TIAB SA 3454yog cov txheej txheem kev lag luam Nyij Pooj rau carbon steel kav rau lub tshuab siab nrog qhov siab tshaj plaws ua haujlwm kub ntawm 350 ° C. Tus qauv suav nrog ob qib:TIAB SA 370thiabTIAB SA 410. Nws siv rau hluav taws xob kuj welded (ERW) los yog seamless kav nrog ib tug nominal txoj kab uas hla ntawm 10.5 hli mus rau 660.4 hli (xws li 6A rau 650A, los yog 1/8B rau 26B).

JIS G 3454 Cov kav hlau yuav tsum tau tsim los siv kev sib xyaw ua ke ntawm cov yeeb nkab steel thiab cov txheej txheem tiav hauv cov lus hauv qab no.

| Lub cim ntawm qib | Lub cim ntawm kev tsim khoom | ||

| Kev tsim cov yeeb nkab | Txoj kev ua tiav | Classification ntawm zinc-coating | |

| TIAB SA 370 TIAB SA 410 | Seamless: S Hluav taws xob kuj welded: E | Kub tiav: H Txias tiav: C Raws li hluav taws xob kuj welded: G | Cov kav dej dub: cov kav dej tsis muab zinc-txheej Cov kav dej dawb: cov kav dej muab zinc-txheej |

Tshwj xeeb, muaj tsib txoj kev tsim khoom:

SH: Kub-tiav seamless steel yeeb nkab;

SC: Cold-tiav seamless steel yeeb nkab;

EH: Kub-tiav hluav taws xob kuj welded steel yeeb nkab;

EC: Txias-tiav hluav taws xob tiv thaiv welded steel yeeb nkab;

EG: Hluav taws xob kuj welded steel yeeb nkab uas tsis yog kub-tiav thiab txias-tiav sawv daws yuav.

Botop Steelyog cov chaw tsim khoom thiab cov khoom siv zoo welded carbon steel kav los ntawm Tuam Tshoj, nrog rau cov khoom lag luam ntawm seamless steel kav. Yog tias koj muaj kev xav tau, thov koj xav tiv tauj peb thiab peb yuav muab kev pabcuam dawb rau koj.

| Lub cim ntawm qib | C | Si | Mn | P | S |

| max | max | — | max | max | |

| TIAB SA 370 | 0.25% | 0.35% | 0.30-0.90% | 0.040% | 0.040% |

| TIAB SA 410 | 0.30% | 0.35% | 0.30-1.00% | 0.040% | 0.040% |

Tso cai rau qhov sib ntxiv ntawm lwm cov alloying ntsiab.

Tensile Strength, Yield Point lossis Pov Thawj Kev Nyuaj Siab, thiab Elongation

| Cim ntawm qib | Tensile zog | Yield point los yog pov thawj kev nyuaj siab | Elongation min,% | |||

| Tensile xeem daim | ||||||

| No.11 or No.12 | No.5 | No.4 | ||||

| N / mm² (MPA) | N / mm² (MPA) | Tensile xeem kev taw qhia | ||||

| min | min | Parallel rau cov yeeb nkab axis | Perpendicular rau cov yeeb nkab axis | Parallel rau cov yeeb nkab axis | Perpendicular rau cov yeeb nkab axis | |

| TIAB SA 370 | 370 | 215 | 30 | 25 | 28 | 23 |

| TIAB SA 410 | 410 | 245 | 25 | 20 | 24 | 19 |

Flattening Test

Thaum qhov kev ncua deb ntawm ob daim hlau mus txog qhov kev ncua deb H, yuav tsum tsis muaj qhov tsis xws luag lossis tawg ntawm cov yeeb nkab steel.

Rau seamless steel raj: H = (1 + e) t / (e + t / D);

Rau ERW steel kav: H = 1/3 D (rau vuam) lossis H = 2/3 D (rau qhov tsis muaj vuam);

H: nrug nruab nrab ntawm flattening daim hlau (mm);

е: tas li tus kheej txhais rau txhua qib ntawm cov yeeb nkab, 0.08 rau STPG 370, 0.07 rau STPG 410;

t: phab ntsa thickness ntawm cov yeeb nkab (mm);

D: sab nraud txoj kab uas hla ntawm cov yeeb nkab (mm);

Flattening Test yog siv tau rau cov kav hlau uas muaj lub taub nominal siab dua 40A (48.6mm).

Kho tau

Bendability siv tau rau cov kav dej uas muaj lub taub nominal ntawm 40 A (48.6) lossis me dua.

Cov yeeb nkab yuav tsum tau khoov 90 ° ntawm lub vojvoog ntawm 6 npaug ntawm nws txoj kab uas hla. Cov phab ntsa yeeb nkab yuav tsum tsis muaj qhov tsis xws luag lossis tawg.

Txhua cov yeeb nkab steel yuav tsum tau ua qhov kev sim siab hydrostatic los yog tsis muaj kev puas tsuaj.

Hydrostatic Test

Khaws ib lub siab rau tsawg kawg 5 vib nas this yam tsis muaj dej ntws.

Tus nqi siab yog cuam tshuam nrog lub sijhawm teev npe ntawm cov yeeb nkab steel.

| Nominal phab ntsa thickness | Daim ntawv teev npe: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Tsawg kawg hydraulic ntsuas siab, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 ib | 12 |

Kev kuaj tsis muaj kev puas tsuaj

Yog tias kev tshuaj xyuas ultrasonic siv, nws yuav tsum ua raws li tus qauv nruj dua li UD chav kawm teeb liab hauv JIS G 0582.

Yog tias kev ntsuas tam sim no raug siv, nws yuav tsum ua raws li tus qauv uas nruj dua li EY chav teeb liab hauv JIS G 0583.

| Nominal txoj kab uas hla | Sab nraud txoj kab uas hla | Phab ntsa thickness | Unit loj | Teem caij naj npawb (Sch No.) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 ib | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 Nws | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 ib | 80 |

| 8 | 1/4 | 13.8 ib | 2.2 | 0.629 ib | 40 |

| 8 | 1/4 | 13.8 ib | 2.4 | 0.675 ib | 60 |

| 8 | 1/4 | 13.8 ib | 3.0 | 0.799 ib | 80 |

| 10 | 3/8 | 17.3 ib | 2.3 | 0.851 ib | 40 |

| 10 | 3/8 | 17.3 ib | 2.8 | 1.00 Nws | 60 |

| 10 | 3/8 | 17.3 ib | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 ib | 2.8 | 1.31 ib | 40 |

| 15 | 1/2 | 21.7 ib | 3.2 | 1.46 ib | 60 |

| 15 | 1/2 | 21.7 ib | 3.7 | 1.64 ib | 80 |

| 20 | 3/4 | 27.2 ib | 2.9 | 1.74 ib | 40 |

| 20 | 3/4 | 27.2 ib | 3.4 | 2.00 Nws | 60 |

| 20 | 3/4 | 27.2 ib | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 Nws | 3.4 | 2.57 ib | 40 |

| 25 | 1 | 34.0 Nws | 3.9 | 2.89 ib | 60 |

| 25 | 1 | 34.0 Nws | 4.5 | 3.27 ib | 80 |

| 32 | 1 1/4 | 42.7 ib | 3.6 | 3.47 ib | 40 |

| 32 | 1 1/4 | 42.7 ib | 4.5 | 4.24 ib | 60 |

| 32 | 1 1/4 | 42.7 ib | 4.9 | 4.57 ib | 80 |

| 40 | 1 1/2 | 48.6 ib | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 ib | 4.5 | 4.89 ib | 60 |

| 40 | 1 1/2 | 48.6 ib | 5.1 | 5.47 ib | 80 |

| 50 | 2 | 60.5 ib | 3.2 | 4.52 ib | 20 |

| 50 | 2 | 60.5 ib | 3.9 | 5.44 ib | 40 |

| 50 | 2 | 60.5 ib | 4.9 | 6.72 ib | 60 |

| 50 | 2 | 60.5 ib | 5.5 | 7.46 ib | 80 |

| 65 | 2 1/2 | 76.3 ib | 4.5 | 7.97 ib | 20 |

| 65 | 2 1/2 | 76.3 ib | 5.2 | 9.12 ib | 40 |

| 65 | 2 1/2 | 76.3 ib | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 ib | 7.0 ib | 12.0 Nws | 80 |

| 80 | 3 | 89.1 ib | 4.5 | 9.39 ib | 20 |

| 80 | 3 | 89.1 ib | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 ib | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 ib | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 ib | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 ib | 5.7 | 13.5 Nws | 40 |

| 90 | 3 1/2 | 101.6 ib | 7.0 ib | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 ib | 8.1 | 18.7 ib | 80 |

| 100 | 4 | 114.3 ib | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 ib | 6.0 | 16.0 Nws | 40 |

| 100 | 4 | 114.3 ib | 7.1 | 18.8 ib | 60 |

| 100 | 4 | 114.3 ib | 8.6 | 22.4 ib | 80 |

| 125 | 5 | 139.8 ib | 5.1 | 16.9 ib | 20 |

| 125 | 5 | 139.8 ib | 6.6 | 12.7 ib | 40 |

| 125 | 5 | 139.8 ib | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 ib | 9.5 ib | 30.5 ib | 80 |

| 150 | 6 | 165.2 ib | 5.5 | 21.7 ib | 20 |

| 150 | 6 | 165.2 ib | 7.1 | 27.7 ib | 40 |

| 150 | 6 | 165.2 ib | 9.3 | 35.8 ib | 60 |

| 150 | 6 | 165.2 ib | 11.0 Nws | 41.8 ib | 80 |

| 200 | 8 | 216.3 ib | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 ib | 7.0 ib | 36.1 ib | 30 |

| 200 | 8 | 216.3 ib | 8.2 | 42.1 ib | 40 |

| 200 | 8 | 216.3 ib | 10.3 | 52.3 ib | 60 |

| 200 | 8 | 216.3 ib | 12.7 ib | 63.8 ib | 80 |

| 250 | 10 | 267.4 ib | 6.4 | 41.2 ib | 20 |

| 250 | 10 | 267.4 ib | 7.8 ib | 49.9 ib | 30 |

| 250 | 10 | 267.4 ib | 9.3 | 59.2 ib | 40 |

| 250 | 10 | 267.4 ib | 12.7 ib | 79.8 ua | 60 |

| 250 | 10 | 267.4 ib | 15.1 | 93.9 ua | 80 |

| 300 | 12 | 318.5 ib | 6.4 | 49.3 ib | 20 |

| 300 | 12 | 318.5 ib | 8.4 | 64.2 ib | 30 |

| 300 | 12 | 318.5 ib | 10.3 | 78.3 ib | 40 |

| 300 | 12 | 318.5 ib | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 ib | 17.4 ib | 129 | 80 |

| 350 | 14 | 355.6 ib | 6.4 | 55.1 ib | 10 |

| 350 | 14 | 355.6 ib | 7.9 ib | 67.7 ib | 20 |

| 350 | 14 | 355.6 ib | 9.5 ib | 81.1 ib | 30 |

| 350 | 14 | 355.6 ib | 11.1 | 94.3 ib | 40 |

| 350 | 14 | 355.6 ib | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 ib | 19.0 Nws | 158 | 80 |

| 400 | 16 | 406.4 ib | 6.4 | 63.1 ib | 10 |

| 400 | 16 | 406.4 ib | 7.9 ib | 77.6 ib | 20 |

| 400 | 16 | 406.4 ib | 9.5 ib | 93.0 ua | 30 |

| 400 | 16 | 406.4 ib | 12.7 ib | 123 | 40 |

| 400 | 16 | 406.4 ib | 16.7 ib | 160 | 60 |

| 400 | 16 | 406.4 ib | 21.4 ib | 203 | 80 |

| 450 | 18 | 457.2 ib | 6.4 | 71.1 ib | 10 |

| 450 | 18 | 457.2 ib | 7.9 ib | 87.5 ib | 20 |

| 450 | 18 | 457.2 ib | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 ib | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 ib | 19.0 Nws | 205 | 60 |

| 450 | 18 | 457.2 ib | 23.8 ib | 254 | 80 |

| 500 | 20 | ib 508.0 | 6.4 | 79.2 ib | 10 |

| 500 | 20 | ib 508.0 | 9.5 ib | 117 | 20 |

| 500 | 20 | ib 508.0 | 12.7 ib | 155 | 30 |

| 500 | 20 | ib 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | ib 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | ib 508.0 | 26.2 ib | 311 | 80 |

| 550 | 22 | 558.8 ib | 6.4 | 87.2 ib | 10 |

| 550 | 22 | 558.8 ib | 9.5 ib | 129 | 20 |

| 550 | 22 | 558.8 ib | 12.7 ib | 171 | 30 |

| 550 | 22 | 558.8 ib | 15.9 ib | 213 | 40 |

| 600 | 24 | 609.6 ib | 6.4 | 95.2 ib | 10 |

| 600 | 24 | 609.6 ib | 9.5 ib | 141 | 20 |

| 600 | 24 | 609.6 ib | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 ib | 7.9 ib | 127 | 10 |

| 650 | 26 | 660.4 ib | 12.7 ib | 203 | 20 |

JIS G 3454 suav nrogteem caij 10, teem caij 20, teem caij 30, teem caij 40, teem caij 60, thiabteem caij 80.

Koj tuaj yeem nyem rau ntawm lub sijhawm No. koj xav pom; peb tau teeb tsa cov ntawv PDF sib xws rau koj qhov yooj yim.

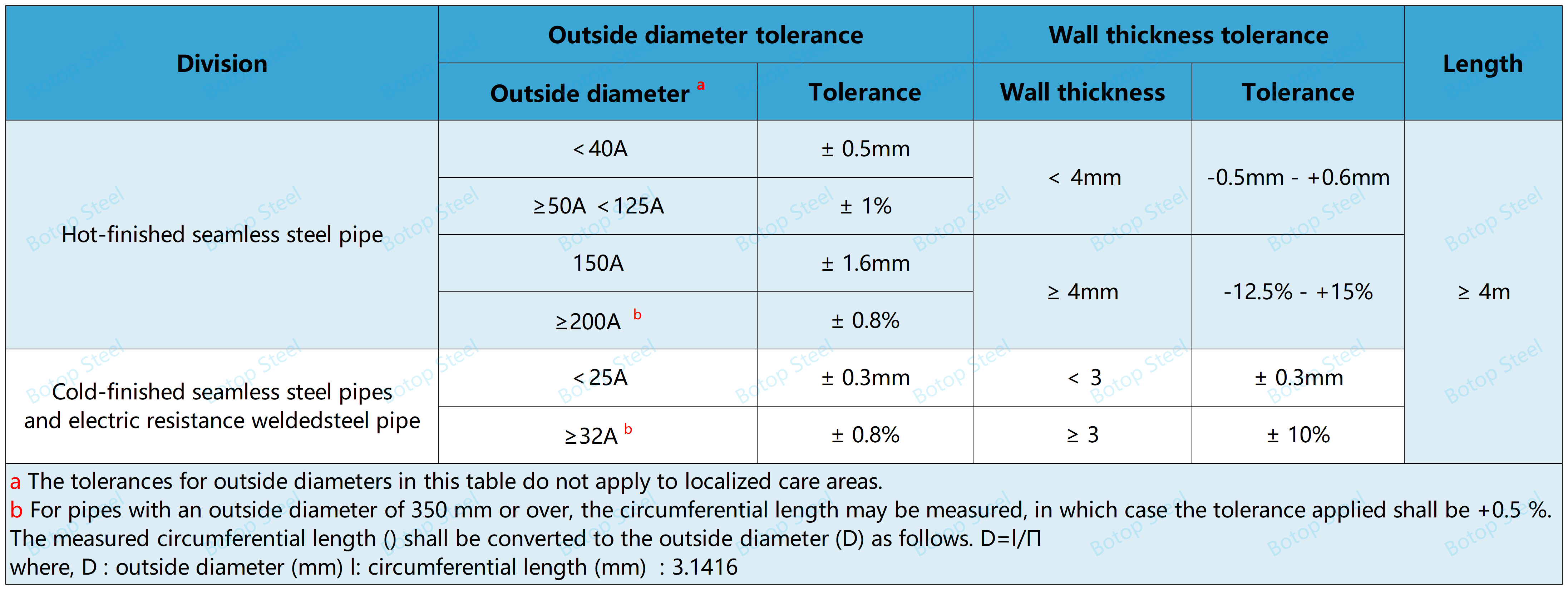

JIS G 3454 Kev kam rau siab rau sab nraud, phab ntsa thickness, eccentricity, thiab ntev yuav tsum ua raws li cov cai hauv qab no.

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua tus xa khoom ntawm carbon steel yeeb nkab nyob rau sab qaum teb Tuam Tshoj, paub txog kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem.

Lub tuam txhab muaj ntau yam carbon steel kav thiab lwm yam khoom, xws li seamless, ERW, LSAW, thiab SSAW steel yeeb nkab, raws li zoo raws li ib tug tag nrho lineup ntawm cov yeeb nkab fittings thiab flanges.

Nws cov khoom tshwj xeeb kuj suav nrog cov qib high-qib alloys thiab austenitic stainless hlau, tsim kom tau raws li qhov xav tau ntawm ntau yam kev siv kav dej.

Thov hu rau peb, peb yuav muab koj cov khoom zoo, txheem steel kav nrog kev tshaj lij thiab kev pabcuam zoo. Botop tos ntsoov yuav pab koj.