AS/NZS 1163qhia txog qhov txias-tsim, tiv taus-welded, structural steel hollow yeeb nkab seem rau kev siv cov qauv thiab engineering yam tsis muaj kev kho cua sov tom qab.

Cov txheej txheem siv tau rau Australia thiab New Zealand.

Navigation Khawm

Kev faib tawm los ntawm Kev Sib Txuas Sib Txuas

AS/NZS 1163 Intermediate Qib Classification

Raw Khoom

Kev tsim khoom

AS/NZS 1163 Chemical Composition

AS/NZS 1163 Tensile Test

AS/NZS 1163 Impact Test

Txias Flattening Test

Kev xeem tsis muaj kev puas tsuaj

Tolerances rau cov duab thiab pawg

Tolerance ntawm Ntev

AS/NZS 1163 SSHS Daim Ntawv Teev Npe ntawm Cov Yeeb Nkab Loj thiab Cov Khoom hnyav suav nrog

Kev kho cov khoom siv sab nrauv thiab kho kom zoo nkauj

Galvanized

AS/NZS 1163 Marking

Daim ntawv thov ntawm AS/NZS 1163

Peb cov khoom muaj feem xyuam

Kev faib tawm los ntawm Kev Sib Txuas Sib Txuas

Peb hom hauv AS / NZS 1163 tuaj yeem raug cais raws li cov duab ntawm ntu ntu, uas yog:

Circular hollow seem (CHS)

Rectangular hollow seem (RHS)

Square Hollow Sections (SHS)

Lub hom phiaj ntawm tsab xov xwm no yog los piav qhia txog cov kev cai rau cov raj steel nrog cov voj voog hollow seem.

AS/NZS 1163 Intermediate Qib Classification

Peb qib nyob rau hauv AS / NZS 1163 raws li qhov tsawg kawg nkaus yield zog (MPA) ntawm cov khoom tiav:

C250, C350 thiab C450.

Ua raws li 0 ℃ low-temperature impact test grade that the steel pipe can meet:

C250L0, C350L0 thiab C450L0.

Tus qauv kuj tseem hais tias txoj hauv kev yog los qhia txog qib ntawm cov yeeb nkab steel yog:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Raw Khoom

kub dov coil los yog Cold-dov coil

Qhov txias-dov coil yog ib qho kub-dov coil uas tau raug txo qis qis dua li ntawm 15%.Lub kauj yuav tsum muaj lub voj voog subcritical annealing uas recrystallizes cov qauv thiab tsim cov ferrite tshiab.Cov txiaj ntsig tshwm sim zoo ib yam li kub-dov coil.

Fine-grained steel yog teev raws li raw khoom rau steel coils.Cov hlau uas muaj austenitic grain loj ntawm tus naj npawb 6 los yog finer thaum kuaj raws li AS 1733.

Cov hlau no yog tsim los ntawm Basic Oxygen Method (BOS) los yog Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob (EAF) cov txheej txheem thiab tuaj yeem ua kom zoo dua los ntawm Lub Nqus Arc Remelting (VAR), Electroslag Remelting (ESR), lossis los ntawm cov txheej txheem steel ua theem nrab xws li Nqus Degassing lossis Calcium Txhaj .

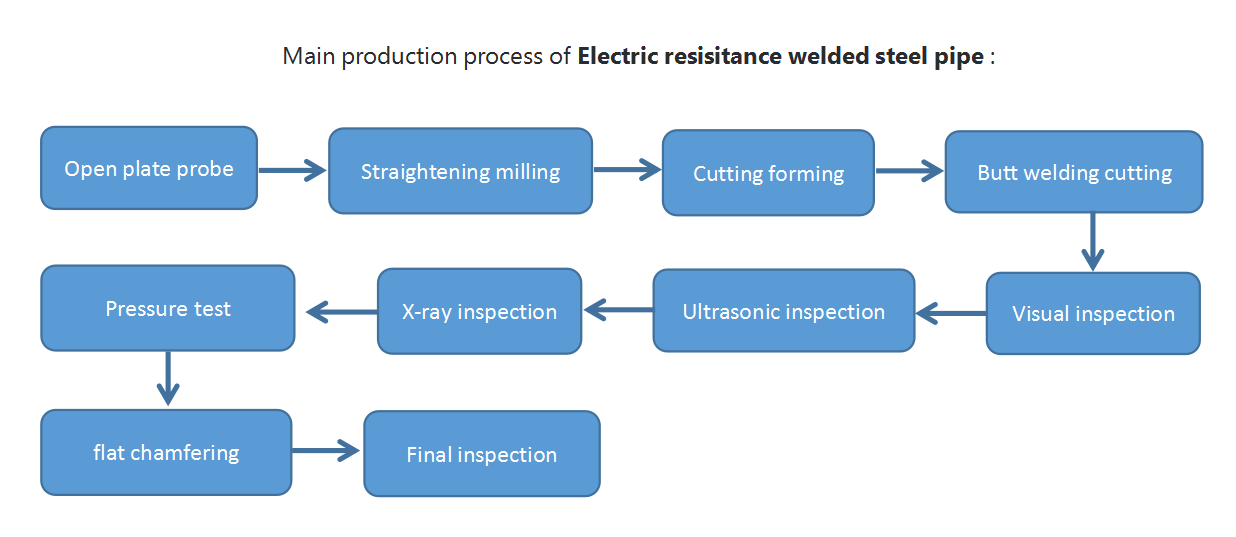

Kev tsim khoom

Cov khoom tiav hollow seem yuav tsum tau tsim los ntawm cov txheej txheem txias-forming thiab sivHluav taws xob tsis kam-welding (ERW)cov txheej txheem los koom nrog cov npoo npoo.

Lub weld seam yuav tsum tau longitudinal thiab yuav tsum tau tshem tawm sab nraud chim siab.

Yuav tsum tsis muaj kev kho cua sov tom ntej ntawm cov khoom tiav.

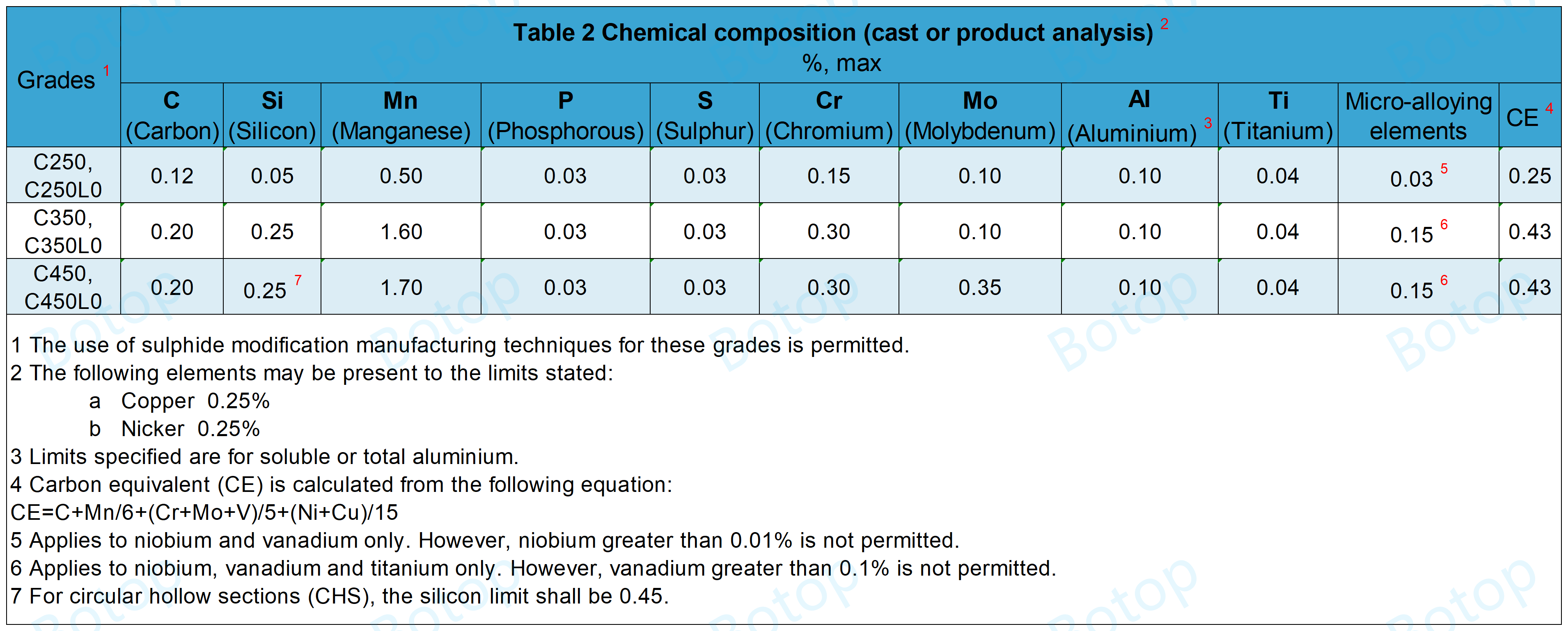

AS/NZS 1163 Chemical Composition

AS / NZS 1163 hauv kev kuaj tshuaj muaj pes tsawg leeg tau muab faib ua ob qhov xwm txheej:

ib rooj plaub yog cov ntaub ntawv raw rau kev kuaj tshuaj muaj pes tsawg leeg,

lwm yam yog cov tiav steel yeeb nkab tshuaj xyuas.

Casting Analysis ntawm hlau

Kev tsom xam ntawm cov hlau yuav tsum tau ua los ntawm txhua qhov cua sov los txiav txim qhov feem ntawm cov ntsiab lus.

Nyob rau hauv rooj plaub uas nws tsis tuaj yeem tau txais cov qauv los ntawm cov kua hlau, kev tshuaj xyuas ntawm cov qauv kuaj coj los ua raws li AS / NZS 1050.1 lossis ISO 14284 tuaj yeem raug tshaj tawm raws li kev tshuaj ntsuam cast.

Kev txheeb xyuas cov hlau yuav tsum ua raws li cov kev txwv rau cov qib uas tsim nyog tau muab rau hauvRooj 2.

Tshuaj ntsuam xyuas cov khoom tiav

AS/NZS 1163tsis tso cai kuaj tshuaj muaj pes tsawg leeg ntawm cov khoom kawg.

Yog tias kev sim ua tiav, nws yuav tsum ua raws li cov kev txwv uas tau muab rau hauvRooj 2thiab tolerances muab rau hauvTable 3.

| TABLE 3 Cov khoom lag luam tsom xam kam rau cov qib muab hauv Table 2 | |

| Lub ntsiab | Kev kam rau siab tshaj qhov siab tshaj plaws |

| C(Carbon) | 0.02 ib |

| Si(Silicon) | 0.05 Nws |

| Mn(Manganese) | 0.1 |

| P(phosphorus) | 0.005 ib |

| S(Sulphur) | 0.005 ib |

| Cr(Chromium) | 0.05 Nws |

| Ni(Nickel) | 0.05 Nws |

| Mo(Molybdenum) | 0.03 ib |

| Cu(Xov tooj) | 0.04 ib |

| AI(Aluminium) (tag nrho) | -0.005 Nws |

| Micro-alloying ntsiab (niobium thiab vanadium nkaus xwb) rauQib C250, C250L0 | 0.06 nrog niobium tsis ntau dua 0.020 |

| Micro-alloying ntsiab (niobium, vanadium, thiab titanium nkaus xwb) rau QibC350, C350L0, C450, C450L0 | 0.19 nrog vanadium tsis ntau tshaj 0.12 |

AS/NZS 1163 Tensile Test

Txoj kev sim: AS 1391.

Ua ntej qhov ntsuas tensile, cov qauv yuav tsum tau muab tso rau qhov kub tsis tshaj 15 min los ntawm qhov kub ntawm 150 ° C thiab 200 ° C.

| Qib | Yam tsawg kawg nkaus tawm los zog | Yam tsawg kawg nkaus tensile zog | Yam tsawg kawg nkaus elongation raws li kev faib ua feem ntawm qhov ntsuas qhov ntev ntawm 5.65√S0 | ||

| ua/t | |||||

| ≤ 15 | > 15 ≤ 30 | > 30 | |||

| MPA | MPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, c350l 0 | 350 | 430 | 16 | 18 | 20 |

| C450, c450l 0 | 450 | 500 | 12 | 14 | 16 |

AS/NZS 1163 Impact Test

Txoj kev sim: ntawm 0 ° C raws li AS 1544.2.

Ua ntej qhov kev ntsuam xyuas qhov cuam tshuam, cov qauv yuav tsum tau ua kom sov los ntawm qhov kub ntawm 150 ° C thiab 200 ° C tsis pub tsawg tshaj 15 min.

| Qib | Ntsuas kub | Yam tsawg kawg nkaus absorbed zog, J | |||||

| Qhov luaj li cas ntawm cov khoom xeem | |||||||

| 10mm × 10mm | 10mm × 7.5 hli | 10mm × 5mm | |||||

| Nruab nrab ntawm 3 xeem | Tus kheej xeem | Nruab nrab ntawm 3 xeem | Tus kheej xeem | Nruab nrab ntawm 3 xeem | Tus kheej xeem | ||

| C250L0 c350l 0 c450l 0 | 0 ℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Txias Flattening Test

Daim ntawv xeem yuav tsum flattened kom txog thaum qhov kev ncua deb ntawm qhov chaw yog 0.75 ua los yog tsawg dua.

Yuav tsum tsis muaj cov cim qhia ntawm cov kab nrib pleb lossis qhov tsis xws luag.

Kev xeem tsis muaj kev puas tsuaj

Raws li cov khoom tsis tas yuav tsum tau ua, welds nyob rau hauv hollow seem ntawm welded lug tej zaum yuav raug mus rau non-destructive ntsuam xyuas (NDE).

Tolerances rau cov duab thiab pawg

| Hom | Ntau yam | Ua siab ntev |

| Yam ntxwv | — | Circular hollow seem |

| Sab nraud qhov ntev (ua) | — | ± 1%, nrog qhov tsawg kawg nkaus ntawm ± 0.5 hli thiab siab tshaj ± 10 hli |

| Thickness (t) | ua ≤ 406,4 mm | 土 10% |

| ua 406,4mm | ± 10% max ± 2 hli | |

| Kev tsis sib haum xeeb (o) | Sab nraud txoj kab uas hla (bo) / phab ntsa thickness (t) ≤100 | ± 2% |

| Kev ncaj | tag nrho ntev | 0.20% |

| Loj (m) | teev hnyav | ≥96% |

Thickness:

Lub thickness (t) yuav tsum tau ntsuas ntawm qhov chaw ntawm tsis tsawg tshaj li 2t (Lub ntsiab lus ntawm 2x phab ntsa thickness) los yog 25 hli, qhov twg tsawg dua, los ntawm weld seam.

out-of-roundness:

Lub out-of-roundness (o) yog muab los ntawm: o = (domax- uamin) / ua × 100

Tolerance ntawm Ntev

| Hom ntev | Ntau yam m | Ua siab ntev |

| Random ntev | 4m mus 16m ib thaj tsam ntawm 2m per xaj khoom | 10% ntawm cov khoom xa tuaj yuav qis dua qhov tsawg kawg nkaus rau qhov kev txiav txim ntau tab sis tsis pub tsawg dua 75% ntawm qhov tsawg kawg nkaus |

| ntev tsis tau teev tseg | TAG NRHO | 0 - + 100 hli |

| Precision ntev | ≤ 6m | 0 - + 5mm |

| 6m ≤ 10m | 0 - + 15mm | |

| ; 10 m | 0 - + (5 + 1mm / m) hli |

AS/NZS 1163 SSHS Daim Ntawv Teev Npe ntawm Cov Yeeb Nkab Loj thiab Cov Khoom hnyav suav nrog

Hauv AS/NZS 1163, cov npe ntawm cov kab mob khaub thuas-tsim qauv hollow seem (SSHS) hauv Australia thiab New Zealand tau muab.

Cov npe no muab cov npe ntu, qhov ntau thiab tsawg ntawm nominal, seem yam ntxwv, thiab qhov zoo.

| Sab nraud txoj kab uas hla | Thickness | Massperunitength | Sab nraud thaj chaw saum npoo | Piv txwv | |

| do | t | ib chav tsev ntev | ib unit mass | ||

| mm | mm | kg/m | m² / m | m²/t | ua/t |

| 6 10.0 | 12.7 TSI | 187 | 1.92 ib | 10.2 | 48.0 Nws |

| 6 10.0 | 9.5 TSI | 141 | 1.92 ib | 13.6 | 64.2 ib |

| 6 10.0 | 6.4 TSI | 95.3 ua | 1.92 ib | 20.1 | 95.3 ua |

| 508.0 ib | 12.7 TSI | 155 | 1.60 ib | 10.3 | 40.0 Nws |

| 508.0 ib | 9.5 TSI | 117 | 1.60 ib | 13.7 ib | 53.5 ib |

| 508.0 ib | 6.4 TSI | 79.2 ib | 1.60 ib | 20.2 | 79.4 ib |

| 457.0 ib | 12.7 TSI | 139 | 1.44 ib | 10.3 | 36.0 Nws |

| 457.0 ib | 9.5 TSI | 105 | 1.44 ib | 13.7 ib | 48.1 ib |

| 457.0 ib | 6.4 TSI | 71.1 ib | 1.44 ib | 20.2 | 71.4 ib |

| 406.4 ib | 12.7 TSI | 123 | 1.28 | 10.4 | 32.0 Nws |

| 406.4 ib | 9.5 TSI | 93.0 ua | 1.28 | 13.7 ib | 42.8 ib |

| 406.4 ib | 6.4 TSI | 63.1 ib | 1.28 | 20.2 | 63.5 ib |

| 355.6 ib | 12.7 TSI | 107 | 1.12 | 10.4 | 28.0 Nws |

| 355.6 ib | 9.5 TSI | 81.1 ib | 1.12 | 13.8 ib | 37.4 ib |

| 355.6 ib | 6.4 TSI | 55.1 ib | 1.12 | 20.3 | 55.6 ib |

| 323.9 ib | 2.7 TSI | 97.5 ua | 1.02 ib | 10.4 | 25.5 ib |

| 323.9 ib | 9.5 TSI | 73.7 ua | 1.02 ib | 13.8 ib | 34.1 ib |

| 323.9 ib | 6.4 TSI | 50.1 ib | 1.02 ib | 20.3 | 50.6 ib |

| 273.1 ib | 9.3 TSI | 60.5 ib | 0.858 ib | 14.2 | 29.4 ib |

| 273.1 ib | 6.4 TSI | 42.1 ib | 0.858 ib | 20.4 ib | 42.7 ib |

| 273.1 ib | 4.8 TSI | 31.8 ib | 0.858 ib | 27.0 Nws | 56.9 ua |

| 219.1 ib | 8.2 TSI | 42.6 ib | 0.688 ib | 16.1 | 26.7 ib |

| 219.1 ib | 6.4 TSI | 33.6 ib | 0.688 ib | 20.5 ib | 34.2 ib |

| 219.1 ib | 4.8 TSI | 25.4 ib | 0.688 ib | 27.1 ib | 45.6 ib |

| 168.3 ib | 71 TSI | 28.2 ib | 0.529 ib | 18.7 ib | 23.7 ib |

| 168.3 ib | 6.4 TSI | 25.6 ib | 0.529 ib | 20.7 ib | 26.3 |

| 168.3 ib | 4.8 TSI | 19.4 ib | 0.529 ib | 27.3 ib | 35.1 ib |

| 165.1 ib | 5.4 TSI | 21.3 | 0.519 ib | 24.4 ib | 30.6 ib |

| 165.1 ib | 5.0 TSI | 19.7 ib | 0.519 ib | 26.3 | 33.0 Nws |

| 165.1 ib | 3.5 TSI | 13.9 Nws | 0.519 ib | 37.2 ib | 47.2 ib |

| 165.1 ib | 3.0 TSI | 12.0 Nws | 0.519 ib | 43.2 ib | 55.0 ua |

| 139.7 ib | 5.4 TSI | 17.9 ib | 0.439 ib | 24.5 ib | 25.9 ib |

| 139.7 ib | 5.0 TSI | 16.6 | 0.439 ib | 26.4 ib | 27.9 ib |

| 139.7 ib | 3.5 TSI | 11.8 ib | 0.439 ib | 37.3 ib | 39.9 ib |

| 139.7 ib | 3.0 TSI | 10.1 | 0.439 ib | 43.4 ib | 46.6 ib |

| 114.3 ib | 6.0 TSI | 16.0 Nws | 0.359 ib | 22.4 ib | 19.1 ib |

| 114.3 ib | 5.4 TSI | 14.5 ib | 0.359 ib | 24.8 ib | 21.2 |

| 114.3 ib | 4.8 TSI | 13.0 Nws | 0.359 ib | 27.7 ib | 23.8 ib |

| 114.3 ib | 4.5 TSI | 12.2 | 0.359 ib | 29.5 ib | 25.4 ib |

| 114.3 ib | 3.6 TSI | 9.83 ib | 0.359 ib | 36.5 ib | 31.8 ib |

| 114.3 ib | 3.2 TSI | 8.77 ib | 0.359 ib | 41.0 Nws | 35.7 ib |

| 101.6 ib | 5.0 TSI | 11.9 ib | 0.319 ib | 26.8 ib | 20.3 |

| 101.6 ib | 4.0 TSI | 9.63 ib | 0.319 ib | 33.2 ib | 25.4 ib |

| 101.6 ib | 3.2 TSI | 7.77 ib | 0.319 ib | 41.1 ib | 31.8 ib |

| 101.6 ib | 2.6 TSI | 6.35 Nws | 0.319 ib | 50.3 | 39.1 ib |

| 88.9 ua | 5.9 TSI | 12.1 | 0.279 ib | 23.1 | 15.1 |

| 88.9 ua | 5.0 TSI | 10.3 | 0.279 ib | 27.0 Nws | 17.8 ib |

| 88.9 ua | 5.5 TSI | 11.3 | 0.279 ib | 24.7 ib | 16.2 |

| 88.9 ua | 4.8 TSI | 9.96 ib | 0.279 ib | 28.1 ib | 18.5 Nws |

| 88.9 ua | 4.0 TSI | 8.38 ib | 0.279 ib | 33.3 | 22.2 |

| 88.9 ua | 3.2 TSI | 6.76 ib | 0.279 ib | 41.3 | 27.8 ib |

| 88.9 ua | 2.6 TSI | 5.53 ib | 0.279 ib | 50.5 ib | 34.2 ib |

| 76.1 ib | 5.9 TSI | 10.2 | 0.239 ib | 23.4 ib | 12.9 ib |

| 76.1 ib | 4.5 TSI | 7.95 ib | 0.239 ib | 30.1 ib | 16.9 ib |

| 76.1 ib | 3.6 TSI | 6.44 ib | 0.239 ib | 37.1 ib | 21.1 |

| 76.1 ib | 3.2 TSI | 5.75 ib | 0.239 ib | 41.6 ib | 23.8 ib |

| 76.1 ib | 2.3 TSI | 4.19 ib | 0.239 ib | 57.1 ib | 33.1 |

| 60.3 | 5.4 TSI | 7.31 Nws | 0.189 ib | 25.9 ib | 11.2 |

| 60.3 | 4.5 TSI | 6.19 ib | 0.189 ib | 30.6 ib | 13.4 |

| 60.3 | 3.6 TSI | 5.03 ib | 0.189 ib | 37.6 ib | 16.8 ib |

| 48.3 ib | 5.4 TSI | 5.71 ib | 0.152 ib | 26.6 ib | 8.9 ib |

| 48.3 ib | 4.0 TSI | 4.37 ib | 0.152 ib | 34.7 ib | 12.1 |

| 48.3 ib | 3.2 TSI | 3.56 ib | 0.152 ib | 42.6 ib | 15.1 |

| 42.4 ib | 4.9 TSI | 4.53 ib | 0.133 ib | 29.4 ib | 8.7 ib |

| 42.4 ib | 4.0 TSI | 3.79 ib | 0.133 ib | 35.2 ib | 10.6 |

| 42.4 ib | 3.2 TSI | 3.09 Nws | 0.133 ib | 43.1 ib | 13.3 |

Kev kho cov khoom siv sab nrauv thiab kho kom zoo nkauj

Qhov tshwm sim

Cov khoom tiav yog tsis muaj qhov tsis zoo ua rau muaj kev ncaj ncees ntawm cov khoom siv.

Kev tshem tawm qhov tsis xws luag

Thaum muaj qhov tsis xws luag raug tshem tawm los ntawm kev xuab zeb, qhov chaw xuab zeb yuav tsum muaj kev hloov pauv zoo.

Qhov seem phab ntsa thickness nyob rau hauv lub sanded cheeb tsam yuav tsum tsis pub tsawg tshaj li 90% ntawm nominal thickness.

Weld Kho ntawm Defects

Welds yuav tsum yog suab, lub weld tau zoo fused yam tsis muaj undercutting los yog sib tshooj.

Lub vuam hlau yuav tsum tau ua haujlwm tsawg kawg yog 1.5 hli saum npoo ntawm qhov dov thiab qhov projecting hlau yuav tsum tau muab tshem tawm los ntawm kev sib tsoo flush nrog lub dov nto.

Galvanized

Galvanized round hollow seem nrog rau sab nraud txoj kab uas hla ntawm ≤ 60.3 hli thiab lwm yam hollow seem ntawm qhov sib npaug ntawm qhov sib npaug yuav tsum muaj peev xwm tiv taus 90 ° khoov ib ncig ntawm grooved mandrel.

Cov txheej txheej galvanized yuav tsum tsis muaj cov cim ntawm cov kab nrib pleb lossis qhov tsis xws luag tom qab kev ua haujlwm khoov.

AS/NZS 1163 Marking

Cov nram qab no tshwm sim tsawg kawg ib zaug hauv cov yeeb nkab steel.

(a) Lub chaw tsim khoom lub npe lossis cim, lossis ob qho tib si.

(b) Lub chaw tsim khoom lossis kev txheeb xyuas zeb, lossis ob qho tib si.

(c) Cov ntawv cim tshwj xeeb, traceable ntawv txheeb xyuas, uas yuav tsum yog nyob rau hauv ib los yog ob qho tib si ntawm cov hauv qab no:

(i) Lub sijhawm thiab hnub tsim khoom ntawm cov khoom.

(ii) Ib tug serialized identification naj npawb rau kev tswj kom zoo / kev ruaj ntseg thiab traceability lub hom phiaj.

Piv txwv:

BOTOP CHINA AS/NZS 1163-C350L0 457 × 12.7CHS × 12000MM Yeeb Nkab NO.001 HEAT NO.000001

Daim ntawv thov ntawm AS/NZS 1163

Architectural thiab Engineering Structures: Siv nyob rau hauv kev txhawb nqa cov vaj tse, xws li cov tsev siab siab thiab chaw ntau pob.

Kev thauj mus los: Siv rau hauv kev tsim cov choj, tunnels, thiab kev tsheb ciav hlau.

Roj, roj, thiab mining: siv rau hauv kev tsim cov roj rigs, cov khoom siv mining, thiab lwm yam conveyor systems.

Lwm yam kev lag luam hnyav: suav nrog cov qauv tsim rau cov chaw tsim khoom thiab cov tshuab hnyav.

Peb cov khoom muaj feem xyuam

Peb yog ib tug zoo welded carbon steel yeeb nkab chaw tsim tshuaj paus thiab tsum los ntawm Tuam Tshoj, thiab kuj yog ib tug seamless steel yeeb nkab stockist, muab koj ib tug ntau yam ntawm cov yeeb nkab steel kev daws teeb meem!

Hot Tags: as/nzs 1163, chs, structural, erw, lwm tus neeg, manufacturers, factories, stockists, tuam txhab uas muag, lag luam wholesale, yuav, nqe, hais, tej, muag, nqi.

Lub sij hawm xa tuaj: Plaub Hlis-21-2024