ASTM A335 P91, kuj hu uaASME SA335 P91, yog seamless ferritic alloy steel yeeb nkab rau kev pabcuam kub, UNS No. K91560.

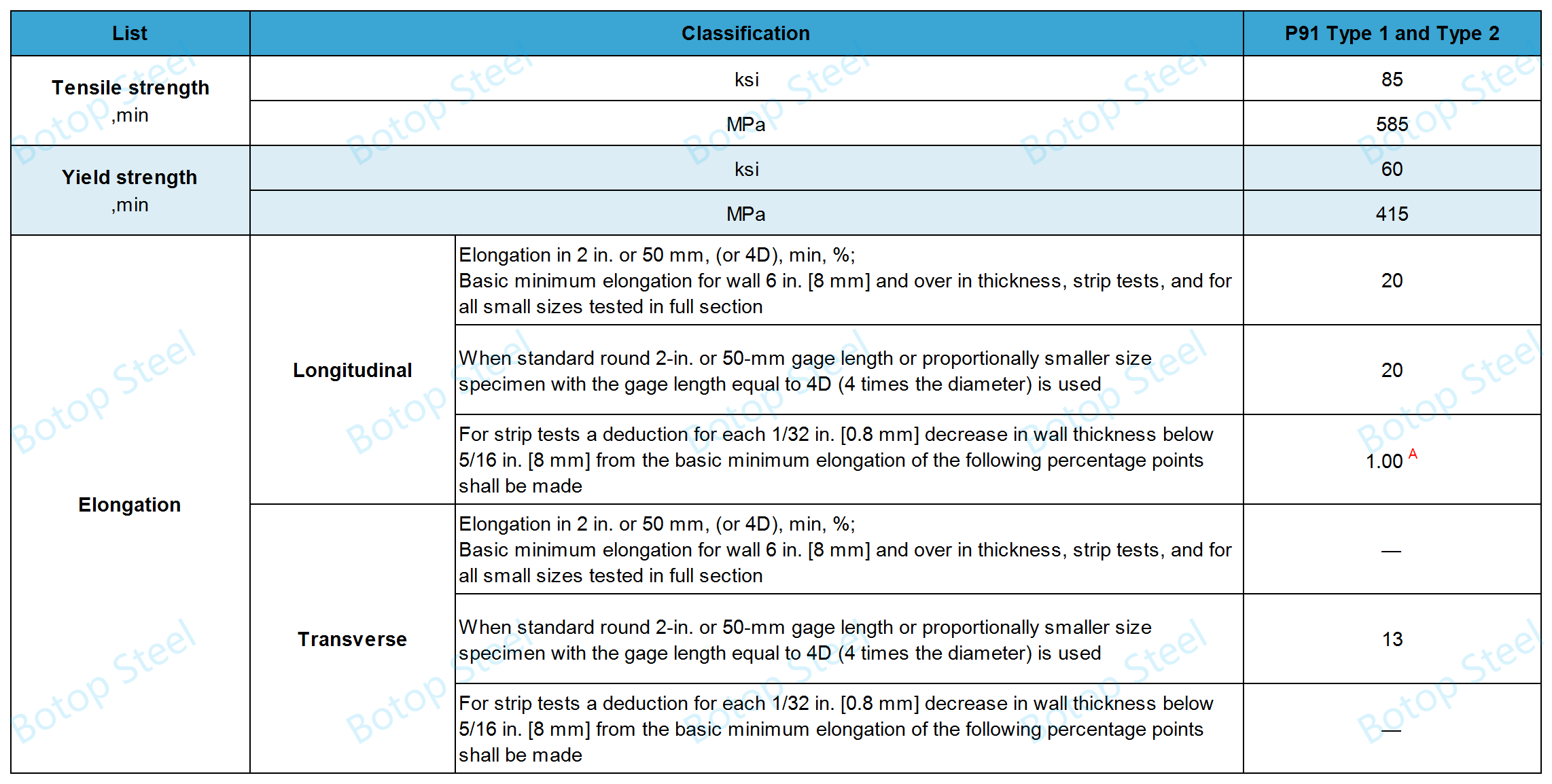

Nws muaj qhov tsawg kawg nkausTensile zog ntawm 585 MPa(85 ksi) thiab yam tsawg kawg nkausyield zog ntawm 415 MPa(60 hli).

P91Feem ntau muaj cov alloying ntsiab xws li chromium thiab molybdenum, thiab ntau yam ntawm lwm yam alloying ntsiab ntxiv, teej tug mus rau lubhigh-alloy hlau, yog li nws muaj zog super thiab zoo heev corrosion kuj.

Tsis tas li ntawd, P91 muaj nyob rau hauv ob hom,Hom 1thiabHom 2, thiab feem ntau yog siv nyob rau hauv cov chaw tsim hluav taws xob, refineries, tshuaj lom neeg cov cuab yeej tseem ceeb, thiab cov kav dej hauv qhov chaw kub thiab muaj zog.

P91 steel yeeb nkab tau muab faib ua ob hom, Hom 1 thiab Hom 2.

Ob hom yog tib yam ntawm cov khoom siv kho tshuab thiab lwm yam kev xav tau xws li kev kho cua sov,nrog me me sib txawv nyob rau hauv tshuaj muaj pes tsawg leeg thiab tshwj xeeb daim ntawv thov tsom.

Tshuaj muaj pes tsawg leeg: Muab piv rau Hom 1, cov tshuaj muaj pes tsawg leeg ntawm Hom 2 yog qhov nruj dua thiab muaj cov alloying ntau dua los muab cov cua sov zoo dua thiab tiv thaiv corrosion.

Daim ntawv thov: Vim yog cov tshuaj muaj txiaj ntsig zoo, Hom 2 yog qhov tsim nyog rau qhov kub thiab txias ntau dua los yog ntau dua corrosive ib puag ncig, lossis hauv cov ntawv thov uas yuav tsum muaj zog dua thiab kav ntev.

ASTM A335 steel yeeb nkab yuav tsum yogseamless.

Seamless manufacturing txheej txheem yog categorized rau hauvkub tiavthiabtxias rub.

Hauv qab no yog ib daim duab ntawm cov txheej txheem kub tiav.

Tshwj xeeb tshaj yog, P91, cov yeeb nkab steel hlau, uas feem ntau siv rau hauv qhov chaw hnyav uas muaj qhov kub thiab txias, cov yeeb nkab steel seamless yog nruj nruj thiab tuaj yeem ua rau tuab-walled, yog li ua kom muaj kev nyab xeeb dua thiab siv tau zoo dua.

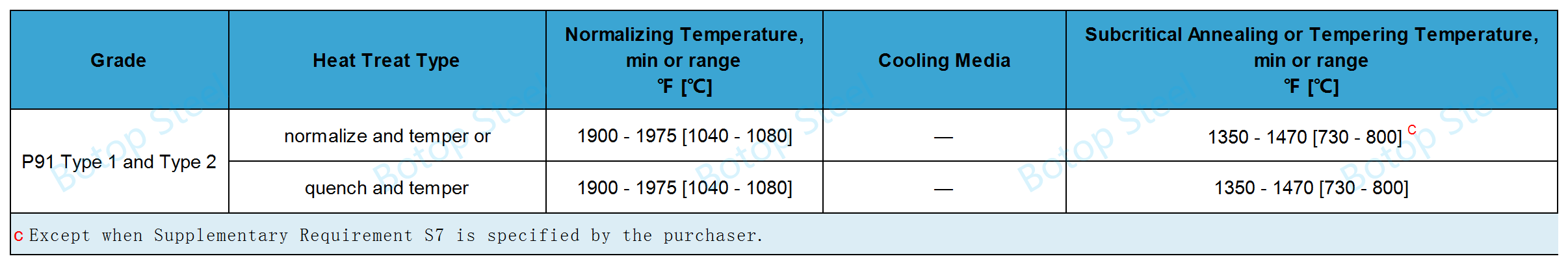

P91 Tag nrho cov kav dej yuav tsum tau kho cua sov kom zoo rau lub microstructure ntawm cov yeeb nkab, txhim kho nws cov khoom siv kho tshuab, thiab txhim khu kev tiv thaiv kub thiab siab.

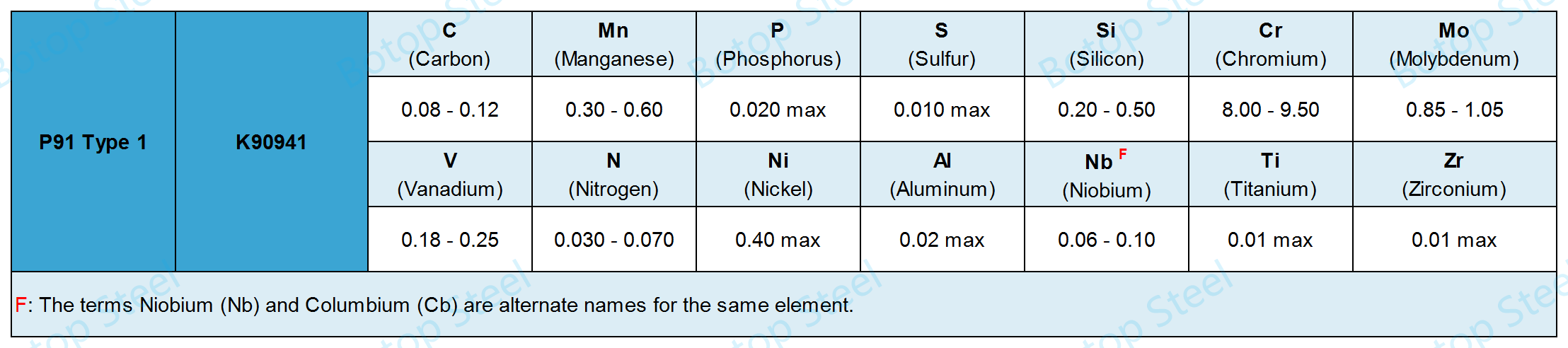

P91 Hom 1 Cov Khoom Siv Tshuaj

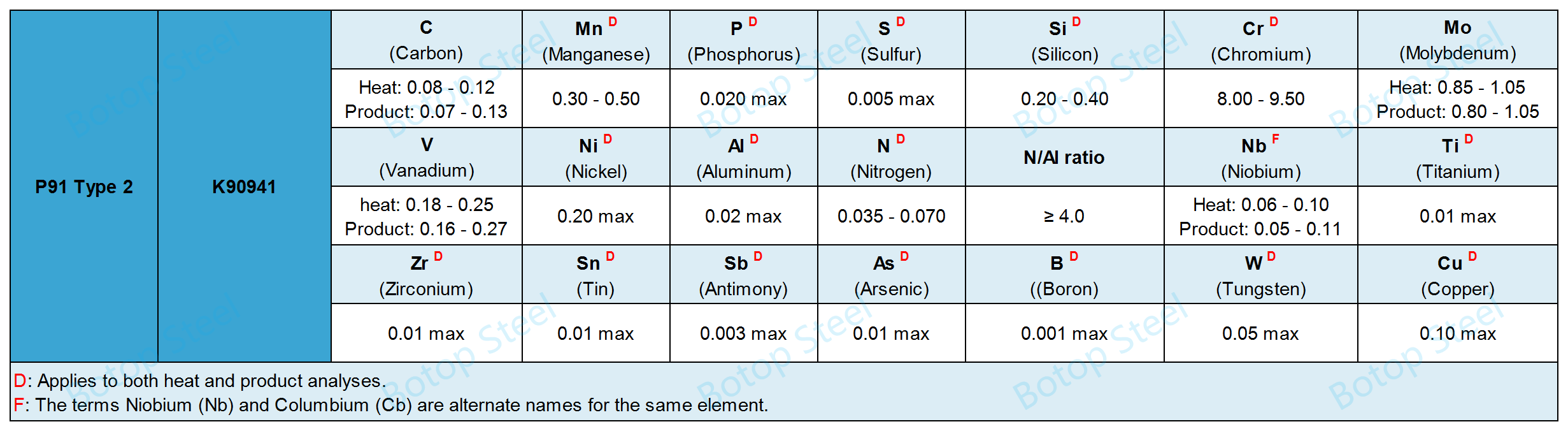

P91 Hom 2 Chemical Cheebtsam

Nrog rau ob daim duab saum toj no, nws yooj yim pom qhov txawv ntawm Hom 1 thiab Hom 2 tshuaj lom neeg thiab kev txwv.

1. Tensile Property

Kev ntsuas tensile feem ntau yog siv los ntsuas qhovyield zog, tensile zog, thiabelongationn ntawm cov yeeb nkab steel kev sim, thiab yog siv dav hauv cov khoom siv ntawm qhov kev sim.

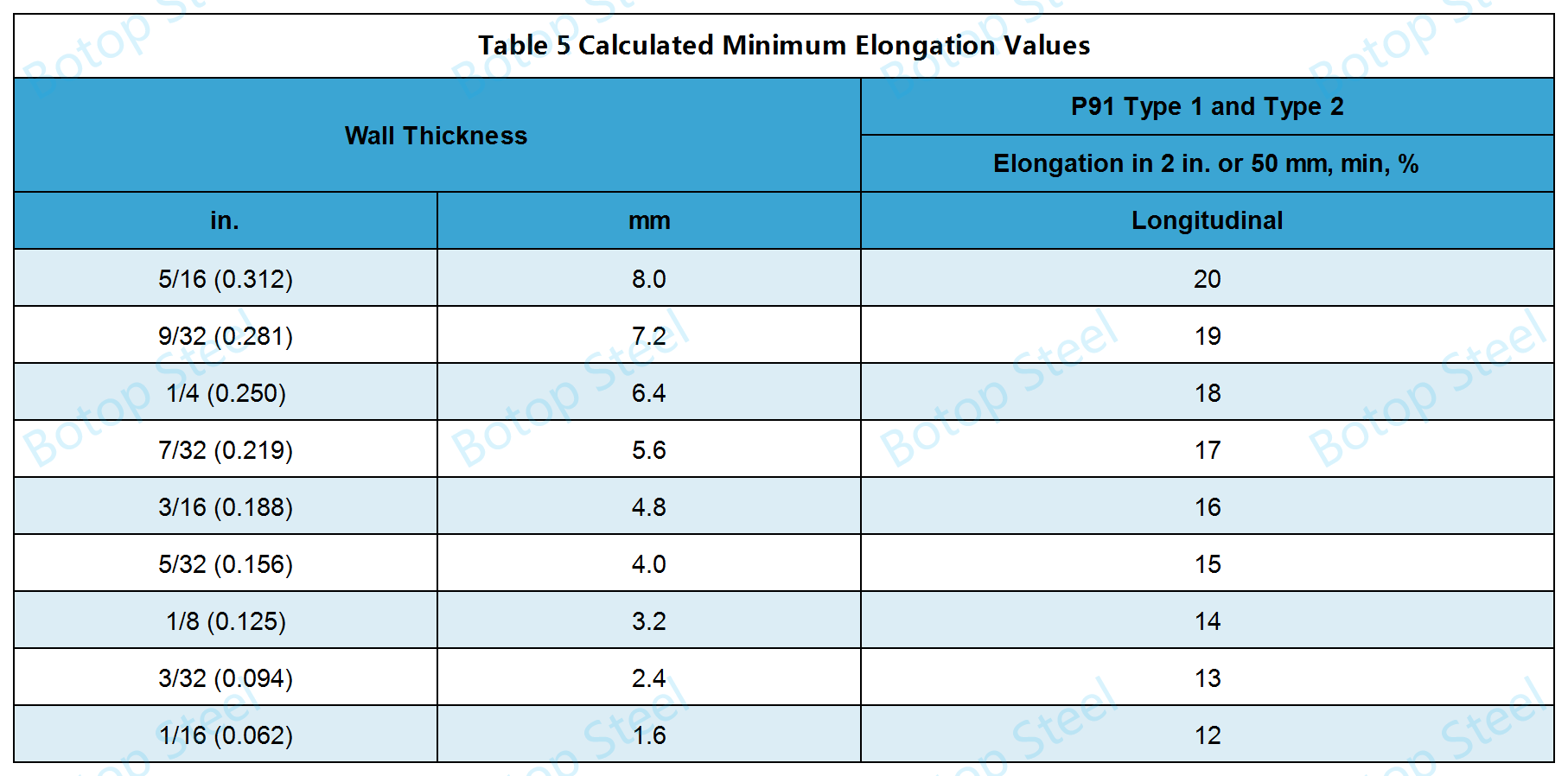

ATable 5 muab cov nqi tsawg kawg nkaus uas xam tau.

Qhov twg phab ntsa thickness nyob nruab nrab ntawm ob qhov tseem ceeb saum toj no, qhov tsawg kawg nkaus elongation tus nqi yog txiav txim los ntawm cov qauv hauv qab no:

Ntev, P91: E = 32t + 15.00 [E = 1.25t + 15.00]

qhov twg:

E = elongation hauv 2 nti lossis 50 mm, %,

t = tiag thickness ntawm specimens, in. [mm].

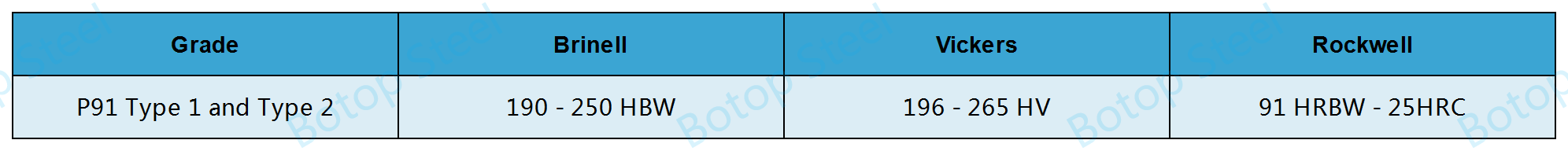

2. Hardness

Muaj ntau txoj kev ntsuas qhov nyuaj tuaj yeem siv tau, suav nrog Vickers, Brinell, thiab Rockwell.

Phab ntsa thickness <0.065 in. [1.7 mm]: Tsis tas yuav tsum tau kuaj hardness;

0.065 in. [1.7 mm] ≤ phab ntsa thickness <0.200 in. [5.1 mm]: Rockwell hardness test yuav tsum siv;

Phab ntsa thickness ≥ 0.200 nyob rau hauv. [5.1 mm]: yeem siv Brinell hardness test lossis Rockwell hardness test.

Vickers hardness test yog muaj feem xyuam rau tag nrho cov phab ntsa thicknesses ntawm tubing. Txoj kev xeem yog ua raws li cov cai ntawm E92.

3. Kev xeem Flattening

Kev sim yuav tsum tau ua raws li Tshooj 20 ntawm ASTM A999 tus qauv.

4. Khoov Test

Khoov 180 ° ntawm chav tsev kub, tsis muaj kab nrib pleb yuav tsum tshwm rau sab nraud ntawm qhov khoov.

Loj> NPS25 lossis D / t ≥ 7.0: Kev sim khoov yuav tsum tau ua yam tsis muaj kev sim ua kom tiaj tus.

5. P91 Cov Kev Pab Cuam Kev Xaiv Xaiv

Cov khoom sim hauv qab no tsis tas yuav tsum muaj cov khoom sim, yog tias tsim nyog tuaj yeem txiav txim siab los ntawm kev sib tham.

S1: Kev soj ntsuam cov khoom

S3: Flattening Test

S4: Hlau Structure thiab Etching Test

S5: Photomicrographs

S6: Photomicrographs rau ib leeg

S7: Lwm Txoj Kev Kho Kub Kub-Qib P91 Hom 1 thiab Hom 2

P91 hydro test yuav tsum ua raws li cov cai hauv qab no.

Sab nraud txoj kab uas hla ≥10in. [250mm] thiab phab ntsa thickness ≤ 0.75in. [19mm]: qhov no yuav tsum yog qhov ntsuas hydrostatic.

Lwm qhov ntau thiab tsawg rau kev kuaj hluav taws xob tsis zoo.

Rau ferritic alloy hlau thiab stainless hlau raj, phab ntsa raug rau lub siab tsis tsawg tshaj li60% ntawm qhov tsawg kawg nkaus yield zog.

Qhov ntsuas dej siab yuav tsum tau tswj kom tsawg 5stsis muaj dej los yog lwm yam tsis xws luag.

Hydraulic siabtuaj yeem suav nrog cov qauv:

P = 2st/D

P = hydrostatic test siab hauv psi [MPa];

S = yeeb nkab phab ntsa kev nyuaj siab nyob rau hauv psi los yog [MPa];

t = teev phab ntsa thickness, nominal phab ntsa thickness raws li tau teev tseg ANSI lub sij hawm tus naj npawb los yog 1.143 lub sij hawm qhov tsawg kawg nkaus phab ntsa thickness, nyob rau hauv. [mm];

D = teev sab nraud txoj kab uas hla, sab nraud txoj kab uas hla raws li teev ANSI yeeb nkab loj, los yog sab nraud txoj kab uas hla xam los ntawm kev ntxiv 2t (raws li tau hais los saum toj no) rau cov teev hauv txoj kab uas hla, in. [mm].

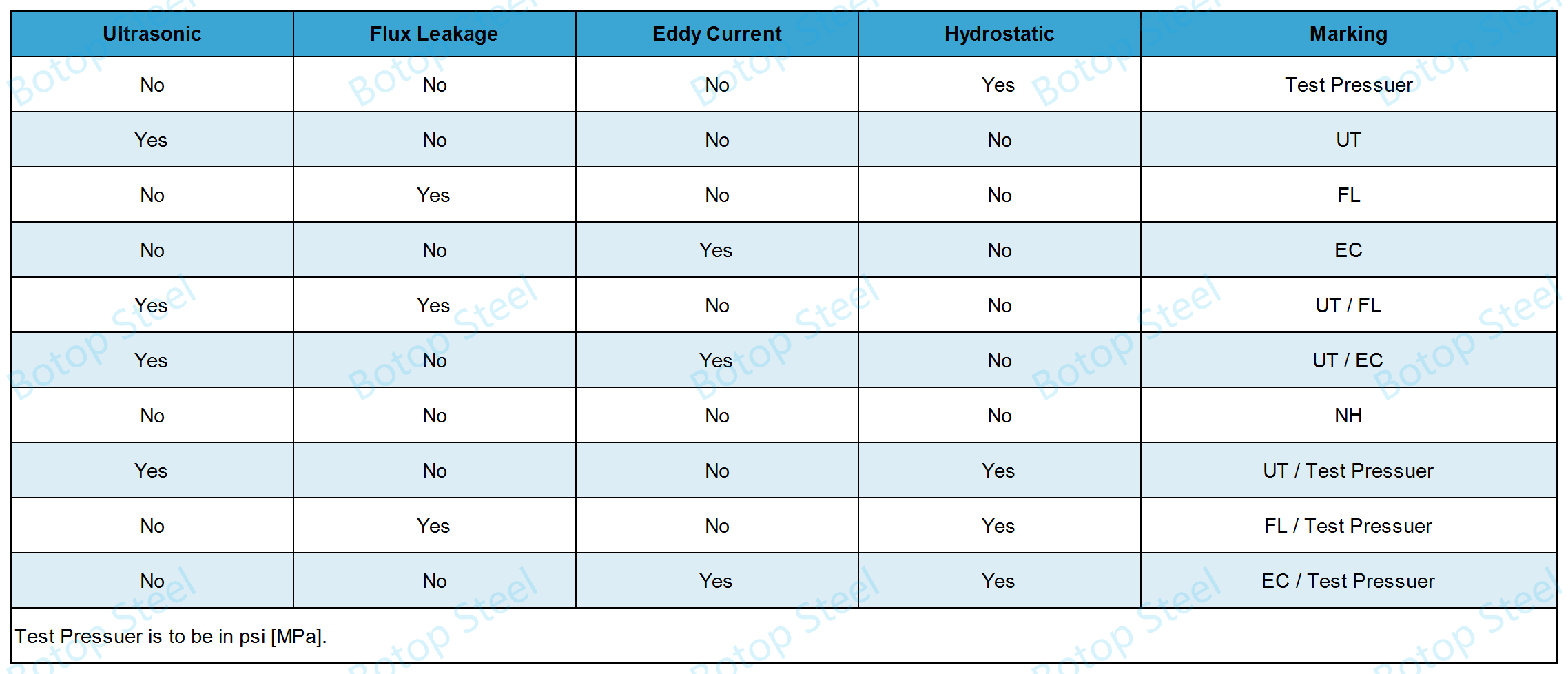

P91 yeeb nkab raug tshuaj xyuas los ntawm txoj kev xeem E213. Tus qauv E213 feem ntau cuam tshuam nrog kev kuaj ultrasonic (UT).

Yog hais tias tshwj xeeb hauv kev txiav txim, nws kuj tuaj yeem raug tshuaj xyuas raws li E309 lossis E570 txoj kev xeem.

Tus qauv E309 feem ntau cuam tshuam nrog kev tshuaj xyuas electromagnetic (eddy tam sim no), thaum E570 yog ib qho kev tshuaj xyuas uas muaj cov eddy tam sim no arrays.

Permissible Variations in Diameter

Rau cov yeeb nkab xaj komhauv txoj kab uas hla, sab hauv txoj kab uas hla yuav tsum tsis txhob sib txawv ntau tshaj ± 1% ntawm qhov teev nyob rau hauv txoj kab uas hla.

Permissible Variations nyob rau hauv Phab ntsa Thickness

Phab ntsa thickness ntsuas yuav tsum tau ua los ntawm mechanical calipers los yog calibrated nondestructive xeem cov khoom uas tsim nyog. Thaum muaj kev tsis sib haum xeeb, qhov ntsuas tau txiav txim siab siv cov tshuab calipers yuav tsum yeej.

Qhov tsawg kawg nkaus phab ntsa thickness thiab sab nraud txoj kab uas hla rau kev soj ntsuam kom ua raws li qhov yuav tsum tau rau cov yeeb nkab uas tau txiav txim los ntawm NPS [DN] thiab lub sij hawm tus naj npawb yog qhia nyob rau hauvASME B36.10M.

Tsis zoo

Deg imperfections raug suav hais tias tsis xws luag yog tias lawv tshaj 12.5% ntawm nominal phab ntsa thickness los yog tshaj qhov tsawg kawg nkaus phab ntsa thickness.

Kev tsis zoo

Mechanical marks, abrasions, and pits, any of which imperfections are deeper than 1/16 in. [1.6 mm].

Cov cim thiab abrasions txhais tau tias yog cov cim cable, dinges, cov cim qhia, yob cov cim, pob khawb, cov qhab nia, cov cim tuag, thiab lwm yam.

Kho

Qhov tsis xws luag yuav raug tshem tawm los ntawm kev sib tsoo, yog tias qhov seem ntawm phab ntsa thickness tsis tsawg tshaj li qhov tsawg kawg nkaus phab ntsa thickness.

Kev kho kuj tuaj yeem ua los ntawm kev vuam tab sis yuav tsum ua raws li cov kev cai ntawm A999.

Txhua qhov kev kho welds hauv P91 yuav tsum ua nrog ib qho ntawm cov txheej txheem vuam thiab cov khoom siv hauv qab no: SMAW, A5.5/A5.5M E90XX-B9:SAW, A5.23/A5.23M EB9 + nruab nrab flux; GTAW, A5.28/A5.28M ER90S-B9; and FCAW A5.29/A5.29M E91TI-B9. Tsis tas li ntawd, cov txiaj ntsig ntawm Ni + Mn cov ntsiab lus ntawm tag nrho cov khoom siv vuam siv los kho vuam P91 Hom 1 thiab Hom 2 yuav tsum tsis pub tshaj 1.0%.

P91 yeeb nkab yuav tsum tau kho cua sov ntawm 1350-1470 ° F [730-800 ° C] tom qab kho vuam.

Sab nraud ntawm cov yeeb nkab uas tau kuaj xyuas steel yuav tsum muaj cov hauv qab no:

Tus neeg tsim khoom lub npe lossis lub cim lag luam; tus lej txheem; qib; ntev thiab ntxiv cim "S".

Cov cim rau hydrostatic siab thiab kev sim tsis muaj kev puas tsuaj hauv cov lus hauv qab no yuav tsum suav nrog.

Yog tias cov yeeb nkab raug kho los ntawm kev vuam, nws yuav tsum raug cim "WR".

p91 Hom (Hom 1 lossis Hom 2) yuav tsum tau qhia.

EN 10216-2: X10CrMoVNb9-1 lossis 1.4903;

JIS G 3462: STPA 28;

GB/T 5310: 10Cr9Mo1VNb;

Cov sib npaug no zoo heev nyob rau hauv tshuaj muaj pes tsawg leeg thiab txhua yam khoom rau ASTM A335 P91.

Khoom sivl: ASTM A335 P91 seamless steel yeeb nkab;

ODLoj: 1/8 "- 24";

WT: raws liASME B36.10cov cai;

Teem caijSCH10, SCH20, SCH30, NPESCH40, SCH60,SCH80, SCH100, SCH120, SCH140 thiab SCH160;

Kev txheeb xyuas:STD (tus qauv), XS (muaj zog ntxiv), lossis XXS (ob npaug ntxiv-muaj zog);

Kev kho kom haum: Qhov ntau thiab tsawg ntawm cov yeeb nkab uas tsis yog tus qauv kuj muaj, qhov ntau thiab tsawg yog muaj raws li qhov kev thov;

Ntev: Tshwj xeeb thiab random ntev;

Daim ntawv pov thawj IBR: Peb tuaj yeem tiv tauj lub koom haum soj ntsuam thib peb kom tau txais daim ntawv pov thawj IBR raws li koj xav tau, peb cov koom haum soj ntsuam kev koom tes yog BV, SGS, TUV, thiab lwm yam;

Xaus: Flat kawg, beveled, los yog composite yeeb nkab kawg;

Nto: Lub teeb yeeb nkab, pleev xim, thiab lwm yam kev tiv thaiv ib ntus, tshem tawm xeb thiab polishing, galvanized thiab yas coated, thiab lwm yam kev tiv thaiv mus ntev;

Ntim: Ntoo rooj plaub, steel siv los yog steel hlau packing, yas los yog hlau yeeb nkab kawg tiv thaiv, thiab lwm yam.