ASTM A519 Cov Lus Qhia Tshwj Xeebtubing yuav tsum tau tsim los ntawm cov txheej txheem seamless thiab yuav tsum tau kub-tiav lossis txias-tiav raws li tau teev tseg.

Rau cov raj puag ncig nrog lub taub sab nraud tsis tshaj 12 3/4 hauv (325 mm).

Cov tubing hlau kuj tuaj yeem tsim nyob rau hauv square, rectangular, lossis lwm yam duab raws li qhov xav tau.

ASTM A519 tuaj yeem raug cais raws li cov khoom siv hlau:Carbon Steelthiab Alloy Steel.

Cov pa roj carbon steelyog subdivided rau hauvTsawg Carbon MT(Mechanical Tubing),High Carbon SteelthiabDesulfurized los yog Rephosphorized, los yog ob qho tib siCarbon Steel, kom haum cov kev xav tau sib txawv ntawm kev lag luam thiab kev thov scenarios.

Thaum tsis muaj qib tau teev tseg, cov chaw tsim khoom muaj kev xaiv muabMT1015 los yog MTX1020qib.

Sab nraud txoj kab uas hla: 13.7 - 325 mm;

Phab ntsa thickness: 2-100mm.

Cov hlau tuaj yeem ua los ntawm txhua qhov txheej txheem.

Cov hlau yuav raug cam khwb cia rau hauv ingots los yog strand cast.

Tubes yuav tsum ua los ntawm aseamless txheej txheemthiab yuav tsum yog kub-tiav lossis txias-tiav, raws li tau teev tseg.

Seamless steel tubes yog cov raj uas tsis muaj welded seams thoob plaws.

Cold-tiav tubesraug pom zoo rau kev xav tau siab ntawm qhov tseeb qhov tseeb thiab qhov zoo ntawm qhov chaw.

Qhov kev txhawj xeeb tseem ceeb yog tus nqi-zoo thiab cov khoom toughness,kub-tiav steel yeeb nkabtej zaum yuav yog qhov kev xaiv tsim nyog.

Tom ntej no yog cov txheej txheem ntau lawm ntawm kub dov seamless steel yeeb nkab.

Cov chaw tsim khoom steel yuav tsum txheeb xyuas qhov kub ntawm txhua lub steel los txiav txim qhov feem pua ntawm cov ntsiab lus.

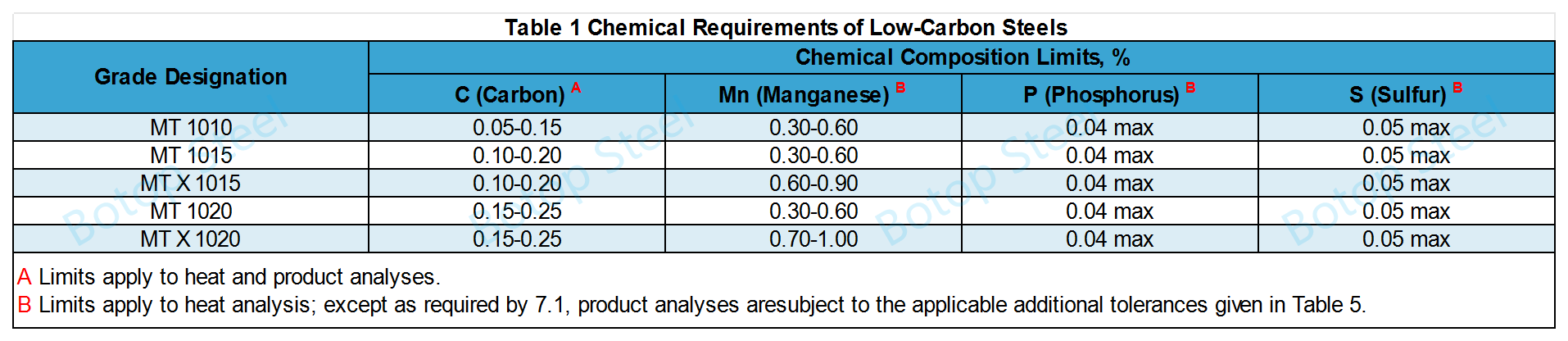

Table 1 Chemical Requirements of Low-Carbon Steels

Cov hlau me me yog cov hlau uas muaj cov ntsiab lus carbon feem ntau tsis tshaj 0.25%. Vim nws cov ntsiab lus qis dua, cov hlau no tau zoo dua ductility thiab malleability thiab tsis tshua muaj zog thiab muaj zog piv rau high-carbon steel.

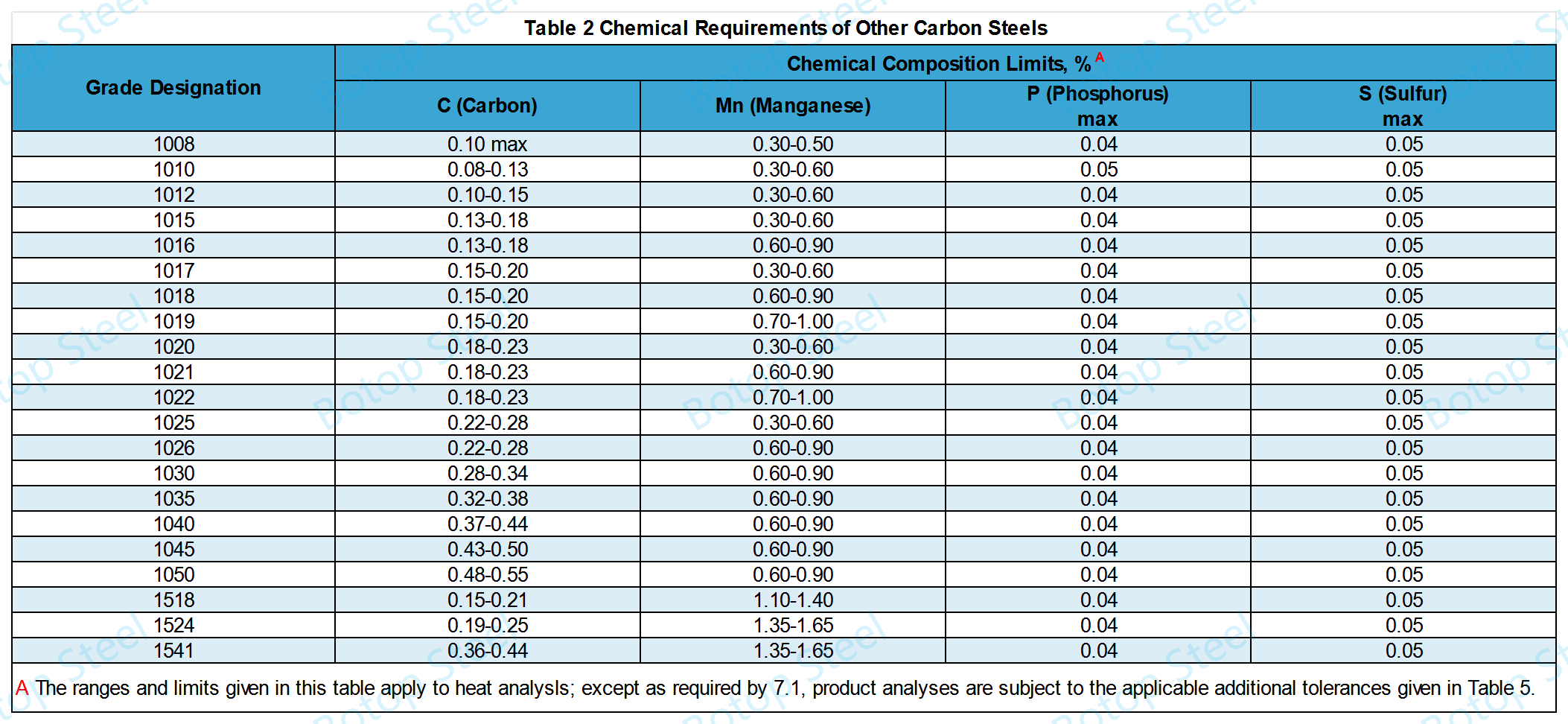

Table 2 Chemical Requirements of Other Carbon Steels

Nruab nrab carbon steels: Muaj nyob nruab nrab ntawm 0.25% thiab 0.60% carbon, lawv muab siab dua hardness thiab lub zog thiab xav tau kev kho cua sov los txhim kho cov khoom.

High carbon hlau: Muaj nyob nruab nrab ntawm 0.60% thiab 1.0% lossis ntau dua cov pa roj carbon monoxide, thiab muab cov hardness siab heev thiab lub zog, tab sis qis toughness.

Table 3 Chemical Requirements for Alloy Steels

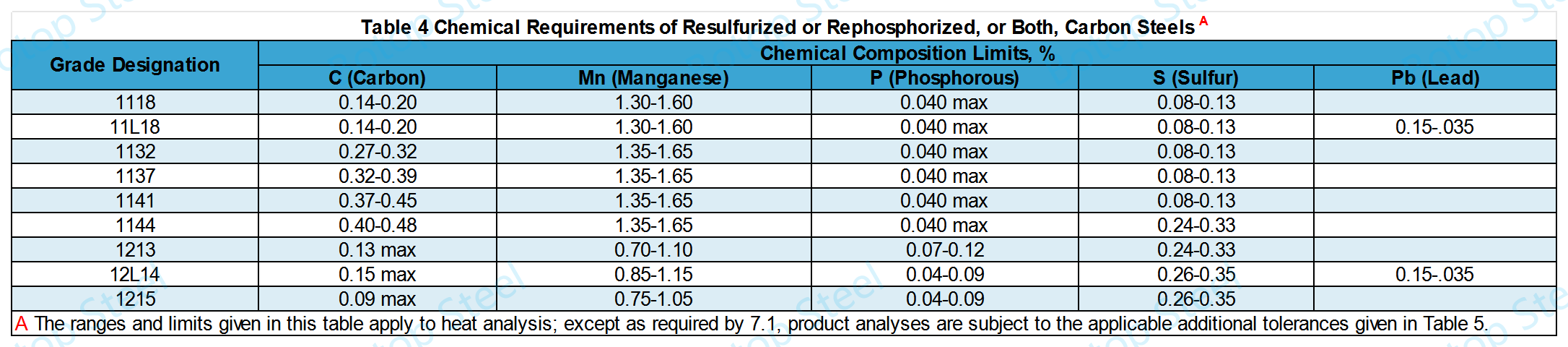

Table 4 Tshuaj Resulfurized los yog Rephosphorized, los yog Ob leeg, Carbon Steels

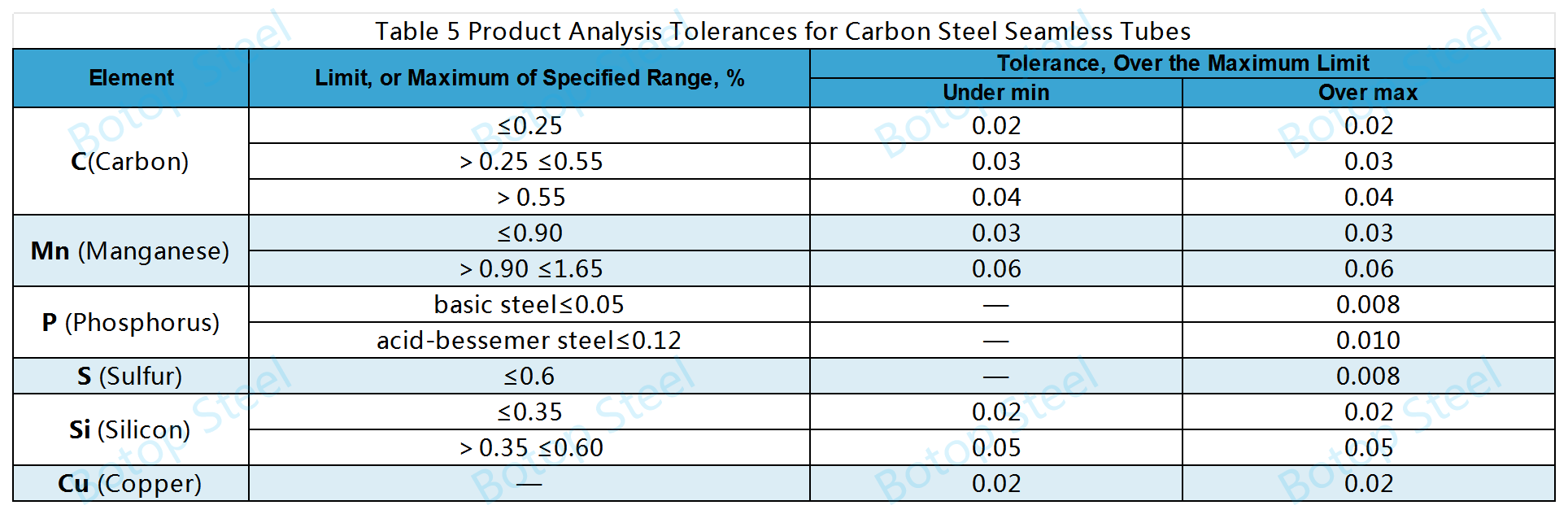

TABLE 5 Cov Kev Ntsuas Cov Khoom Uas Muaj Kev Pom Zoo Tshaj lossis Hauv Cov Kev Qhia tshwj xeeb lossis txwv

Cov chaw tsim khoom yuav tsum tsuas yog hais kom soj ntsuam cov khoom yog tias nws xav tau los ntawm kev txiav txim.

ASTM A519 suav nrog cov khoom sim hauv qab no:

Hardness Test; Kev ntsuam xyuas nruj; Kev kuaj tsis raug; Flaring Test; Steel Cleanliness thiab Hardenability.

| Qib Qib | Hom yeeb nkab | Qhov xwm txheej | Siv zog | Yield zog | Elongation hauv 2in [50mm],% | Rockwell, Hardness B Scale | ||

| ksi ua | Mpa | ksi ua | Mpa | |||||

| 1020 | Carbon Steel | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 ib | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Carbon Steel | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 ib | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 ib | Carbon Steel | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 ib | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 ib | Carbon Steel | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 ib | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Carbon Steel | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 ib | 70 | 485 ib | 6 | 86 | ||

| A | 68 | 470 ib | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized los yog Rephosphorized, los yog Ob leeg, Carbon Steels | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 ib | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 ib | Resulfurized los yog Rephosphorized, los yog Ob leeg, Carbon Steels | HR | 70 | 485 ib | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 ib | 43 | 295 | 15 | 75 | ||

| 4 130 | Alloy Steels | HR | 90 | 620 | 70 | 485 ib | 20 | 89 |

| SR | 105 | 725 ib | 85 | 585 ib | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4 140 | Alloy Steels | HR | 120 | 825 ib | 90 | 620 | 15 | 100 |

| SR | 120 | 825 ib | 100 | 690 ib | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 ib | 90 | 620 | 20 | 100 | ||

HR-Kub Rolled, CW-Cold Worked, SR-Stress Relieved, A-Annealed thiab N-Normalized.

Sab nraud txoj kab uas hla

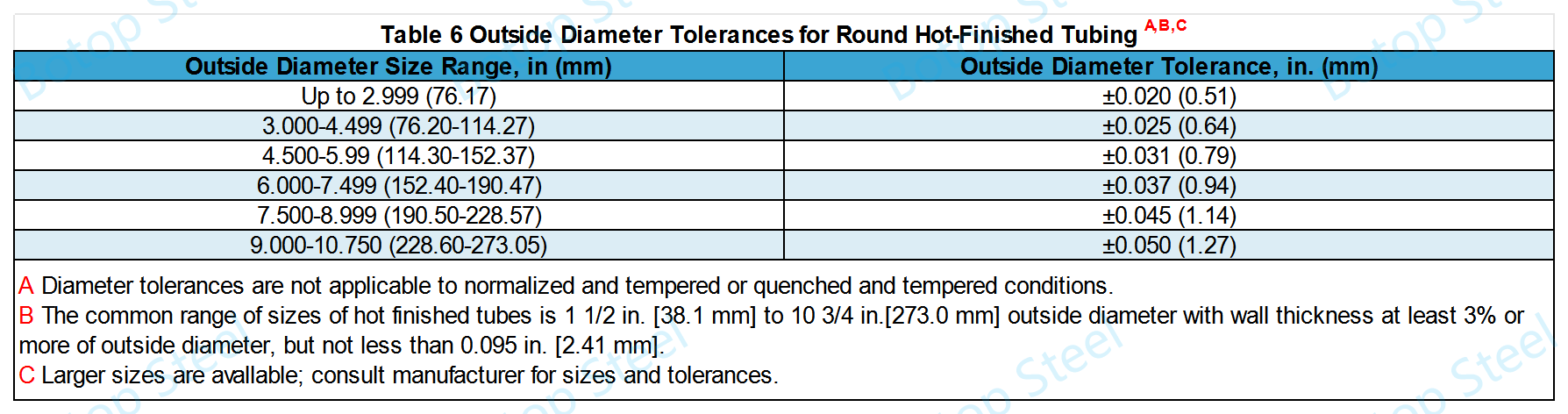

Table 6 Sab Nraud Qhov Siab Zoorau Round Kub-Tiav Tubing

Table 12 Sab Nrauv Qhov Siab Tolerances rauHauv av Seamless Tubing

| Loj Sab Nraud Diameter, hauv [mm] | Sab nraud txoj kab uas hla rau qhov ntau thiab ntev muab, hauv. [mm] | |||

| Tshaj | Hauv qab | Tshaj | Hauv qab | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] Thaum L≤16ft [4.9m] | 0.000 | 0.004 [0.10] Thaum L> 16ft [4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] Thaum L≤16ft [4.9m] | 0.000 | 0.006 [0.15] Thaum L> 16ft [4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] Thaum L≤12ft [3.7m] | 0.000 | 0.006 [0.15] Thaum L≤16ft [4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] Thaum L≤12ft [3.7m] | 0.000 | 0.006 [0.15] Thaum L≤16ft [4.9m] | 0.000 |

Phab ntsa Thickness kam rau ua

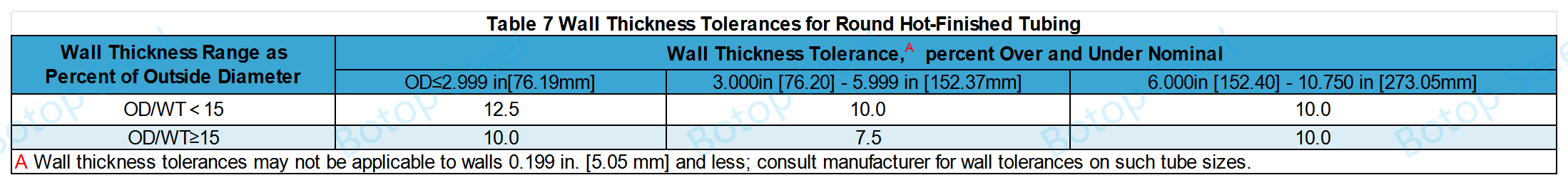

Table 7 Phab Ntsa Thickness Tolerancesrau Round Kub-Tiav Tubing

Table 10 Phab Ntsa Thickness Tolerancesrau Round Cold-Ua Haujlwm Tubing

| Phab ntsa Thickness ranges li Feem pua ntawm Sab Nrauv Txoj Kab | Phab ntsa Thickness kam rau ua dua thiab hauv qab nominal,% | |

| OD≤1.499in [38.07mm] | OD≥1.500 hauv [38.10mm] | |

| OD/WT ≤ 25 | 10.0 | 7.5 |

| OD/WT > 25 | 12.5 ib | 10.0 |

Sab nraud thiab sab hauv txoj kab uas hla Tolerance

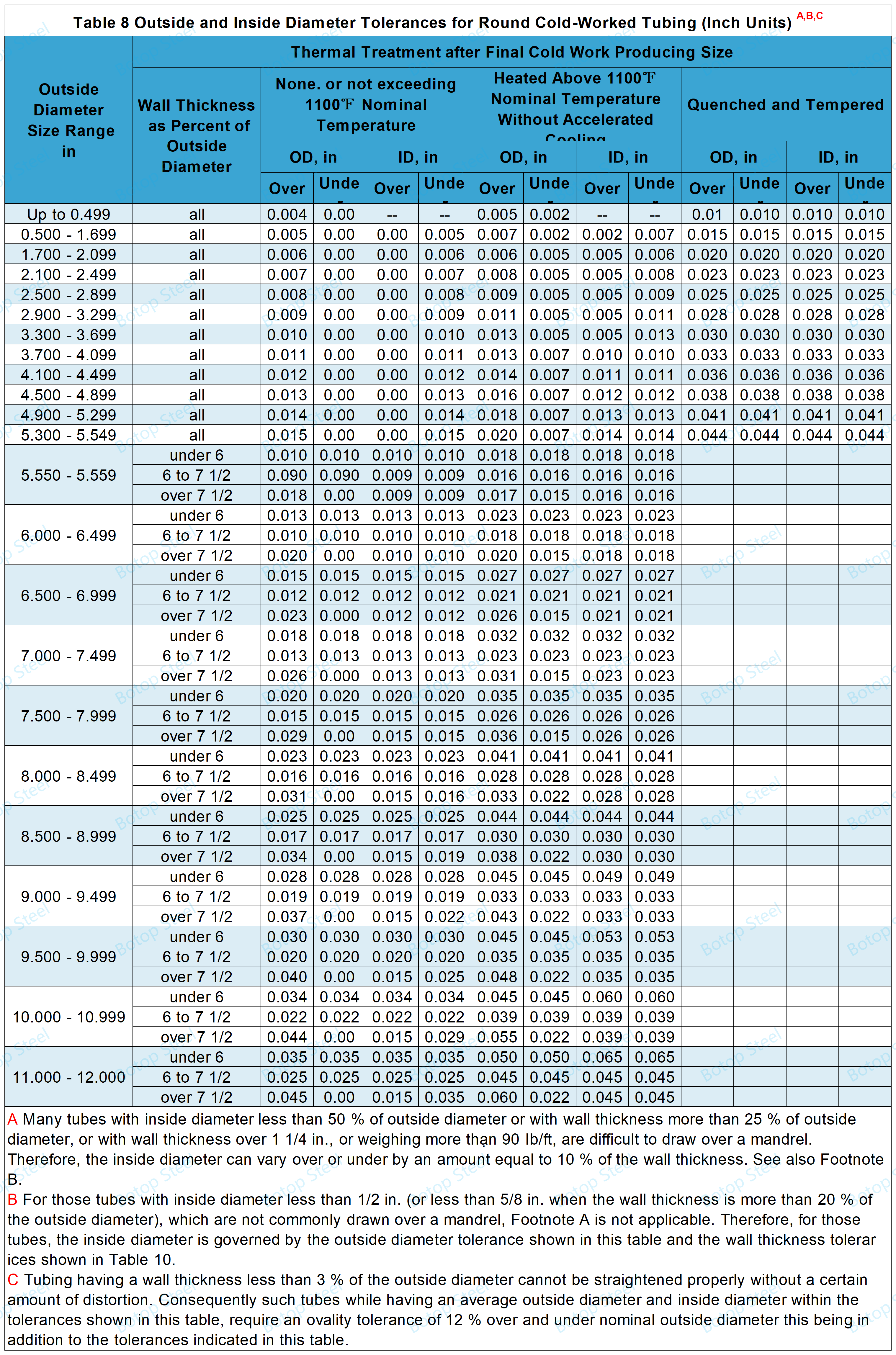

Table 8 Sab nraud thiab sab hauv txoj kab uas hla Tolerances rauRound Cold-Ua Haujlwm Tubing (Inch Units)

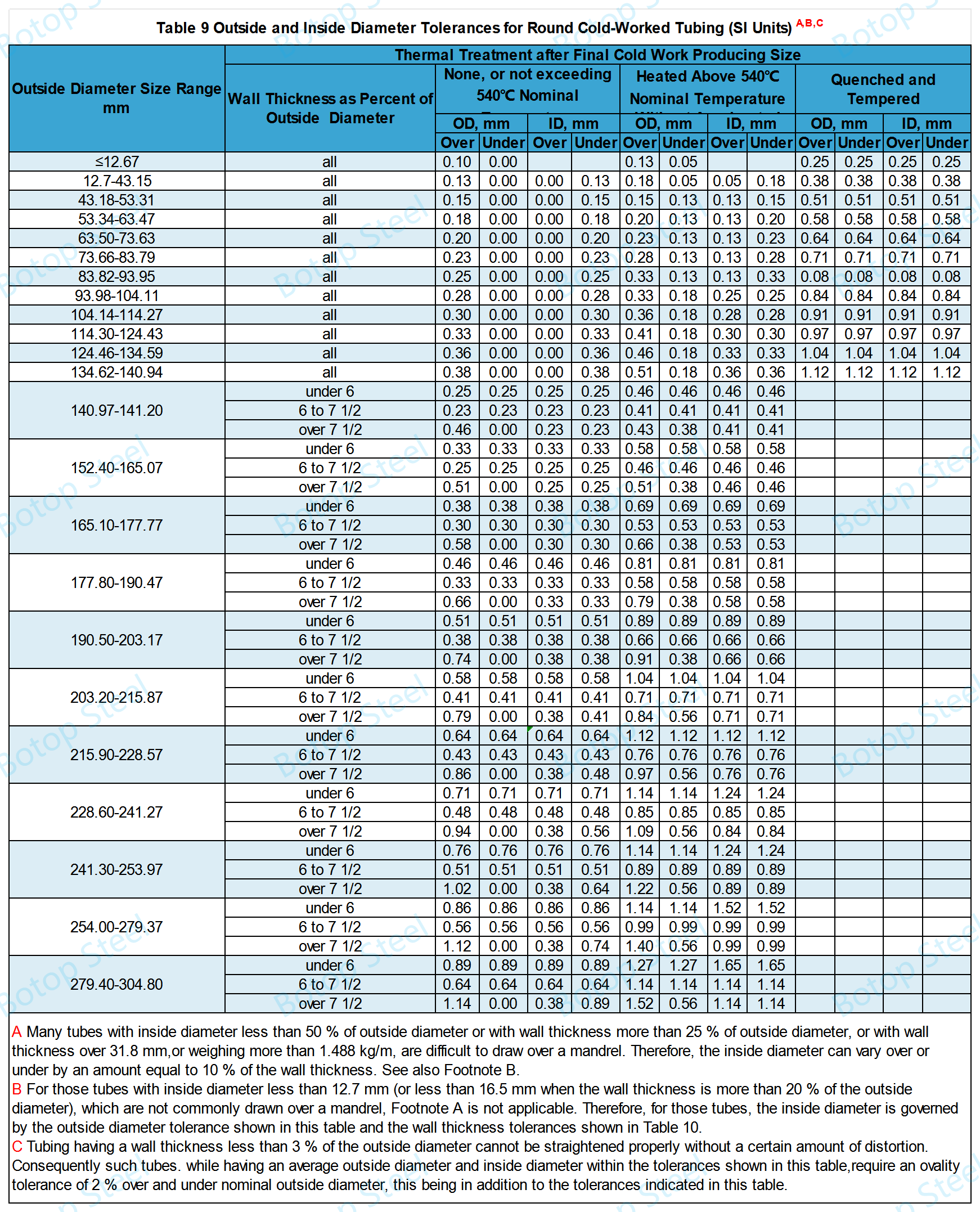

Table 9 Sab nraud thiab sab hauv txoj kab uas hla TolerancesRau Round Cold-Worked Tubing (SI Units)

Sab nraud txoj kab uas hla thiab phab ntsa Thickness kam rau ua

Table 11 Sab Nraud Txoj kab uas hla thiab phab ntsa Tolerancesrau Rough-Tig Seamless Steel Tubing

| Specified Loj Sab Nraud Diameter, hauv. [mm] | Sab nraud txoj kab uas hla, hauv. [mm] | Phab ntsa Thickness, % |

| 6 3/4 [171.4] | ± 0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ± 0.010 [0.25] | ± 12.5 |

Ntev Ntev

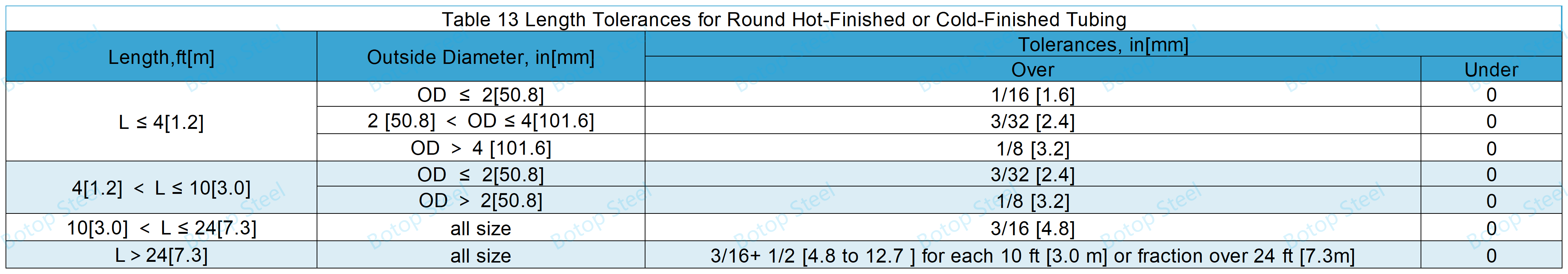

Table 13 Length Tolerancesrau Round Kub-Tiav lossis Cold-Finished Tubing

Kev Ncaj Ncees Tolerance

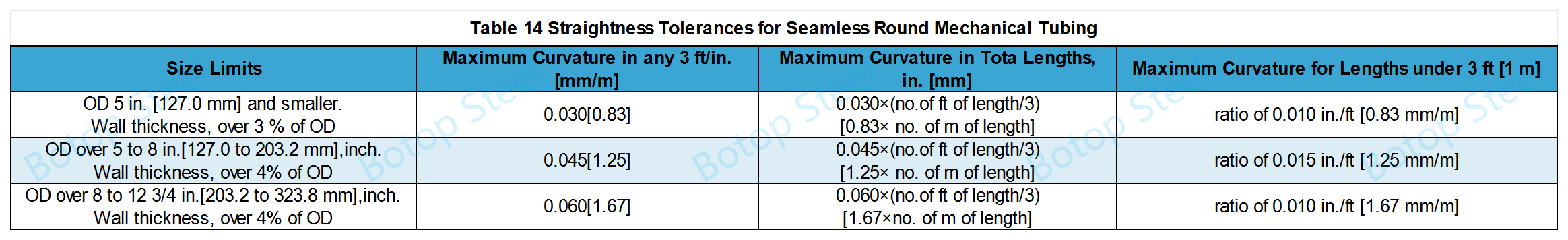

Table 14 Kev Ncaj Ncees Tolerancesrau Seamless Round Mechanical Tubing

Cov yeeb nkab yuav tsum tau coated nrog ib zaj duab xis ntawm cov roj ua ntej molding los tiv thaiv xeb.

Cov roj tiv thaiv xeb kuj tseem tuaj yeem siv rau sab hauv thiab sab nrauv ntawm cov yeeb nkab.

Aviation thiab aerospace: kev tsim khoom ntawm cov khoom tseem ceeb xws li cov tshuab dav hlau thiab cov tshuab txhawb nqa dav hlau.

Kev lag luam hluav taws xob: Drilling khoom thiab high-pressure boiler piping manufacturing.

Machinery thiab cov cuab yeej tsim khoom: Cov khoom tseem ceeb uas ua rau muaj ntau yam kev lag luam thiab cov khoom siv.

Cov khoom siv ua kis las: Kev tsim cov tsheb kauj vab ua haujlwm siab thiab lwm qhov chaw ua kis las.

Lub tsev thiab kev tsim kho: Cov txheej txheem kev txhawb nqa rau cov tsev thiab kev siv hauv qhov chaw muaj kev kub ntxhov.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, thiab lwm yam. Cov ntaub ntawv no tuaj yeem suav tias yog qhov sib npaug ntawm qee cov carbon thiab alloy steels hauv ASTM A519.

2. DIN 1629: St52, St37.4, etc.

3. JIS G3445: STKM13A, STKM13B, thiab lwm yam. Cov no yog cov pa roj carbon steel raj siv rau kev siv tshuab thiab kev tsim qauv.

4. BS 6323: CFS 3, CFS 4, CFS 8, thiab lwm yam. Cov no yog seamless thiab welded steel hlab rau automotive, mechanical, thiab general engineering lub hom phiaj.

5. GB / T 8162: 20#, 45#, 40Cr, 20CrMo, thiab lwm yam. Seamless steel hlab thiab cov kav dej rau cov qauv dav dav thiab cov qauv siv tshuab.

6. ISO 683-17: 100Cr6, thiab lwm yam, feem ntau siv hauv kev tsim cov kabmob, tuaj yeem nrhiav tau daim ntawv thov hauv kev tsim kho tshuab thiab muaj cov ntawv zoo sib xws rau qee cov hlau alloy ntawm ASTM A519.

Thaum xaiv cov khoom sib npaug, nws yog ib qho tseem ceeb uas yuav tsum tau xa mus rau cov ncauj lus kom ntxaws txog cov tshuaj lom neeg thiab cov cuab yeej cuab yeej cuab tam kom paub meej tias cov khoom uas tau xaiv yuav ua tau raws li qhov yuav tsum tau ua ntawm daim ntawv thov tshwj xeeb.

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua tus xa khoom ntawm carbon steel yeeb nkab nyob rau sab qaum teb Tuam Tshoj, paub txog kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem. Lub tuam txhab muaj ntau yam carbon steel kav thiab lwm yam khoom, xws li seamless, ERW, LSAW, thiab SSAW steel yeeb nkab, raws li zoo raws li ib tug tag nrho lineup ntawm cov yeeb nkab fittings thiab flanges.

Nws cov khoom tshwj xeeb kuj suav nrog cov qib high-qib alloys thiab austenitic stainless hlau, tsim kom tau raws li qhov xav tau ntawm ntau yam kev siv kav dej.