ASTM A501 Qib Byog ib qho kub-tsim welded thiab seamless carbon steel yeeb nkab nrog lub zog tensile yam tsawg kawg nkaus ntawm 448 MPa (65,000 psi) rau ntau yam kev siv cov qauv.

ASTM A501 Cov Lus Qhia Tshwj Xeebyog rau fabrication thiab kev ua tau zoo ntawm kub-tsim welded thiab seamless carbon steel tubing rau structural daim ntaub ntawv.

Cov raj hlau no tuaj yeem yog xim dub (tsis muaj xim) lossis kub-dipped galvanized, tom kawg uas tau nce corrosion kuj los ntawm cov txheej txheem galvanizing, ua rau nws haum rau ntau yam ntawm ib puag ncig.

Cov yeeb nkab steel no tau siv dav hauv cov txuas hniav, cov tsev, thiab ntau lwm yam kev siv cov txheej txheem.

ASTM A501 faib cov yeeb nkab steel rau hauv peb qib,qib A, qib B, thiab qib C.

Qib B yog qhov siv dav tshaj plaws ntawm peb qib vim tias nws muab cov khoom sib npaug zoo rau kev siv ntau yam qauv.

Cov hlau yuav tsum tau ua los ntawmyooj yim-oxygen lossis hluav taws xob-arc-kuav steel-ua txheej txheem.

Cov hlau yuav raug cam khwb cia rau hauv ingots los yog strand cast.

Thaum cov hlau sib txawv ntawm cov qib sib txawv tau raug muab tso tseg, cov neeg tsim khoom steel yuav tsum txheeb xyuas cov khoom hloov pauv tau thiab tshem tawm nws siv cov txheej txheem tsim uas cais cov qib zoo.

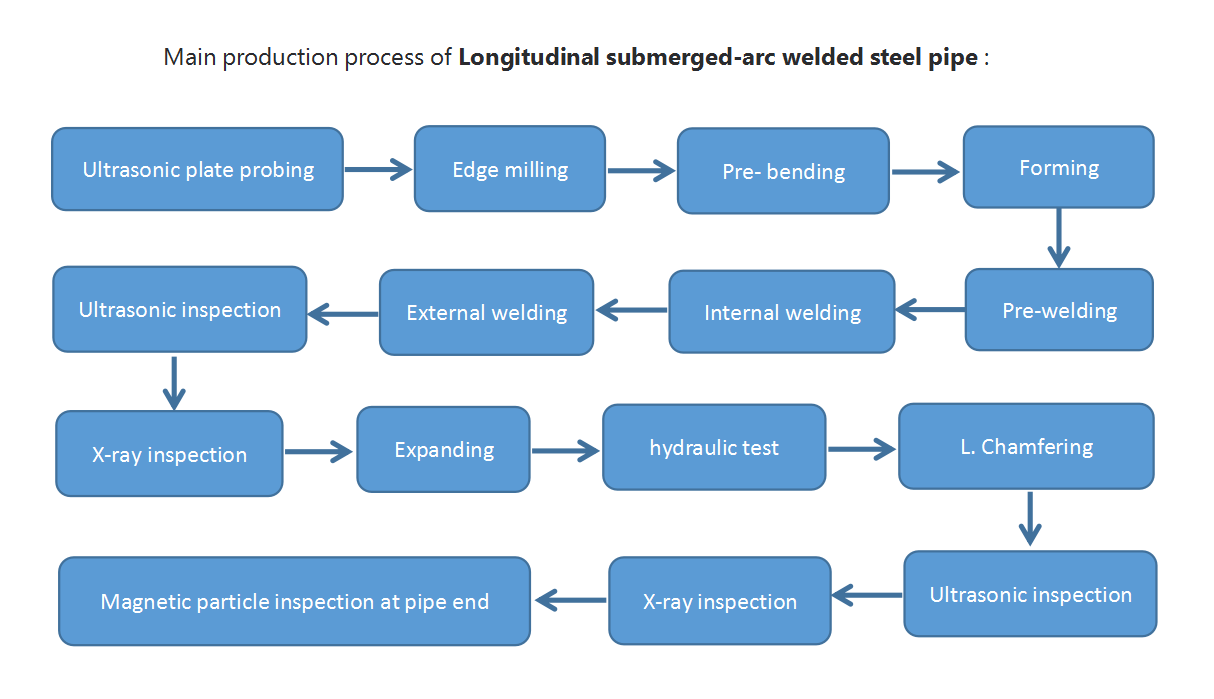

Tubing yuav tsum tau ua los ntawm ib qho ntawm cov txheej txheem hauv qab no:seamless; furnace-butt-welding (nruam vuam); Hluav taws xob tsis kam vuam (ERW) lossis submerged arc vuam (SAW)ua raws li kev rov ua kom sov thoob plaws hauv ntu ntu thiab kub sib sau los ntawm kev txo lossis shaping txheej txheem, lossis ob qho tib si.

SAW vuam txheej txheem yog subdivided rau hauvLSAW(SAWL) thiab SSAW (HSAW).

Kev tsim cov duab kawg yuav tsum tau ua los ntawm cov txheej txheem kub txheej txheem.

Nws yuav tsum tau tso cai ntxiv ib qho kev kho cua sov rau cov tubing nrog phab ntsa thickness ntau dua 13 hli [1/2 hauv].

| ASTM A501 Qib B Cov Tshuaj Txhuam Hniav,% | |||

| Kev sib xyaw | Qib B | ||

| Kev Ntsuas Kub | Kev tshuaj xyuas khoom | ||

| C (Carbon)B | max | 0.22 | 0.26 |

| Manganese (Mn)B | max | 1.40 Nws | 1.45 Nws |

| P (phosphorus) | max | 0.030 Nws | 0.040 ib |

| S (Sulfur) | max | 0.020 ib | 0.030 Nws |

| Kub (Copper)B (thaum tooj liab tau teev tseg) | min | 0.20 ib | 0.18 |

| BRau txhua qhov txo qis ntawm 0.01 feem pua ntawm cov ntsiab lus qis dua qhov siab tshaj plaws rau cov pa roj carbon monoxide, qhov nce ntawm 0.06 feem pua ntawm cov ntsiab lus siab tshaj qhov teev siab tshaj plaws rau manganese tau tso cai, nce mus txog qhov siab tshaj plaws ntawm 1.60% los ntawm kev ntsuas cua sov thiab 1.65% los ntawm kev tshuaj xyuas khoom | |||

Kev txheeb xyuas cov khoom yuav tsum tau ua los ntawm kev kuaj cov qauv coj los ntawm ob qhov ntev ntawm cov tubing los ntawm txhua qhov ntau ntawm 500 qhov ntev, lossis ib feem ntawm qhov ntawd, lossis ob daim ntawm cov khoom siv tiaj tus dov los ntawm txhua qhov sib npaug ntawm cov khoom sib xws.

Tensile specimens yuav tsum ua raws li qhov yuav tsum tau muaj ntawm Test Methods and Definitions A370, Appendix A2.

| ASTM A501 Qib B Tensile Requirements | |||

| Sau npe | Phab ntsa Thickness mm [hauv] | Qib B | |

| Tensile zog, min, psi [MPa] | Tag nrho | 65000 [448] | |

| Yield zog, min, psi [MPa] | ≤ 25 [1] | 46,000 [315] | |

| > 25 [1] thiab ≤ 50 [2] | 45,000 [310] | ||

| > 50 [2] thiab ≤ 76 [3] | 42,500 [290] | ||

| 76 [3] thiab ≤ 100 [4] | 40,000 [280] | ||

| Elongation, min, % | — | 24 | |

| Impact Zog | min,nruab nrab, ft/Ibf [J] | — | 20 [27] |

| min,ib leeg, ft/Ibf [J] | — | 14 [19] | |

Cov qauv ntsuas kev sib tw yuav tsum yog cov qauv ntsuas qhov ntev ntev los yog cov qauv kuaj kab ntev.

Rau welded tubing, ib qho kev kuaj kab ntev ntev yuav tsum tau muab coj los ntawm qhov chaw tsawg kawg 90 ° los ntawm qhov vuam thiab yuav tsum tau npaj yam tsis muaj flattening hauv qhov ntsuas qhov ntev.

Longitudinal strip xeemCov qauv yuav tsum tau tshem tawm tag nrho cov burrs.

Kev ntsuas kev sib tw yuav tsum tsis muaj qhov tsis zoo ntawm qhov chaw uas yuav cuam tshuam nrog kev txiav txim siab ntawm cov khoom tensile.

Phab ntsa thicknesses ≤ 6.3mm [0.25in] tsis tas yuav muaj kev cuam tshuam.

| ASTM A501 Dimensional kam rau ua | ||

| Sau npe | thaj tsam | Nco tseg |

| Sab nraud Diameter (OD) | ≤48mm (1.9 nyob rau hauv) | ± 0.5 hli [1/48 nyob rau hauv] |

| ≥50mm (2 nti) | ± 1% | |

| Phab ntsa Thickness (T) | Specified phab ntsa thickness | ≥90% |

| Qhov hnyav | teev hnyav | 96.5% -110% |

| Ntev (L) | ≤7m (22 ft) | 6mm (1/4in) - 13mm (1/2in) |

| 7-14m (22-44 ft) ntev | 6mm (1/4 ") - 19mm (3/4") | |

| Kev ncaj | Ntev yog nyob rau hauv imperial units (ft) | L / 40 |

| Length units yog metric (m) | L / 50 | |

Cov txheej txheem tubing yuav tsum tsis muaj qhov tsis xws luag thiab yuav tsum muaj qhov ua tiav zoo los ntawm cov txheej txheem kub dov.

Thaum qhov tob ntawm qhov tsis xws luag nyob rau saum npoo ntawm cov yeeb nkab ntau tshaj 10% ntawm nominal phab ntsa thickness, cov defects yuav tsum raug xam tias yog tsis ua raws. Kev kho los ntawm vuam yuav tsum tso cai tsuas yog thaum pom zoo ntawm tus neeg yuav khoom thiab cov chaw tsim khoom. Ua ntej yuav kho los ntawm vuam, qhov tsis xws luag yuav tsum tau muab tshem tawm tag nrho los ntawm kev txiav los yog kev sib tsoo.

Rau cov txheej txheem yeeb nkab kom kub-dip galvanized, txheej txheej no yuav tsum ua raws li cov kev xav tau ntawm SpecificationASTM A53.

Txhua qhov ntev ntawm cov qauv tubing yuav tsum raug cim los ntawm txoj kev tsim nyog, xws li dov, stamping, stamping, lossis pleev xim.

Cov cim ASTM A501 yuav tsum muaj cov ntaub ntawv hauv qab no raws li qhov tsawg kawg nkaus:

Tus neeg tsim khoom lub npe

Hom lossis cov cim lag luam

Loj

Lub npe ntawm tus qauv (tsis tas yuav tsum luam tawm xyoo)

Qib

Rau cov qauv raj <50 hli [2 nyob rau hauv] OD, nws tso cai rau kos cov ntaub ntawv hlau ntawm ib daim ntawv uas txuas rau txhua pob.

ASTM A501 Qib B steel sib xyaw ua ke lub zog thiab ductility nrog cov txheej txheem kub-txheej txheem ntau lawm, ua rau nws haum rau ntau yam kev siv cov qauv.

Lub tsev thiab kev tsim kho: Feem ntau yog siv rau hauv kev tsim vaj tsev thiab kev tsim kho cov ntaub ntawv uas yuav tsum tau muaj zog thiab durability ntawm cov ntaub ntawv robust. Qhov no suav nrog cov tsev, chaw ua kis las, txuas hniav, thiab lwm yam qauv.

Cov Khoom Siv Muaj: Vim nws lub zog siab, nws yog qhov tsim nyog rau kev siv hauv cov chaw muaj xws li cov chaw tsim khoom thiab cov tsev khaws khoom uas cov qauv kev ntseeg siab yog qhov tseem ceeb.

Kev thauj mus los infrastructure: Qib no yog siv rau hauv kev tsim cov tsheb thauj mus los, suav nrog cov chaw tsheb ciav hlau, tshav dav hlau, thiab kev hla kev loj.

Cov Qauv Txheej Txheem: Nws kuj yog feem ntau siv rau hauv kev tsim khoom ntawm cov khoom siv xws li kab, kab teeb, thiab trusses, uas tsim cov txheej txheem ntawm ntau yam qauv.

Kev tsim khoom siv: Hauv kev tsim cov khoom siv hnyav thiab cov tshuab, nws tuaj yeem siv rau qhov chaw uas yuav tsum muaj cov khoom siv muaj zog.

Cov chaw tsim khoom yuav tsum muab cov neeg yuav khoom nrog daim ntawv pov thawj ntawm kev ua raws li cov khoom lag luam raug kuaj, kuaj, thiab tshuaj xyuas raws li qhov kev qhia tshwj xeeb no thiab lwm yam yuav tsum tau teev tseg hauv daim ntawv xaj lossis daim ntawv cog lus thiab tag nrho cov kev xav tau no tau ua tiav. Daim ntawv pov thawj ntawm kev ua raws cai yuav tsum suav nrog tus lej tshwj xeeb thiab lub xyoo ntawm kev tshaj tawm.

Botop Steel yog qhov zoo tshaj plaws Welded Carbon Steel Pipe chaw tsim tshuaj paus thiab cov muag khoom los ntawm Tuam Tshoj, kuj yog seamless steel yeeb nkab stockist.

Botop Steel muaj kev cog lus ruaj khov rau kev ua tau zoo thiab siv cov kev tswj xyuas nruj thiab kev sim raukom ntseeg tau cov khoom. Nws pab neeg muaj kev paub dhau los muab cov kev daws teeb meem ntawm tus kheej thiab cov kws tshaj lij kev txhawb nqa, nrog rau kev tsom mus rau cov neeg siv khoom txaus siab. Peb tos ntsoov yuav ua haujlwm nrog koj.