ASTM A500 hlauyog txias-tsim welded thiab seamless carbon steel structural tubing rau welded, riveted, los yog bolted txuas hniav thiab lub tsev cov qauv thiab cov hom phiaj dav dav.

Navigation Khawm

Hollow Section Shape

Qib Classification

Qhov Loj

Cov khoom siv raw

Kev tsim khoom

Tube End Hom

Kev kho cua sov

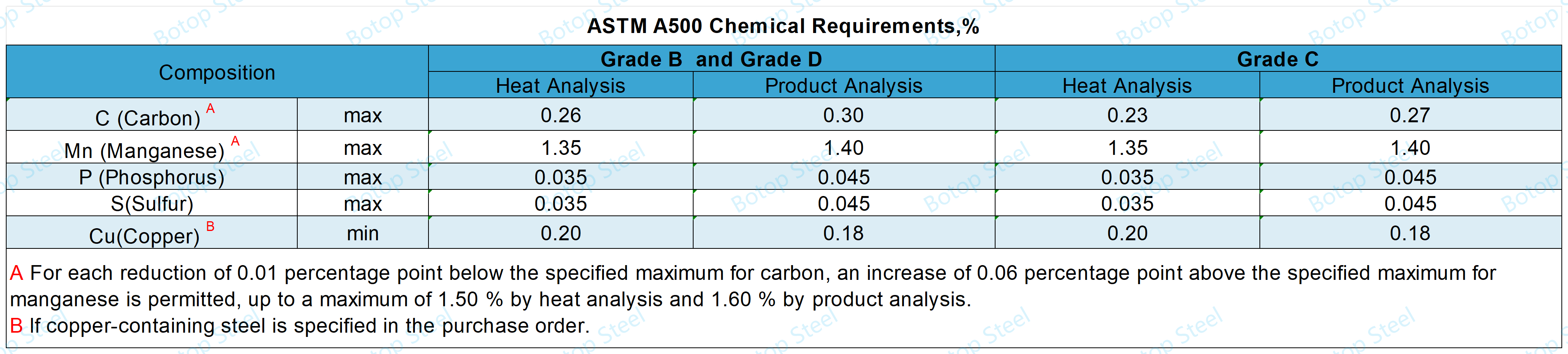

Tshuaj muaj pes tsawg leeg ntawm ASTM A500

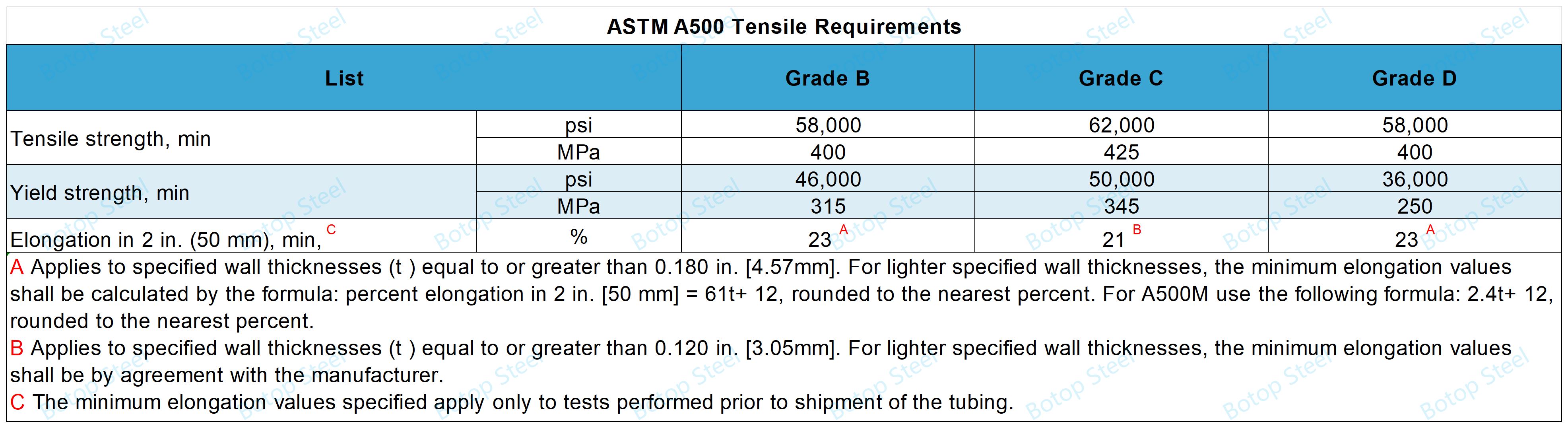

Tensile Requirements ntawm ASTM A500

Flattening Test

Flaring Test

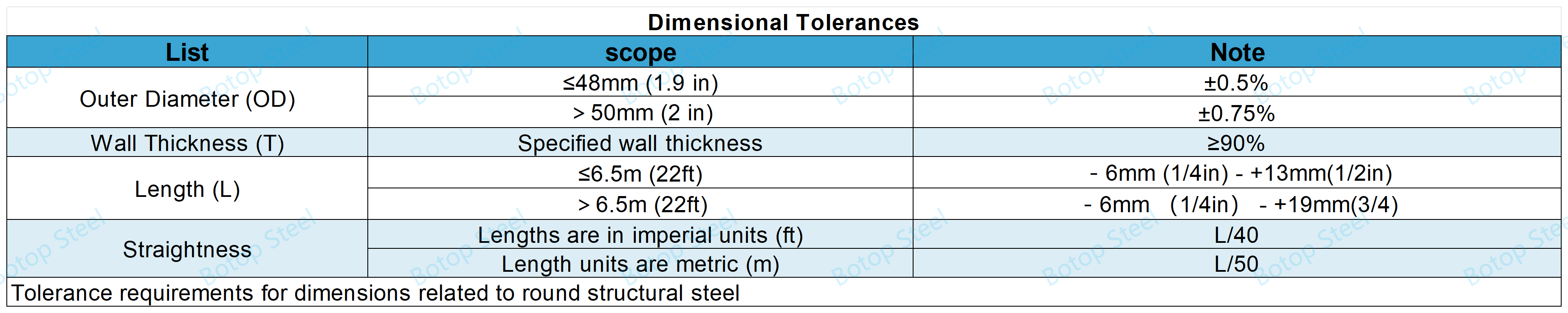

Dimensional kam rau ua ntawm ASTM A500

Tube Marking

Daim ntawv thov ntawm ASTM A500

Lwm cov ntaub ntawv ntawm ASTM A500

Peb cov khoom muaj feem xyuam

Hollow Section Shape

Nws tuaj yeem yoground, square, rectangular, los yog lwm yam tshwj xeeb cov qauv duab.

Kab lus no tsom mus rau qhov yuav tsum tau ua ntawm ASTM A500 rau puag ncig cov qauv hlau.

Qib Classification

ASTM A500 faib cov yeeb nkab steel rau hauv peb qib,qib B, qib C, thiab qib D.

Nws yog tsim nyog sau cia tias yav dhau los versions ntawm ASTM A500 kuj muaj Qib A, uas tau raug tshem tawm nyob rau hauv qhov tseeb version ntawm 2023.

Qhov Loj

Rau cov hlab nrog sab nraud txoj kab uas hla ≤ 2235mm [88in] thiab phab ntsa thickness ≤ 25.4mm [1in].

Cov khoom siv raw

Cov hlau yuav tsum tau ua los ntawm ib lossis ntau qhov txheej txheem hauv qab no:yooj yim oxygen los yog hluav taws xob rauv.

Basic Oxygen Txheej Txheem: Qhov no yog ib txoj hauv kev niaj hnub nrawm ntawm cov hlau ntau lawm, uas txo cov ntsiab lus ntawm cov pa roj carbon monoxide los ntawm kev tshuab pa rau hauv cov npua hlau, thaum tshem tawm lwm yam tsis xav tau xws li sulfur thiab phosphorus. Nws yog qhov tsim nyog rau kev tsim khoom sai ntawm cov hlau ntau ntau.

Cov Txheej Txheem Hluav Taws Xob Hluav Taws Xob: Cov Txheej Txheem Hluav Taws Xob Hluav Taws Xob siv lub tshuab hluav taws xob kub kub kom yaj cov seem thiab ncaj qha txo cov hlau, thiab tshwj xeeb tshaj yog tsim nyog rau kev tsim cov qib tshwj xeeb thiab tswj cov khoom sib xyaw ua ke, nrog rau cov khoom me me.

Kev tsim khoom

Seamless los yog vuam txheej txheem.

Welded tubing yuav tsum tau ua los ntawm cov hlau tiaj tus los ntawm cov txheej txheem hluav taws xob-tiv taus-welding (ERW). Weld seam yuav tsum tau welded los ntawm kev ua kom lub zog ntawm cov yeeb nkab.

Cov kav dej uas tsim los ntawm cov txheej txheem vuam feem ntau tsis muaj cov vuam sab hauv.

Tube End Hom

Yog tias tsis xav tau tshwj xeeb, cov raj xa dej yuav tsum yogtiaj tusthiab ntxuav ntawm burrs.

Kev kho cua sov

Qib B thiab Qib C

Nws tuaj yeem ua rau annealed lossis kev ntxhov siab.

Annealing yog ua tiav los ntawm cua sov lub raj mus rau qhov kub thiab txias thiab maj mam txias nws. Annealing rearranges lub microstructure ntawm cov khoom los txhim kho nws toughness thiab uniformity.

Kev ntxhov siab feem ntau ua tiav los ntawm kev ua kom sov cov khoom mus rau qhov kub thiab txias (feem ntau qis dua li ntawm annealing) ces tuav nws rau ib lub sij hawm thiab ces txias nws. Qhov no yuav pab tiv thaiv kom tsis txhob cuam tshuam lossis tawg ntawm cov khoom thaum lub sijhawm ua haujlwm tom ntej xws li vuam lossis txiav.

Qib D

Yuav tsum tau kho cua sov.

Nws yuav tsum tau ua ntawm qhov kub ntawm qhov tsawg kawg nkaus1100 ° F (590 ° C) rau 1 teev ib 25 hli phab ntsa thickness.

Tshuaj muaj pes tsawg leeg ntawm ASTM A500

Txoj Kev Xeem: ASTM A751.

Tensile Requirements ntawm ASTM A500

Cov qauv yuav tsum tau ua raws li cov kev cai ntawm ASTM A370, Appendix A2.

Flattening Test

Welded Round Structural Tubes

Welddkev siv hluav taws xobtyog: Siv cov khoom siv tsawg kawg yog 4 ntiv tes (100 mm) ntev, flatten cov qauv nrog lub vuam ntawm 90 ° mus rau qhov kev taw qhia ntawm kev thauj khoom kom txog rau thaum qhov kev ncua deb ntawm daim hlau yog tsawg dua 2/3 ntawm sab nraud ntawm cov yeeb nkab. cov qauv yuav tsum tsis txhob tawg lossis tawg ntawm qhov chaw sab hauv lossis sab nraud thaum lub sijhawm ua haujlwm no.

Tube ductility test: txuas ntxiv flatten tus qauv kom txog rau thaum qhov kev ncua deb ntawm daim hlau yog tsawg dua 1/2 ntawm cov yeeb nkab sab nraud. nyob rau lub sijhawm no, cov yeeb nkab yuav tsum tsis txhob muaj cov kab nrib pleb lossis tawg ntawm sab hauv thiab sab nrauv.

Kev ncaj nceestyog: Txuas ntxiv kom tiaj tus qauv kom txog thaum muaj kev puas tsuaj los yog kom txog thaum tus txheeb ze phab ntsa thickness yuav tsum tau ua. Yog tias cov ntaub ntawv pov thawj ntawm ply tev, cov khoom tsis ruaj khov, lossis tsis tiav welds tau pom thaum lub sij hawm qhov kev sim flattening, cov qauv yuav raug txiav txim tsis txaus siab.

Seamless Round Structural Tubes

Qauv Length: Qhov ntev ntawm cov qauv siv los kuaj yuav tsum tsis pub tsawg dua 2 1/2 hauv (65 mm).

Kev kuaj ductility: Tsis muaj kev tawg los yog tawg, cov qauv yog flattened ntawm cov phaj sib npaug kom txog thaum qhov kev ncua deb ntawm daim hlau yog tsawg dua tus nqi "H" xam los ntawm cov qauv hauv qab no:

H=(1+e)t/(e+t/D)

H = nrug ntawm flattening daim hlau, hauv. [mm],

e = deformation rau ib chav tsev ntev (qhov tsis tu ncua rau qib ntawm cov hlau, 0.07 rau Qib B, thiab 0.06 rau Qib C),

t = teev phab ntsa thickness ntawm tubing, hauv. [mm],

D = teev sab nraud txoj kab uas hla ntawm tubing, in. [mm].

Kev ncaj nceestyog: Txuas ntxiv kom tiaj tus qauv kom txog thaum cov qauv tawg lossis cov phab ntsa ntawm cov qauv sib ntsib.

Ua tsis tiavckev cai: Laminar tev lossis cov khoom tsis muaj zog uas pom thoob plaws hauv qhov kev sim flattening yuav yog lub hauv paus rau kev tsis lees paub.

Flaring Test

Kev ntsuas flaring yog muaj rau cov raj puag ncig ≤ 254 mm (10 in) inch, tab sis tsis tas yuav tsum tau ua.

Dimensional kam rau ua ntawm ASTM A500

Tube Marking

Cov ntaub ntawv hauv qab no yuav tsum suav nrog:

Tus neeg tsim khoom lub npe: Qhov no tuaj yeem yog cov chaw tsim khoom lub npe lossis cov ntawv luv.

Hom lossis Trademark: Lub npe hom lossis cov cim lag luam siv los ntawm cov chaw tsim khoom kom paub qhov txawv ntawm nws cov khoom.

Specification Designator: ASTM A500, uas yuav tsum tsis suav nrog xyoo ntawm kev tshaj tawm.

Ntawv Qib: B, C lossis D qib.

Rau cov qauv raj ≤ 100mm (4in) hauv txoj kab uas hla, cov ntawv cim tuaj yeem siv los kos cov ntaub ntawv qhia kom meej.

Daim ntawv thov ntawm ASTM A500

Vim nws cov khoom siv zoo heev thiab kev sib txuas, ASTM A500 steel yeeb nkab yog siv rau hauv ntau yam qauv uas yuav tsum tau ua kom muaj zog thiab muaj zog.

Kev tsim kho: Siv los txhawb kev tsim vaj tsev xws li framing systems, ru tsev, arch tsim cov ntsiab lus, thiab cov kab puag ncig.

Kev tsim kho choj: Rau cov khoom siv ntawm cov txuas hniav, xws li cov kab uas hla cov kabmob thiab cov trusses rau cov txuas hniav.

Industrial infrastructure: Hauv cov tsev lag luam loj xws li cov chaw siv roj thiab roj, cov nroj tsuag tshuaj, thiab cov mills steel, cov kav hlau puag ncig yog siv los tsim cov qauv kev txhawb nqa thiab kev xa cov kav dej.

Kev thauj mus los: Rau cov phiajcim tsheb, cov ncej teeb, thiab cov guardrail struts.

Machinery manufacturing: Raws li ib feem ntawm cov tshuab thiab cov cuab yeej hnyav, xws li cov tshuab ua liaj ua teb, cov khoom siv mining, thiab kev tsim kho tshuab.

Cov khoom siv: Siv rau hauv cov kav dej rau dej, roj, khoom siv roj av, thiab lwm yam, thiab ua cov kav hlau thiab cable tiv thaiv.

Cov chaw ua kis las: Hauv kev tsim cov chaw ua kis las, cov kav hlau puag ncig yog siv los ua bleachers, teeb pom kev zoo, thiab lwm yam kev txhawb nqa.

Rooj tog thiab kho kom zoo nkauj: Round structural steel raj yog siv los ua cov rooj tog hlau, xws li ob txhais ceg rau cov rooj thiab cov rooj zaum, nrog rau cov khoom zoo nkauj rau niaj hnub tsim sab hauv.

laj kab thiab railing systems: Siv raws li cov ncej rau fencing thiab railing systems, tshwj xeeb tshaj yog nyob rau hauv lub structural zog thiab durability yuav tsum tau.

Lwm cov ntaub ntawv ntawm ASTM A500

ASTM A501 Cov Lus Qhia Tshwj Xeeb: Qhov no yog tus qauv rau kub-tsim carbon steel structural tubing, zoo ib yam li ASTM A500, tab sis muaj feem xyuam rau cov txheej txheem kub-forming manufacturing.

ASTM A252, ASTM A252: Txuj rau steel yeeb nkab piles siv nyob rau hauv lub hauv paus thiab piling ua hauj lwm.

ASTM A106 1: Seamless carbon steel yeeb nkab, feem ntau siv nyob rau hauv high-temperature ib puag ncig.

ASTM A53: Lwm hom carbon steel yeeb nkab rau kev siv lub siab thiab kev siv tshuab, dav siv hauv kev hloov pauv dej.

TS EN 10210: Hauv Tebchaws Europe, EN 10210 tus qauv qhia cov txheej txheem kev xa khoom rau cov txheej txheem kub ua haujlwm hollow, uas muaj cov ntawv thov zoo sib xws rau ASTM A500.

CSA G40.21: Tus qauv Canadian uas muab ntau yam qauv zoo steels hauv ntau qib zog uas tuaj yeem siv rau cov ntawv zoo sib xws.

JIS G3466: Japanese Industrial Standard rau square thiab rectangular raj ntawm carbon steel rau kev siv cov qauv siv.

TIAB SA 4923: Indian Standard rau txias-tsim welded los yog seamless carbon steel structural hollow seem.

AS/NZS 1163: Australian thiab New Zealand cov qauv rau cov qauv steel raj thiab hollow seem.

Peb cov khoom muaj feem xyuam

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua cov pa roj carbon steel yeeb nkab xa khoom nyob rau sab qaum teb Tuam Tshoj, paub txog nws cov kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem. Lub tuam txhab cov khoom lag luam dav suav nrog seamless, ERW, LSAW, thiab SSAW steel kav, nrog rau cov yeeb nkab fittings, flanges, thiab cov hlau tshwj xeeb.

Nrog rau kev cog lus muaj zog rau kev ua tau zoo, Botop Steel siv cov kev tswj hwm nruj thiab kev ntsuam xyuas kom ntseeg tau tias muaj kev ntseeg siab ntawm nws cov khoom. Nws pab neeg muaj kev paub dhau los muab cov kev daws teeb meem ntawm tus kheej thiab cov kws tshaj lij kev txhawb nqa, nrog rau kev tsom mus rau cov neeg siv khoom txaus siab.

Hot Tags: astm a500 qib b, astm a500 qib c, astm a500 qib d.

Post lub sij hawm: May-04-2024