ASTM A334 Tubes yog cov pa roj carbon thiab alloy steel raj tsim los rau cov ntawv thov kub qis thiab tsim siv cov txheej txheem seamless thiab welded.

Qee qhov khoom loj yuav tsis muaj nyob rau hauv qhov kev qhia tshwj xeeb no vim tias cov phab ntsa hnyav dua muaj qhov cuam tshuam tsis zoo rau cov khoom siv hluav taws xob tsawg.

Qib Classification

ASTM A334 muaj ntau qib rau qhov sib txawv ntawm qhov kub thiab txias.

Qib 1, Qib 3, Qib 6, Qib 7, Qib 8, Qib 9, thiab Qib 11.

Cov qhab nia sib thooj raualloy steel raj yog Qib 3, Qib 7, Qib 8, Qib 9, thiab Qib 11.

Txhua qib ntawm cov hlau muaj nws tus kheej tshwj xeeb cov tshuaj muaj pes tsawg leeg thiab cov cuab yeej cuab tam, nrog rau qhov ntsuas kub tsawg kawg nkaus uas yuav tsum tau ua.

Cov txheej txheem tsim khoom

Cov raj yuav tsum tau ua los ntawm covseamlesslos yog tsis siv neegtxheej txheem vuamtsis muaj qhov sib ntxiv ntawm cov hlau muab tub lim hauv kev ua haujlwm vuam.

Kev kho cua sov

Qib 1, 3, 6, 7, thiab 9

Ua kom zoo los ntawm cua sov kom tsis txhob tsawg dua 1550 ° F [845 ° C] thiab txias hauv huab cua los yog hauv chav txias ntawm lub qhov cub cua sov.

Yog xav tau tempering, nws yuav tsum tau sib tham.

Rau cov qib saum toj no ntawm seamless steel hlab nkaus xwb:

Rov ua kom sov thiab tswj kev ua haujlwm kub thiab qhov kub ntawm qhov kub ntawm qhov ua tiav kom tiav qhov kub ntawm 1550 - 1750 ° F [845 - 955 ℃] thiab txias hauv qhov cua sov cua sov los ntawm qhov pib kub tsis pub tsawg dua 1550 ° F [ 845 °C].

Qib 8

Xaiv ib qho ntawm cov hauv qab no rau kev kho cua sov.

Quenched thiab Tempered;

Ob chav Normalized thiab Tempered.

Qib 11

Seb puas yuav anneal Qib 11 raj yog ib qho kev pom zoo ntawm tus neeg yuav khoom thiab tus neeg muag khoom.

Thaum Qib 11 cov hlab yog annealed lawv yuav tsum normalized nyob rau hauv thaj tsam ntawm 1400 - 1600℉ [760 - 870 ° C].

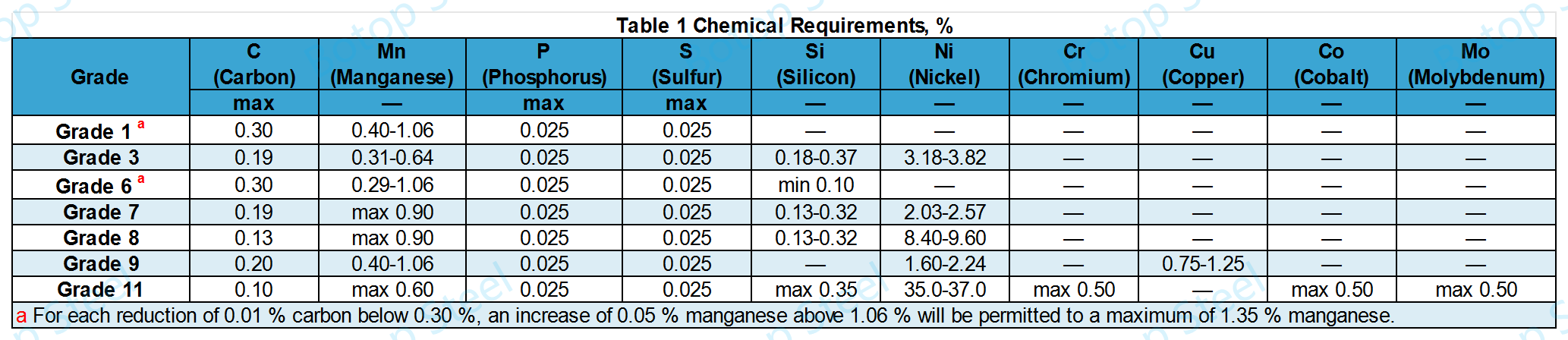

ASTM A334 Tshuaj muaj pes tsawg leeg

Rau Qib 1 lossis Qib 6 steels, nws tsis raug tso cai los muab cov qib alloying rau txhua yam uas tsis yog cov uas xav tau.Txawm li cas los xij, nws raug tso cai ntxiv cov khoom tsim nyog rau deoxidation ntawm cov hlau.

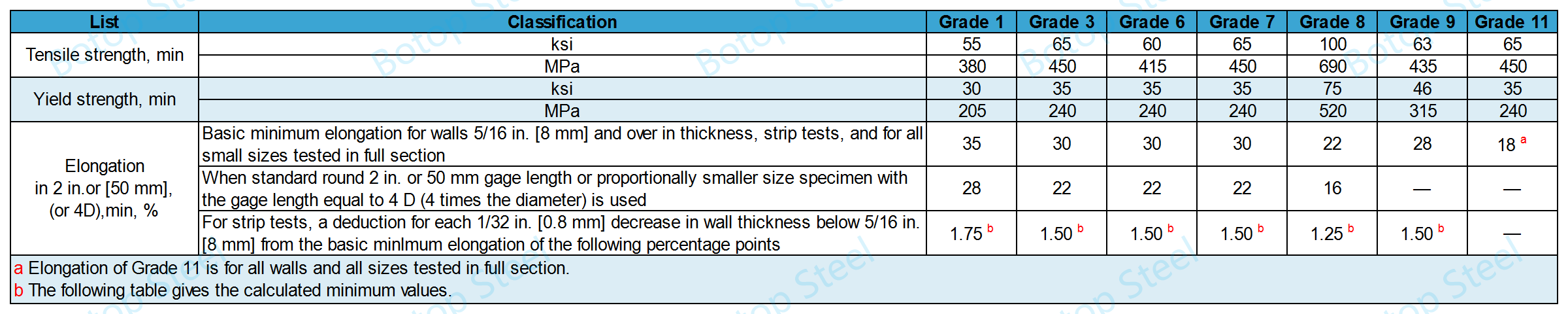

ASTM A334 Mechanical Tests

Cov cuab yeej cuab tam yuav tsum tsis txhob siv rau tubing me dua 1/8 nyob rau hauv.

1. Tensile Property

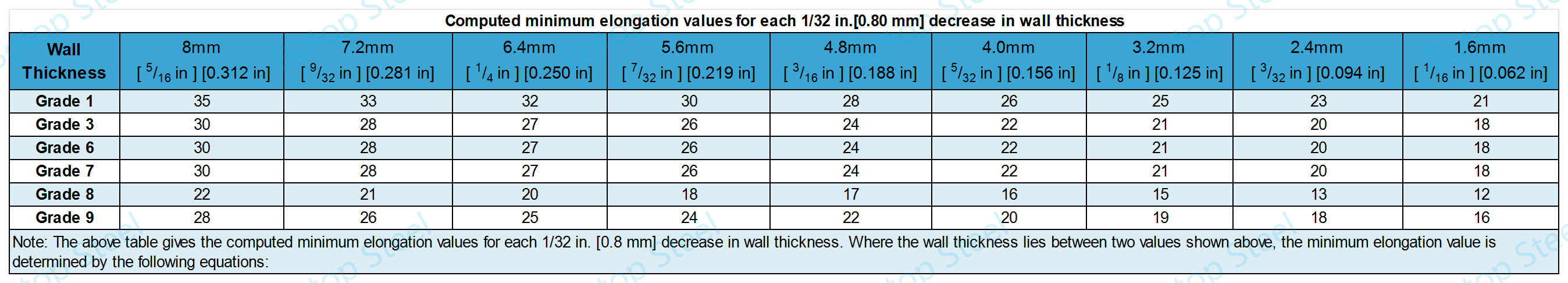

Yam tsawg kawg elongation xam rau txhua 1/32 nti [0.80 mm] txo cov phab ntsa thickness:

Rau cov raj me dua 1/2 nyob rau hauv. [12.7 mm] nyob rau hauv sab nraud txoj kab uas hla, elongation qhov tseem ceeb muab rau cov qauv strips yuav tsum siv.

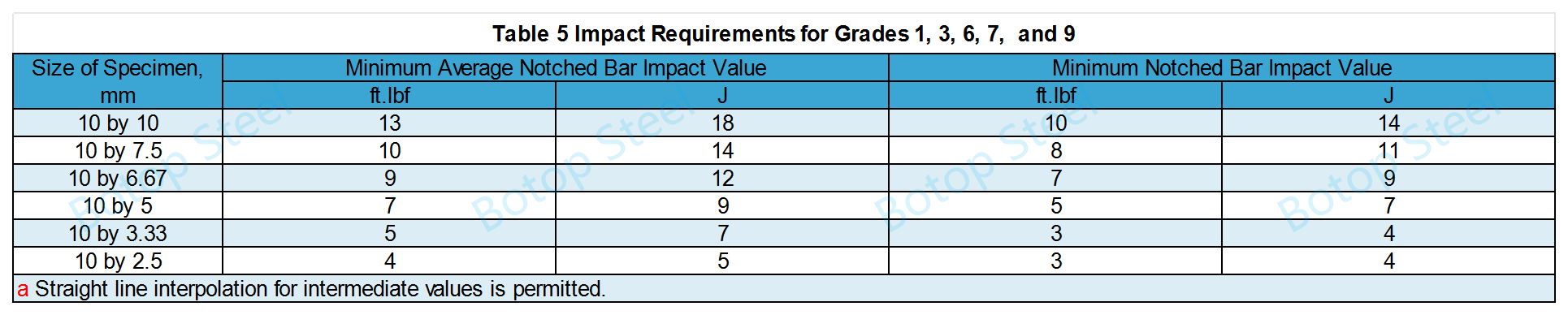

2. Cov kev sim cuam tshuam

Xaiv qhov ntsuas kub thiab qhov cuam tshuam zoo raws li qib thiab phab ntsa thickness.

Impact zog

Impact kub

| Qib | Impact Test Temperature | |

| ℉ | ℃ | |

| Qib 1 | -50 | -45 |

| Qib 3 | -150 | -100 |

| Qib 6 | -50 | -45 |

| Qib 7 | -100 | -75 |

| Qib 8 | -320 | -195 |

| Qib 9 | -100 | -75 |

3. Hardness Test

| Qib | Rockwell | Brinell |

| Qib 1 | B 85 | 163 |

| Qib 3 | B 90 | 190 |

| Qib 6 | B 90 | 190 |

| Qib 7 | B 90 | 190 |

| Qib 8 | — | — |

| Qib 11 | B 90 | 190 |

4. Kev xeem Flattening

Ib qho kev sim flattening yuav tsum tau ua rau ntawm cov qauv ntawm txhua qhov kawg ntawm ib lub raj tiav ntawm txhua qhov tab sis tsis yog ib qho siv rau kev sim flare lossis flange.

5. Flare Test (Seamless Tubes)

Ib qho kev sim flare yuav tsum tau ua rau ntawm cov qauv ntawm txhua qhov kawg ntawm ib lub raj tiav ntawm txhua qhov ntau, tab sis tsis yog ib qho uas siv rau kev sim flattening.

6. Flange Test (Welded Tubes)

Ib qho kev sim flange yuav tsum tau ua rau ntawm cov qauv los ntawm txhua qhov kawg ntawm ib lub raj tiav ntawm txhua qhov ntau, tab sis tsis yog ib qho uas siv rau kev kuaj flattening.

7. Rov qab Flattening Test

Rau cov raj welded, ib qho kev ntsuas rov qab flattening yuav tsum tau ua rau ntawm cov qauv ntawm txhua 1500 ft [460 m] ntawm cov tubing tiav.

Hydrostatic lossis Nondestructive Electric Test

Txhua cov yeeb nkab yuav tsum tsis muaj hluav taws xob kuaj lossis kuaj hydrostatically raws li Specification A1016/A1016M.

Daim ntawv thov rau ASTM A334 Steel Pipe

Feem ntau yog siv los thauj cov kua lossis cov pa roj xws li cov nkev, roj, thiab lwm yam tshuaj uas tsis tshua muaj kub.

1. Cryogenic piping systems: Feem ntau siv rau hauv kev tsim cov kav dej rau kev thauj mus los ntawm cov kua dej cryogenic (xws li cov roj ntsha liquefied, kua nitrogen).Vim nws cov khoom zoo heev cryogenic, nws muaj peev xwm tswj tau txhua yam muaj zog thiab toughness ntawm qhov kub thiab txias.

2. Thaum tshav kub kub exchangers thiab condensers: Thaum tshav kub kub exchangers thiab condensers tuaj yeem siv tau los ua kom txias lossis cua sov txheej txheem kev tshaj tawm, tshwj xeeb tshaj yog nyob rau hauv kev lag luam tshuaj thiab petrochemical.

3. Cov hlab ntsha siab: kuj tseem siv tau los tsim cov hlab ntsha uas tsim los rau kev ua haujlwm cryogenic.Cov hlab ntsha no tuaj yeem siv los khaws cov tshuaj cryogenic lossis rau cov txheej txheem tshwj xeeb.

4. Cov tshuab tub yees thiab khoom siv: Cov raj no yog siv rau kev thauj mus los ntawm cov tub yees, tshwj xeeb tshaj yog cov khoom siv uas tsis tshua muaj kub-resistant.

ASTM A334 Sib npaug Standard

TS EN 10216-4: Npog cov raj uas tsis yog-alloyed thiab alloyed steel, uas tau teev cov yam ntxwv ntawm qhov kub thiab txias.

TIAB SA 3460: Muaj feem xyuam rau cov hlau alloy hlau rau kev pabcuam cryogenic.

GB/T 18984: siv rau seamless steel raj rau cryogenic siab hlab ntsha.Nws qhia meej txog kev tsim thiab tsim cov raj hlau uas haum rau qhov chaw tsis tshua muaj kub.

Txawm hais tias cov qauv no yuav txawv ntawm cov ntsiab lus thiab cov kev xav tau tshwj xeeb, lawv zoo sib xws hauv lawv lub hom phiaj thiab daim ntawv thov, uas yog los xyuas kom meej kev nyab xeeb thiab kev ua tau zoo ntawm cov kav hlau steel hauv qhov chaw cryogenic.

Peb cov khoom muaj feem xyuam

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua tus xa khoom ntawm carbon steel yeeb nkab nyob rau sab qaum teb Tuam Tshoj, paub txog kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem.

Lub tuam txhab muaj ntau yam carbon steel kav thiab lwm yam khoom, xws li seamless, ERW, LSAW, thiab SSAW steel yeeb nkab, raws li zoo raws li ib tug tag nrho lineup ntawm cov yeeb nkab fittings thiab flanges.Nws cov khoom tshwj xeeb kuj suav nrog cov qib high-qib alloys thiab austenitic stainless hlau, tsim kom tau raws li qhov xav tau ntawm ntau yam kev siv kav dej.

Hot Tags: ASTM A334, carbon steel yeeb nkab, ASTM a334 gr 6, astm a334 gr 1.

Post lub sij hawm: May-20-2024