ASTM A513 steel hlauyog cov pa roj carbon thiab alloy steel yeeb nkab thiab raj ua los ntawm kub dov los yog txias-kuav los tiag steel li raw khoom los ntawm hluav taws xob tsis kam vuam (ERW) txheej txheem, uas yog dav siv nyob rau hauv txhua yam ntawm txhua yam qauv.

Navigation Khawm

ASTM A513 Hom thiab Cov Cuab Yeej Cuab Yeej

Qib Classification

ASTM A513 Loj Ntau Yam

Hollow Section Shape

Cov khoom siv raw

ASTM A513 Cov txheej txheem tsim khoom

Kev kho kub

Vuam Seam Handling

Tshuaj muaj pes tsawg leeg ntawm ASTM A513

Mechanical Properties ntawm ASTM A513

Hardness Test

Flattening Test

Flaring Test

Hydrostatic Test Round Tubing

Nondestructive Electric Test

Tolerances rau Round Pipe Dimensions

Tolerance ntawm Square thiab Rectangular Tube Dimensions

Qhov tshwm sim

Txheej

Kos npe

Daim ntawv thov ASTM A513

Peb Qhov Zoo

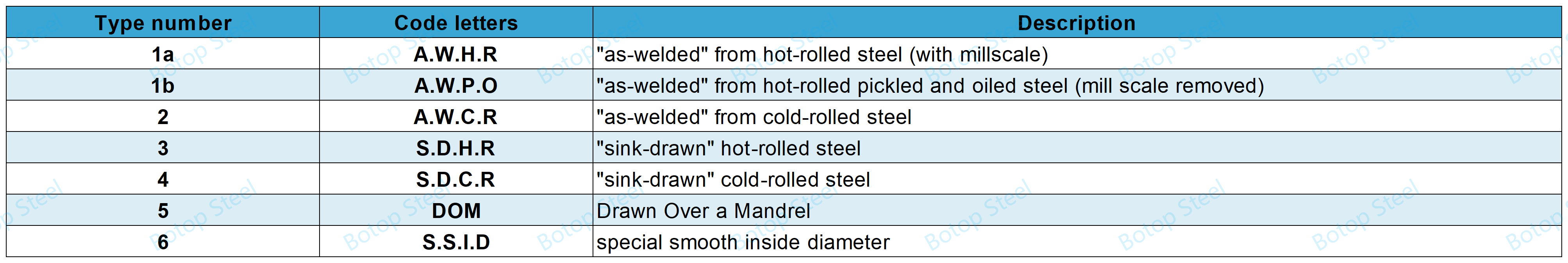

ASTM A513 Hom thiab Cov Cuab Yeej Cuab Yeej

Kev faib tawm yog nyob ntawm qhov sib txawv lossis cov txheej txheem ntawm cov yeeb nkab steel.

Qib Classification

ASTM A513 tuaj yeem yog cov pa roj carbon lossis hlau alloy, nyob ntawm daim ntawv thov tiag tiag.

Carbon Steel

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 1025, 1025, 1025 1033, 1035, 1040, 1050, 1060, 1524.

Alloys hlau

1340, 4118, 4130, 4140, 5130, 8620, 8630.

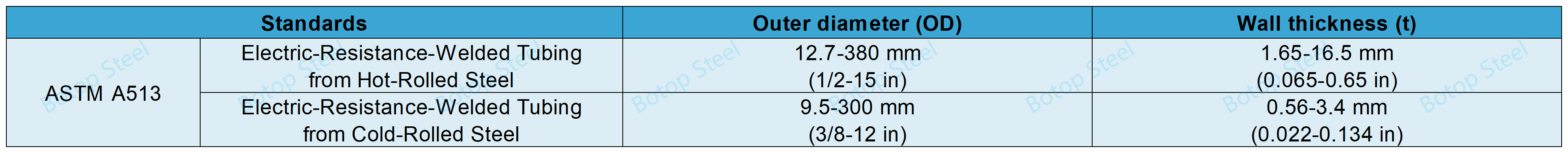

ASTM A513 Loj Ntau Yam

Hollow Section Shape

Hloov

Square los yog duab plaub

Lwm cov duab

xws li streamlined, hexagonal, octagonal, puag ncig hauv thiab hexagonal lossis octagonal sab nraud, ribbed sab hauv lossis tawm, daim duab peb sab, puag ncig thiab D duab.

Cov khoom siv raw

Cov hlau tuaj yeem ua los ntawm txhua qhov txheej txheem.

Thawj melting yuav suav nrog cais degassing los yog refining thiab tej zaum yuav ua raws li theem nrab melting, xws li electro slag los yog nqus-arc remelting.

Cov hlau yuav raug cam khwb cia rau hauv ingots los yog strand cast.

ASTM A513 Cov txheej txheem tsim khoom

Tubes yuav tsum tau ua los ntawm covHluav taws xob tsis kam-welded (ERW)txheej txheem thiab yuav tsum tau ua los ntawm kub dov los yog txias dov hlau raws li tau teev tseg.

ERW yeeb nkab yog txheej txheem ntawm kev tsim cov vuam los ntawm coiling cov khoom siv hlau rau hauv lub tog raj kheej thiab siv cov kev tiv thaiv thiab siab raws nws qhov ntev.

Kub Rolled Steel: Nyob rau hauv cov txheej txheem ntau lawm, kub-dov hlau yog thawj rhuab nyob rau hauv high kub, cia cov hlau yuav dov nyob rau hauv ib tug yas lub xeev, uas ua rau nws yooj yim los hloov cov duab thiab loj ntawm cov hlau. Thaum kawg ntawm cov txheej txheem kub dov, cov khoom feem ntau yog scaled thiab deformed.

Cold-Rolled Steel: Cold-dov hlau yog dov ntxiv tom qab cov khoom tau txias kom ua tiav qhov xav tau loj thiab cov duab. Cov txheej txheem no feem ntau yog ua nyob rau hauv chav tsev kub thiab ua rau cov hlau nrog zoo nto zoo thiab ntau qhov ntev.

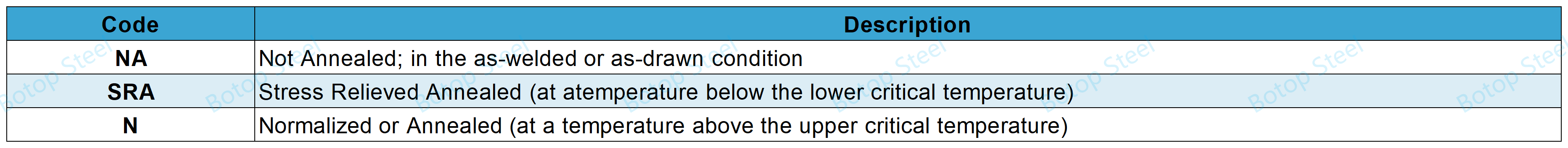

Kev kho kub

Thaum lub thermal mob tsis tau teev tseg, lub raj yuav muab tau rau hauv NA mob.

Thaum qhov kev kho cua sov kawg tau teev tseg, qhov nruj oxide yog qhov qub.

Thaum qhov chaw tsis muaj oxide tau teev tseg, lub raj yuav ci ntsa iab los yog pickled ntawm qhov chaw tsim khoom xaiv.

Vuam Seam Handling

Sab nraud welds yuav tsum tau ntxuav

Internal welds yuav muaj qhov siab sib txawv nyob ntawm seb hom.

Cov kev cai tshwj xeeb tuaj yeem pom hauv ASTM A513, ntu 12.3.

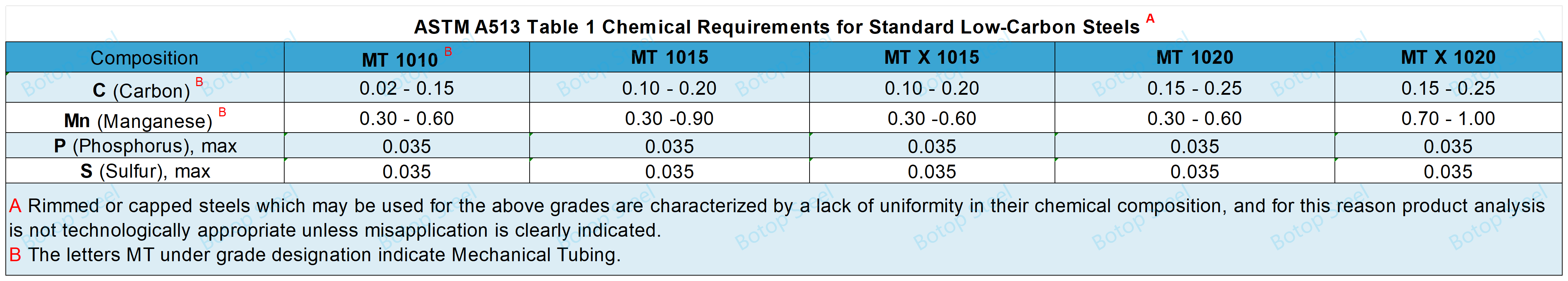

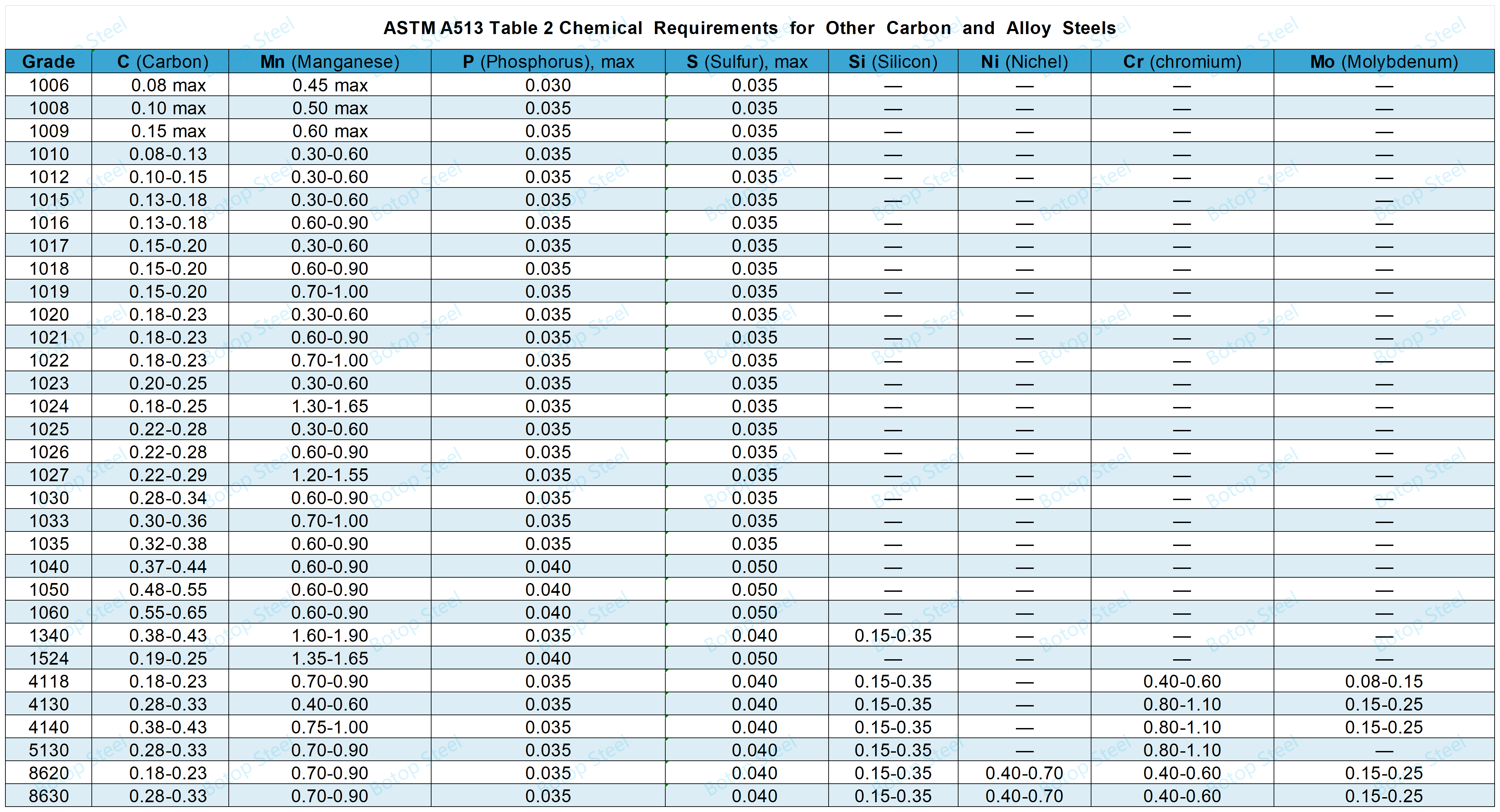

Tshuaj muaj pes tsawg leeg ntawm ASTM A513

Cov hlau yuav tsum ua raws li cov txheej txheem tshuaj lom neeg uas tau teev tseg hauv Table 1 lossis Table 2.

Thaum cov qib carbon steel raug txiav txim los ntawm tus qauv, nws tsis tso cai los muab cov qib alloy uas tshwj xeeb hu rau qhov sib ntxiv ntawm cov khoom uas tsis yog cov teev hauv Tables I thiab 2.

Yog tias tsis muaj qib qhia, qib MT 1010 txog MT 1020 muaj.

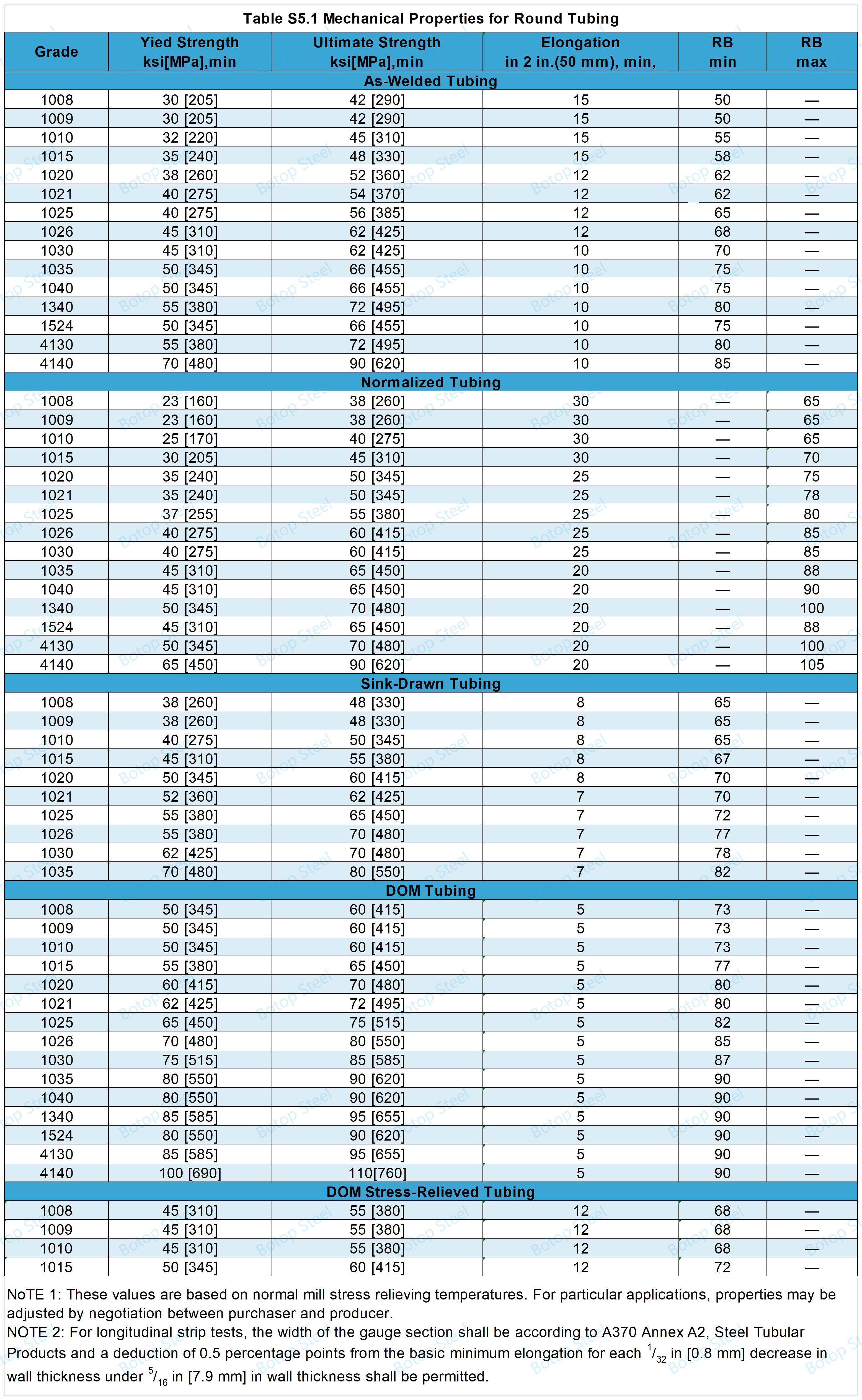

Mechanical Properties ntawm ASTM A513

Kev ntsuas tensile yuav tsum tau ua ib zaug ib zaug.

Thaum "Yuav tsum tau Tensile Properties" tau teev nyob rau hauv Daim Ntawv Txiav Txim Siab, cov tubing puag ncig yuav tsum ua raws li qhov yuav tsum tau muaj tensile thiab tsis tas yuav tsum tau ua rau cov kev txwv hardness qhia hauv Table 5.

Hardness Test

1% ntawm tag nrho cov raj hauv txhua qhov ntau thiab tsis pub tsawg dua 5 lub raj.

Flattening Test

Cov hlab ntsha thiab cov hlab ntsha uas tsim lwm cov duab thaum lawv puag ncig yog siv tau.

Tsis muaj qhov qhib hauv qhov vuam yuav tsum tau ua kom txog thaum qhov kev ncua deb ntawm cov phiaj yog tsawg dua li ob feem peb ntawm qhov qub sab nraud ntawm lub raj.

Tsis muaj cov kab nrib pleb lossis tawg hauv lub hauv paus hlau yuav tsum tshwm sim kom txog thaum qhov kev ncua deb ntawm daim hlau yog tsawg tshaj li ib feem peb ntawm cov thawj sab nraud txoj kab uas hla ntawm cov tubing tab sis nyob rau hauv tsis muaj tsawg tshaj li tsib lub sij hawm lub thickness ntawm lub tubing phab ntsa.

Cov ntaub ntawv pov thawj ntawm cov lamination lossis cov khoom siv hluav taws kub yuav tsum tsis txhob tsim thaum lub sij hawm flattening txheej txheem, thiab lub vuam yuav tsum tsis txhob pom qhov raug mob.

Nco tseg: Thaum qhov qis D-rau-t piv tubing raug sim, vim tias qhov kev cuam tshuam vim yog geometry yog qhov tsis tsim nyog ntawm qhov chaw sab hauv ntawm qhov chaw rau rau thiab kaum ob teev, cov kab nrib pleb ntawm cov chaw no yuav tsum tsis txhob ua rau tsis lees paub yog tias qhov sib piv D-to-t tsawg dua 10.

Flaring Test

Cov hlab ntsha thiab cov hlab ntsha uas tsim lwm cov duab thaum lawv puag ncig yog siv tau.

Ib feem ntawm lub raj kwv yees li 4 hauv [100 mm] ntev yuav tsum sawv ntsug flared nrog lub cuab yeej muaj 60 ° nrog lub kaum sab xis kom txog thaum lub raj ntawm lub qhov ncauj ntawm qhov flare tau nthuav dav 15% ntawm txoj kab uas hla sab hauv, tsis muaj qhov tawg lossis tsis pom qhov tsis zoo.

Hydrostatic Test Round Tubing

Tag nrho cov tubing yuav tau txais kev kuaj hydrostatic.

Khaws qhov tsawg kawg nkaus ntsuas ntsuas dej tsis pub tsawg tshaj 5s.

Lub siab yog xam raws li:

P = 2st/D

P= yam tsawg kawg nkaus hydrostatic xeem siab, psi lossis MPa,

S= tso cai fiber ntau kev nyuaj siab ntawm 14,000 psi los yog 96.5 MPa,

t= teev phab ntsa thickness, in. or mm,

D= teev sab nraud txoj kab uas hla, in. los yog mm.

Nondestructive Electric Test

Nws yog lub hom phiaj ntawm qhov kev sim no kom tsis lees txais cov hlab ntsha uas muaj kev raug mob.

Txhua lub raj yuav tsum raug kuaj nrog qhov ntsuas hluav taws xob tsis zoo raws li Kev Xyaum E213, Xyaum E273, Xyaum E309, lossis Xyaum E570.

Tolerances rau Round Pipe Dimensions

Yog xav paub ntxiv, thov mus saib lub rooj sib tham hauv tus qauv.

Sab nraud

Rooj 4Diameter Tolerances rau Hom I (AWHR) Round Tubing

Table 5Txoj kab uas hla rau Hom 3, 4, 5, thiab 6 (SDHR, SDCR, DOM, thiab SSID) Round Tubing

Table 10Diameter Tolerances rau Hom 2 (AWCR) Round Tubing

Phab ntsa Thickness

Table 6Phab ntsa Thickness kam rau ua rau Hom I (AWHR) Round Tubing (Inch Units)

Table 7Phab ntsa Thickness kam rau ua rau Hom I (AWHR) Round Tubing (SI units)

Table 8Phab ntsa Thickness Tolerances ntawm Hom 5 thiab 6 (DOM thiab SSID) Round Tubing (Inch Units)

TAB 9Phab ntsa Thickness Tolerances ntawm Hom 5 thiab 6 (DOM thiab SSID) Round Tubing (SI Units)

Table 11Phab ntsa Thickness Tolerances rau Hom 2 (AWCR) Round Tubing (Inch Units)

Table 12Phab ntsa Thickness Tolerances rau Hom 2 (AWCR) Round Tubing (SI units)

Ntev

Table 13Txiav-Length Tolerances rau Lathe-Cut Round Tubing

Table 14Ntev Tolerances rau Punch-, Saw-, lossis Disc-Cut Round Tubing

Squareness

Table 15Tolerance (Inch) rau Squareness ntawm Txiav (Txawm Kawg) Thaum Qhia Txog Round Tubing

Tolerance ntawm Square thiab Rectangular Tube Dimensions

Yog xav paub ntxiv, thov mus saib lub rooj sib tham hauv tus qauv.

Sab nraud

Table 16Tolerances, Sab Nraud Dimensions Square thiab Rectangular Tubing

Radii ntawm Corners

Table 17Radii ntawm Corners ntawm Hluav Taws Xob-Resistance-Welded Square thiab Rectangular Tubing

Ntev

Table 18Ntev Tolerances-Square thiab Rectangular Tubing

Twist Tolerances

Table 19Twist Tolerances Electric-Resistance-Welded rau Square thiab Rectangular-Mechanical Tubing

Qhov tshwm sim

Cov tubing yuav tsum tsis muaj qhov raug mob thiab yuav tsum muaj cov neeg ua haujlwm tiav.

Txheej

Tubing yuav tsum tau coated nrog ib zaj duab xis ntawm roj ua ntej xa mus rau retard xeb.

Tiv thaiv kom tsis txhob xeb tshwm sim hauv lub sijhawm luv luv.

Yog hais tias qhov kev txiav txim hais tias tubing raug xa mus yam tsis muaj xeb retarding roj, zaj duab xis ntawm cov roj teeb meem los tsim yuav nyob twj ywm rau saum npoo.

Kos npe

Qhov saum npoo ntawm cov hlau yog cim siv txoj kev tsim nyog thiab muaj cov ntaub ntawv hauv qab no:

Chaw tsim tshuaj paus lub npe los yoghom

Qhov loj me

Hom

tus neeg yuav khoom tus lej xaj,

Tus qauv naj npawb, ASTM A513.

Barcodes kuj tseem siv tau los ua ib txoj hauv kev txheeb xyuas ntxiv.

Daim ntawv thov ASTM A513

Automotive kev lag luam: Siv nyob rau hauv automotive rooj thav duab, ncua kev kawm ntawv Cheebtsam, steering kab, brackets, thiab lwm yam tsheb structural Cheebtsam.

Kev tsim kho kev lag luam: Raws li cov khoom siv txhawb nqa rau cov qauv tsim, xws li cov kav dej scaffolding, guardrails, railings, thiab lwm yam.

Tshuabmkev tsim khoom: Siv nyob rau hauv kev tsim khoom ntawm ntau yam khoom siv, xws li hydraulic system thooj voos kheej kheej, rotating qhov chaw, bearings, thiab lwm yam.

Cov khoom siv ua liaj ua teb: Hauv kev tsim cov tshuab ua liaj ua teb, siv los ua cov qauv ntawm cov khoom siv ua liaj ua teb, kev sib kis, thiab lwm yam.

Furniture Manufacturing: Siv nyob rau hauv kev tsim cov rooj tog hlau ntau yam, xws li cov txee, rooj zaum rooj, txaj ncej, thiab lwm yam.

Cov khoom siv ua kis las: nyob rau hauv cov chaw ua kis las thiab cov cuab yeej tsim khoom, siv los ua cov khoom siv hlau, xws li cov khoom siv dag zog, cov hom phiaj ntaus pob, cov hom phiaj ncaws pob, thiab lwm yam.

Kev lag luam chaw: siv nyob rau hauv kev tsim cov khoom siv conveyor, rollers, tso tsheb hlau luam, thiab lwm yam khoom siv hauv kev lag luam.

Peb Qhov Zoo

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua cov pa roj carbon steel yeeb nkab xa khoom nyob rau sab qaum teb Tuam Tshoj, paub txog nws cov kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem. Lub tuam txhab cov khoom lag luam dav suav nrog seamless, ERW, LSAW, thiab SSAW steel kav, nrog rau cov yeeb nkab fittings, flanges, thiab cov hlau tshwj xeeb.

Nrog rau kev cog lus muaj zog rau kev ua tau zoo, Botop Steel siv cov kev tswj hwm nruj thiab kev ntsuam xyuas kom ntseeg tau tias muaj kev ntseeg siab ntawm nws cov khoom. Nws pab neeg muaj kev paub dhau los muab cov kev daws teeb meem ntawm tus kheej thiab cov kws tshaj lij kev txhawb nqa, nrog rau kev tsom mus rau cov neeg siv khoom txaus siab.

Hot Tags: ASTM A513, carbon steel, hom 5, hom 1, dom.

Post lub sij hawm: May-07-2024