ASTM A513 steel hlauyog cov pa roj carbon thiab alloy steel yeeb nkab thiab raj ua los ntawm kub dov los yog txias dov hlau ua raw khoom los ntawm kev ua haujlwm vuam (ERW), uas yog siv dav hauv txhua yam ntawm cov khoom siv tshuab.

Hom 5nyob rau hauv tus qauv ASTM A513 yog hais txog covDrawn Over Mandrel (DOM)cev.

DOM tubing yog tsim los ntawm thawj zaug ua ib lub raj welded thiab tom qab ntawd txias kos nws los ntawm kev tuag thiab dhau mandrels kom tiav rau qhov kev ua siab ntev dua thiab ua kom zoo dua qhov tiav piv rau lwm hom welded tubing.

Tus Qauv Ua Haujlwm: ASTM A513

Khoom siv: Kub-dov los yog Cold-rolled Steel

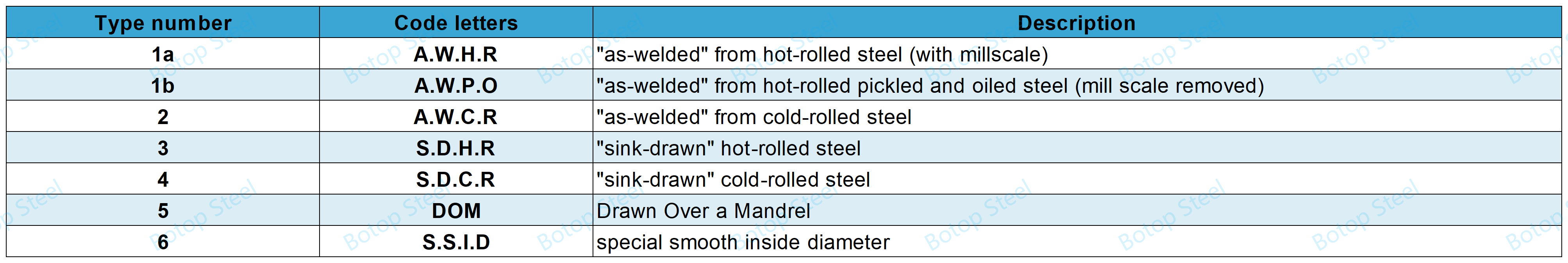

Hom:Hom 1 (1a lossis 1b)Hom 2, Hom 3, Hom 4, Hom 5, Hom 6.

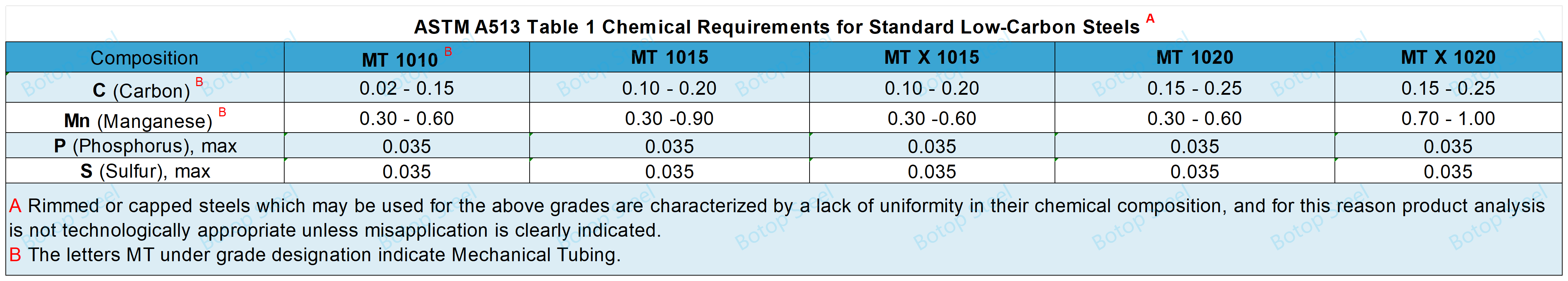

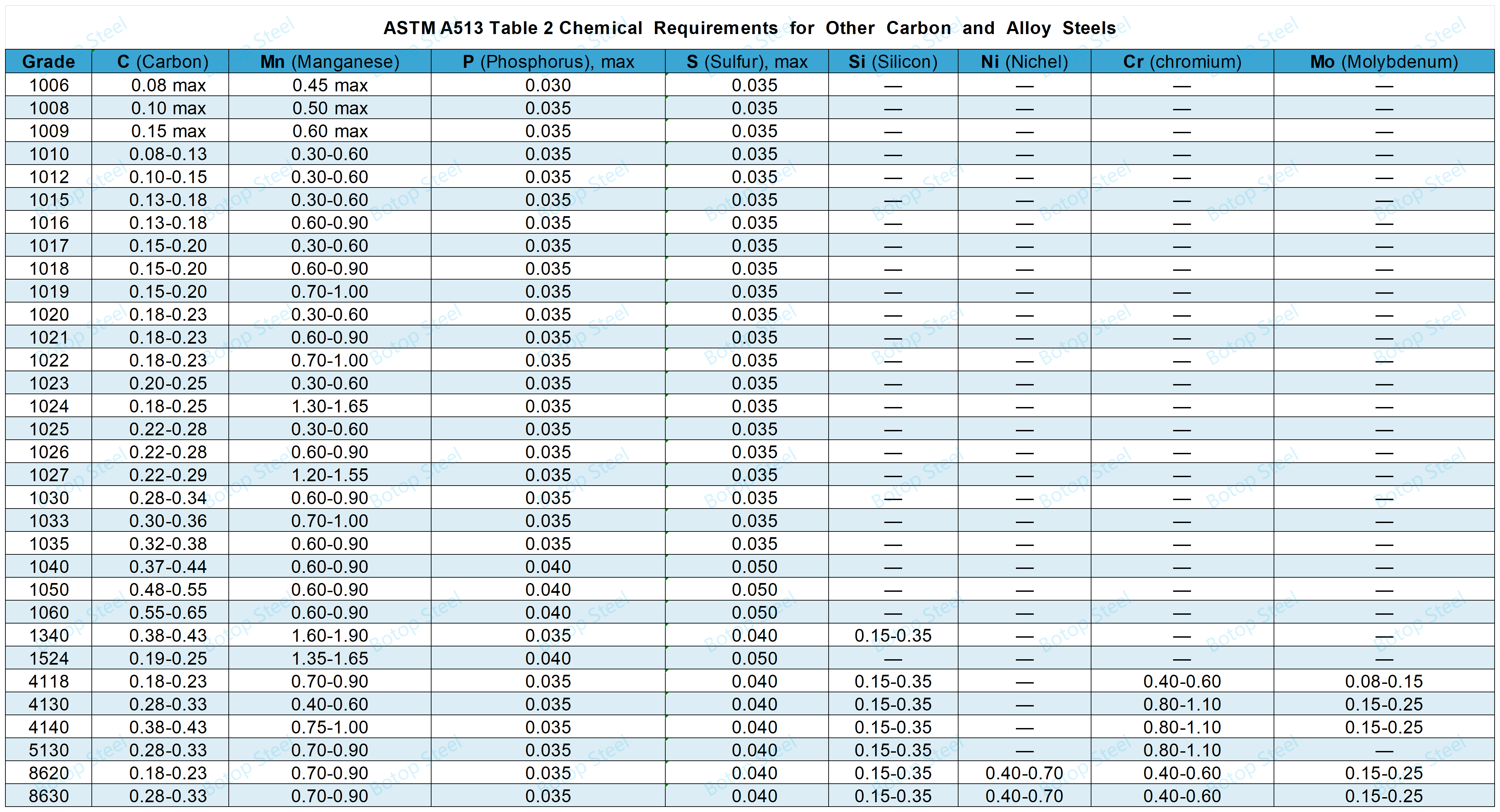

Qib: MT 1010, MT 1015, 1006, 1008, 1009 thiab lwm yam.

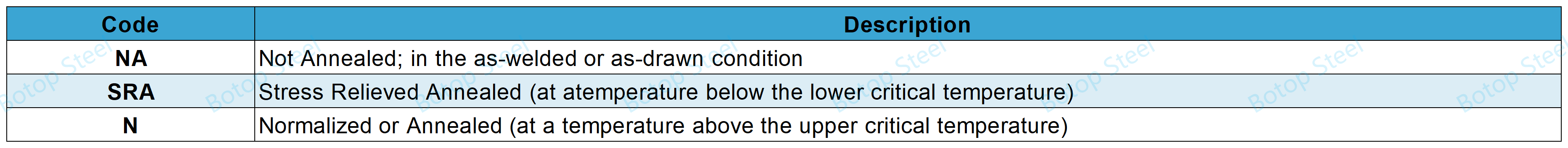

Kev kho cua sov: NA, SRA, N.

Loj thiab phab ntsa thickness

Hollow seem duab: Hloov, square, lossis lwm yam duab

Ntev

Total Quantity

ASTM A513 Hom yog qhov sib txawv raws li cov xwm txheej sib txawv lossis cov txheej txheem ntawm cov yeeb nkab steel.

ASTM A513 round tubing hom 5 qib qib yog:

1008, 1009, 1010, 1015, 1020, 1021, 1025, 1026, 1030, 1035, 1040, 1340, 1524, 4130, 4140.

Hloov

Square los yog duab plaub

Lwm cov duab

xws li streamlined, hexagonal, octagonal, puag ncig sab hauv thiab hexagonal lossis octagonal sab nraud, ribbed sab hauv lossis tawm, daim duab peb sab, puag ncig, thiab D duab.

Kub dov los yog Cold-rolled Steel

Cov khoom siv raw rau kev tsim cov Kub-kuav los yog Cold-rolled Steel tuaj yeem tsim los ntawm txhua tus txheej txheem.

Kub Rolled Steel: Nyob rau hauv cov txheej txheem ntau lawm, kub-dov hlau yog thawj rhuab nyob rau hauv high kub, cia cov hlau yuav dov nyob rau hauv ib tug yas lub xeev, uas ua rau nws yooj yim los hloov cov duab thiab loj ntawm cov hlau. Thaum kawg ntawm cov txheej txheem kub dov, cov khoom feem ntau yog scaled thiab deformed.

Cold-Rolled Steel: Cold-dov hlau yog dov ntxiv tom qab cov khoom tau txias kom ua tiav qhov xav tau loj thiab cov duab. Cov txheej txheem no feem ntau yog ua nyob rau hauv chav tsev kub thiab ua rau cov hlau nrog zoo nto zoo thiab ntau qhov ntev.

Tubes yuav tsum tau ua los ntawm covHluav taws xob tsis kam-welded (ERW)txheej txheem.

ERW yeeb nkab yog txheej txheem ntawm kev tsim cov vuam los ntawm coiling cov khoom siv hlau rau hauv lub tog raj kheej thiab siv cov kev tiv thaiv thiab siab raws nws qhov ntev.

Cov hlau yuav tsum ua raws li cov txheej txheem tshuaj lom neeg uas tau teev tseg hauv Table 1 lossis Table 2.

| Qib | Yied zog ksi [MPa], min | Qhov kawg lub zog ksi [MPa], min | Elongation hauv 2 nti (50 mm), min, | RB min | RB max |

| DOM Tubing | |||||

| 1008 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1009 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1010 | 50 [345] | 60 [415] | 5 | 73 | — |

| 1015 | 55 [380] | 65 [450] | 5 | 77 | — |

| 1020 | 60 [415] | 70 [480] | 5 | 80 | — |

| 1021 ib | 62 [425] ib. | 72 [495] ib. | 5 | 80 | — |

| 1025 | 65 [450] | 75 [515] | 5 | 82 | — |

| 1026 | 70 [480] | 80 [550] | 5 | 85 | — |

| 1030 | 75 [515] | 85 [585] | 5 | 87 | — |

| 1035 ib | 80 [550] | 90 [620] | 5 | 90 | — |

| 1040 | 80 [550] | 90 [620] | 5 | 90 | — |

| 1340 ib | 85 [585] | 95 [655] | 5 | 90 | — |

| 1524 ib | 80 [550] | 90 [620] | 5 | 90 | — |

| 4 130 | 85 [585] | 95 [655] | 5 | 90 | — |

| 4 140 | 100 [690] | 110 [760] | 5 | 90 | — |

| DOM Stress-Relieved Tubing | |||||

| 1008 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1009 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1010 | 45 [310] | 55 [380] | 12 | 68 | — |

| 1015 | 50 [345] | 60 [415] | 12 | 72 | — |

Lus Cim 1: Cov txiaj ntsig no yog ua raws li qhov qub zeb kev ntxhov siab-relieving kub. Rau cov ntawv thov tshwj xeeb, cov khoom yuav raug kho los ntawm kev sib tham ntawm tus neeg yuav khoom thiab cov neeg tsim khoom.

Lus Cim 2: Rau kev ntsuam xyuas txoj hlua ntev, qhov dav ntawm qhov ntsuas yuav tsum yog raws li A370 Annex A2, Cov Khoom Siv Hlau Tubular, thiab txiav tawm ntawm 0.5 feem pua cov ntsiab lus los ntawm qhov yooj yim elongation yam tsawg kawg nkaus rau txhua qhov.1/32hauv [0.8 mm] txo cov phab ntsa thickness hauv qab5/16nyob rau hauv [7.9 mm] nyob rau hauv phab ntsa thickness yuav tsum tau tso cai.

1% ntawm tag nrho cov raj hauv txhua qhov ntau thiab tsis pub tsawg dua 5 lub raj.

Cov hlab ntsha thiab cov hlab ntsha uas tsim lwm cov duab thaum lawv puag ncig yog siv tau.

Tag nrho cov tubing yuav tau txais kev kuaj hydrostatic.

Khaws qhov tsawg kawg nkaus ntsuas ntsuas dej tsis pub tsawg tshaj 5s.

Lub siab yog xam raws li:

P = 2st/D

P= yam tsawg kawg nkaus hydrostatic xeem siab, psi lossis MPa,

S= tso cai fiber ntau kev nyuaj siab ntawm 14,000 psi los yog 96.5 MPa,

t= teev phab ntsa thickness, in. or mm,

D= teev sab nraud txoj kab uas hla, in. los yog mm.

Nws yog lub hom phiaj ntawm qhov kev sim no kom tsis lees txais cov hlab ntsha uas muaj kev raug mob.

Txhua lub raj yuav tsum raug kuaj nrog qhov ntsuas hluav taws xob tsis zoo raws li Kev Xyaum E213, Xyaum E273, Xyaum E309, lossis Xyaum E570.

Sab nraud

Table 5Txoj kab uas hla rau Hom 3, 4, 5, thiab 6 (SDHR, SDCR, DOM, thiab SSID) Round

Phab ntsa Thickness

Table 8Phab ntsa Thickness Tolerances ntawm Hom 5 thiab 6 (DOM thiab SSID) Round Tubing (Inch Units)

TAB 9Phab ntsa Thickness Tolerances ntawm Hom 5 thiab 6 (DOM thiab SSID) Round Tubing (SI Units)

Ntev

Table 13Txiav-Length Tolerances rau Lathe-Cut Round Tubing

Table 14Ntev Tolerances rau Punch-, Saw-, lossis Disc-Cut Round Tubing

Squareness

Table 16Tolerances, Sab Nraud Dimensions Square thiab Rectangular Tubing

Kos cov ntaub ntawv hauv qab no kom tsim nyog rau txhua tus pas lossis pob.

cov chaw tsim khoom lub npe lossis hom, qhov loj me, hom, tus neeg yuav khoom tus lej xaj, thiab tus lej tshwj xeeb no.

Barcoding yog qhov siv tau raws li kev txheeb xyuas ntxiv.

Tubing yuav tsum tau coated nrog ib zaj duab xis ntawm roj ua ntej xa mus rau retard xeb.

Yog qhov kev txiav txim qhia tias tubing yuav raug xa tsis tauxeb retarding roj, zaj duab xis ntawm cov roj teeb meem rau kev tsim khoom yuav nyob twj ywm rau saum npoo.

Nws tuaj yeem tiv thaiv qhov chaw ntawm cov yeeb nkab los ntawm kev ua haujlwm nrog cov dej noo thiab oxygen hauv huab cua, yog li tsis txhob xeb thiab xeb.

Tseeb tiag, thaum lub roj nplua nyeem yooj yim lossis cov yeeb yaj kiab roj yooj yim tuaj yeem muab qee qhov kev tiv thaiv ib ntus, rau cov ntawv thov kom muaj kev tiv thaiv ntau dua, kev kho corrosion tsim nyog yuav tsum tau xaiv los ntawm rooj plaub.

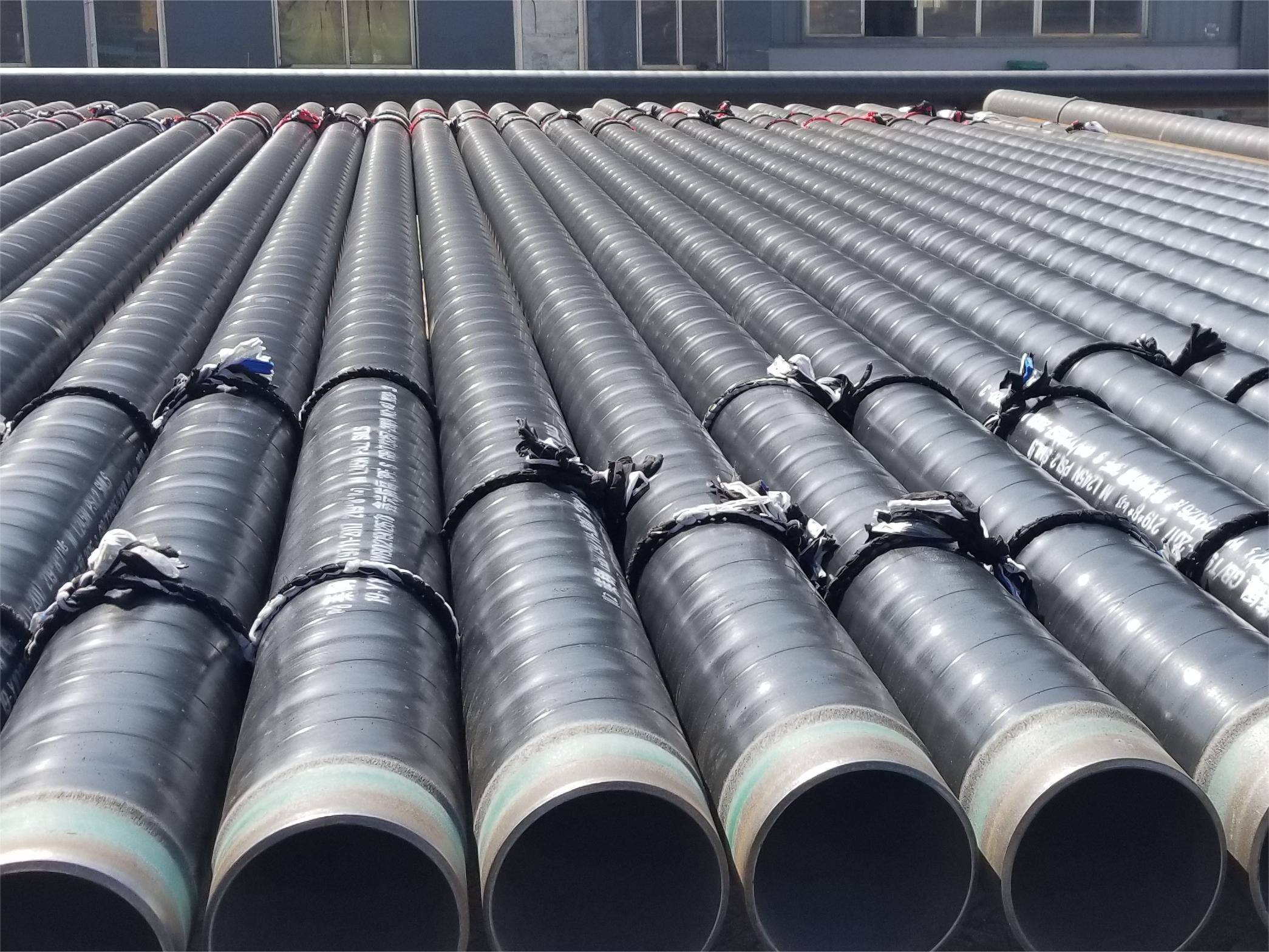

Piv txwv li, rau cov kav dej faus, a3 PEB(peb-txheej polyethylene) txheej yuav siv tau los muab kev tiv thaiv corrosion mus ntev; rau cov kav dej, ibFBE(fusion-bonded epoxy hmoov) txheej tuaj yeem siv tau, thaumgalvanizedKev kho mob tuaj yeem yog qhov kev xaiv zoo hauv ib puag ncig uas yuav tsum muaj kev tiv thaiv zinc corrosion.

Nrog rau cov cuab yeej tshwj xeeb tiv thaiv corrosion, kev pabcuam lub neej ntawm cov yeeb nkab tuaj yeem txuas ntxiv thiab nws cov haujlwm tseem ceeb.

High precision: Me me qhov ntev ntev dua li lwm cov welded raj.

Nto zoo: Smooth nto yog qhov zoo tagnrho rau cov ntawv thov kom zoo nkauj zoo nkauj thiab qhov tsis zoo ntawm qhov chaw tsawg.

Lub zog thiab durability: Cov txheej txheem kos duab txias txhim kho cov khoom siv kho tshuab, ua rau nws tsim nyog rau cov ntawv thov kev ntxhov siab.

Machineability: Yooj yim rau tshuab vim nws cov qauv microstructure thiab cov khoom zoo ib yam thoob plaws hauv cov khoom.

Automotive kev lag luam: rau kev tsim khoom ntawm cov khoom tseem ceeb xws li tsav shafts, bearing raj, steering kem, thiab suspension systems.

Aerospace Cheebtsam: rau kev tsim cov bushings thiab cov yam ntxwv tsis tseem ceeb rau cov dav hlau.

Muaj tshuab: Siv dav hauv kev tsim cov ncej, lub zog, thiab lwm yam, vim lawv qhov yooj yim ntawm machining thiab durability.

Cov khoom siv ncaws pob: Cov khoom siv xws li cov tsheb kauj vab ua haujlwm siab thiab cov khoom siv qoj ib ce.

Zog sector: siv nyob rau hauv brackets los yog roller Cheebtsam rau solar panels.

Peb yog ib qho ntawm cov ua welded carbon steel yeeb nkab thiab seamless steel yeeb nkab manufacturers thiab cov neeg muag khoom los ntawm Tuam Tshoj, nrog rau ntau yam zoo steel yeeb nkab hauv Tshuag, peb tau cog lus los muab koj ntau yam kev daws teeb meem ntawm cov yeeb nkab steel.

Xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb, peb tos ntsoov yuav pab koj nrhiav cov yeeb nkab steel zoo tshaj plaws rau koj cov kev xav tau!