API (American Petroleum Institute Standard) 5L yog tus txheej txheem thoob ntiaj teb rau cov yeeb nkab steel siv hauv cov kav dej thauj mus los.

API 5L npog steel yeeb nkab rau ntau yam kev siv rau kev thauj mus los ntawm cov pa roj, roj, thiab lwm yam kua.Hnub pib siv ntawm 46th tsab: pib lub Kaum Ib Hlis 1, 2018.

Yog tias koj tsuas yog xav tau lub tswv yim dav dav ntawm API 5L, thov nyemAPI 5L Pipe Specification Txheej txheem cej luam.

Navigation Khawm

Dab tsi tau hloov kho hauv API 5L 46th

Keeb kwm ntawm API 5L PSL

Kev faib tawm ntawm cov qib steel thiab cov yeeb nkab qib

Txais Lub Xeev Xa Khoom

Raw Materials rau cov yeeb nkab steel

Hom Hlau Yeeb Nkab thiab Tube Xaus Npog los ntawm API 5L

Kev tsim cov txheej txheem rau PSL2 Steel Tubing

Kev tshuaj xyuas qhov tshwm sim thiab qhov tsis xws luag ntawm API 5L

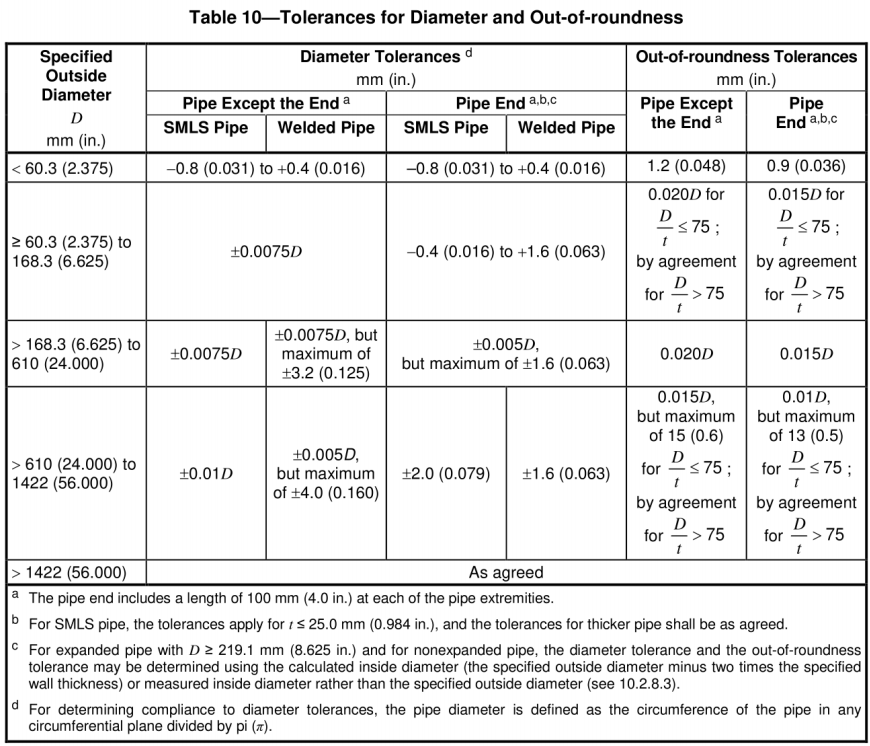

Dimensional Inspection (Dimensional Deviations)

API 5L Test Yam khoom

Pipe Marking thiab qhov chaw

Txuj kev sib npaug

Peb cov khoom muaj feem xyuam

Dab tsi tau hloov kho hauv API 5L 46th

Hloov tshiab

Hloov kho thiab nthuav cov kev cai rau cov pob qij txha milled;

Hloov kho cov cai rau cov yeeb nkab kawg perpendicularity;

Hloov kho hardness xeem yuav tsum tau rau API 5LPSL 2 kav rau qaub ib puag ncig thiab API 5L PSL 2 kav rau offshore ib puag ncig;

Tshiab

API 5L PSL 2 yeeb nkab rau cov ntawv thov uas xav tau cov yas yas ntev ntev.

Keeb kwm ntawm API 5L PSL

PSL: Pipeline Specification Level abbreviation;

Muab faib rau: API 5L PSL 1 thiab API 5L PSL 2.

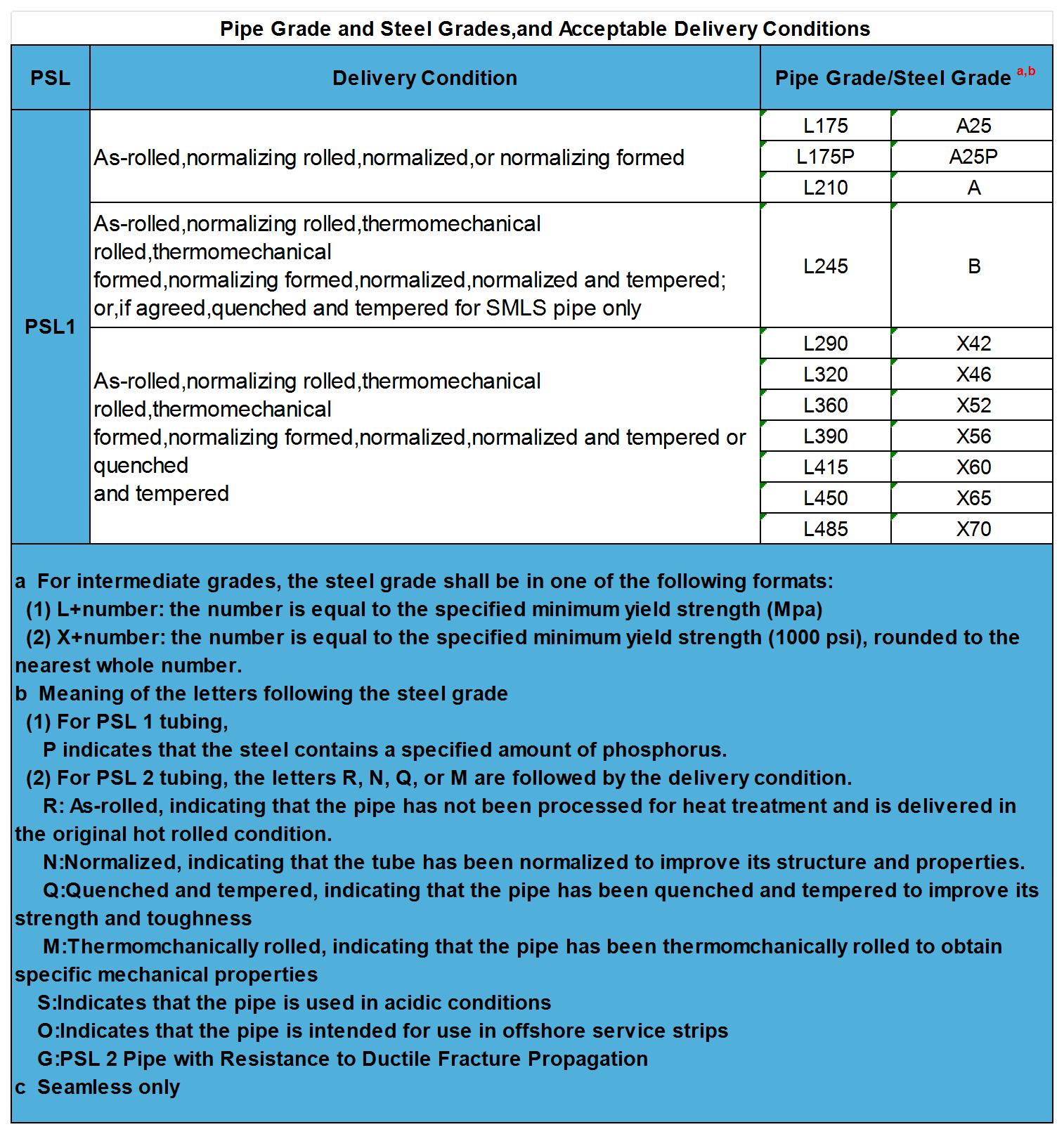

Kev faib tawm ntawm cov qib steel thiab cov yeeb nkab qib

L + num( tsab ntawv L yog ua raws li qhov tsawg kawg nkaus yield zog hauv MPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + num(tus lej tom qab tsab ntawv X qhia qhov tsawg kawg nkaus yield zog hauv 1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Thiab qib a thiab qib b.Qib A = L210 Qib B = L 2459

Kev lees txais lub xeev

Lus Cim: L415/X60 lossis qib siab dua yuav tsum tsis txhob siv rau qhov L360/X52 lossis qib qis dua yam tsis muaj kev pom zoo ntawm tus neeg yuav khoom.

Raw Materials rau cov yeeb nkab steel

Ingot, billet, billet, strip (coil) los yog phaj.

Nco tseg:

1. Cov khoom siv raw rauAPI 5L PSL2steel yeeb nkab yuav tsum zoo-grain sedimented steel.

2. Hlau sawb (coil) los yog phaj siv rau kev tsim cov API 5L PSL2 steel yeeb nkab yuav tsum tsis txhob dais tack welds.

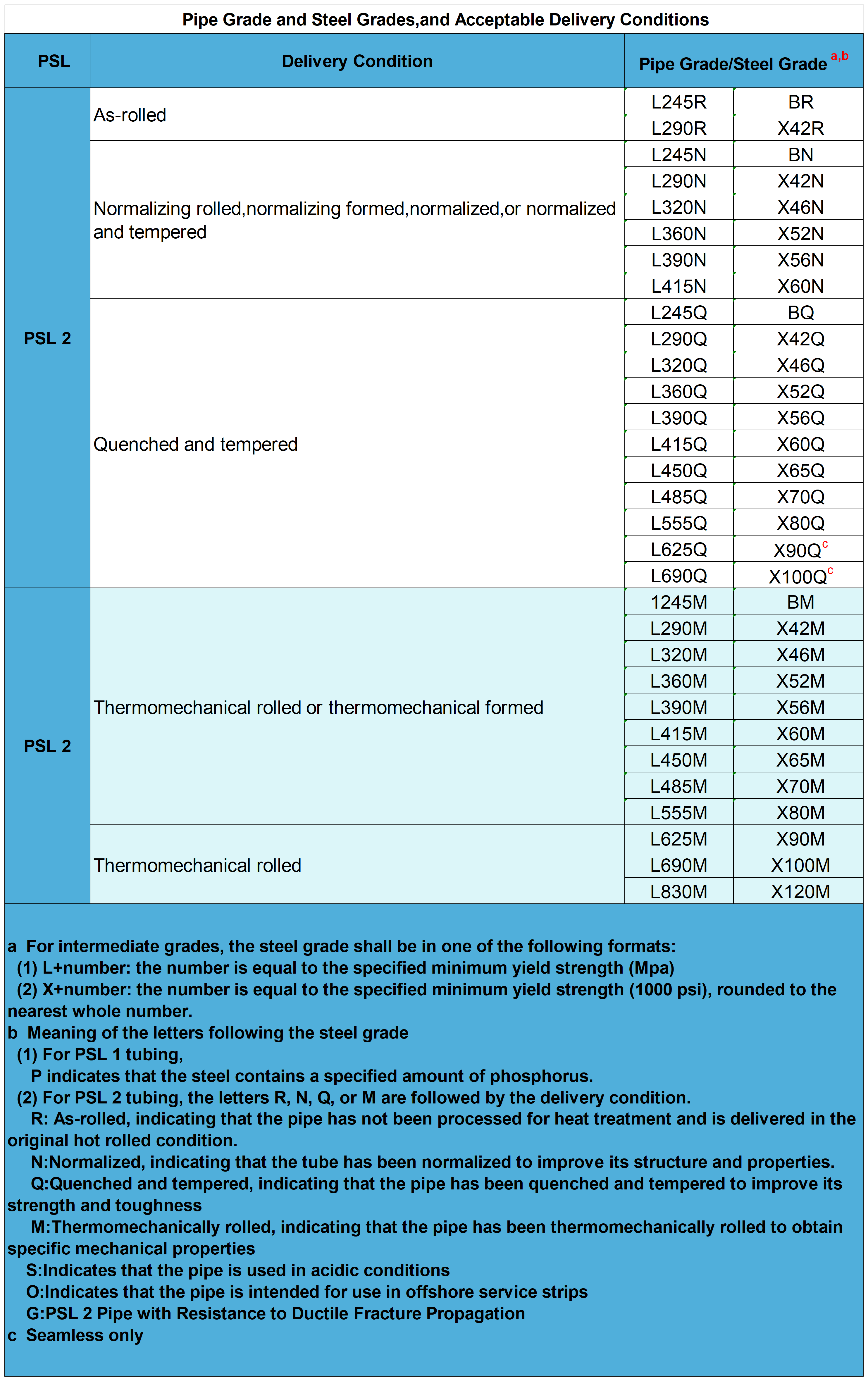

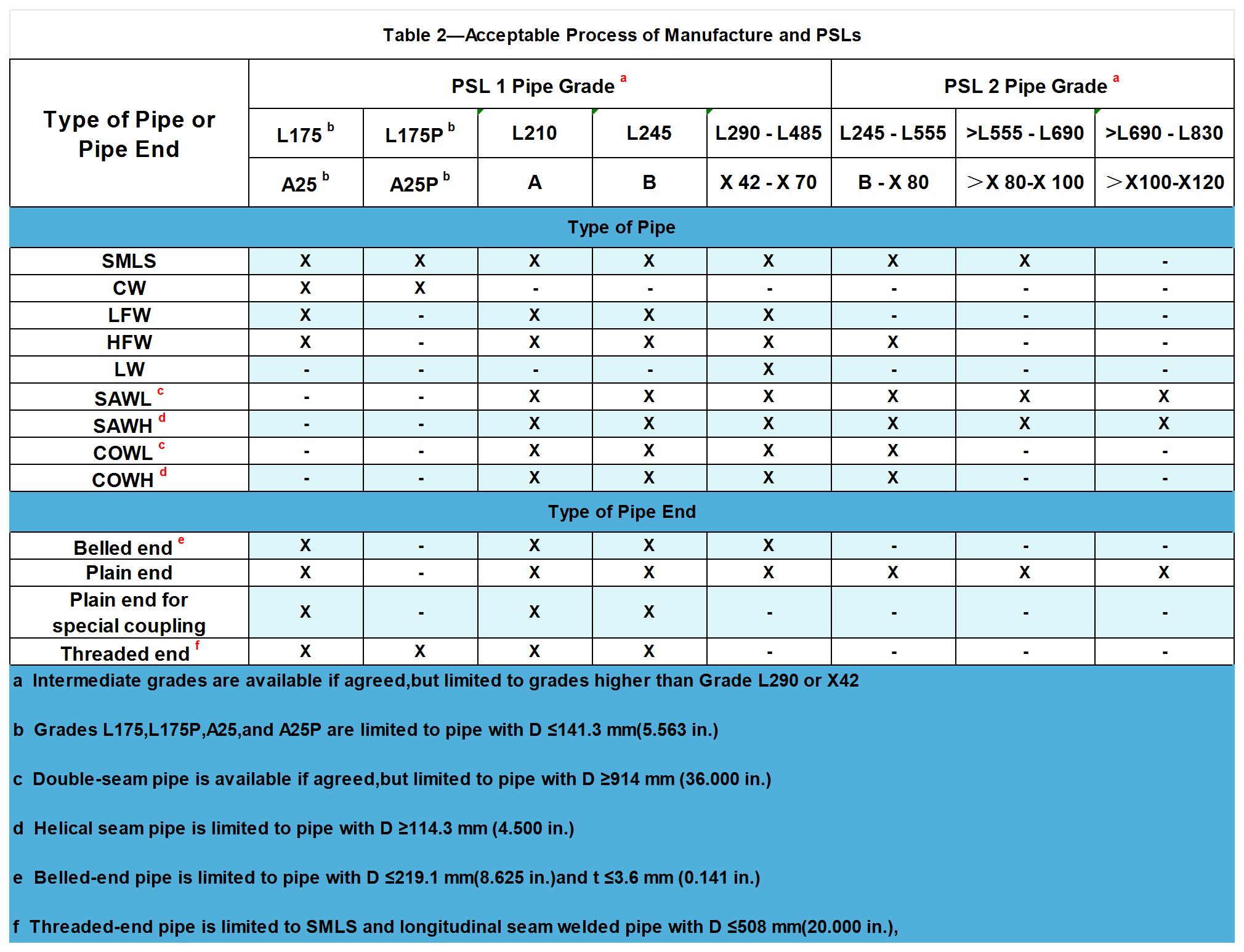

Hom Hlau Yeeb Nkab thiab Tube Xaus Npog los ntawm API 5L

Welded steel yeeb nkab

CW Tube:Txheej txheem ntawm kev tsim cov seam los ntawm cua sov lub sawb nyob rau hauv lub cub tawg thiab mechanically nias lub tsim edgestogether, nyob rau hauv successive coils ntawm lub sawb tau koom ua ke los muab ib tug nruam ntws ntawm strip rau vuam zeb.

COVPip:Tubular cov khoom uas muaj ib tug helical seam ua los ntawm ib tug ua ke ntawm roj arc hlau arc thiab submerged arc vuam, nyob rau hauv cov pa roj arc vuam hlaws yog tsis tag tshem tawm los ntawm lub submerged arc vuam hlaws.

COWL Cov yeeb nkab:Tubular cov khoom uas muaj ib los yog ob longitudinal seams tsim los ntawm ib tug ua ke ntawm cov roj hlau arc thiab submerged arc vuam, nyob rau hauv cov roj hlau arc weld hlaws tsis tag tshem tawm los ntawm submerged arc vuam hla dhau.

EW Tube:Tubular khoom uas muaj ib tug longitudinal seam tsim los ntawm tsawg-los yog high-frequency hluav taws xob vuam.

HFW Tube:EWpipe tsim 'nrog lub vuam tam sim no zaus sib npaug los yog ntau dua 70 kHz.

LFW Tube:EW yeeb nkab yog tsim nrog vuam tam sim no zaus ntawm tsawg dua 70 kHz.

LW cev:Tubular khoom muaj ib tug longitudinal seam ua los ntawm laser vuam.

SAWH Pipe:Tubular khoom muaj ib tug helical seam ua los ntawm submerged arc vuam txheej txheem.

SAWLCov yeeb nkab:Tubular khoom uas muaj ib los yog ob longitudinal seams ua los ntawm submerged arc vuam.

Seamless Steel Yeeb Nkab

SMLS cev:Kub dov seamless steel yeeb nkab thiab txias dov seamless steel yeeb nkab, muaj ib co lwm txoj kev, xws li txias drawing, txias drawing, forging, thiab lwm yam.

API 5L PSL2 Yeeb Nkab hom rau kev siv tshwj xeeb

Resistance to Ductile Fracture Propagation (G)

Sour Service Condition Pipe (S)

Offshore Service Condition Pipe (O)

Yuav tsum tau Longitudinal Yas Strain Capacity Pipe

Pipe End Hom

Qhov (Socket End), Flat End, Tshwj Xeeb Clamp Flat End, Threaded End.

Nco tseg:

1. Qhov (socket) xaus, yeeb nkab kawg rau cov clamps tshwj xeeb, thiab cov yeeb nkab threaded kawg yog rau API 5L PSL1 nkaus xwb.

2. L175 P/A25 P steel qib API 5L PSL1 steel yeeb nkab yuav tsum tau machined nrog threaded xaus, thiab API 5L PSL1 steel yeeb nkab ntawm lwm qib steel yuav tsum machined nrog flat ends.

3. API 5L PSL 2 raj yuav tsum tau xa nrog lub tiaj tiaj.

Kev tsim cov txheej txheem rau PSL2 Steel Tubing

| Table 3—Txoj Kev Ua Tau Zoo rau PSL 2 Yeeb Nkab | ||||

| Hom yeeb nkab | Pib Materia | Yeeb nkab txoj kev | Cov yeeb nkab kub Kev kho mob | Kev xa khoom Qhov xwm txheej |

| SMLS | Ingot, paj, los yog billet | Raws li dov | — | R |

| Normalizing tsim | — | N | ||

| Kub sib sau | normalizing | N | ||

| Quenching thiab tempering | Q | |||

| Kub sib sau thiab txias ua tiav | normalizing | N | ||

| Quenching thiab tempering | Q | |||

| HFW | Normalizing-dov coil | Txias txoj kev | Kev kho cua sova ntawm weld cheeb tsam nkaus xwb | N |

| Thermomechanical-kuav los tiag coil | Txias txoj kev | Kev kho cua sova ntawm weld cheeb tsam nkaus xwb | M | |

| Kev kho cua sova ntawm weld cheeb tsam thiab kev ntxhov siab relieving ntawm tag nrho cov yeeb nkab | M | |||

| Raws li dov los yog thermomechanical-dov coil | Txias txoj kev | normalizing | N | |

| Quenching thiab tempering | Q | |||

| Txias txoj kev ua raws li kub txo nyob rau hauv kev tswj kub ua rau normalized mob | — | N | ||

| Cold forming ua raws li thermomechanical txoj kev o cev | — | M | ||

| SAW los yog COV | Normalized los yog normalizing- dov kauj los yog phaj | Txias txoj kev | — | N |

| Raws li dov thermomechanical-kuav los tiag normalizing-dov, los yog normalized | Txias txoj kev | normalizing | N | |

| Thermomechanical-kuav los tiag coil los yog phaj | Txias txoj kev | — | M | |

| Quenched thiab tempered phaj | Txias txoj kev | — | Q | |

| Raws li dov thermomechanical-kuav los tiag normalizing-dov, los yog normalized coil los yog phaj | Txias txoj kev | Quenching thiab tempering | Q | |

| Raws li dov thermomechanical-kuav los tiag normalizing-dov, los yog normalized coil los yog phaj | Normalizing tsim | — | N | |

| aSaib ISO 5L 8.8 rau kev kho cua sov | ||||

Kev tshuaj xyuas qhov tshwm sim thiab qhov tsis xws luag ntawm API 5L

Qhov tshwm sim

Sab nrauv ntawm cov yeeb nkab yuav tsum du thiab tsis muaj qhov tsis xws luag uas yuav cuam tshuam rau lub zog thiab kev sib khi ntawm cov yeeb nkab.

Qhov Tseem Ceeb

Nibbled edges:Nibbled npoo tuaj yeem pom zoo los ntawm kev kuaj pom.

Arc hlawv:Arc kub hnyiab yuav tsum raug txiav txim raws li qhov tsis zoo.

Arc burns yog ib tug xov tooj ntawm localized chaw tsis xws luag tsim los ntawm melting ntawm hlau nto los ntawm lub arc ntawm lub electrode los yog grounding electrode thiab nto ntawm cov yeeb nkab steel.

Cov chaw sib cuag yog qhov chaw sib tshuam nyob ze ntawm txoj kab vuam ntawm EW yeeb nkab, tshwm sim los ntawm kev sib cuag ntawm electrode muab cov vuam tam sim no thiab qhov chaw ntawm cov yeeb nkab.

Delamination:Ib qho kev delamination lossis suav nrog uas txuas mus rau saum npoo ntawm cov yeeb nkab lossis lub ntsej muag beveled thiab yog> 6.4 mm (0.250 in) nyob rau hauv qhov ntev ntawm qhov kev tshuaj ntsuam pom yuav tsum suav tias yog qhov tsis xws luag.

Geometric sib txawv:Ib qho kev sib txawv ntawm geometric (piv txwv li, ib lub tiaj tiaj lossis pout, thiab lwm yam), uas tsis yog lub qhov dej poob, tshwm sim los ntawm txoj kev ua cov raj raj lossis kev tsim khoom.Qhov kev ncua deb ntawm qhov taw tes huab thiab qhov txuas ntxiv ntawm lub cev contour ntawm lub raj, piv txwv li, qhov tob tshaj 3.2 hli (0.125 hauv), yuav tsum suav tias yog qhov tsis xws luag.

Poob qhov yuav tsum yog ≤ 0.5 D nyob rau hauv txhua qhov kev taw qhia.

Hardness: Thaum kev soj ntsuam pom pom pom tias muaj kev nyuaj siab, yuav tsum tau siv lub hardness tester los ua qhov kev ntsuam xyuas hardness, thiab ib qho taw tes indentation nrog tus nqi hardness ntau tshaj 35 HRC, 345 HV10, los yog 327 HBW yuav tsum raug xam tias muaj teeb meem thaum loj. ntawm qhov indentation yog ntau tshaj 50 mm (2.0 in) nyob rau hauv ib qho kev taw qhia.

Kev Kho Mob

Thov xa mus rau qhov yuav tsum tau muaj nyob rau hauv API 5L Appendix C rau kev tuav.

Dimensional Inspection (Dimensional Deviations)

Pipe Weight Chart thiab Weight Deviation

Qhov hnyav Formula

M = (DT) × T × C

M yog qhov loj ntawm ib chav tsev ntev;

D yog qhov qhia tawm sab nraud, qhia hauv millimeters (inch);

T yog qhov tshwj xeeb phab ntsa thickness, qhia hauv millimeters (inch);

C yog 0.02466 rau kev suav hauv SI units thiab 10.69 rau kev suav hauv USC units.

PIPE WEIGHT charts thiab Teem sijhawm

yeeb nkab luj rooj hauv API 5L yog hais txogISO 4200 UASthiabASME B36.10M, uas muab cov qauv tsim nyog rau cov yeeb nkab nrog cov txheej txheem sab nraud thiab cov phab ntsa tuab.

Teem caij 40 thiab Teem caij 80tau txuas hauv qab no, yog tias koj xav pom cov yeeb nkab puv sijhawm,thov nias ntawm no!

Qhov hnyav sib txawv

Qhov zoo ntawm txhua cov yeeb nkab txheeb ze rau qhov theoretical: hnyav: 95% ≤ theoretical hnyav ≤ 110;

Kev sib txawv thiab cov raj tshwj xeeb tshwj xeeb: 5% ≤ 110% ntawm qhov ntsuas qhov ntsuas;

L175, L175P, A25, thiab A25P steel qib: 95% ≤ 110% ntawm qhov hnyav theoretical.

Sab nraud txoj kab uas hla thiab phab ntsa Thickness Range

| Table 9 - Tso cai qhia tawm sab nraud thiab qhia txog phab ntsa tuab | ||

| Specified Sab Nraud Diameter D mm (hauv.) | Specified Phab ntsa Thickness t mm (hauv.) | |

| Qhov loj me tshwj xeeba | Qhov ntau thiab tsawg | |

| ≥10.3 (0.405) rau <13.7 (0.540) | — | ≥1.7 (0.068) txog 2.4 (0.094) |

| ≥13.7 (0.540) rau <17.1 (0.675) | — | ≥2.2 (0.088) txog 3.0 (0.118) |

| ≥17.1 (0.675) rau <21.3 (0.840) | — | ≥2.3 (0.091) txog 3.2 (0.125 |

| ≥21.3 (0.840) rau <26.7 (1.050) | — | ≥2.1 (0.083) txog 7.5(0.294) |

| ≥26.7(1.050) rau <33.4(1.315) | — | ≥2.1 (0.083) txog 7.8 (0.308) |

| ≥33.4(1311}5) rau <48.3 (1.900) | — | ≥2.1 (0.083) txog ≤10.0 (0.394) |

| ≥48.3 (1.900) rau <60.3 (2.375) | — | ≥2.1 (0.083) txog ≤12.5 (0.492) |

| ≥60.3 (2.375) rau <73.0 (2.875) | ≥2.1 (0.083) txog 3.6 (0.141) | > 3.6 (0.141) txog ≤14.2 (0.559) |

| ≥73.0 (2.875) rau <88.9(3.500) | ≥2.1 (0.083) txog 3.6 (0.141) | > 3.6 (0.141) txog ≤20.0 (0.787) |

| ≥88.9 (3.500) rau <101.6(4.000) | ≥2.1 (0.083) txog 4.0 (0.156) | > 4.0 (0.156) txog ≤22.0 (0.866) |

| ≥101.6 (4.000) rau <168.3 (6.625) | ≥2.1 (0.083) txog 4.0 (0.156) | > 4.0(0.156) txog ≤25.0 (0.984) |

| ≥168.3 (6.625) rau <219.1 (8.625) | ≥2.1 (0.083) txog 4.0 (0.156 | > 4.0 (0.156) txog ≤40.0(1.575) |

| ≥219.1 (8.625) rau <273.1 (10.750) | ≥3.2 (0.125) txog 4.0 (0.156 | > 4.0 (0.156) txog ≤40.0 (1.575 |

| ≥273.1 (10.750) rau <323.9 (12.750) | ≥3.6 (0.141) txog 5.2 (0.203) | > 5.2 (0.203) txog ≤45.0 (1.771) |

| ≥323.9(12.750) rau <355.6(14.000) | ≥4.0 (0.156) txog 5.6 (0.219) | > 5.6 (0.219) rau <45.0(1.771 |

| ≥355.6(14.000) rau <457(18.000) | ≥4.5 (0.177) txog 7.1 (0.281) | > 7.1 (0.281) to <45.0(1.771 |

| ≥457 (18.000) rau <559 (22.000) | ≥4.8 (0.188) txog 7.1 (0.281) | > 7.1 (0.281) txog ≤45.0(1.771) |

| ≥559 (22,000) rau <711(28,000) | ≥5.6 (0.219) txog 7.1 (0.281) | > 7.1 (0.281) txog ≤45.0(1.771) |

| ≥711 (28.000) rau <864(34.000) | ≥5.6(0.219) txog 7.1 (0.281) | > 7.1 (0.281) txog ≤52.0 (2.050) |

| ≥864 (34.000) rau <965(38.000) | — | ≥5.6 (0.219) txog 52.0 (2.050) |

| ≥965 (38.000) rau <1422 (56.000) | — | ≥6.4 (0.250) txog 52.0 (2.050) |

| ≥1422 (56.000) rau <1829 (72.000) | — | ≥9.5 (0.375) txog ≤52.0 (2.050 |

| ≥1829(72.000) rau <2134(84.000) | — | ≥10.3 (0.406) txog ≤52.0 (2.050) |

| aCov yeeb nkab uas muaj qhov sib xyaw ua ke ntawm txoj kab uas hla sab nraud thiab cov phab ntsa tuab yog txhais tau tias yog cov yeeb nkab tshwj xeeb lub teeb loj;lwm cov kev sib xyaw ua ke muab rau hauv cov lus no txhais tau tias yog cov kav dej tsis tu ncua. | ||

Diameter thiab Roundness Deviation

Phab ntsa Thickness Deviation

| Table 11 — Kev kam rau siab rau phab ntsa tuab | |

| Phab ntsa Thickness t mm (hauv.) | Tolerancesa mm (hauv.) |

| SMLS cevb | |

| ≤4.0 (0.157) | +0.6 (0.024) -0.5 (0.020) |

| > 4.0 (0.157) rau <25.0 (0.984) | +0.150t -0.125 t |

| ≥25.0 (0.984) | +3.7 (0.146) lossis + 0.1t, qhov twg yog qhov ntau dua -3.0 (0.120) lossis -0.1t, qhov twg yog qhov ntau dua |

| Welded yeeb nkabcd | |

| ≤5.0 (0.197) | ± 0.5 hli (0.020) |

| > 5.0 (0.197) txog <15.0 (0.591) | ± 0.1t |

| ≥15.0 (0.591) | ± 1.5 (0.060) |

| aYog hais tias qhov kev txiav txim yuav qhia txog qhov kev zam txim rau cov phab ntsa tuab me dua li cov nqi siv tau muab rau hauv cov lus no, qhov ntxiv rau kev kam rau cov phab ntsa tuab yuav tsum tau nce ntxiv los ntawm tus nqi txaus los tswj cov kev kam rau siab. bRau cov yeeb nkab nrog D2 355.6 mm (14.000 in.) thiab 1 2 25.0 mm (0.984 in.), phab ntsa thickness kam rau ua hauv zos tuaj yeem tshaj qhov ntxiv rau cov phab ntsa thickness los ntawm ib qho ntxiv 0.05t, muab qhov ntxiv rau qhov loj (saib 9.14) tsis tshaj. cQhov ntxiv kam rau ua rau phab ntsa thickness tsis siv rau qhov chaw weld. dSaib 9.13.2 rau kev txwv ntxiv. | |

Ntev Deviation

Taag-ntev tubing tolerances: Ntev sib txawv yuav tsum yog 500 hli (20 nti).

Random ntev yeeb nkab tolerances:

| Table 12—Kev kam rau siab rau Random Length Pipe | |||

| Random Ntev Lub npe m (ft) | Yam tsawg kawg nkaus m (ft) | Yam tsawg kawg nruab nrab ntev Rau txhua yam khoom xaj m (ft) | Qhov siab tshaj plaws m (ft) |

| Threaded-thiab-coupled Pipe | |||

| 6 (20) | 4.88 (16.0) Nws. | 5.33 (17.5) Nws. | 6.86 (22.5 hli) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2 Nws) | 10.29 (33.8) Nws. |

| 12 (40) | 6.71 (22.0) Nws. | 10.67 (35.0) Nws. | 13.72 (45.0 Nws |

| Plain-end Pipe | |||

| 6 (20) | 2.74 (9.0) Nws. | 5.33 (17.5) Nws. | 6.86 (22.5 hli) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2 Nws) | 10.29 (33.8) Nws. |

| 12 (40) | 4.27 (14.0 Nws | 10.67 (35.0) Nws. | 13.72 (45.0) Nws. |

| 15 (50) | 5.33 (17.5) Nws. | 13.35 (43.8) Nws. | 16.76 (55.0) Nws. |

| 18 (60) | 6.40 (21.0 Nws | 16.00 (52.5 Nws.) | 19.81 (65.0) Nws. |

| 24 (80) | 8.53 (28.0) Nws. | 21.34 (70.0) Nws. | 25.91 (85.0) Nws. |

Kev ncaj ncees Deviation

Tag nrho qhov sib txawv ntawm txoj kab ncaj nraim rau tag nrho qhov ntev ntawm cov yeeb nkab yuav tsum yog <0.2% ntawm cov yeeb nkab ntev;

Kev sib txawv hauv zos los ntawm txoj kab ncaj nraim yuav tsum yog <3.2 hli (0.125 hauv) tshaj li 1.5 m (5.0 ft) ntev ntawm txhua cov yeeb nkab kawg.

Bevel lub kaum sab xis

Tube nrog t> 3.2 hli (0.125 nyob rau hauv) ca xaus yuav tsum tau machined nrog ib tug weld bevel nrog ib tug bevel kaum ntawm 30 ° -35 °.

Dav ntawm Develed Root Surface

1.6 hli (0.063 hauv) nrog qhov sib txawv ntawm ± 0.8 hli (0.031 hauv).

Ntau yam ntawm Sab Hauv Lub khob hliav qab (tsuas yog rau seamless steel yeeb nkab)

| Table 13-Qhov siab tshaj plaws ntawm Sab Hauv Taper rau SMLS Yeeb Nkab | |

| Specified Phab ntsa Thickness t mm (hauv.) | Qhov siab tshaj plaws ntawm Taper qib |

| <10.5(0.413) | 7.0 ib |

| 10.5 (0.413) rau <14.0 (0.551) | 9.5 ib |

| 14.0 (0.551) rau <17.0 (0.669) | 11.0 Nws |

| ≥17.0 (0.669) | 14.0 Nws |

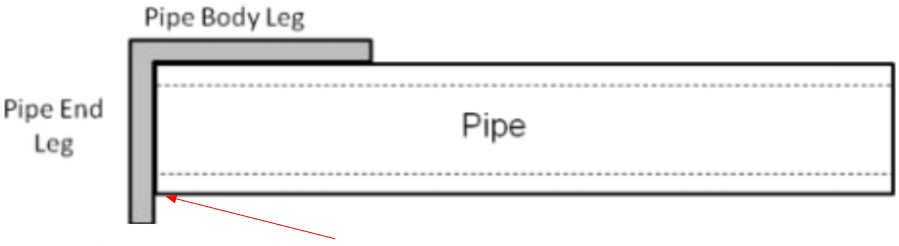

Pipe End Squareness (tawm-ntawm-squareness)

Qhov tawm ntawm-squareness yog ntsuas raws li qhov sib txawv ntawm qhov kawg ntawm cov yeeb nkab thiab cov yeeb nkab kawg ceg, uas yuav tsum yog 1.6 hli (0.063 nyob rau hauv.).

Vuam Seam Deviation

Sawb / Sheet Misalignment:

Rau electro-welded (EW) thiab laser-welded (LW) yeeb nkab, lub misalignment yuav tsum tsis txhob ua rau ib tug seem phab ntsa thickness ntawm weld uas yog tsawg tshaj li qhov tsawg kawg nkaus tso cai phab ntsa thickness.

Rau Submerged Arc Welded (SAW) thiab Combination Welded (COW) yeeb nkab, qhov kev ua tsis zoo yuav tsum tsis pub tshaj qhov sib thooj qhov tseem ceeb hauv Table 14 ntawm API 5L.

Burrs (Electro-welded (EW) thiab laser-welded (LW) raj):

Sab nrauv burrs yuav tsum tau muab tshem tawm mus rau qhov dej ntws tawm (nrog rau cov khoom siv hauv paus).

Internal burrs yuav tsum tsis txhob ncua 1.5 hli (0.060 nyob rau hauv) tshaj lub contour ntawm lub raj, thiab phab ntsa thickness ntawm lub point ntawm burr tshem tawm yuav tsum tsis txhob tsawg tshaj li qhov tsawg kawg nkaus tso cai phab ntsa thickness.

Weld Qhov siab(Submerged Arc Welding (SAW) thiab Combination Welding (COW) Pipe):

Tshem tawm qhov siab ntawm qhov txuas sab hauv qhov tsawg kawg nkaus ntawm 100 hli (4.0 hauv) ntawm cov yeeb nkab kawg ntawm txhua qhov kawg ntawm cov yeeb nkab, thiab zom cov vuam kom tsis txhob nce siab tshaj 0.5 hli (0.020 hauv) saum npoo. ntawm cov yeeb nkab uas nyob ib sab.

API 5L Test Yam khoom

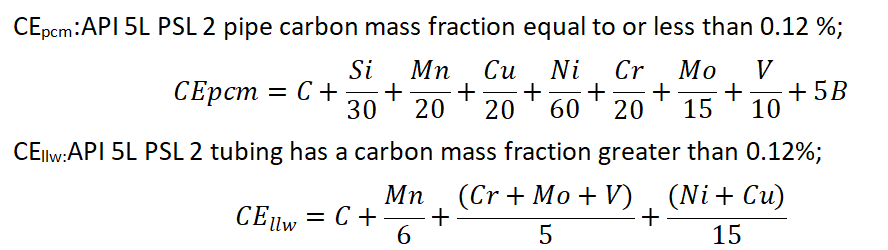

Tshuaj muaj pes tsawg leeg

Txoj Kev Xeem: Xa mus rau ISO 9769 lossis ASTM A751.

Cov tshuaj muaj pes tsawg leeg ntawm API 5L PSL1 thiab API 5L PSL2 steel yeeb nkab t> 25.0 mm (0.984 nyob rau hauv) yuav tsum tau txiav txim los ntawm kev sib tham raws li cov tshuaj muaj nyob rau hauv cov rooj sib tham.

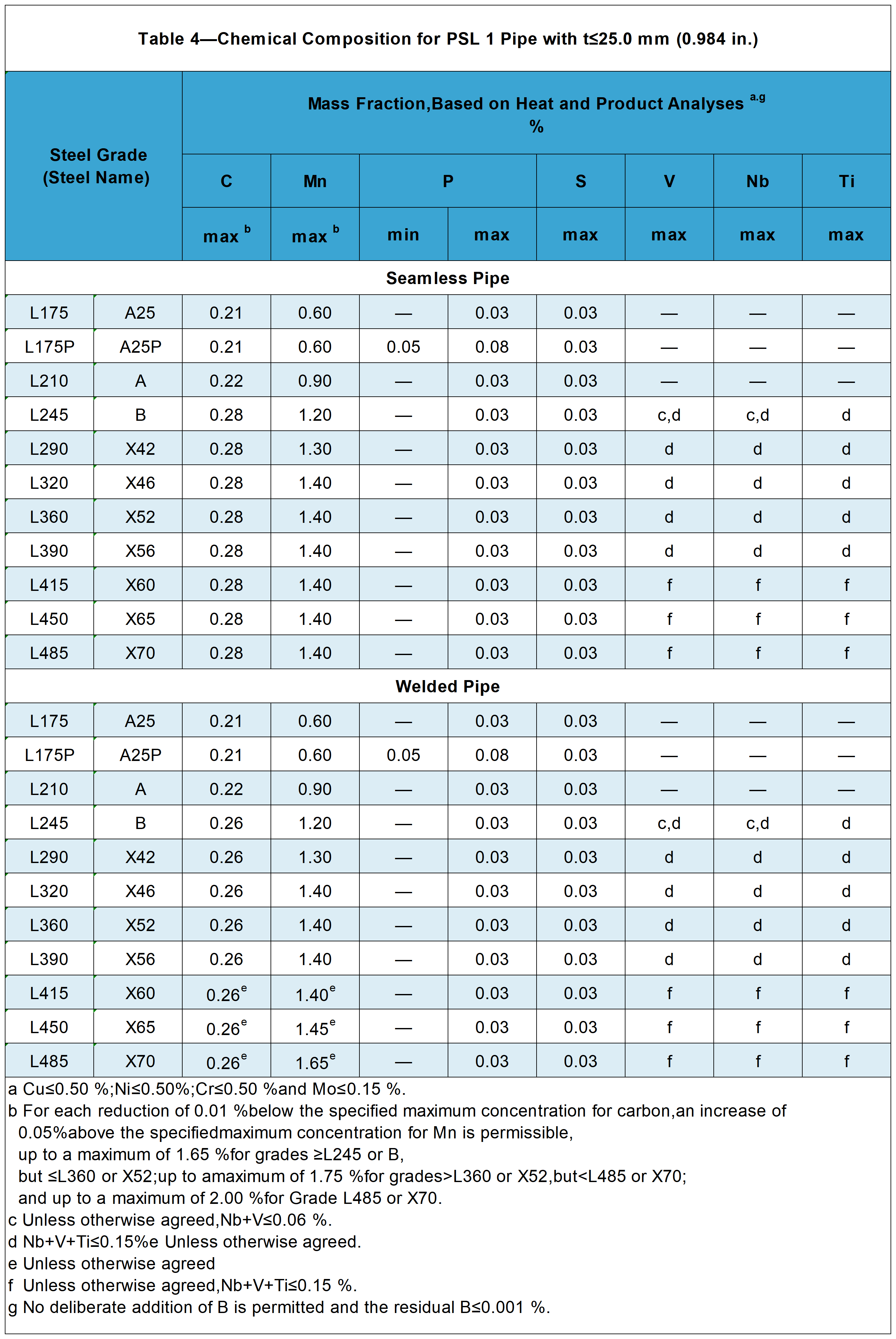

Tshuaj muaj pes tsawg leeg rau PSL 1 Pipe nrog t≤25.0 mm (0.984 in.)

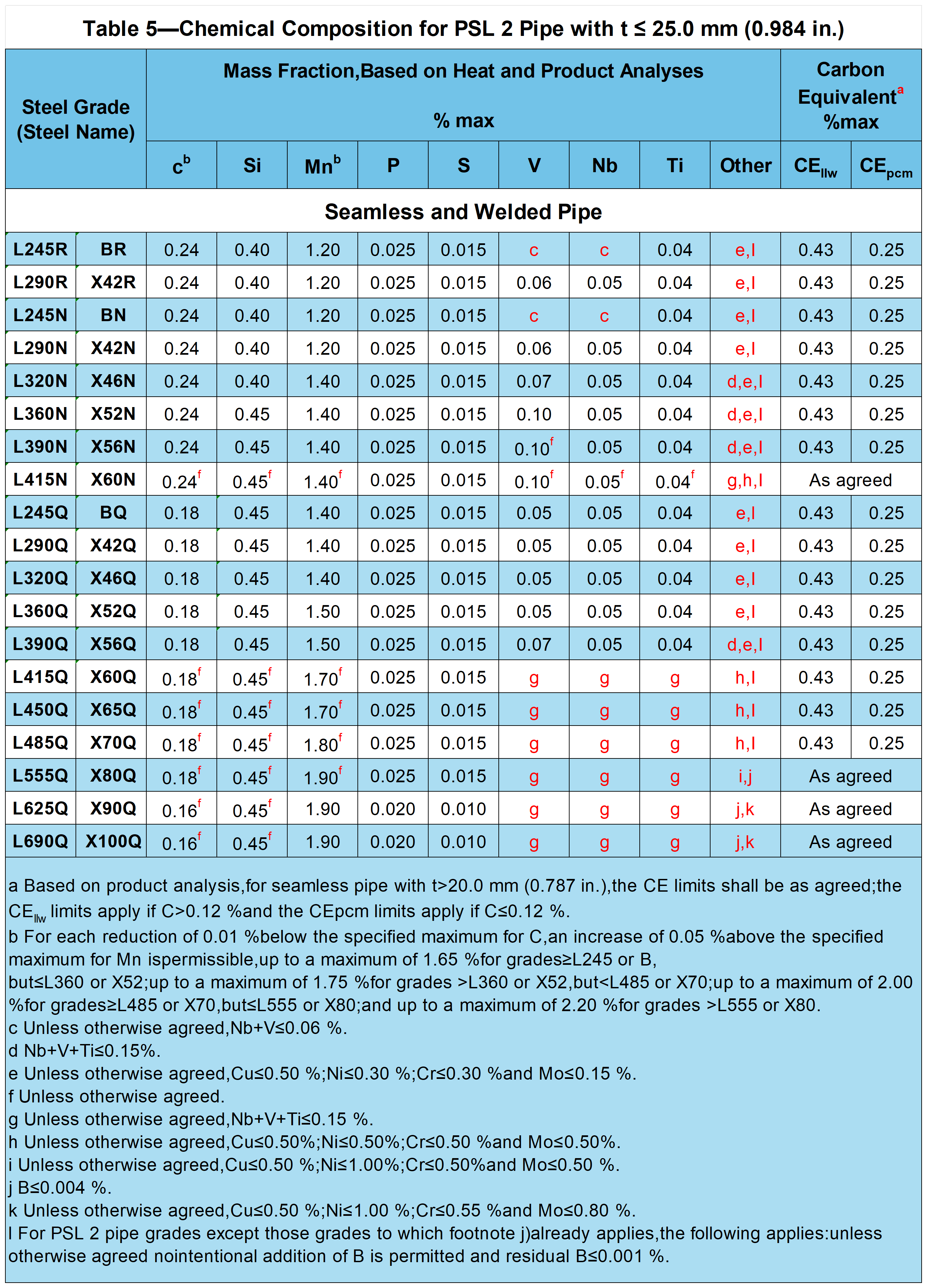

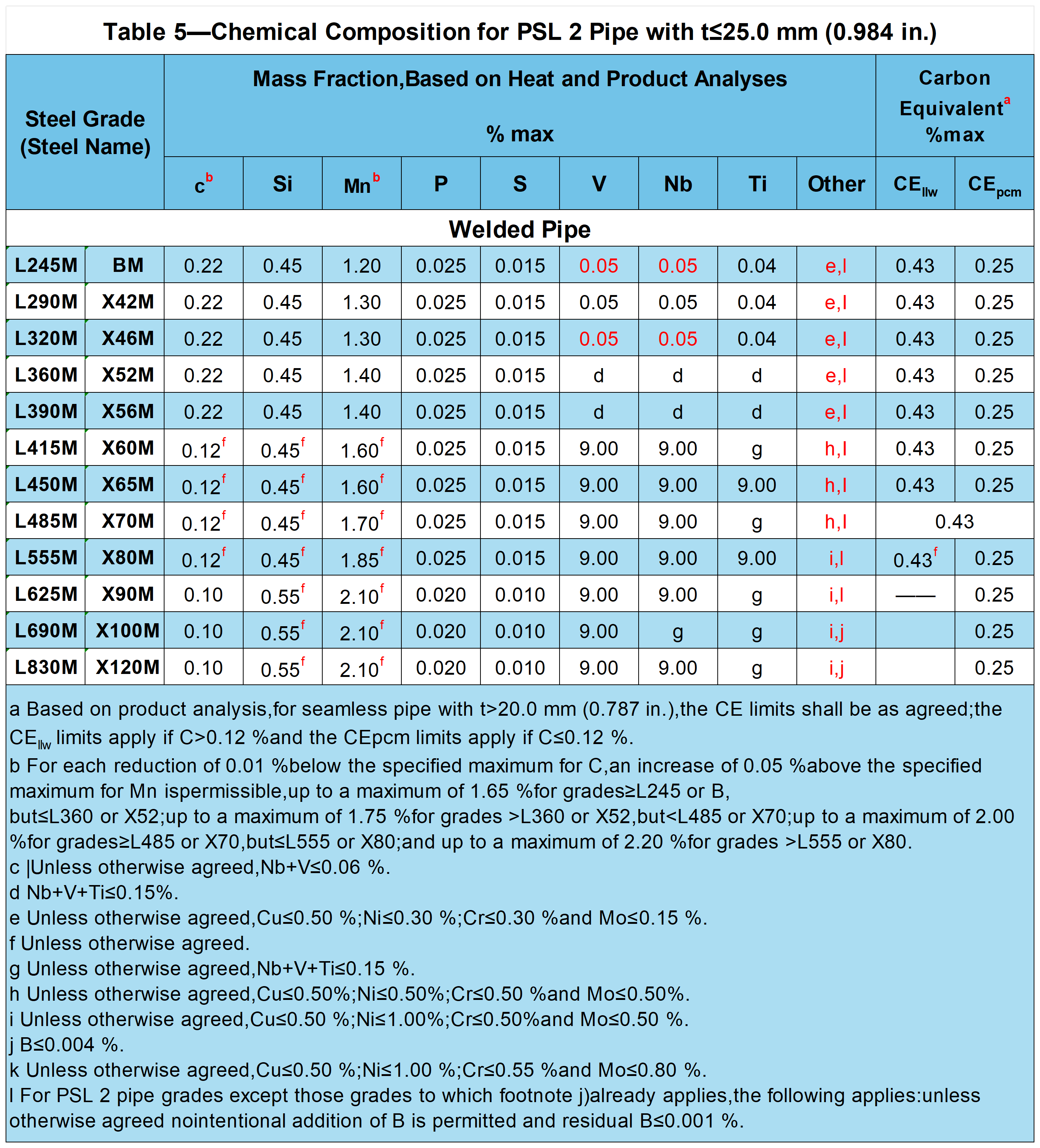

Tshuaj muaj pes tsawg leeg rau PSL 2 yeeb nkab nrog t≤25.0 hli (0.984 nyob rau hauv.)

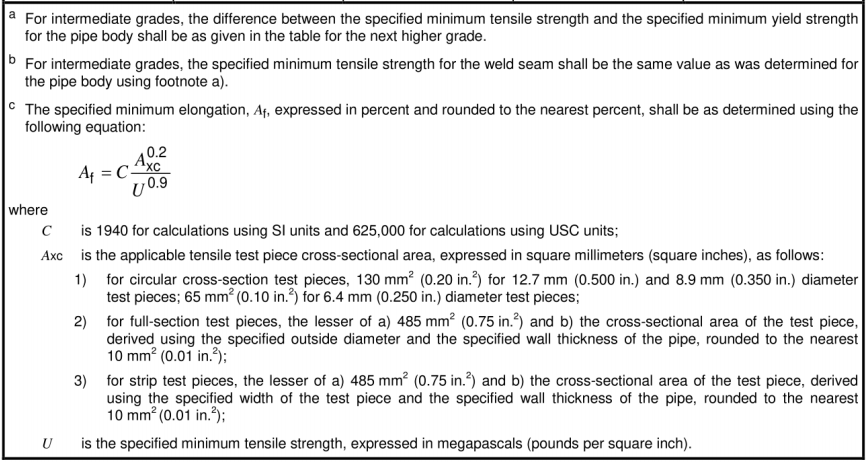

Tensile Properties

Txoj Kev Xeem: Yuav tsum ua raws li ISO 6892-1 lossis ASTM A370.

Qhov yuav tsum tau ua rau cov txiaj ntsig ntawm Tensile Test rau PSL 1 Pipe

| Table 6—Yuav tsum muaj rau cov txiaj ntsig ntawm Tensile Test rau PSL 1 Pipe | ||||

| Qib Qib | Lub cev ntawm Seamless thiab Welded Yeeb Nkab | Weld Seam ntawm EW, LW, SAW, and COW Pipe | ||

| Yield zoga Rrau.5 MPa (psi) | Tensile zoga Rm MPa (psi) | Elongation (50mm lossis 2 nti) Af % | Tensile zogb Rm MPa (psi) | |

| min | min | min | min | |

| L175 los yog A25 | 175 (25,400) hnub | 310 (45,000) | c | 310 (45,000) |

| L175P los yog A25P | 175 (25,400) hnub | 310 (45,000) | c | 310 (45,000) |

| L210 los yog A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 los yog B | 245 (35,500) | 415 (60,200) hnub | c | 415 (60,200) hnub |

| L290 los yog X42 | 290 (42,100) hnub | 415 (60,200) hnub | c | 415 (60,200) hnub |

| L320 los yog X46 | 320 (46,400) hnub | 435 (63,100) hnub | c | 435 (63,100) hnub |

| L360 los yog X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) teev |

| L390 los yog X56 | 390 (56,600) teev | 490 (71,100) hnub | c | 490 (71,100) hnub |

| L415 los yog X60 | 415 (60,200) hnub | 520 (75,400) hli | c | 520 (75,400) hli |

| L450 los yog X65 | 450 (65,300) | 535 (77,600) | c | 535 (77,600) |

| L485 los yog X70 | 485 (70,300) hnub | 570 (82,700) | c | 570 (82,700) |

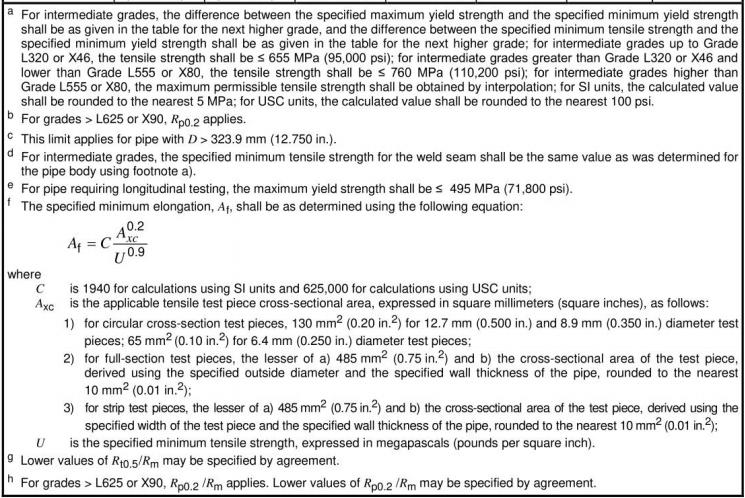

Qhov yuav tsum tau ua rau cov txiaj ntsig ntawm Tensile Test rau PSL 2 Yeeb Nkab

| Table 7—Yuav tsum muaj rau cov txiaj ntsig ntawm Tensile Test rau PSL 2 Yeeb Nkab | |||||||

| Qib Qib | Lub cev ntawm Seamless thiab Welded Yeeb Nkab | Weld Seam ntawm HFW SAW thiab CoW tub | |||||

| Yield zoga Rto.5 MPa (psi) | Tensile zoga Rm MPa (psi) | Piv txwvac Rt0,5 ua/Rm | Elongation (ntawm 50 mm los yog 2 in.) Af % | Tensile Lub zogd Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R los yog BR L245N or BN L245Q los yog BQ L245M or BM | 245 (35.500) | 450 (65.300) Nws.e | 415 (60.200) | 655 (95,000) | 0.93 ua | f | 415 (60.200) |

| L290R or X42R L290N or X42N L290Q los yog X42Q L290M or X42M | 290 (42.100) Nws. | 495 ib (71.800) Nws. | 415 (60.200) | 655 (95,000) | 0.93 ua | f | 415 (60.200) |

| L320N or X46N L320Q or X46Q L320M or X46M | 320 (46.400) Nws. | 525 (76.100) Nws. | 4 35 (63.100) Nws. | 655 (95,000) | 0.93 ua | f | 4 35 (63.100) Nws. |

| L360N or X52N L360Q or X52Q L360M or X52M | 360 (52.200) | 530 (76.900) Nws. | 460 (66.700) Nws. | 760 ib (110.200) Nws. | 0.93 ua | f | 460 (66.700) Nws. |

| L390N or X56N L390Q or X56Q L390M or X56M | 390 (56.600) | 545 ib (79,000) | 490 ib (71.100) Nws. | 760 ib (110.200) Nws. | 0.93 ua | f | 490 ib (71.100) Nws. |

| L390N or X56N L390Q or X56Q L390M or X56M | 390 (56.600) | 545 ib (79,000) | 490 ib (71.100) Nws. | 760 ib (110.200) Nws. | 0.93 ua | f | 490 ib (71.100) Nws. |

| L415N or X60 N L415Q or X60 Q L415M or X60M | 415 (60.200) | 565 ib (81.900) | 520 (75.400) Nws. | 760 ib (110.200 Nws | 0.93 ua | f | 520 (75.400) Nws. |

| L450Q or X65Q L450M or X65M | 450 (65.300) Nws. | 600 (87,000) | 5 35 (77.600) Nws. | 760 ib (110.200) Nws. | 0.93 ua | f | 5 35 (77.600) Nws. |

| L485Q or X70 Q L485M or X70M | 485 ib (70.300) Nws. | 6 35 (92.100) Nws. | 570 ib (82,700) | 760 ib (110.200) Nws. | 0.93 ua | f | 570 ib (82,700) |

| L555Q or X80Q L555M or X80M | 555 (80,500) | 705 ib (102.300 Nws.) | 625 (90,600) | 825 ib (119.700 Nws.) | 0.93 ua | f | 625 (90,600) |

| L625M or X90M | 625 (90,600) | 775 ib (112.400 Nws.) | 695 ib (100.800) | 915 ib (132.700 Nws.) | 0.95 ib | f | 695 ib (100.800) |

| L625Q or X90 Q | 625 (90,600) | 775 ib (112.400 Nws.) | 695 ib (100.800) | 915 ib (132.700 Nws.) | 0.97 ibg | f | — |

| L690M or X100M | 690 ib (100,000)b | 840 ib (121.800 Nws.)b | 760 ib (110.200) Nws. | 990 ua (143.600) Nws. | 0.97 ibh | f | 760 ib (110.200) Nws. |

| L690Q or X100Q | 690 ib (100,000) b | 840 ib (121.800 Nws.)b | 760 ib (110.200) Nws. | 990 ua (143.600) Nws. | 0.97 ibh | f | — |

| L830M or X120M | 8 30 (120.400) Nws.b | 1050 (152.300 Nws.)b | 915 ib (132.700 Nws.) | 1145 ib (166.100) Nws. | 0.97 ibh | f | 915 ib (132.700 Nws.) |

Qhov feem pua elongation ntawm kev tawg yuav tsum tau tshaj tawm rau cov qauv nrog lub ntsuas qhov ntev ntawm 50 mm (2 in).

Rau cov qauv nrog lub ntsuas qhov ntev tsawg dua 50 hli (2 hauv), elongation ntawm kev tawg yuav tsum tau hloov mus rau elongation ntawm 50 hli (2 hauv) raws li ISO 2566-1 lossis ASTM A370.

Hydrostatic Pressure Test

Txoj Kev Xeem: API 5L 10.2.6.

Txhua qhov ntau thiab tsawg ntawm seamless (SMLS) yeeb nkab thiab welded yeeb nkab nrog D ≤ 457 hli (18.000 hauv) yuav tsum muaj lub sijhawm ruaj khov tsis pub tsawg tshaj 5 vib nas this.welded yeeb nkab nrog D> 457 hli (18.000 hauv) yuav tsum muaj lub sijhawm ruaj khov tsis pub tsawg tshaj 10 vib nas this.

Khoov Test

Test Methods: Kev xeem dabtsi yog khoov yuav tsum ua raws li cov cai ntawm ISO 8491 lossis ASTM A370.

Tsis muaj ib feem ntawm cov qauv yuav tsum tawg thiab lub vuam yuav tsis tawg.

Qib L175P / A25P yog phosphorus-txhim kho hlau uas muaj kev ua haujlwm zoo dua qub dua li L175 / A25 steel tab sis nyuaj dua rau khoov.

Flattening Test

Txoj Kev Xeem: Kev ntsuas compression yuav tsum ua raws li cov kev cai ntawm ISO 8492 lossis ASTM A370.

Qhov kev ncua deb ntawm ob daim hlau yuav tsum yog tias tsis muaj qhov tawg ntawm qhov vuam yuav tshwm sim kom txog rau thaum qhov kev ncua deb tau mus txog.

Guided Bending Test

Txoj Kev Xeem: Cov kev taw qhia khoov yuav tsum ua raws li cov cai ntawm ISO 5173 lossis ASTM A370.

Hardness Test

Kev xeem txoj kev: Hardness test raws li ISO 6506, ISO 6507, ISO 6508, los yog ASTM A370.

Thaum pom cov pob txha tsis txaus ntseeg nyob rau hauv qhov kev tshuaj ntsuam xyuas, yuav tsum tau siv lub hardness tester portable hardness tester.

CVN Impact Test rau API 5L PSL2 Steel Pipe

Kev Ntsuas Cov Txheej Txheem: Kev ntsuas qhov cuam tshuam charpy yuav tsum ua tau raws li cov cai ntawm ASTM A370.

DWT Test rau API 5L PSL2 Welded Yeeb Nkab

Txoj kev xeem: Kev xeem DWT yuav tsum ua raws li API5 L3.

Macro-Inspection thiab Metallographic Test

Sab hauv thiab sab nraud weld deviations ntawm submerged arc welded (SAW) thiab combi-welded (COW) yeeb nkab yuav tsum raug kuaj xyuas los ntawm kev tshuaj xyuas macroscopic.

Rau cov raj uas xav tau kev kho cua sov, kev kuaj xyuas hlau yuav tsum tau ua kom paub tseeb tias tag nrho HAZ tau raug kho kom zoo nyob rau hauv tag nrho cov phab ntsa thickness.

Rau cov raj uas tsis xav tau kev kho cua sov, kev kuaj xyuas metallographic yuav tsum tau ua kom paub tseeb tias tsis muaj qhov seem uas tsis muaj martensite.

Kev Ntsuas Tsis Zoo (tsuas yog rau peb lub hom phiaj tshwj xeeb API 5L PSL2 kav)

Test method: API 5L Annex E.

Pipe Marking thiab qhov chaw

Common marking ntsiab rau steel raj:

Pipe Chaw tsim tshuaj paus lub npe lossis kos npe;

Kos npe "API Spec 5L".(Feem ntau abbreviated rau API 5L.) Cov khoom ua raws li ntau tshaj ib tus qauv siv tau yuav raug cim nrog lub npe ntawm txhua tus qauv.

Specified Sab Nraud Diameter

Specified phab ntsa thickness

Qib yeeb nkab (steel name)

Hom yeeb nkab

Length (cov kav dej ntev hauv m mus rau qhov ze tshaj 0.01 m (hauv ft mus rau qhov ze tshaj kaum ntawm ko taw))

Qhov chaw ntawm cov yeeb nkab steel markings

D ≤ 48.3 hli (1.900 nyob rau hauv) steel yeeb nkab: Tabs uas txuas ntxiv tsim raws li qhov ntev ntawm cov yeeb nkab steel lossis uas tuaj yeem ruaj ntseg rau cov yeeb nkab steel.

Cov yeeb nkab nrog D> 48.3 hli (1.900 hauv):

Sab nrauv: Pib ntawm ib qho taw tes ntawm sab nraud ntawm cov yeeb nkab ntawm 450 mm thiab 760 mm (1.5 ft thiab 2.5 ft) los ntawm ib kawg ntawm cov yeeb nkab.

Sab hauv nto: Pib kos rau sab hauv ntawm cov yeeb nkab yam tsawg kawg 150 hli (6.0 nyob rau hauv) los ntawm ib kawg ntawm cov yeeb nkab.

Txuj kev sib npaug

Cov qauv thoob ntiaj teb thiab hauv cheeb tsam cov yeeb nkab thiab raj cov qauv uas API 5L yog qhov sib npaug lossis, nyob rau qee qhov xwm txheej, ib qho kev xaiv, nrog rau ntau cov qauv kev thov tshwj xeeb:

International thiab regional qauv

1. ISO 3183 - Cov kav dej thoob ntiaj teb rau kev lag luam roj thiab roj luam tawm los ntawm Lub Koom Haum Thoob Ntiaj Teb rau Kev Tswj Xyuas Txheej Txheem thiab ze ze rau API 5L.

2. EN 10208 - European Standard rau cov kav hlau rau kev thauj mus los ntawm cov roj av thiab cov kua dej.

3. GB / T 9711 - Suav teb tus qauv rau kev thauj mus los hauv cov kav dej hauv kev lag luam roj thiab roj.

4. CSA Z245.1 - Canadian Standard npog kab yeeb nkab rau kev thauj mus los ntawm cov roj thiab roj.

5. GOST 20295 - Lavxias teb sab Standard rau steel kab yeeb nkab rau kev thauj mus los ntawm cov roj thiab cov khoom siv roj.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards rau kab yeeb nkab rau kev lag luam roj thiab roj.

7. JIS G3454, G3455, G3456 - Japanese Industrial Standards rau kis tau tus mob ntawm cov chav kawm siab sib txawv.

8. DIN EN ISO 3183 - German Industrial Standard raws li ISO 3183 rau kab yeeb nkab.

9. AS 2885 - Australian Standard rau kab yeeb nkab tshuab rau kev thauj mus los ntawm roj thiab roj.

Application Specific Standards

1. API 5CT - American Petroleum Institute standard for oil well casing and tubing, uas, txawm tias feem ntau siv hauv cov roj qhov dej, kuj tseem ceeb hauv kev lag luam roj thiab roj.

2. ASTM A106 - American Society for Testing and Materials standard for seamless and welded carbon steel pipe for high-temperature service.

3. ASTM A53 - National Institute for Testing and Materials standard for seamless and welded carbon steel yeeb nkab, feem ntau yog siv rau kev thauj mus los ntawm cov dej hauv chav tsev kub lossis qis dua.

4. ISO 3834 - Lub koom haum thoob ntiaj teb rau Standardization tus qauv rau cov kev xav tau zoo, tsom mus rau kev ruaj ntseg zoo rau cov hlau welded.

5. dnv-os-f101 - Norwegian kev faib tawm haiv neeg tus qauv rau submarine piping systems rau offshore roj thiab roj xa mus pipelines.

6. MSS SP-75 - Manufacturers Cov Txheej Txheem Koom Tes tus qauv tsom rau lub zog siab, txoj kab loj loj ncig welded steel yeeb nkab fittings.

Kev Tswj Xyuas Kev Tswj Xyuas Zoo thiab Environmental Suitability Standards

1. NACE MR0175 / ISO 15156 - Cov khoom siv rau cov khoom siv hauv cov roj thiab cov roj rho tawm hauv qhov chaw muaj sulfur-muaj hydrocarbon ib puag ncig, uas, tshwj xeeb tshaj yog cov kev xaiv ntawm cov khoom siv, yog qhov tseem ceeb rau kev ua kom muaj kev tiv thaiv corrosion ntawm cov khoom siv hauv kev lag luam roj thiab roj.

Peb cov khoom muaj feem xyuam

API 5L PSL1 & PSL2 GR.B Longitudinal Submerged-arc Welded yeeb nkab

API 5L GR.B X60 X65 X70 PSL1 / PSL 2 LSAW Carbon Steel Pipe

API 5L GR.B Hnyav Phab Ntsa Thickness Seamless Steel Yeeb Nkab rau Mechanical Processing

API 5L Gr.X52N PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 rau kev pabcuam qaub

API 5L X42-X80 / API 5L X52 / PSL1 & PSL2 Roj thiab Roj Carbon Seamless Steel Yeeb Nkab

API 5L GR.B Seamless Kab Yeeb Yeeb Nkab rau Kev Ruaj Ntseg thiab Cov Qauv

API 5L / ASTM A106 / ASTM A53 Gr.B Seamless Carbon Steel Yeeb Nkab

BotopSteel yog Tuam Tshoj ProfessionalWelded Carbon Steel Pipes Chaw tsim tshuaj paus & tsumTshaj 16 Xyoo nrog 8000+ Tons ntawm Seamless Linepipe hauv Tshuag Txhua Lub Hlis.Peb npaj tau teb rau koj hauv 24 ob peb teev sai sai tom qab tau txais ib qho kev thov thiab tseem yuav txhim kho kev sib nrig tsis txwv qhov zoo thiab lub koom haum nyob ib ncig ntawm lub peev xwm.

Tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,lwm tus neeg, manufacturers, factories, stockists, tuam txhab uas muag, wholesale, muas, nqe, hais, tej, muag, nqi.

Post lub sij hawm: Mar-22-2024