ASTM A53 AWcev steelHom Ehauv A53 specification, tsim los ntawm cov txheej txheem vuam, thiab muaj nyob rau hauv qib A thiab qib B.

Nws yog feem ntau haum rau kev siv tshuab thiab siab thiab feem ntau yog siv los ua lub hom phiaj dav dav rau kev xa cov pa, dej, roj, thiab huab cua.

Qhov zoo ntawm ERW steel yeeb nkab, xws litus nqi qisthiabsiab productivity, ua nws cov khoom ntawm kev xaiv rau ntau daim ntawv thov kev lag luam.

Botop Steelyog ib tug zoo welded carbon steel yeeb nkab chaw tsim tshuaj paus thiab tsum los ntawm Tuam Tshoj, thiab kuj yog ib tug seamless steel yeeb nkab stockist, muab koj ib tug ntau yam ntawm cov yeeb nkab steel kev daws teeb meem!

Peb cov khoom muag tau zoo stocked thiab peb muaj peev xwm ua tau raws li peb cov neeg siv khoom xav tau sai rau ntau qhov ntau thiab tsawg.

ASTM A53 / A53M suav nrog hom thiab qib hauv qab no:

Hom E: Hluav taws xob tiv taus-welded, Qib A thiab B.

Hom S: Seamless, Qib A thiab B.

Hom F: Rauv-taub qab-welded, nruam welded Qib A thiab B.

Hom EthiabHom Syog ob hom yeeb nkab siv dav. Piv txwv li,Hom Ffeem ntau yog siv rau cov raj me me. Vim muaj kev nce qib hauv vuam tshuab, txoj kev tsim khoom no tau siv tsawg dua.

Nominal Diameter: DN 6 - 650 [NPS 1/8 - 26];

Sab nraud: 10.3 - 660 mm [0.405 - 26 nyob rau hauv.];

Phab ntsa thickness thiab steel yeeb nkab luj kab kos:

ASTM A53 kuj tso cai rau cov khoom siv ntawm cov yeeb nkab nrog lwm qhov ntev muab cov yeeb nkab ua tau raws li tag nrho lwm cov kev cai ntawm qhov kev qhia no.

ERWyog dav siv los tsim puag ncig, square, thiab rectangular carbon thiab tsawg alloy steel kav.

Cov khoom hauv qab no yog cov txheej txheem ntau lawm rau kev tsim khoomround ERW steel yeeb nkab:

a) Kev npaj khoom siv: Cov khoom pib feem ntau yog kub dov steel coils. Cov coils no yog thawj zaug flattened thiab sheared mus rau qhov yuav tsum tau dav.

b) tsim: Maj mam, dhau los ntawm cov yob, cov sawb yog tsim rau hauv ib qho qhib lub voj voog tubular qauv. Thaum lub sijhawm txheej txheem no, cov npoo ntawm cov sawb tau maj mam coj los ze zog ua ke hauv kev npaj rau vuam.

c) Vuam: Tom qab tsim cov qauv tubular, cov npoo ntawm cov hlau sawb yog rhuab los ntawm hluav taws xob tsis kam nyob rau hauv qhov chaw vuam. Lub high-frequency tam sim no tau dhau los ntawm cov khoom siv, thiab cov cua sov uas tsim los ntawm kev ua haujlwm yog siv los ua kom sov cov npoo mus rau lawv qhov melting point, thiab tom qab ntawd lawv tau welded ua ke los ntawm kev kub siab.

d) Deburring: Tom qab vuam, weld burrs (ntau hlau los ntawm vuam) raug tshem tawm ntawm sab hauv thiab sab nraud ntawm cov yeeb nkab kom ntseeg tau tias muaj qhov sib luag hauv cov yeeb nkab.

e) Qhov loj me thiab qhov ntev: Tom qab vuam thiab deburring tiav lawm, cov hlab tau dhau los ntawm lub tshuab sizing rau kev kho qhov ntev kom ntseeg tau tias lawv ua tau raws li qhov tseeb txoj kab uas hla thiab roundness. Cov hlab yog ces txiav mus rau predetermined lengths.

f) Kev tshuaj xyuas thiab kuaj: Cov yeeb nkab steel yuav raug soj ntsuam nruj thiab tshuaj xyuas, suav nrog kev kuaj ultrasonic, kuaj hydrostatic, thiab lwm yam, kom ntseeg tau tias cov yeeb nkab steel zoo ua tau raws li cov qauv thiab cov kev qhia tshwj xeeb.

g) Kev kho deg: Thaum kawg, cov yeeb nkab steel yuav raug kho ntxiv xws li kub dip galvanizing, pleev xim, lossis lwm yam kev kho saum npoo los muab kev tiv thaiv corrosion ntxiv thiab zoo nkauj.

Welds hauv Hom E lossis Hom F Qib Bcov yeeb nkab yuav tsum tau kho cua sov lossis lwm yam kev kho tom qab vuam kom tsis txhob muaj martensite.

Kev kho cua sov yuav tsum yog tsawg kawg1000 ° F [540 ° C].

Thaum cov yeeb nkab txias tau nthuav dav, qhov nthuav dav yuav tsum tsis pub tshaj1.5%ntawm qhov teev sab nraud ntawm cov yeeb nkab.

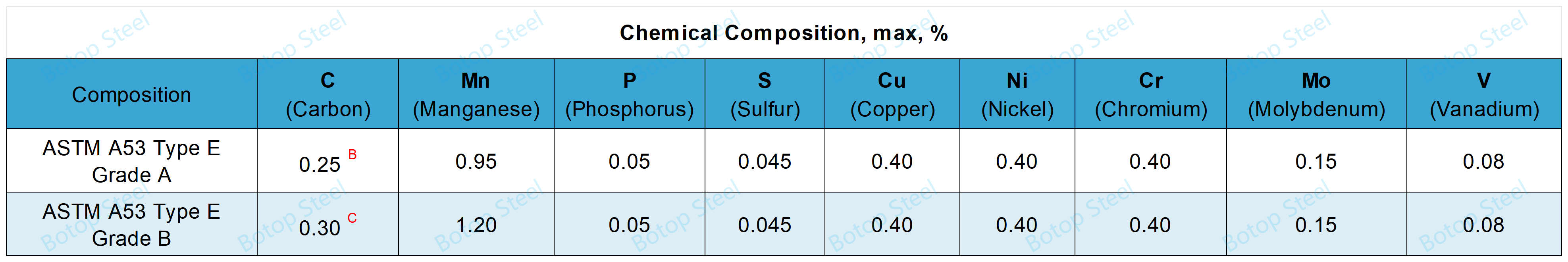

ATsib lub ntsiabCu, Ni, Cr, Mo, thiabVua ke yuav tsum tsis pub tshaj 1.00%.

BRau txhua qhov kev txo qis ntawm 0.01% qis dua cov pa roj carbon siab tshaj plaws, qhov nce ntawm 0.06% ntawm manganese saum toj no qhov siab tshaj plaws yuav raug tso cai mus txog qhov siab tshaj ntawm 1.35%.

CRau txhua qhov kev txo qis ntawm 0.01% qis dua cov pa roj carbon siab tshaj plaws, qhov nce ntawm 0.06% ntawm manganese saum toj no qhov siab tshaj plaws yuav raug tso cai mus txog qhov siab tshaj ntawm 1.65%.

Tensile Khoom

| Sau npe | Kev faib tawm | Qib A | Qib B |

| Tensile zog, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Yield zog, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation nyob rau hauv 50 mm [2 nyob rau hauv.] | Nco tseg | A,B | A,B |

Nco tseg A: Qhov tsawg kawg nkaus elongation hauv 2 hauv [50 mm] yuav tsum tau txiav txim siab los ntawm cov kab zauv hauv qab no:

e = 625,000 [1940] A0.2/U0.9

e = yam tsawg kawg nkaus elongation nyob rau hauv 2 nyob rau hauv los yog 50 mm nyob rau hauv feem pua, sib npaug mus rau qhov ze feem pua

A = qhov tsawg dua ntawm 0.75 in2[500 hli2] thiab qhov chaw seem ntawm qhov ntsuas qhov nro, suav nrog qhov ntsuas sab nraud ntawm cov yeeb nkab, lossis qhov dav ntawm qhov ntsuas qhov nro thiab qhov ntsuas phab ntsa tuab ntawm cov yeeb nkab, suav nrog tus nqi sib npaug mus rau qhov ze tshaj 0.01 hauv2 [1 hli2].

U = qhov tsawg kawg nkaus tensile zog, psi [MPa].

Nco tseg B: Saib Table X4.1 lossis Table X4.2, qhov twg yog siv tau, rau qhov tsawg kawg nkaus elongation qhov tseem ceeb uas yuav tsum tau muaj rau ntau yam kev sib txuas ntawm qhov nro ntsuas qhov loj me thiab teev qhov tsawg kawg nkaus tensile lub zog.

Khoov Test

Rau cov yeeb nkab DN ≤ 50 [NPS ≤ 2], qhov ntev txaus ntawm cov yeeb nkab yuav tsum muaj peev xwm khoov txias mus txog 90 ° nyob ib ncig ntawm lub cylindrical mandrel, lub cheeb ntawm kaum ob npaug ntawm qhov teev sab nraud ntawm cov yeeb nkab, tsis muaj kev tawg ntawm ib feem thiab tsis qhib qhov vuam.

Muab ob npaug rau-muaj zog(qib hnyav:XXS) yeeb nkab hla DN 32 [NPS 1 1/4] yuav tsum tsis txhob raug kuaj khoov.

Flattening Test

Kev ntsuas flattening yuav tsum tau ua rau ntawm cov yeeb nkab welded tshaj DN 50 hauv qhov hnyav ntxiv (XS) lossis sib dua.

Haum rau Hom E, Qib A thiab B; thiab Hom F, Qib B raj.

Seamless steel raj tsis tas yuav tsum tau kuaj.

Lub Sijhawm Xeem

Rau txhua qhov ntau thiab tsawg ntawm Hom S, Hom E, thiab Hom F Qib B piping, qhov kev sim siab yuav tsum tau tswj kom tsawg kawg ntawm 5s.

Kev ntsuas hydrostatic yuav tsum tau siv, tsis muaj qhov xau los ntawm cov vuam seam lossis lub cev yeeb nkab.

Kuaj Siab

Plain-end yeeb nkabyuav tsum tau kuaj hydrostatically rau lub siab siv tau muab rau hauvTabla X 2.2,

Threaded-thiab-coupled yeeb nkabyuav tsum tau kuaj hydrostatically rau lub siab siv tau muab rau hauvTabla X 2.3.

Rau cov kav hlau steel nrog DN ≤ 80 [NPS ≤ 80], qhov ntsuas siab yuav tsum tsis pub tshaj 17.2MPa;

Rau cov kav hlau steel nrog DN >80 [NPS >80], qhov ntsuas siab yuav tsum tsis pub tshaj 19.3MPa;

Kev sim siab dua tuaj yeem xaiv tau yog tias muaj kev xav tau tshwj xeeb engineering, tab sis qhov no yuav tsum muaj kev sib tham ntawm cov chaw tsim khoom thiab cov neeg siv khoom.

Kos npe

Yog tias cov yeeb nkab tau kuaj hydrostatically, lub cim yuav tsum qhia qhovxeem siab.

Cov kev cai hauv qab no siv rau Hom E thiab Hom F Qib B Yeeb Nkab.

Seamless yeeb nkab muaj cov kev cai ntxiv uas tsis tau tham hauv daim ntawv no.

Kev sim

Cov kav dej uas tsim los ntawm cov tshuab tsis-kub-stretch expansion thiab contraction tshuab: DN ≥ 50 [NPS ≥ 2], covweldsnyob rau hauv txhua ntu ntawm cov yeeb nkab yuav tsum tau xeem dhau qhov kev ntsuas hluav taws xob uas tsis muaj kev puas tsuaj, thiab cov qauv kev sim yuav tsum ua raws li cov kev cai.E213, E273, E309 lossis E570txheem.

ERW kav dej ua los ntawm kub- stretch-txo txoj kab uas hla tshuab: DN ≥ 50 [NPS ≥ 2]Txhua ntuntawm cov yeeb nkab yuav tsum tau kuaj xyuas tag nrho los ntawm kev kuaj hluav taws xob tsis muaj kev puas tsuaj, uas yuav tsum tau ua raws li qhovE213, E309 ,lubE570qauv.

Lus Cim: Kub Stretch Expansion Diameter Tshuab yog lub tshuab uas txuas ntxiv ncab thiab nyem cov hlab steel los ntawm cov chais ntawm qhov kub thiab txias los kho lawv cov diameters thiab phab ntsa thicknesses.

Kos npe

Yog tias lub raj tau raug kuaj xyuas tsis muaj kev puas tsuaj, nws yuav tsum tau qhiaNDEntawm lub cim.

Pawg

± 10%.

Cov yeeb nkab DN ≤ 100 [NPS ≤ 4], hnyav li ib pawg.

Pipes DN> 100 [NPS> 4], hnyav hauv ib daim.

Txoj kab uas hla

Rau cov yeeb nkab DN ≤40 [NPS≤ 1 1/2], OD variation yuav tsum tsis pub tshaj ± 0.4 hli [1/64 in.].

Rau cov yeeb nkab DN ≥50 [NPS> 2], OD variation yuav tsum tsis pub tshaj ± 1%.

Thicknesses

Qhov tsawg kawg nkaus phab ntsa thickness yuav tsum tsis txhob tsawg dua87.5%ntawm cov phab ntsa thickness.

sib dua tshaj qhov hnyav ntxiv (XS) hnyav:

a) Plain-kawg yeeb nkab: 3.66 - 4.88m [12 - 16 ft], Tsis ntau tshaj 5% ntawm tag nrho cov naj npawb.

b) ob-random ntev: ≥ 6.71 m [22 ft], Qhov nruab nrab qhov ntev ntawm 10.67m [35 ft].

c) ib leeg-random lengths: 4.88 -6.71m [16 - 22 ft], tsis ntau tshaj 5% ntawm tag nrho cov xov tooj ntawm threaded lengths furnished yog jointers (ob daim ua ke ua ke).

Ntxiv-muaj zog (XS) hnyav lossis hnyav dua: 3.66-6.71 m [12 - 22 ft], tsis ntau tshaj 5% tag nrho cov yeeb nkab 1.83 - 3.66 m [6 - 12 ft].

Rau ASTM A53 steel yeeb nkab tiav yog muaj nyob rau hauv dub los yog galvanized.

Dub: Steel tubing yam tsis muaj kev kho deg, feem ntau yog muag ncaj qha tom qab kev tsim khoom, rau cov ntawv thov uas tsis muaj kev tiv thaiv corrosion ntxiv.

Galvanized kav yuav tsum tau raws li qhov yuav tsum tau muaj.

Txheej txheem

Cov zinc yuav tsum tau coated sab hauv thiab sab nraud los ntawm cov txheej txheem kub-dip.

Raw Khoom

Cov zinc siv rau txheej yuav tsum yog txhua qib ntawm zinc ua raws li qhov yuav tsum tau ua ntawm SpecificationASTM B6.

Qhov tshwm sim

Galvanized yeeb nkab yuav tsum tsis muaj qhov tsis muaj coated, huab cua npuas, flux deposits, thiab ntxhib slag inclusions. Cov pob, pob, globules, lossis ntau cov zinc deposits uas cuam tshuam nrog kev npaj siv ntawm cov khoom yuav tsum tsis txhob tso cai.

Galvanized txheej hnyav

Yuav tsum tau txiav txim siab los ntawm kev kuaj tev raws li kev xeem ASTM A90.

Txheej hnyav yuav tsum tsis pub tsawg tshaj 0.55 kg/m² [1.8 oz/ft²].

ASTM A53 ERW steel yeeb nkabfeem ntau yog siv rau hauv kev siv qis rau nruab nrab-siab xws li kev tsim vaj tsev hauv nroog, kev tsim kho, thiab cov yeeb nkab kho tshuab. Feem ntau siv cov xwm txheej suav nrog kev xa dej, chav dej, huab cua, thiab lwm yam kua dej uas tsis tshua muaj siab.

Nrog zoo weldability, lawv tsim nyog rau kev ua haujlwm nrog coiling, dabtsi yog khoov, thiab flanging.