Carbon steel yeeb nkabyog cov yeeb nkab ua los ntawm carbon steel nrog cov tshuaj muaj pes tsawg leeg uas, thaum ntsuas thermally, tsis pub tshaj 2.00% rau carbon thiab 1.65% manganese.

Carbon steel yeeb nkab yog cov khoom siv dav siv hauv kev lag luam los thauj cov kua thiab roj.

Navigation Khawm

Kev faib tawm ntawm Carbon Steel Pipe

Carbon Steel Pipe Size Range

Common Executive Standards rau Carbon Steel Pipe

Cov ntsiab lus tseem ceeb ntawm Carbon Steel Pipe

Carbon Steel Yeeb Nkab Txheej

Qhov zoo ntawm Carbon Steel Pipe

Disadvantages ntawm Carbon Steel Yeeb Nkab

Kev siv carbon steel yeeb nkab

Yuav Ua Li Cas Xaiv Cov Khoom Siv Hluav Taws Xob Cov Khoom Siv Hluav Taws Xob

Txog Peb

Kev faib tawm ntawm Carbon Steel Pipe

Kev faib tawm los ntawm Lub Hom Phiaj

Cov kav dej muaj zog: feem ntau yog siv rau hauv kev tsim vaj tsev, xws li kev txhawb nqa lub tsev, txuas hniav, thiab cov qauv kev lag luam.

Cov kav dej thauj mus los: Cov kav dej carbon steel no yog siv los thauj cov kua dej xws li roj, roj, thiab dej.

Mechanical Tubes: Siv nyob rau hauv machinery thiab automation qhov tseeb qhov ntev thiab cov cuab yeej tshwj xeeb xav tau.

Boiler Tubes: Tshwj xeeb rau qhov kub thiab txias ib puag ncig, xws li boilers hauv chaw nres tsheb fais fab thiab roj refineries.

Roj thiab roj zoo tubing: siv rau hauv cov roj thiab roj rho tawm, uas yuav tsum muaj peev xwm tiv taus huab cua siab thiab tshuaj corrosion.

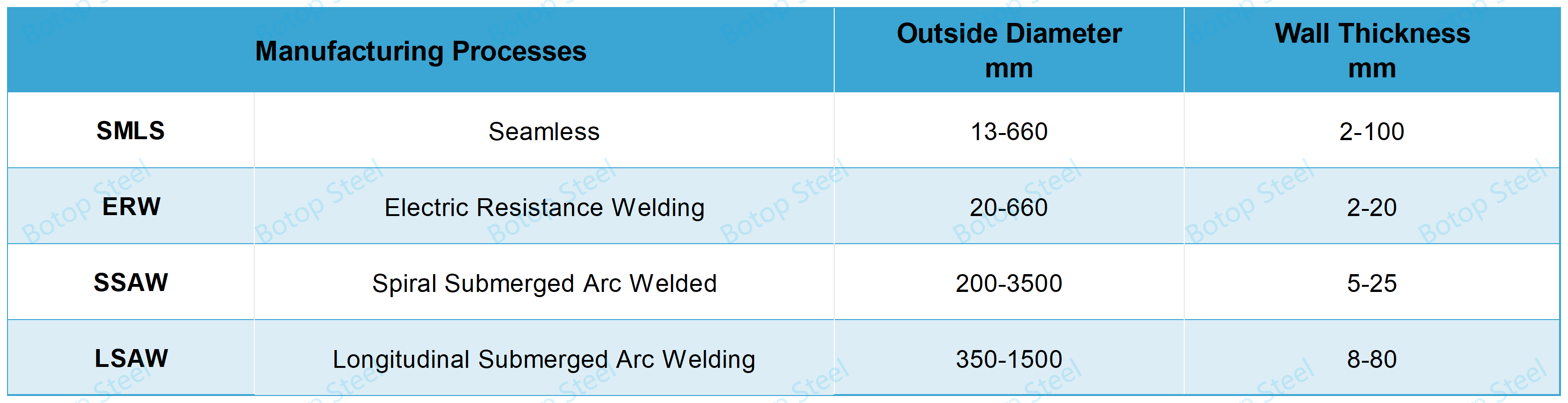

Kev faib tawm raws li txheej txheem tsim khoom

Seamless steel yeeb nkab: steel yeeb nkab ua los ntawm kub tiav los yog txias tiav txheej txheem, tsis muaj welded seam, feem ntau siv nyob rau hauv lub sij hawm ntawm kev kub siab.

Welded steel yeeb nkab: ua los ntawm steel phaj los yog sawb kauj rau hauv lub raj, los ntawm txoj kev vuam ntawm kev ua molding.

Welded steel yeeb nkab tuaj yeem categorized raws li txheej txheem vuam:

Resistance Welded Steel Yeeb Nkab (ERW): Welded yob-tsim yeeb nkab los ntawm high-frequency kuj cua sov, zus tau tej cov carbon steel yeeb nkab nrog ib tug me me txoj kab uas hla thiab ceev ntau lawm ceev.

Submerged Arc Welded Yeeb Nkab (SAW): siv cov txheej txheem tsis siv neeg submerged arc vuam los tsim cov pa roj carbon steel kav nrog cov kab loj dua lossis cov phab ntsa tuab.

SAWsteel yeeb nkab kuj tuaj yeem muab faib uaLSAW(Longitudinal Submerged Arc Vuam) thiabSSAW(Spiral Submerged Arc Welded) raws li cov kev taw qhia ntawm vuam seam.

Yog koj xav paub qhov txawvntawm SMLS, ERW, LSAW, SSAW, koj tuaj yeem nias mus xyuas nws.

Carbon Steel Pipe Size Range

Common Executive Standards rau Carbon Steel Pipe

ASTM A106 1: Seamless carbon steel yeeb nkab rau kev pabcuam kub.

ASTM A53: Welded thiab seamless steel raj rau kev pabcuam dav dav thiab siab.

ASTM A333 Cov khoom lag luam: Seamless thiab welded steel yeeb nkab rau kev pab cuam qis.

API 5L: Steel yeeb nkab specification rau cov kav dej thauj mus los siv hauv kev lag luam roj thiab roj.

TIAB SA 2440: Medium-heavy carbon steel raj rau kev tsim qauv thiab kev ua haujlwm siab.

TS EN 10210: Kub-tsim structural steel raj rau cov hom phiaj.

TS EN 10219: Cold-formed welded structural steel kav rau kev tsim qauv.

JIS G3452: Carbon steel kav rau cov kav dej dav dav.

JIS G3454: Carbon steel kav rau siab piping.

AS/NZS 1163: Cold-formed structural steel hlab thiab hollow seem rau cov khoom siv thiab cov kav dej structural.

Cov ntsiab lus tseem ceeb ntawm Carbon Steel Pipe

Tube Loj

Qhov tsis zoo ntawm cov pa roj carbon steel yeeb nkab yog qhov tseem ceeb los xyuas kom muaj kev txhim kho thiab ua haujlwm ntawm cov kav dej.

Sab nraud txoj kab uas hla (OD): Txoj kab uas hla ntawm sab nraud ntawm cov yeeb nkab, yog ncaj qha ntsig txog cov yeeb nkab txuas thiab kev teeb tsa.

Sab hauv txoj kab uas hla (ID): txoj kab uas hla ntawm sab hauv ntawm cov yeeb nkab, uas cuam tshuam rau tus nqi ntws thiab cov dej ntws.

Phab ntsa thickness (WT): lub thickness ntawm phab ntsa ntawm cov yeeb nkab, uas yog ib qho tseem ceeb rau lub siab kam rau siab thiab rigidity ntawm cov yeeb nkab.

Ntev (L): Cov yeeb nkab tuaj yeem yog qhov ruaj khov lossis ntev ntev.

Roundness thiab straightness: txiav txim siab lub installation zoo ntawm cov yeeb nkab thiab kev sib khi ntawm kev sib txuas.

Tube kawg hom: Lub raj kawg tuaj yeem ua tiaj tus, beveled, lossis threaded kom haum rau ntau hom kev sib txuas.

Tshuaj muaj pes tsawg leeg

Cov tshuaj muaj pes tsawg leeg ntawm carbon steel yeeb nkab txiav txim siab nws hardness, lub zog, toughness, thiab corrosion kuj.

Cov pa roj carbon (C): nce hardness thiab zog, tab sis ntau dhau yuav txo toughness.

Manganese (Mn): Ua kom muaj zog thiab hnav tsis kam thaum tuav zoo toughness.

Silicon (Si): Txhim khu elasticity thiab kub tsis kam.

Sulfur (S)thiabphosphorus (P): feem ntau suav hais tias yog impurities thiab yuav tsum tau khaws cia nyob rau theem qis vim lawv txo qhov toughness thiab weldability.

Lwm yam alloying ntsiab(xws li chromium, npib tsib xee, molybdenum): tuaj yeem txhim kho cov cuab yeej tshwj xeeb thiab tiv thaiv corrosion.

Mechanical Properties

Cov cuab yeej cuab tam tsis ncaj qha cuam tshuam rau kev ruaj ntseg ntawm carbon steel yeeb nkab nyob rau hauv kev pab cuam.

Tensile zog: muaj peev xwm ntawm cov khoom siv los tiv thaiv kev puas tsuaj hauv kev nro.

Yield zog: qhov siab tshaj plaws uas cov khoom raug raug ua ntej nws pib deform mus tas li.

Elongation: Ib qho qhia txog lub peev xwm ntawm cov khoom siv los deform plastically, qhov twg nws tuaj yeem elongate ua ntej tawg.

Hardness: Lub peev xwm ntawm cov khoom siv los tiv thaiv qhov chaw hauv cheeb tsam, feem ntau ntsuas los ntawm Brinell, Rockwell, lossis Vickers hardness tests.

Impact test: Ib qho kev ntsuam xyuas cuam tshuam ua rau ntawm qhov kub thiab txias los ntsuas qhov toughness ntawm cov khoom.

Thaum xaiv cov pa roj carbon steel raj, cov kev txwv tseem ceeb no yuav tsum ua raws li cov kev cai tshwj xeeb thiab cov qauv siv.

Carbon Steel Yeeb Nkab Txheej

Txheej txheej tiv thaiv rau cov pa roj carbon steel yeeb nkab yog ib qho tseem ceeb ntawm kev tiv thaiv corrosion thiab ncua lub neej yeeb nkab. Cov txheej txheem sib txawv muab cov qib sib txawv ntawm kev tiv thaiv thiab tsim nyog rau kev ua haujlwm sib txawv thiab cov xwm txheej.

Cov hauv qab no yog qee hom txheej txheej txheej rau carbon steel yeeb nkab:

Epoxy txheej: muab zoo adhesion thiab tshuaj tiv thaiv thiab feem ntau yog siv rau kev tiv thaiv corrosion thiab underwater daim ntaub ntawv.

Polyurethane txheej: Muab cov huab cua zoo heev thiab kev puas tsuaj thiab siv nyob rau hauv qhov chaw raug sab nraud.

Zinc-nplua nuj coatings: Muaj feem pua ntawm zinc hmoov, lawv muab kev tiv thaiv cathodic thiab tsim nyog rau thaj chaw marine thiab kev lag luam.

Galvanizing: Muab kev tiv thaiv cathodic los ntawm kub-dipping los yog electroplating zinc thiab yog ib txwm siv los tiv thaiv corrosion.

Aluminium plating: muab kev tiv thaiv zoo tshaj rau galvanizing nyob rau hauv tej yam kev mob, tshwj xeeb tshaj yog nyob rau hauv high-temperature ib puag ncig.

Polyethylene (PE) txheej: Muab tshuaj lom neeg zoo thiab cuam tshuam thiab feem ntau yog siv rau hauv cov kav dej hauv av.

Polypropylene (PP) txheej: zoo ib yam li PE txheej tab sis muaj kev ua tau zoo dua ntawm qhov kub siab dua.

Cement mortar hauv ob sab phlu: Haum rau cov kav dej phwj tuaj thiab cov kav dej kom tsis txhob muaj cov kab mob hauv lub cev thiab cov dej paug.

Roj hmab hauv ob sab phlu: Muab kev tiv thaiv lub cev thiab txo cov corrosion thiab puas los ntawm cov kua dej.

Txhua hom txheej muaj nws cov kev thov tshwj xeeb, qhov zoo, thiab qhov tsis zoo. Ntau yam xws li tus nqi, kev tsim kho, kev ua neej nyob, kev cuam tshuam ib puag ncig, thiab kev saib xyuas yuav tsum tau xav txog thaum xaiv cov txheej txheem tsim nyog.

Qhov zoo ntawm Carbon Steel Pipe

Carbon steel yeeb nkab muaj ntau yam zoo uas ua rau nws cov khoom ntawm kev xaiv rau ntau daim ntawv thov kev lag luam.

1.Nqe zoo: pheej yig dua stainless hlau lossis hlau alloy, nws yog qhov kev xaiv zoo tshaj plaws rau cov haujlwm loj thiab cov kav dej ntev.

2. Mechanical zog: Lawv muaj cov khoom siv kho tshuab zoo, suav nrog lub zog tensile siab thiab cuam tshuam tsis kam. Qhov no txhais tau hais tias nws tuaj yeem tiv taus kev kub ntxhov thiab hnyav ua haujlwm ib puag ncig.

3. Kev ua haujlwm yooj yim: Yooj yim rau txiav, vuam, thiab cov duab rau tom qab installation thiab txij nkawm.

4. Zoo thermal conductivity: Cov pa roj carbon steel yog cov khoom siv hluav taws xob zoo ntawm cov cua sov thiab tsim nyog rau kev siv xws li cov khoom siv hluav taws xob sib hloov thiab cov cua sov uas yuav tsum tau hloov cov cua sov kom zoo.

5. Kub kub tsis kam: Nws tuav nws lub cev ntawm qhov kub thiab txias thiab haum rau ib puag ncig uas xav tau kev ua haujlwm siab, xws li chav tshuab.

6. Kev rov ua dua tshiab: Nws yog cov khoom siv rov ua dua tshiab uas tuaj yeem xa rov qab mus rau qhov cub kom rov siv dua thaum kawg ntawm lub lim tiam siv.

7. Abrasion tsis kam: Lub hardness zoo tso cai rau kev puas tsuaj zoo thaum xa cov ntaub ntawv abrasive thiab yog, piv txwv li, dav siv rau cov khoom siv hauv kev lag luam mining thiab hmoov tuav.

8. Kev sib haum xeeb: Tau tshaj ntau hom kev sib txuas thiab fittings, nrog rau ntau yam khoom siv thiab khoom siv yooj yim.

Disadvantages ntawm Carbon Steel Yeeb Nkab

Txawm hais tias cov pa roj carbon steel kav tau siv dav hauv ntau daim ntawv thov kev lag luam vim lawv ntau qhov zoo, lawv kuj muaj qee qhov tsis zoo lossis kev txwv.

1. Yooj yim rau corrosion: Tshwj xeeb tshaj yog nyob rau hauv ntub los yog corrosive ib puag ncig. Corrosion tuaj yeem ua rau cov phab ntsa tuab ntawm cov yeeb nkab steel, ua rau muaj kev pheej hmoo ntawm kev tawg thiab thaum kawg ua rau kom tawg lossis tsis ua haujlwm.

2. Cov nqi kho mob: Txhawm rau tiv thaiv corrosion thiab txuas ntxiv lawv lub neej kev pabcuam, cov kav dej carbon steel yuav xav tau kev tiv thaiv ntxiv xws li cov txheej txheej, cov ntaub qhwv, lossis cov txheej txheem tiv thaiv cathodic. Kev saib xyuas tsis tu ncua thiab kev tshuaj xyuas yuav tsum tau nyob thoob plaws hauv lub neej ntawm cov yeeb nkab, uas ntxiv rau tag nrho cov nqi.

3. Tsis tsim nyog siv nrog qee yam tshuaj: Carbon steel yog rhiab heev rau tej yam tshuaj thiab tej zaum yuav corrode sai dua nyob rau hauv tus ntawm cov tshuaj no. Piv txwv li, cov pa roj carbon steel muaj qhov cuam tshuam rau kev ntxhov siab corrosion tawg nyob rau hauv ib puag ncig nrog siab concentrations ntawm hydrogen sulfide.

4. Kev txwv kub: Txawm hais tias carbon steels tuaj yeem tiv taus ntau qhov kub thiab txias, cov khoom siv ntawm cov hlau deteriorate ntawm qhov kub siab heev, ua rau cov khoom siv txo qis thiab nkag mus (deformation los ntawm lub sij hawm ntev mus rau siab loads).

5. Tsawg-kub embrittlement: Thaum qhov kub thiab txias, ob qho tib si toughness thiab brittleness raug txo, uas ua rau brittle puas nyob rau hauv kev cuam tshuam.

6. Teeb meem hnyav: Cov kav dej carbon steel hnyav dua li lwm cov ntaub ntawv, xws li cov yas, thiab tej zaum yuav ua rau muaj kev xav tau ntxiv thiab cov nqi rau kev txhim kho thiab kev txhawb nqa.

7. Thermal expansion: Thermal expansion uas tshwm sim thaum lub sij hawm kub hloov, tshwj xeeb tshaj yog nyob rau hauv cov kav dej ntev. Qhov no yuav tsum tau coj mus rau hauv tus account hauv kev tsim thiab kev teeb tsa cov kav dej kom tsis txhob muaj kev ntxhov siab thiab deformations tshwm sim los ntawm kev hloov kub.

Xaiv cov yeeb nkab zoo rau cov kev cai ntawm ib daim ntawv thov tshwj xeeb thiab / lossis kev siv cov kev tiv thaiv tsim nyog yog qhov tseem ceeb los ua kom muaj kev vam meej.

Kev siv carbon steel yeeb nkab

1. Kev lag luam roj thiab roj:Siv dav hauv kev thauj mus los ntawm cov roj av, roj av, thiab lwm yam khoom siv roj av, ob qho tib si hauv kev thauj mus los hauv cov kav dej ntev thiab hauv cov kav dej thiab cov roj zoo.

2. Kev lag luam tshuaj thiab petrochemical: Cov kev lag luam no xav tau cov kav dej uas tiv taus qhov kub thiab txias los thauj cov tshuaj thiab cov kua dej thiab yog li feem ntau siv cov kav dej tshwj xeeb uas kho cov pa roj carbon steel.

3. Kev tsim khoom: tuaj yeem siv los tsim cov khoom siv rau cov tshuab thiab cov khoom siv, cov kav dej, thiab lwm yam.

4. Lub tsev thiab kev tsim kho: Hauv kev tsim kho, lawv tau siv los ua cov pob txha ntawm lub tsev xws li kab teeb, kab, thiab lwm yam kev txhawb nqa. Nws kuj yog siv rau hauv kev tsim khoom ntawm scaffolding thiab lwm yam khoom ib ntus.

5. Dej thiab dej phwj tuaj: Siv dav hauv cov kav dej rau kev thauj cov dej thiab dej phwj tuaj, cov kav dej steel feem ntau coated nrog cov txheej txheej tsim nyog, uas yog siv los tiv thaiv cov kav dej los ntawm kev xeb thiab ua rau lawv lub neej ntev.

6. Kev lag luam hluav taws xob: Hauv cov chaw tsim hluav taws xob, lawv tau siv los thauj cov cua kub, siab zog. Lawv kuj tuaj yeem siv los ua cov boilers thiab cov cua kub exchangers.

7. Cua sov thiab cua txias tshuab: Rau kev thauj cov xov xwm lossis chav nyob hauv nruab nrab cua sov thiab cua txias tshuab.

8. Marine kev lag luam: Siv nyob rau hauv kev tsim kho nkoj rau thav duab cov qauv, cov kav dej, thiab ntau yam kev siv.

9. Thermal fais fab chaw nres tsheb: Rau chav dej thiab kev thauj mus los hauv cov chaw siv hluav taws xob thermal.

10. Cov qauv thiab engineering: Feem ntau yog siv los txhawb cov qauv rau cov txuas hniav, tunnels, subway systems, thiab cov chaw pej xeem loj.

Carbon steel kav feem ntau xaiv raws li lawv txoj kab uas hla, phab ntsa thickness, ntev, txheej txheem tsim, thiab seb puas yuav tsum tau coatings ntxiv los yog linings yuav tsum tau tiv thaiv corrosion. Thaum siv lawv, nws yog ib qho tseem ceeb uas yuav tau xav txog qhov kub, siab, thiab hom xov xwm hauv qhov chaw ua haujlwm.

Yuav Ua Li Cas Xaiv Cov Khoom Siv Hluav Taws Xob Cov Khoom Siv Hluav Taws Xob

1. Kev tsim nyog thiab kev lees paub:Xyuas tias tus neeg muag khoom cov khoom ua raws li cov qauv kev lag luam thoob ntiaj teb thiab hauv tsev thiab nws muaj kev tswj hwm kev tswj hwm zoo (xws li ISO 9001).

2. Cov khoom zoo: Puas yog tus neeg muag khoom muab cov ntaub ntawv ntsuam xyuas ntawm cov tshuaj muaj pes tsawg leeg thiab cov khoom siv tshuab ntawm cov khoom siv raw thiab cov khoom tiav. Thiab nkag siab txog kev ntsuas kev ruaj ntseg, suav nrog kev tshuaj xyuas, kev sim, thiab kev tswj xyuas zoo thaum lub sijhawm tsim khoom.

3. Muaj peev xwm ntau lawm: Ntsuam xyuas seb tus neeg muag khoom qhov loj thiab cov peev txheej puas tuaj yeem ua tau raws li qhov yuav tsum tau ua. Tshawb xyuas seb cov txheej txheem tsim khoom thiab cov cuab yeej siv los ntawm tus neeg muag khoom puas tau kho tshiab kom ntseeg tau cov khoom zoo.

4. Kev lag luam lub koob npe nrov: Xav txog tus neeg muag khoom kev paub hauv kev lag luam carbon steel yeeb nkab. Kev ua lag luam mus sij hawm ntev feem ntau yog txuam nrog kev ntseeg siab. Nug cov lus tawm tswv yim thiab cov lus pom los ntawm cov neeg siv khoom uas twb muaj lawm, tshwj xeeb tshaj yog hais txog cov khoom zoo thiab kev pabcuam txaus siab.

5. Kev pabcuam thiab kev txhawb nqa:Tus neeg muag khoom puas muab kev pabcuam zoo rau cov neeg siv khoom, suav nrog kev teb sai thiab daws teeb meem. Seb tus neeg muag khoom tuaj yeem muab kev txhawb nqa kev tshaj lij hauv cov txheej txheem ntawm kev xaiv cov khoom, kev piav qhia kev ua haujlwm, thiab kev teeb tsa.

6. Nqe thiab nqi: Sib piv cov lus hais los ntawm cov neeg muag khoom sib txawv kom ntseeg tau tias tus nqi yog raws li qib kev lag luam thiab tus nqi zoo. Saib xyuas cov nqi zais uas tshwm sim los ntawm kev thauj mus los, ntim khoom, tuaj yeem ncua sijhawm, thiab lwm yam.

7. Lub sijhawm xa khoom:Txawm hais tias cov neeg muag khoom tuaj yeem cog lus thiab ua tau raws li lub sijhawm xa khoom xa tuaj, ntsuas tus neeg xa khoom lub network kom ntseeg tau tias cov khoom tuaj yeem xa khoom nyab xeeb thiab raws sijhawm.

8. Kev pab cuam tom qab muag: Nkag siab txog tus neeg muag khoom txoj cai kev pab cuam tom qab muag, xws li kev xa rov qab thiab kev sib pauv, kev tswj tsis zoo, thiab lwm yam.

9. Lub tuam txhab cov ntaub ntawv tshawb fawb: Siv cov peev txheej online kom tau txais cov ntaub ntawv ntxiv. Piv txwv li, tuam txhab websites, kev lag luam forums, social media, thiab lwm yam.

10. Kev mus xyuas qhov chaw: Yog tias ua tau, koj tuaj yeem mus ntsib tus neeg muag khoom cov chaw tsim khoom, thiab cov chaw tsim khoom ntawm tus kheej.

11. Cov qauv kuaj: Cov qauv tuaj yeem thov rau kev kuaj xyuas kom paub tseeb tias qhov tseeb ntawm cov khoom ua tau raws li qhov yuav tsum tau ua.

Thoob plaws hauv txoj kev xaiv, kev ntsuam xyuas dav dav thiab kev txiav txim siab zoo yog qhov tseem ceeb. Xyuas kom meej tias tus neeg muag khoom koj xaiv tsis yog tsuas yog superior ntawm tus nqi, tab sis yog qhov kev xaiv zoo tshaj plaws ntawm qhov zoo, kev ntseeg siab, thiab tag nrho cov nqi.

Txog Peb

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua cov pa roj carbon steel yeeb nkab xa khoom nyob rau sab qaum teb Tuam Tshoj, paub txog nws cov kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem. Lub tuam txhab cov khoom lag luam dav suav nrog seamless, ERW, LSAW, thiab SSAW steel kav, nrog rau cov yeeb nkab fittings, flanges, thiab cov hlau tshwj xeeb.

Nrog rau kev cog lus muaj zog rau kev ua tau zoo, Botop Steel siv cov kev tswj hwm nruj thiab kev ntsuam xyuas kom ntseeg tau tias muaj kev ntseeg siab ntawm nws cov khoom. Nws pab neeg muaj kev paub dhau los muab cov kev daws teeb meem ntawm tus kheej thiab cov kws tshaj lij kev txhawb nqa, nrog rau kev tsom mus rau cov neeg siv khoom txaus siab.

Hot Tags: carbon steel yeeb nkab, lwm tus neeg, manufacturers, hoobkas, stockists, tuam txhab, lag luam wholesale, yuav, nqe, hais, tej, muag, nqi.

Post lub sij hawm: May-03-2024