Qib B thiab Qib C yog ob qib sib txawv raws li tus qauv ASTM A500.

ASTM A500 1yog tus qauv tsim los ntawm ASTM International rau txias tsim welded thiab seamless carbon steel structural tubing.

Tom ntej no, cia peb sib piv thiab sib piv lawv hauv ntau txoj hauv kev kom nkag siab tias qhov zoo sib xws thiab qhov sib txawv lawv muaj.

Qhov txawv

ASTM A500 Qib B thiab C sib txawv hauv cov tshuaj muaj pes tsawg leeg, tensile zog, thiab cov chaw siv.

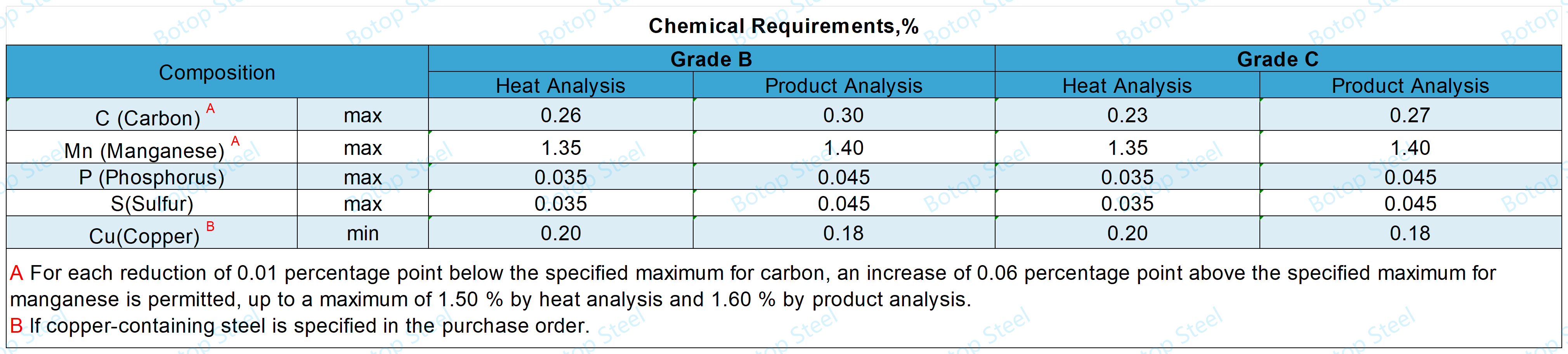

Qhov sib txawv ntawm cov tshuaj muaj pes tsawg leeg

Nyob rau hauv ASTM A500 tus qauv, muaj ob txoj kev tshuaj ntsuam rau cov tshuaj muaj pes tsawg leeg ntawm steel: thermal tsom xam thiab cov khoom tsom xam.

Kev ntsuas cua sov yog ua thaum lub sijhawm melting ntawm cov hlau. Nws lub hom phiaj yog los xyuas kom meej tias cov tshuaj muaj pes tsawg leeg ntawm cov hlau ua tau raws li qhov yuav tsum tau muaj ntawm tus qauv tshwj xeeb.

Kev tshuaj xyuas cov khoom, ntawm qhov tod tes, yog ua tom qab cov hlau twb tau ua rau hauv cov khoom. Txoj kev tshuaj ntsuam no yog siv los xyuas kom meej tias cov tshuaj muaj pes tsawg leeg ntawm cov khoom kawg ua tau raws li qhov yuav tsum tau ua.

Tsis yog qhov xav tsis thoob, cov ntsiab lus carbon ntawm Qib C yog me ntsis qis dua li qib B, uas txhais tau tias Qib C muaj zog zoo dua thaum vuam thiab molding.

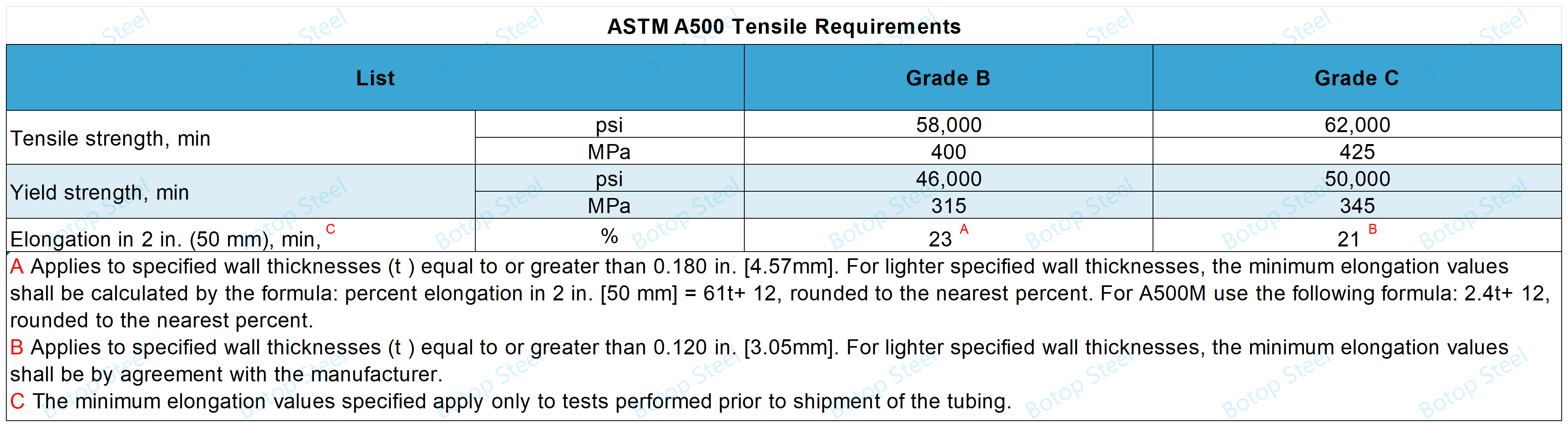

Qhov sib txawv ntawm Tensile Properties

Qib B: Feem ntau muaj qhov siab ntawm ductility, tso cai rau nws mus txuas ntxiv hauv kev nro yam tsis muaj kev tawg, thiab tsim nyog rau cov qauv uas yuav tsum tau khoov lossis deformation.

Qib C: Nws muaj zog tensile ntau dua thiab muaj zog tawm los vim nws cov tshuaj muaj pes tsawg leeg, tab sis tej zaum yuav yog me ntsis ductile dua qib B.

Qhov sib txawv hauv Daim Ntawv Thov

Txawm hais tias ob qho tib si siv rau hauv cov qauv siv thiab kev txhawb nqa, qhov tseem ceeb yog txawv.

Qib B: Vim nws zoo dua vuam thiab tsim cov khoom, nws yog feem ntau siv rau hauv lub tsev, kev tsim kho choj, kev txhawb nqa lub tsev, thiab lwm yam, tshwj xeeb tshaj yog thaum cov qauv yuav tsum tau welded thiab khoov.

Qib C: Vim nws lub zog ntau dua, nws feem ntau yog siv rau hauv cov ntawv thov uas yuav tsum muaj kev thauj khoom ntau dua, xws li kev tsim kho, kev txhawb nqa tshuab hnyav, thiab lwm yam.

Kev sib koom siab

Thaum Qib B thiab Qib C txawv ntawm ntau txoj hauv kev, lawv kuj qhia cov yam ntxwv sib xws.

Tib Hla-section Shape

Hollow seem duab yog puag ncig, square, rectangular, thiab oval.

Kev kho cua sov

Txhua yam tso cai rau cov hlau kom muaj kev ntxhov siab-relieved los yog annealed.

Tib Cov Kev Xeem Xeem

Qib B thiab C yuav tsum tau ua kom tau raws li qhov yuav tsum tau muaj ntawm ASTM A500 rau kev tsom xam thermal, tshuaj ntsuam xyuas khoom, ntsuas tensile, Flattening Test, Flaring Test, thiab Wedge Crush Test.

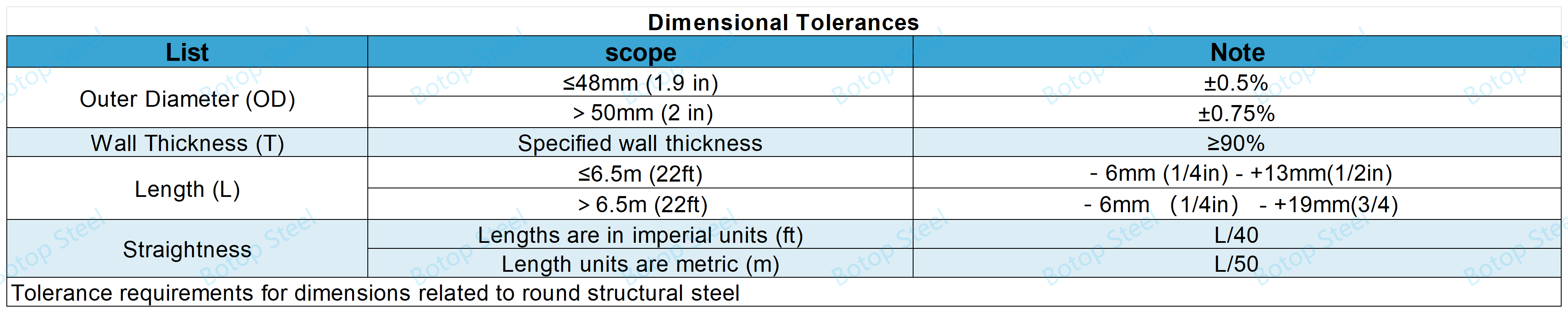

Tib Dimensional Tolerance

Piv txwv ntawm ib puag ncig hollow seem.

Peb cov khoom muaj feem xyuam

Hauv kev xaiv seb puas yuav siv ASTM A500 Qib B lossis Qib C tubing, yuav tsum xav txog qhov tseeb ntawm engineering thiab cov nqi tsim nyog.

Piv txwv li, rau cov qauv uas tsis xav tau lub zog siab tab sis zoo toughness, Qib B yuav yog qhov kev xaiv pheej yig dua. Rau cov haujlwm uas xav tau ntau lub zog thiab lub peev xwm thauj khoom, Qib C muab qhov tsim nyog ua tau zoo, txawm tias tus nqi siab dua.

Hot Tags: astm a500, qib b, qib c, qib b vs c.

Post lub sij hawm: May-05-2024