AWWA C213 steel yeeb nkabyog FBE txheej siv rau sab hauv thiab sab nrauv ntawm cov yeeb nkab steel siv rau hauv cov kav dej hauv av lossis dej hauv qab dej.

Cov txheej no muab kev tiv thaiv kev tiv thaiv corrosion thiab ua kom ntseeg tau tias kev ua haujlwm ntawm cov kav dej txuas ntxiv rau lub sijhawm ntev hauv qhov chaw hauv av lossis submerged.

Cov yeeb nkab sab nraud ≥ 660mm [24in] .Epoxy resin hauv ob sab phlu nrog kev nkag mus rau cov yeeb nkab rau kev tshuaj xyuas thiab tu.

Cov yeeb nkab steel diameters <660mm [24in] kuj tseem tsim nyog, yog tias muaj qhov tsim nyog ntawm kev tshuaj xyuas kev ncaj ncees ntawm txheej sab hauv.

Fusion Bonded Epoxy (FBE)yog ib qho khoom siv qhuav hmoov thermosetting epoxy resin uas, thaum ua haujlwm los ntawm tshav kub, tsim cov tshuaj tiv thaiv rau ntawm cov yeeb nkab steel thaum tuav nws cov khoom.

Cov epoxy hmoov yuav tsum muaj cov khoom siv sib xyaw ua ke uas muaj cov epoxy resin, curing agent, catalyst, filler, colorant, flow control agent, thiab UV inhibitor.

Cov ntaub ntawv yuav tsum ua raws li cov kev cai ntawm lubSafe Drinking Water Act.

Thaum yuav tsum tau ua raws li NSF, cov ntaub ntawv hauv kev sib cuag nrog cov dej haus yuav tsum tau ntawv pov thawj rau NSF/ANSI/CAN Standard 61.

Feem ntau, qhov siab tshaj plaws ntawm daim ntawv thov kub rau coatings yog kwv yees li65 ° C (150 ° F). Ntxiv mus, lub neej kev pab cuam ntawm lub txheej yog txo los ntawm kev tswj cov kub kub rau lub sij hawm ntev.

Thaum ua ntawv thov rau cov khoom preheated los ntawm electrostatic spraying, fluidized txaj los yog huab cua txau thiab tom qab ntawd kho, epoxy hmoov tsim ib txheej txheej tiv thaiv.

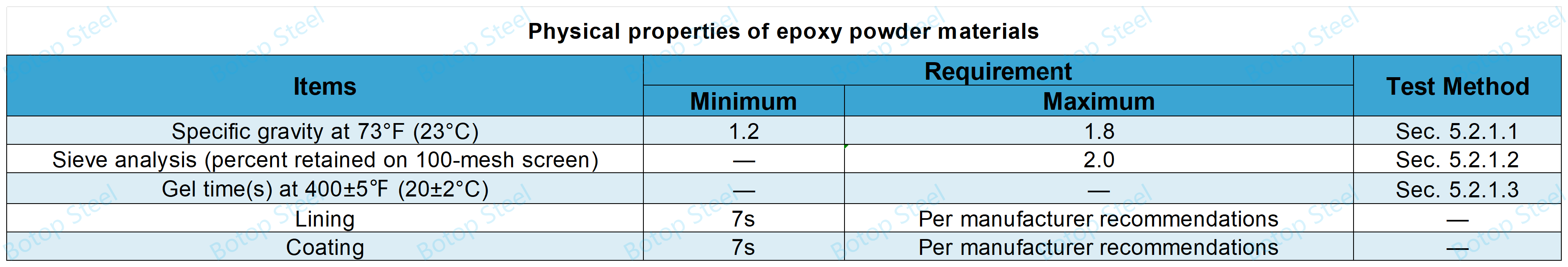

Cov haujlwm tshwj xeeb yog raws li hauv qab no:

Kev tshuaj xyuas yeeb nkab thiab kev kho ua ntej

Qhov saum npoo yuav tsum tsis muaj qhov tsis xws luag cuam tshuam rau cov khoom kawg, xws li burrs, gouges, thiab weld spatters, uas tuaj yeem raug tshem tawm los ntawm kev xuab zeb.

thiab qhov chaw yuav tsum tsis muaj av nkos, zeb xim, siv quav ciab, thee tar, asphalt, roj, roj, chlorides, thiab lwm yam khoom txawv teb chaws los yog cov kab mob combustible uas yuav ignite ntawm fusion bonded epoxy daim ntawv thov kub. Tshem tawm cov pob pom ntawm cov roj thiab roj los ntawm kev so nrog cov kuab tshuaj uas tsis muaj qhov seem.

Kev npaj nto

Siv cov xuab zeb qhuav qhuav los ntxuav qhov xeb ntawm cov yeeb nkab steel.

Blasting Environment Requirements: Thaum qhov kub ntawm cov yeeb nkab steel yog 3 ° C (5 ℉) siab tshaj qhov dej dew point kub.

Nto huv huv: Qhov saum npoo ntawm cov yeeb nkab steel descaled yuav tsum ua raws li SSPC-SP10 / NACE No. 2.

Nto Roughness: Anchor grain qhov tob hauv thaj tsam ntawm 51-102 μm (2.0-4.0 mil) ntsuas raws li ASTM D4417. Qhov no tuaj yeem ntsuas nrog lub thauj tog rau nkoj qauv topper lossis lub thauj tog rau nkoj qauv ntsuas.

Nto roughness uas tob dhau los yog ntiav dhau yuav cuam tshuam rau kev ua haujlwm ntawm FBE txheej kawg.

Nco tseg: Thov nco ntsoov lub sijhawm luv ntawm qhov ua tiav ntawm qhov descaling thiab txheej txheej txheej kom tsis txhob flash rusting.

Huab cua huv

Cov huab cua tsis muaj pa paug yuav tsum tau siv los tshuab cov plua plav, grit, lossis lwm yam khoom txawv teb chaws los ntawm cov txheej txheem npaj ntawm cov yeeb nkab uas tsis cuam tshuam rau qhov chaw ntxuav, lwm cov yeeb nkab ntxuav, lossis cov yeeb nkab yuav tsum tau coated los yog lined.

Cov yeeb nkab cua sov

Thaum tshav kub kub steel yeeb nkab siv qhov cua sov uas yuav tsum tsis txhob kis kab mob ntawm cov yeeb nkab, tab sis yuav tsum tsis pub tshaj 274 ° C (525 ° F ).

Kev kub siab dua tuaj yeem hloov kho lub cev thiab cov yam ntxwv toughness ntawm cov hlau.

Qhov kub ntawm cov yeeb nkab steel tuaj yeem ntsuas tau siv tus pas ntsuas kub ntsuas lossis ntsuas ntsuas qhov ntsuas qhov muag.

Yog tias muaj xim xiav tshwm sim, cov yeeb nkab yuav tsum tau txias rau qhov kub thiab txias thiab rov ua dua.

Txheej txheej txheej

FBE hmoov yog uniformly siv rau saum npoo ntawm cov rhuab steel yeeb nkab los ntawm melting txaj, electrostatic spraying, los yog cua txau.

Grooves, beveled, los yog cov hauv paus hniav yuav tsum tsis txhob FBE coated.

Thaum siv cov roj hmab-gasketed pob qij txha los yog cov khoom siv sib txuas, cov epoxy yuav tsum txuas mus rau qhov kawg ntawm cov yeeb nkab tshwj tsis yog tus neeg yuav khoom tau teev tseg.

Txias

Kev txias tuaj yeem ua nrog cua lossis dej.

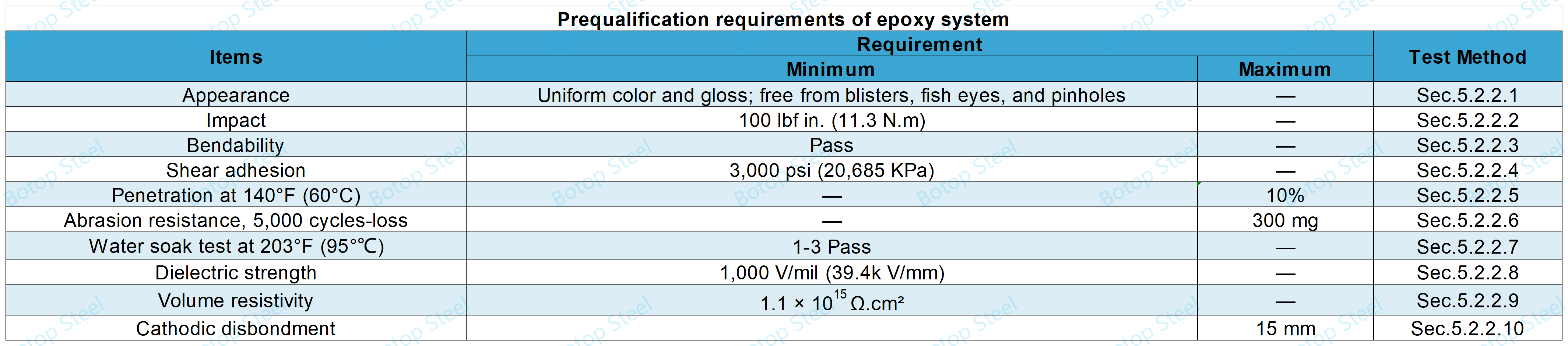

PQT: Muas AWWA C213 Dej Transmission Steel Yeeb Nkab nyob rau hauv me me mus sib hais ua ntej yuav khoom loj. Prequalification los yog kev ntsuam xyuas yog ua los xyuas kom meej tias ib yam khoom los yog system ua tau raws li cov kev cai thiab kev ua tau zoo.

Qhov no suav nrog kev sim kuaj, ntsuas kev ua haujlwm, thiab lwm yam txheej txheem.

Qhov tshwm sim

Lub epoxy yuav tsum yog feem ntau du.

Cov epoxy yuav tsum tsis muaj hlwv, tawg, npuas, delamination, lossis lwm yam tsis xws luag.

Kev tsis zoo ntawm cov tshuaj pleev ib ce, xws li sags, dimpling, scuffing, curtaining, over spray, thiab/los yog txiv kab ntxwv-tev, yuav tsis raug xam tias yog vim li cas rau kev tsis lees paub lossis kho.

Kev tshuaj xyuas hluav taws xob rau kev txuas ntxiv (tsawg-voltage so test)

Txheej txuas ntxiv yuav tsum tau kuaj xyuas raws li NACE SPO490.

Rau cov ntaubnrog ib tug tuab ntawm 20 mils (508 um) los yog tsawg dua, ib tug tsawg-voltage nyiaj so koobtsheej ntes teeb nyob rau hauv lub siab tshaj plaws ntawm 75 V yuav tsum tau siv raws li NACE SPO188.

Yog tias cov hnub so ntau tshaj li tus lej hauv qab txheej txheej yuav tsum tau muab tshem tawm thiab rov ua dua tshiab.

Sab nraud txoj kab uas hla (OD) <14in (360 mm), 1 hnub so / meter (3 ft).

Sab nraud txoj kab uas hla (OD) ≥ 14in (360 mm), 1 hnub so / 25 ft² (2.3 mm²).

Siv cov hnub so uas tau soj ntsuam, kho lawv, thiab rov sim dua.

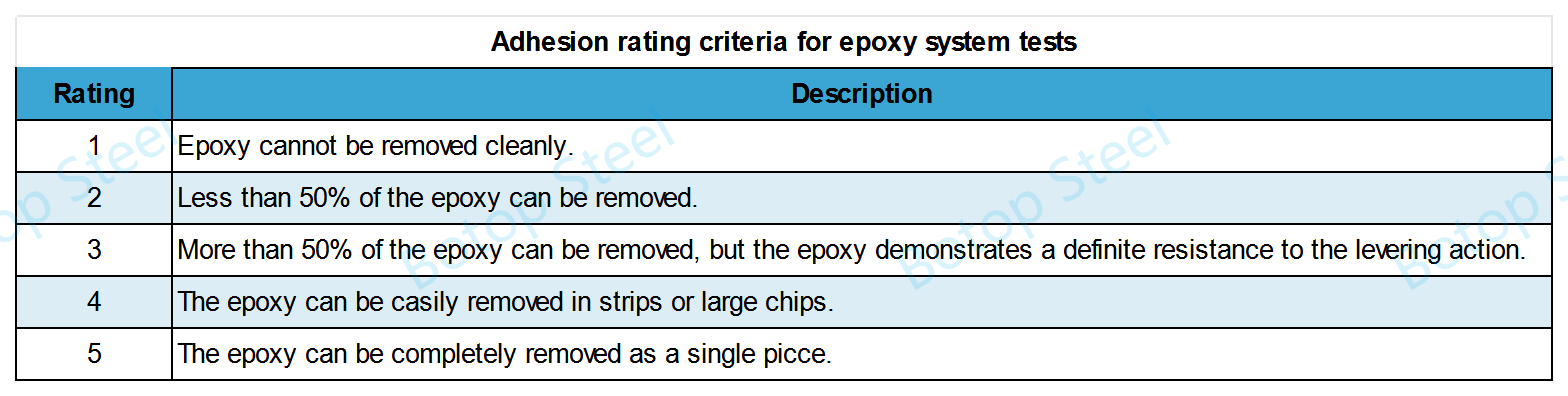

Adhesion

Adhesion ntawm kho epoxy rau saum npoo ntawm cov yeeb nkab tuaj yeem ua tiav los ntawm kev thawb ib rab riam ntse los ntawm epoxy mus rau saum npoo ntawm cov yeeb nkab thiab siv cov plowing suab nyob rau hauv ib qho kev sim kom tshem tawm cov epoxy los ntawm cov yeeb nkab.

Lub epoxy yuav tsum tau ua raws li tag nrho cov yeeb nkab ntawm cov yeeb nkab kom ruaj khov tiv thaiv qhov kev ua haujlwm plowing thiab tsis muaj cov khib nyiab nkig thiab ua tau raws li qhov xav tau.adhesion ntsuas ntawm 1-3.

Thickness

Lub thickness ntawm kho cov zaj duab xis yuav tsum tsis txhob tsawg tshaj li 305um (12mil), nrog rau weld seams.

Nyob rau hauv lub qub version ntawm AWWA C213, muaj ib tug txwv ntawm 406 um (16 mils) lub siab tshaj plaws txheej thickness, uas tau raug tshem tawm nyob rau hauv lub tshiab version vim hais tias ntawm qhov nyuaj rau ua tau raws li qhov yuav tsum tau ua nyob rau hauv lub tiag tiag tiam txheej txheem.

Kev kuaj ntxiv

Kev ntsuam xyuas ntxiv tuaj yeem raug teev los txiav txim siab qhov ua tau zoo ntawm epoxy.

1. Hla ntu porosity.

2. Interface porosity.

3. Kev ntsuas cua sov (DSC).

4. Kev ruaj khov (khoov tau).

5. Dej ntub dej.

6. Kev cuam tshuam.

7. Cathodic disbondment test.

Nws yuav tsum tau sau meej meej nrog lub npe ntawm cov chaw tsim khoom, hom khoom, batch lossis ntau tus lej, hnub tsim khoom, thiab kev cia khoom.

Feem ntau yog rau cov kav dej

Cov txheej txheem sab nrauv feem ntau yog siv los tiv thaiv cov kav dej los ntawm ib puag ncig corrosion, thaum cov txheej txheem sab hauv yog siv los tiv thaiv cov dej paug, txo cov kev sib txhuam, thiab ua kom ntev cov yeeb nkab. Cov txheej txheem no pab ua kom muaj kev ntseeg siab thiab ua haujlwm ntev ntawm cov kav dej, ua raws li cov qauv kev huv, thiab txo qhov kev xav tau ntawm kev saib xyuas.

ANSI/AWWA C203: Coal-Tar Protective Coatings and Linings for Steel Water Pipe.

ANSI/AWWA C209: Daim kab xev txheej rau cov kav dej steel thiab fittings.

ANSI/AWWA C210: Liquid-Epoxy Coatings and Linings for Steel Water Pipe and Fittings.

Botop Steel yog qhov zoo tshaj plaws WeldedCarbon Steel Yeeb Nkabchaw tsim tshuaj paus thiab tsum los ntawm Tuam Tshoj, kuj yog ib tug seamless steel yeeb nkab stockist.

Botop Steel muaj kev cog lus ruaj khov rau kev ua tau zoo thiab siv cov kev tswj xyuas nruj thiab kev sim raukom ntseeg tau cov khoom. Nws pab neeg muaj kev paub dhau los muab cov kev daws teeb meem ntawm tus kheej thiab cov kws tshaj lij kev txhawb nqa, nrog rau kev tsom mus rau cov neeg siv khoom txaus siab. Peb tos ntsoov yuav ua haujlwm nrog koj.