Cov khoom xaj, txhua qib, tsawg dua 40.000 lb (18 144 kg) | + 10.-5.0 + 10,-35 ib -2.5 -1.75 Nws -15 -3.5 -1.75 Nws -3.5 |

Nco tseg:

1.Weight tolerances siv rau qhov ntsuas qhov hnyav rau threaded-thiab-coupled yeeb nkab thiab rau cov tabulated los yog xam qhov hnyav rau cov yeeb nkab-kawg. Qhov twg tsis zoo phab ntsa thickness tolerances me dua li cov teev nyob rau hauv cov lus saum toj no tau teev los ntawm tus neeg yuav khoom, qhov ntxiv qhov hnyav rau qhov ntev yuav tsum tau nce mus rau 22.5 feem pua tsawg dua qhov wail thickness tsis kam kam rau ua.

2.Rau carloads muaj li ntawm cov yeeb nkab los ntawm ntau tshaj ib yam khoom, lub carload tolerances yuav tsum tau siv nyob rau hauv ib tug neeg txiav txim yam khoom.

3. Lub siab ntev rau cov khoom xaj siv rau tag nrho cov yeeb nkab xa mus rau cov khoom xaj.