CovAPI 5Ltxheem cov npe raj raws li lawv qhov tsawg kawg nkaus yield zog. Yog li ntawd,X52 (L360) muaj qhov tsawg kawg nkaus lub zog ntawm 52,200 psi (360 MPa).

X52 = L360, yog ob txoj hauv kev qhia tib qib yeeb nkab hauv API 5L tus qauv.

X52yog qib nruab nrab hauv API 5L, sib txuas ua haujlwm siab nrog kev lag luam. Dav siv nyob rau hauv roj thiab roj tsheb thauj mus los, kev tsim kho tej yaam num, submarine pipelines, thiab lwm yam.

Botop Steelyog ib lub chaw tsim khoom ntawm tuab-walled loj-inch ob-sided submerged arc LSAW steel yeeb nkab nyob rau hauv Suav teb.

1. Qhov chaw: Cangzhou City, Hebei Province, Suav teb;

2. Kev nqis peev tag nrho: 500 lab RMB;

3. Lub Hoobkas cheeb tsam: 60,000 square meters;

4. Txhua xyoo muaj peev xwm: 200,000 tons ntawm JCOE LSAW steel kav;

5. Cov khoom siv: Cov khoom siv ntau lawm thiab cov khoom siv kuaj;

6. Tshwj xeeb: LSAW steel yeeb nkab ntau lawm;

7. Ntawv pov thawj: API 5L tau ntawv pov thawj.

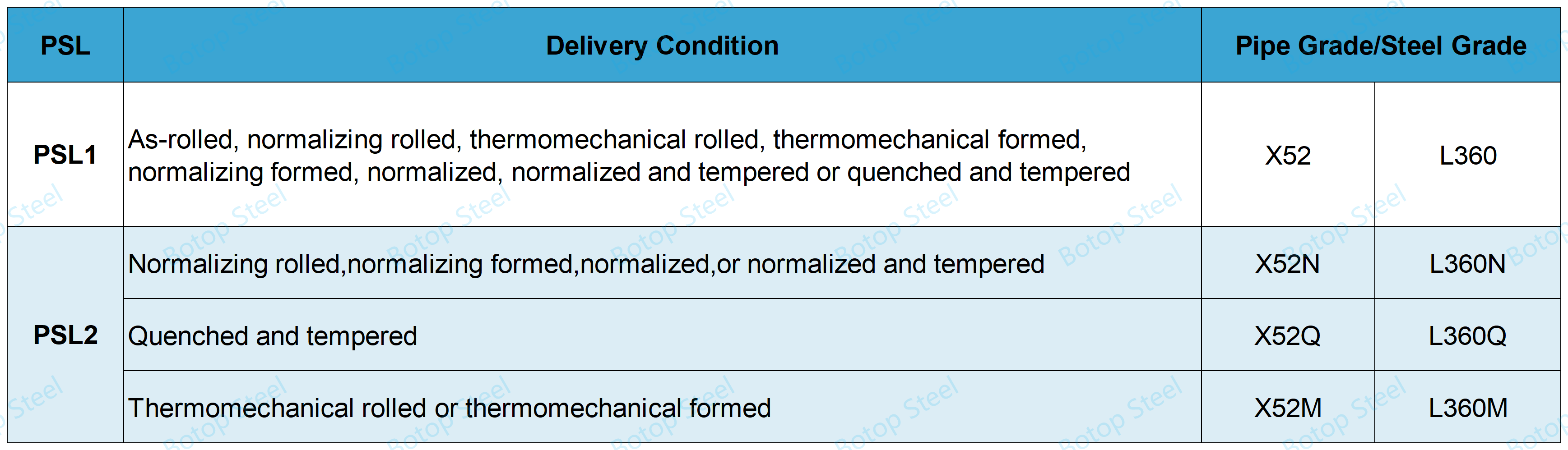

API 5L X52 Classification

Nyob ntawm qib PSL thiab kev xa khoom, X52 tuaj yeem faib raws li hauv qab no:

PSL1: X52;

PSL2:X52N lossis L360N;X52Q lossis L360Q;X52M or L360M.

Hauv PSL2, tsab ntawv suffix hais txog hom kev kho cua sov cov khoom yuav tsum raug xa mus ua ntej xa khoom kawg. Koj tuaj yeem pom covyam khoom xa tuajhauv qab no kom paub meej ntxiv.

Kev Xa Khoom

Pib Khoom

Ingots, paj, billets, coils, los yog daim hlau.

Rau PSL 2 yeeb nkab, cov hlau yuav tsum raug tua thiab ua raws li kev coj ua zoo.

Lub kauj lossis phaj siv rau kev tsim cov yeeb nkab PSL 2 yuav tsum tsis muaj kev kho welds.

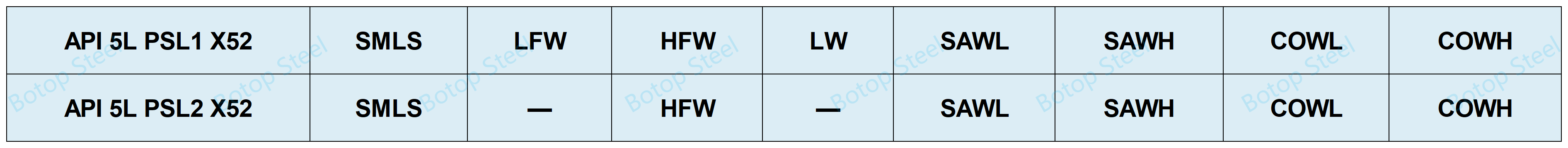

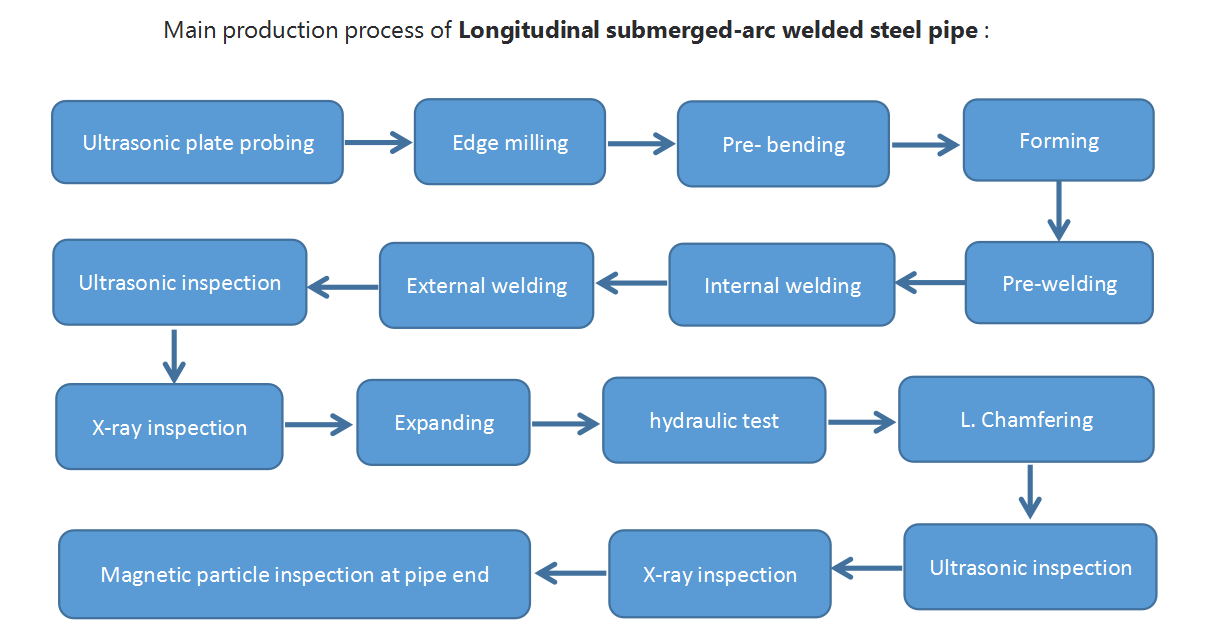

API 5L X52 Manufacturing Txheej txheem

X52 raj tuaj yeem tsim tau siv ntau txoj kev tsim cov raj kom tau raws li qhov xav tau ntawm engineering sib txawv.

Txhawm rau kom paub ntau ntxiv txog lub ntsiab lus ntawm lub ntsiab lus Manufacturing Process,nias ntawm no.

SAWLyog qhov kev daws teeb meem zoo tshaj plaws rauloj-inch, tuab-walledcov kav hlau.

Cov ntsiab lus "SAWL"thiab"LSAW"ob leeg xa mus rau Longitudinal Submerged Arc Welded, tab sis raug xa mus rau qhov sib txawv ntawm cov cheeb tsam sib txawv, qhov sib txawv, lo lus "LSAW" yog siv dav hauv kev lag luam.

LSAW yeeb nkab tej zaum yuav muab ob npaug rau welded vim cov cuab yeej txwv nyob rau hauv zus tau tej cov loj-inch yeeb nkab, thiab cov welds yuav tsum nyob ib ncig ntawm 180 ° sib nrug.

Pipe End Hom rau API 5L X52

PSL1 Hlau Yeeb Nkab Kawg: Tswb kawg lossis Plain kawg;

PSL2 Hlau Yeeb Nkab Kawg: Plain kawg;

Rau cov yeeb nkab ncaj kawgcov cai hauv qab no yuav tsum tau ua raws li:

Lub ntsej muag kawg ntawm t ≤ 3.2 hli (0.125 hauv) cov yeeb nkab kawg yuav tsum yog square txiav.

Plain-kawg raj nrog t> 3.2 hli (0.125 nyob rau hauv) yuav tsum tau beveled rau vuam. Lub kaum sab xis yuav tsum yog 30-35 ° thiab qhov dav ntawm lub hauv paus ntsej muag ntawm bevel yuav tsum yog 0.8 - 2.4 hli (0.031 - 0.093 nyob rau hauv).

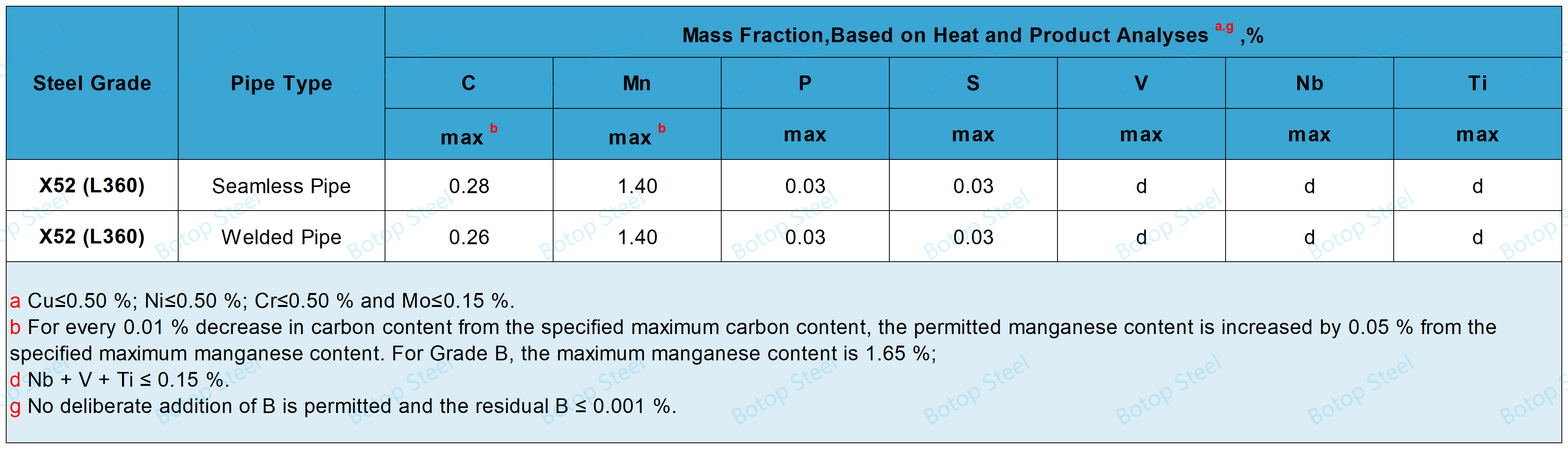

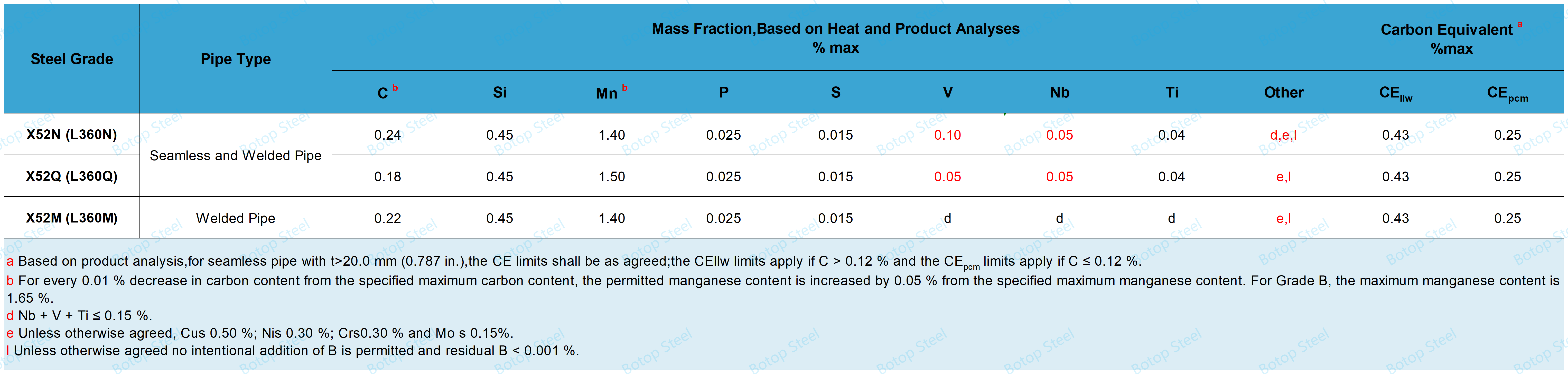

API 5L X52 Chemical Composition

Cov tshuaj muaj pes tsawg leeg ntawm PSL1 thiab PSL2 steel yeeb nkab t> 25.0 hli (0.984 hauv) yuav tsum txiav txim siab los ntawm kev pom zoo.

Chemical Composition rau PSL 1 Pipe nrog t ≤ 25.0 mm (0.984 in.)

Chemical Composition rau PSL 2 Pipe nrog t ≤ 25.0 mm (0.984 in.)

Rau PSL2 steel yeeb nkab khoom soj ntsuam nrog acarbon cov ntsiab lus ≤0.12%, carbon sib npaug CEpcm uatuaj yeem suav nrog cov qauv hauv qab no:

CEpcm ua= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

Rau PSL2 steel yeeb nkab khoom soj ntsuam nrog aCov ntsiab lus carbon> 0.12%, carbon sib npaug CElwjtuaj yeem suav nrog cov qauv hauv qab no:

CElwj= C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

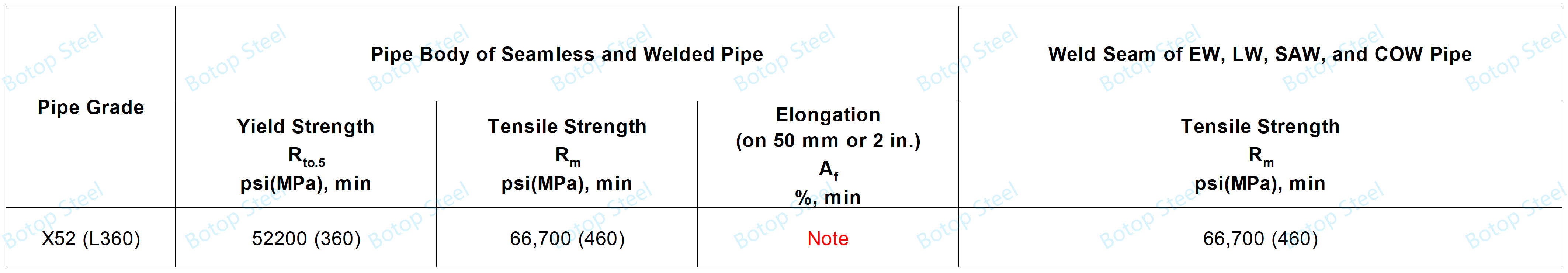

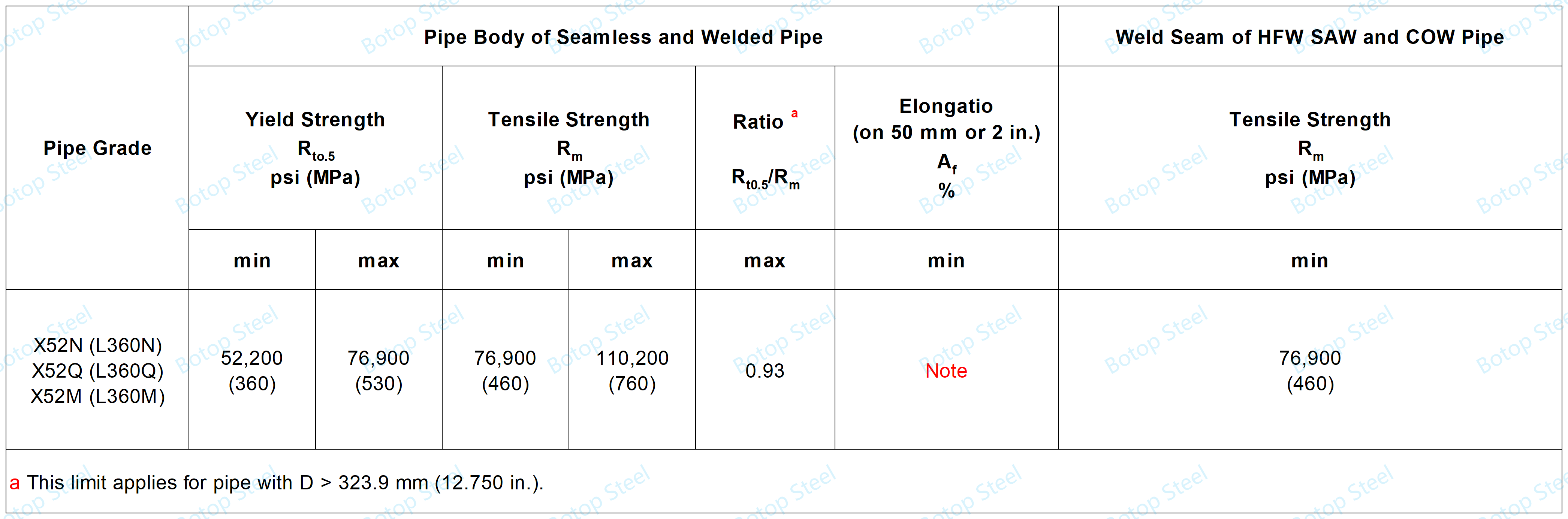

API 5L X52 Mechanical Properties

Tensile Properties

Tensile test ntsuas peb qhov tseem ceeb:yield zog, tensile zog, thiabelongation.

PSL1 X52 Tensile Properties

PSL2 X52 Tensile Properties

Nco tseg: Yam tsawg kawg nkaus elongation, Afyuav tsum tau txiav txim siab siv cov kab zauv hauv qab no:

Af= C × (Axc0.2/U0.9)

Cyog 1940 rau kev suav siv SI units thiab 625,000 rau kev suav nrog USC units;

Axc yog qhov siv tau tensile xeem piece cross-sectional cheeb tsam, qhia nyob rau hauv square millimeters (square inches), raws li nram no:

1) rau kev sib tw hla ntu, 130 mm2(0.20 hli.2) rau 12.7 hli (0.500 nyob rau hauv.) thiab 8.9 hli (0.350 nyob rau hauv.) txoj kab uas hla xeem daim; 65mm ib2(0.10 hli.2) rau 6.4 hli (0.250 nyob rau hauv.) txoj kab uas hla xeem daim;

2) rau tag nrho-section xeem daim, qhov tsawg dua ntawm a) 485 mm2(0.75 hli.2) thiab b) thaj tsam ntawm qhov kev sib tw ntawm daim ntawv xeem, T tau muab los ntawm kev siv cov txheej txheem sab nraud thiab cov phab ntsa tuab ntawm cov yeeb nkab, sib npaug mus rau qhov ze tshaj 10 hli2(0.01 hli.2);

3) rau strip test pieces, qhov tsawg dua ntawm a) 485 mm2(0.75 hli.2) thiab b) thaj tsam ntawm qhov kev sib tw ntawm daim ntawv xeem, muab tau los ntawm qhov dav dav ntawm daim ntawv xeem thiab cov txheej txheem phab ntsa thickness ntawm cov yeeb nkab, sib npaug mus rau qhov ze tshaj 10 hli.2(0.01 hli.2);

Uyog qhov tsawg kawg nkaus tensile lub zog, qhia nyob rau hauv megapascals (phaus ib square inch).

Lwm yam Mechanical Experiments

Cov kev xeem hauv qab no siv rauSAW yeeb nkab hom. Rau lwm hom yeeb nkab, saib Tables 17 thiab 18 ntawm API 5L.

Weld qhia dabtsi yog khoov kuaj;

Cold-formed welded yeeb nkab hardness kuaj;

Macro soj ntsuam ntawm welded seam;

thiab tsuas yog rau PSL2 steel yeeb nkab: CVN cuam tshuam kuaj thiab DWT xeem.

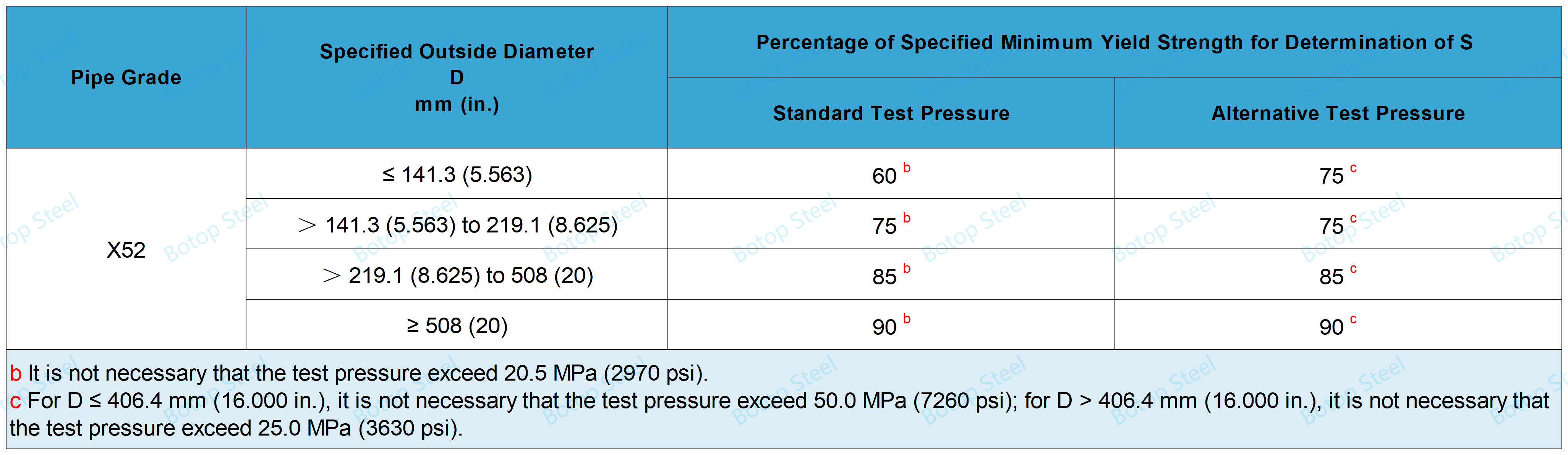

Hydrostatic Test

Lub Sijhawm Xeem

Txhua qhov ntau thiab tsawg ntawm seamless thiab welded steel hlab nrog D ≤ 457 mm (18 in.):xeem lub sij hawm ≥ 5s;

Welded steel yeeb nkab D> 457 mm (18 nyob rau hauv.):xeem lub sij hawm ≥ 10s.

Kev sim ntau zaus

Txhua cov yeeb nkab steel.

Kev sim siab

Kev ntsuas hydrostatic siab P ntawm aplain-end steel yeeb nkabtuaj yeem suav tau los ntawm kev siv cov mis.

P = 2st/D

Syog lub hoop stress. tus nqi yog sib npaug rau qhov tsawg kawg nkaus tawm lub zog ntawm cov yeeb nkab steel xa feem pua, hauv MPa (psi);

tyog lub thickness ntawm phab ntsa, qhia nyob rau hauv millimeters (inch);

Dyog qhov teev sab nraud txoj kab uas hla, qhia hauv millimeters (inch).

Kev tshuaj xyuas tsis zoo

Rau SAW tubes, ob txoj kev,UT(ultrasonic testing) los yogRT(radiographic kuaj), feem ntau yog siv.

ET(electromagnetic testing) tsis siv rau SAW raj.

Welded seams ntawm welded kav ntawm qib ≥ L210 / A thiab txoj kab uas hla ≥ 60.3 mm (2.375 hauv) yuav tsum tsis txhob raug tshuaj xyuas kom tag nrho tuab thiab ntev (100%) raws li tau teev tseg.

UT cov kev xeem tsis muaj kev puas tsuaj

RT kev kuaj xyuas tsis muaj kev puas tsuaj

Cold Sizing thiab Cold Expansion

Txias sizing thiab txias expansion yog ob hom kev ua haujlwm siv hauv kev tsim cov LSAW raj los xyuas kom meej tias cov raj ua tiav qhov ntev thiab cov khoom siv tshuab. Ob qho txheej txheem yog cov txheej txheem ua haujlwm txias, qhov twg cov duab thiab qhov loj ntawm lub raj raug kho ntawm chav tsev kub.

Qhov sizing ratio ntawmtxias expansioncov raj yuav tsum tsis pub tsawg tshaj 0.003 thiab yuav tsum tsis txhob ntau tshaj 0.015.

Qhov luaj li cas ntawmtxias lojsteel yeeb nkab yuav tsum tsis txhob ntau tshaj 0.015, tshwj tsis yog nyob rau hauv cov nram no:

a) Cov yeeb nkab yog tom qab normalized los yog quenched thiab tempered;

b) Tag nrho cov yeeb nkab steel yeeb nkab yog tom qab kev ntxhov siab.

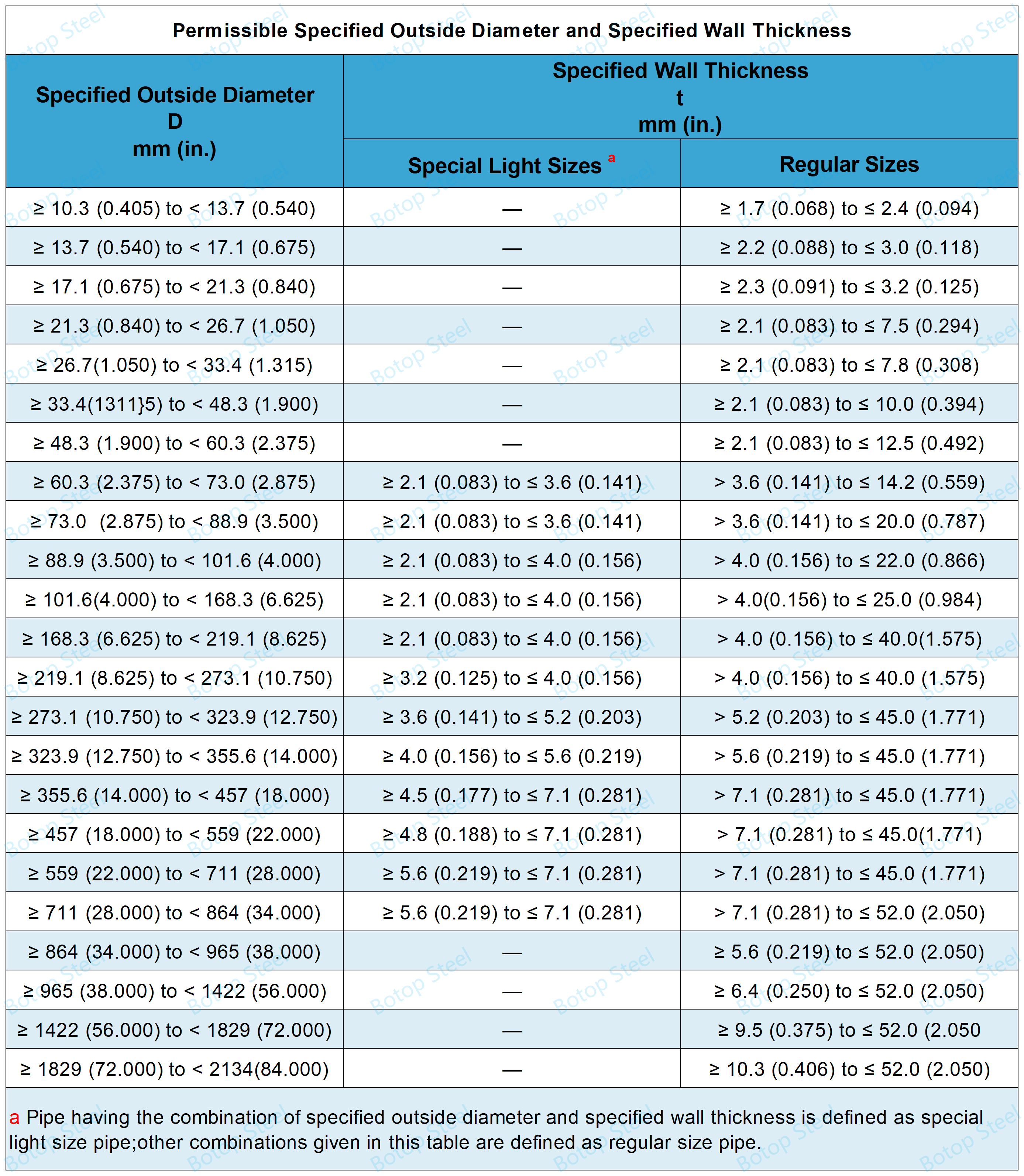

Qhia tawm sab nraud thiab phab ntsa Thickness

Cov nqi tsim nyog rau kev teev sab nraud diameters thiab teev cov phab ntsa thicknesses ntawm cov yeeb nkab steel yog muab rau hauvISO 4200 UASthiabASME B36.10M.

Dimensional Tolerances

Thov nyem rau ntawm daim ntawv xiav ntawm sab xis kom pom qhov ntev ntev, cov cai yuav tsum tau teev nyob rau hauvAPI 5L Qib Bkom paub meej.

API 5L X52 Daim Ntawv Thov

API 5L X52 steel yeeb nkab yog siv dav hauv ntau daim ntawv thov tseem ceeb vim nws cov khoom siv zoo heev thiab muaj peev xwm hloov mus rau qhov chaw nyuaj.

Kev thauj roj thiab roj: Qhov no yog ib qho ntawm feem ntau siv rau API 5L X52. Feem ntau yog siv rau kev thauj mus los ntawm cov roj thiab roj kav ntev, tshwj xeeb tshaj yog thaum muaj kev kub siab sab hauv.

Kev tsim kho thiab infrastructure: tuaj yeem siv los tsim cov qauv kev txhawb nqa rau cov choj thiab cov tsev. Nws kuj tseem siv tau rau hauv kev tsim cov braces lossis lwm cov qauv kev thauj khoom, tshwj xeeb tshaj yog nyob rau qhov ntev ntev lossis siab load-bearing capacities.

Subsea pipelines: Subsea pipeline tej yaam num muaj ib tug tshwj xeeb xav tau rau corrosion-resistant thiab high-lub zog kav, thiab API 5L X52 excels nyob rau hauv no hais txog. Nws tiv taus dej hiav txwv thiab tswj kev ncaj ncees thiab kev ua haujlwm ntawm cov raj xa dej, ua rau nws zoo tagnrho rau kev sib txuas rau cov khoom siv roj thiab roj av.

Peb Cov Khoom Muag

Txuj: API 5L;

PSL1: X52 lossis L360;

PSL2: X52N, X52Q, X52M lossis L360N, L360Q, L360M;

Tube Hom: Welded Carbon Steel Yeeb Nkab;

Cov txheej txheem tsim khoom: LSAW, SAWL lossis DSAW;

Sab nraud txoj kab uas hla: 350 - 1500;

Phab ntsa Thickness: 8 - 80mm;

Length: Kwv yees ntev los yog random ntev;

Cov Sijhawm Pipe: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 thiab SCH160.

Kev txheeb xyuas: STD, XS, XXS;

Txheej: Xim, kua roj vanish, 3LPE, FBE, 3LPP, HDPE, galvanized, epoxy zinc-nplua nuj, cement hnyav, thiab lwm yam.

Packing: Waterproof ntaub, rooj ntoo, steel siv los yog steel hlau bundling, yas los yog hlau yeeb nkab kawg tiv thaiv, thiab lwm yam. Customized.

Cov khoom sib txuam: khoov, flanges, yeeb nkab fittings, thiab lwm yam khoom sib txuam muaj.