API 5L X70 yog API 5L cov ntaub ntawv qib rau kab yeeb nkab nrog qhov tsawg kawg nkaus tawm los ntawm 70,000 psi.Nws feem ntau yog siv rau kev thauj mus los ntawm cov pa roj, roj, thiab dej.

Yog xav paub ntxiv txog API 5L-46th, koj tuaj yeemnias ntawm no!

API 5L X70 nta

High yield zog: Yam tsawg kawg nkaus yield zog ntawm 70,000 psi (kwv yees li 485 MPa), haum rau siab sab hauv.

Zoo toughness: tswj kev ua haujlwm ntawm qhov kub qis rau cov cheeb tsam txias thiab kev siv dej hiav txwv sib sib zog nqus.

Weldability zoo heev: Lub zog muaj zog thaum tuav zoo weldability, nrog welds txuam cov khoom ntawm lub hauv paus hlau.

Corrosion kuj: tuaj yeem txhim kho los ntawm kev tswj cov tshuaj muaj pes tsawg leeg thiab kev kho tom qab (xws li txheej txheej), tsim nyog rau thaj chaw sab nrauv thiab corrosive.

Environmental suitability: tuaj yeem tsim los siv rau hauv cov qauv av, offshore, thiab acid kev pabcuam ib puag ncig.

Sustainability: Txo kev cuam tshuam ib puag ncig thiab txhim kho kev sib kis tau zoo raws li cov khoom siv rov ua dua tshiab.

API 5L X70 Kev faib tawm

Tube Hom: Welded thiab Seamless Steel Yeeb Nkab

Khoom specification qib: API 5L X70 PSL1 thiab API 5L X70 PSL2

Kev tsim cov yeeb nkab: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

Pipe kawg hom: Belled kawg, Plain kawg

Cov khoom siv raw

Ingots, billets, billets, strips (coils), los yog daim hlau ua raw khoom rau kev tsim cov kav hlau.

Cov khoom siv raw rau PSL2 steel yeeb nkab yuav tsum yog cov nplua-grain sedimented steel.

Tsis tas li ntawd, steel sawb (coil) los yog phaj siv rau kev tsim cov PSL2 steel yeeb nkab yuav tsum tsis txhob dais ib qho muab tub lim.

API 5L X70 Pipe Manufacturing Txheej txheem

| Hom yeeb nkab | SMLS | LFW | HFW | LW | SAWLc | SAWHd | COWLc | COVd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | — | X | — | X | X | X | X |

cOb chav-seam yeeb nkab yog muaj yog pom zoo, tab sis txwv rau cov yeeb nkab nrog D ≥ 914 mm.

dHelical seam yeeb nkab yog txwv rau cov yeeb nkab nrog D ≥ 114.3 hli.

Pipe End Hom rau API 5L X70

| Cov yeeb nkab kawg | Belled kawge | Plain kawg |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | — | X |

eBelled-kawg yeeb nkab yog txwv rau cov yeeb nkab nrog D ≤219.1 hli thiab t≤ 3.6 hli.

Kev xa khoom zaum kawg

API 5L X70 lub xeev xa khoom kawg (qhov kawg kev kho cua sov ntawm cov yeeb nkab steel tiav) tuaj yeem muab faib ua: dov, normalizing dov, thermo-mechanical dov, thermo-mechanical forming, normalizing forming, normalizing, normalizing thiab tempering los yog quenching thiab tempering.

| PSL | Kev Xa Khoom | Qib Qib / Hlau Qib | |

| PSL1 | Raws li dov, normalizing dov, thermomechanical dov, thermomechanical tsim, normalizing tsim, normalized, normalized thiab tempered los yog quenched thiab tempered | X 70 | l485 ua |

| PSL 2 | Quenched thiab tempered | x70 qw | l485 qw |

| Thermomechanical dov los yog thermomechanical tsim | X 70 M | l485m ua | |

Cov kev xa khoom no xyuas kom meej tias API 5L X70 tubing ua tau zoo nyob rau hauv ntau yam kev siv sib txawv, xws li siv nyob rau hauv high-pressure, low-temperature, los yog corrosive ib puag ncig.

Tshuaj muaj pes tsawg leeg

API 5L X70 PSL1 Tshuaj muaj pes tsawg leeg

Cov tshuaj lom neeg muaj pes tsawg leeg ntawm API 5L X70 PSL1 steel yeeb nkab suav nrog cov pa roj carbon tsawg, cov manganese tsawg, thiab tsawg tsawg ntawm phosphorus, sulfur, thiab silicon.Tsis tas li ntawd, alloying ntsiab xws li chromium, npib tsib xee thiab tooj liab yog ntxiv los txhim kho lub zog thiab corrosion kuj.Micro-alloying ntsiab xws li vanadium, molybdenum thiab titanium ntxiv optimize durability thiab yield zog, kom ntseeg tau tias kev ua tau zoo nyob rau hauv ib puag ncig nyuaj.

| Tshuaj muaj pes tsawg leeg rau PSL 1 Pipe nrog t≤25.0 mm (0.984 in.) | |||||||||

| Qib Steel (Lub npe steel) | Loj Fraction, Raws li kev ntsuas kub thiab cov khoom lag luamua ag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | min | max | max | max | max | max | ||

| Seamless Yeeb Nkab | |||||||||

| l485 ua | X 70 | 0.28 ib | 1.40 Nws | — | 0.03 ib | 0.03 ib | f | f | f |

| Welded yeeb nkab | |||||||||

| l485 ua | X 70 | 0.26e | 1.65 ibe | — | 0.03 ib | 0.03 ib | f | f | f |

| a Cu≤0.50%; Ni≤0.50%; Cr≤0.50% thiab Mo≤0.15%. b Rau txhua qhov kev txo qis ntawm 0.01% hauv qab cov ntsiab lus siab tshaj plaws rau cov pa roj carbon, qhov nce ntawm 0.05% saum toj no qhov siab tshaj plaws concentration rau Mn tso cai, mus txog qhov siab tshaj ntawm 1.65% rau qib ≥L245 lossis B, tab sis ≤L360 lossis X52;mus txog qhov siab tshaj ntawm 1.75% rau qib> L360 lossis X52, tab sis thiab mus txog qhov siab tshaj ntawm 2.00% rau Qib L485 lossis X70. e Yog tsis pom zoo f Yog tsis pom zoo, Nb+V+Ti≤0.15%. g Tsis txhob txhob txwm ua ntxiv ntawm B raug tso cai thiab cov seem B≤0.001%. | |||||||||

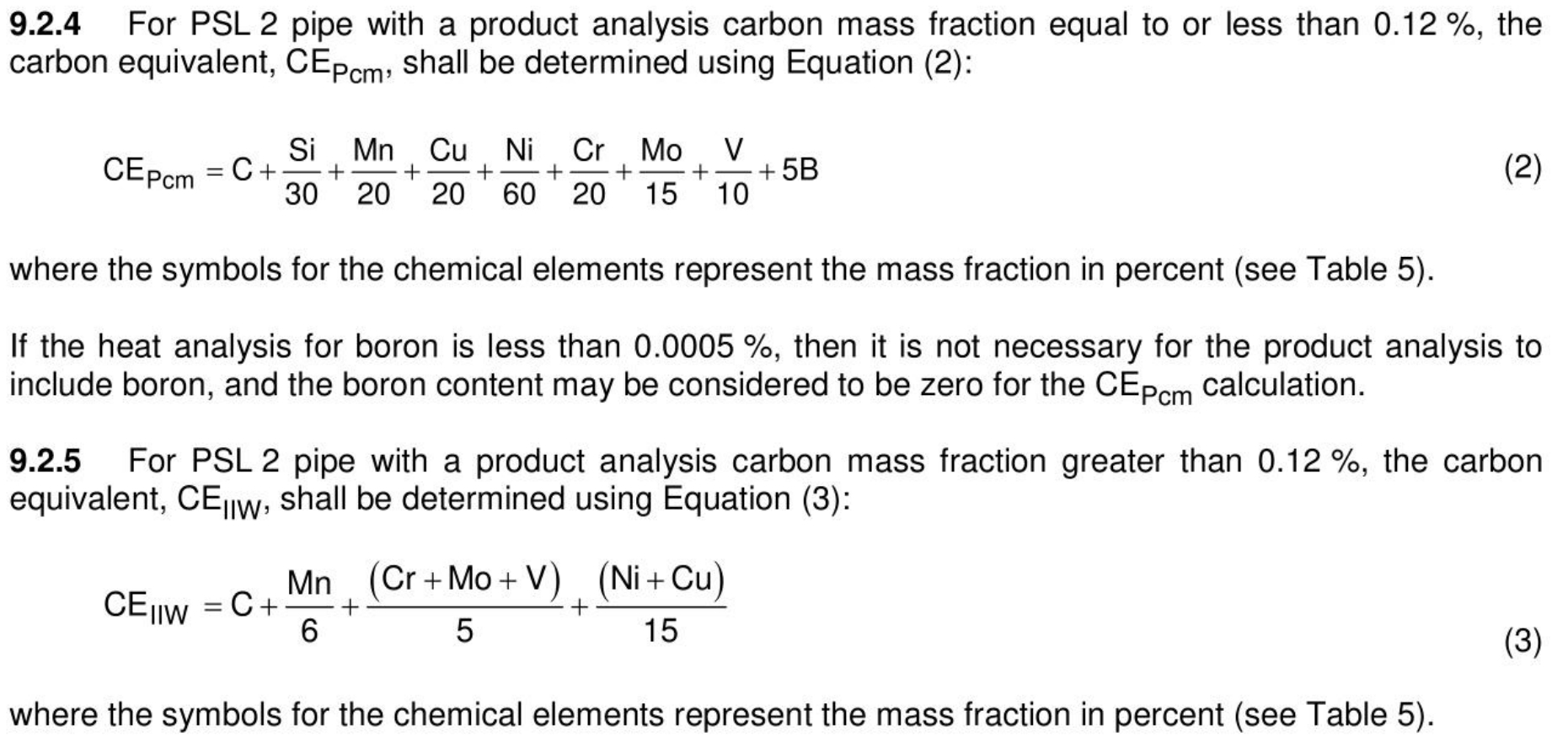

API 5L X70 PSL2 Tshuaj muaj pes tsawg leeg

Cov tshuaj muaj pes tsawg leeg ntawm API 5L X70 PSL2 suav nrog kev tswj hwm cov pa roj carbon, manganese, sulfur, thiab phosphorus, nrog rau kev txiav txim siab ntawm silicon, chromium, nickel, thiab tooj liab.Kev tswj hwm nruj nruj tsis yog tsuas yog txhim kho lub zog tawm los thiab lub zog ntawm cov yeeb nkab tab sis kuj txhim kho corrosion kuj nyob rau hauv huab cua.Tsis tas li ntawd, cov kab kawm xws li vanadium, molybdenum, thiab titanium tau raug hloov kho kom txhim kho kev ua tau zoo, ua X70 PSL2 zoo tagnrho rau kev sib tw cov kev pheej hmoo siab.

| Chemical Composition rau PSL 2 Pipe nrog t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| Qib Steel (Lub npe steel) | Loj Fraction, Raws li kev ntsuas kub thiab cov khoom lag luam % max | Cov pa roj carbon Sib npauga % max | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Lwm yam | CEllw | CEEB | ||

| Seamless thiab Welded yeeb nkab | ||||||||||||

| l485 qw | x70 qw | 0,18f ua | 0.45 ib f | 1.80 ibf | 0.025 ib | 0.015 ib | g | g | g | h, kuv | 0.43 ib | 0.25 |

| Welded yeeb nkab | ||||||||||||

| l485m ua | X 70 M | 0.12 f | 0.45 ibf | 1.70 ibf | 0.025 ib | 0.015 ib | g | g | g | h, kuv | 0.43 ib | |

| a Raws li kev txheeb xyuas cov khoom lag luam, rau cov yeeb nkab seamless nrog t> 20.0 hli (0.787 nyob rau hauv.), CE txwv yuav tsum tau ua raws li kev pom zoo;CEllw txwv siv yog C> 0.12 %, thiab CEpcm txwv siv yog C≤0.12%. b Rau txhua qhov txo qis ntawm 0.01% qis dua qhov siab tshaj plaws rau C, nce ntawm 0.05% siab tshaj qhov teev siab tshaj plaws rau Mn impermissible, mus txog qhov siab tshaj ntawm 1.65% rau qib≥L245 lossis B, but≤L360 lossis X52;mus txog qhov siab tshaj ntawm 1.75% rau qib>L360 lossis X52, tab sisL555 los yog X80. c Yog tsis pom zoo, Nb+V≤0.06%. d Nb+V+Ti≤0.15%. e Tshwj tsis yog tias pom zoo, Cu≤0.50%; Ni≤0.30%; Cr≤0.30% thiab Mo≤0.15%. f Yog tsis pom zoo. g Yog tsis pom zoo, Nb+V+Ti≤0.15%. h Tshwj tsis yog tias pom zoo, Cu≤0.50%; Ni≤0.50%; Cr≤0.50% thiab Mo≤0.50%. Yog tias tsis pom zoo, Cu≤0.50%; Ni≤1.00%; Cr≤0.50% thiab Mo≤0.50%. j B≤0.004 %. k Tshwj tsis yog tias pom zoo, Cu≤0.50%; Ni≤1.00%; Cr≤0.55% thiab Mo≤0.80%. l Rau PSL 2 cov yeeb nkab qib tshwj tsis yog cov qib uas cov lus hauv qab no tau siv, cov hauv qab no siv tau: tshwj tsis yog tias pom zoo txwv tsis pub ntxiv ntawm B yog tso cai thiab seem B≤0.001%. | ||||||||||||

Tshuaj muaj pes tsawg leeg rau Sour Service Conditions API 5L X70 PSL2

Cov kev pabcuam qaub yog hais txog kev siv cov kav dej hauv ib puag ncig uas muaj hydrogen sulfide (H₂S), uas tuaj yeem ua rau hydrogen sulfide stress corrosion cracking (HIC) thiab sulfide stress corrosion cracking (SSCC).

Kev kho cov tshuaj muaj pes tsawg leeg: Nyob rau hauv cov xwm txheej no, cov tshuaj muaj pes tsawg leeg ntawm cov raj xa dej yuav tsum raug kho kom tsim nyog los txhim kho lawv cov kev tiv thaiv corrosion.Feem ntau, qhov no suav nrog txo cov pa roj carbon ntsiab lus ntawm cov khoom siv thiab ntxiv cov ntsiab lus alloying xws li molybdenum (Mo) thiab npib tsib xee (Ni), uas ua rau kom cov corrosion kuj thiab hardness ntawm cov khoom.

| Table H.1—Chemical Composition rau yeeb nkab nrog t≤25.0 mm (0.984 in.) | |||||||||||

| Qib Steel | Loj Fraction Raws li kev ntsuas kub thiab cov khoom lag luam% max | Cov pa roj carbon Sib npauga % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Lwm yamc,d | CEllw | CEEB | |

| SMLS thiab welded yeeb nkab | |||||||||||

| L485QS or X70 QS | 0.16 | 0.45 ib | 1.65 ib | 0.020 ib | 0.003 e | 0.09 ib | 0.05 Nws | 0.06 ib | g, kuv, k | 0.42 ib | 0.22h |

| Welded yeeb nkab | |||||||||||

| L485MS or X70MS | 0.10 | 0.45 ib | 1.60 ib | 0.020 ib | 0.002 ibe | 0.10 | 0.08 ib | 0.06 ib | g,j, ib | — | 0.22 |

Cov ncauj lus kom ntxaws tuaj yeem pom hauv API 5L Cov Ntawv Ntxiv H.

Tshuaj muaj pes tsawg leeg ntawm API 5L X70 PSL2 rau Offshore Service Conditions

Offshore cov kev pab cuam cuam tshuam nrog rau ib puag ncig marine, suav nrog raug dej ntsev thiab huab cua huab cua.Cov xwm txheej no xav tau cov kav dej uas muaj kev tiv thaiv corrosion siab thiab txaus toughness los tiv thaiv cov dej ntsev corrosion thiab kub tsis tshua muaj kev cuam tshuam.

Kev hloov kho ntawm cov tshuaj muaj pes tsawg leeg: Rau kev pab cuam offshore, cov hlau ntawm cov yeeb nkab feem ntau yog nce hauv chromium (Cr), npib tsib xee (Ni) thiab molybdenum (Mo) los txhim kho nws cov kev tiv thaiv rau seawater corrosion.Tus nqi ntawm micro-alloying ntsiab xws li vanadium (V) thiab niobium (Nb) kuj yuav raug hloov kho kom zoo rau qhov toughness ntawm qhov kub thiab txias.

| Table J.1—Chemical Composition rau yeeb nkab nrog t≤25.0 mm (0.984 in.) | ||||||||||||

| Qib Steel | Loj Fraction Raws li kev ntsuas kub thiab cov khoom lag luam max % | Cov pa roj carbon Sib npaug max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Lwm yamc | CElwj | CEPcm | ||

| SMLS thiab welded yeeb nkab | ||||||||||||

| l485 qw | x70 qw | 0.17 ib | 0.45 ib | 1.75 ib | 0.020 ib | 0.010 ib | 0.10 | 0.05 Nws | 0.06 ib | e ,hnu | 0.42 ib | 0.23g |

| Welded yeeb nkab | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 ib | 1.75 ib | 0.020 ib | 0.010 ib | 0.10 | 0.08 ib | 0.06 ib | e ,hnu | — | 0.22 |

Cov ncauj lus kom ntxaws tuaj yeem pom hauv API 5L Cov Ntawv Ntxiv J.

Tsis tas li ntawd, cov tshuaj muaj pes tsawg leeg ntawm cov yeeb nkab steel rau cov kev pabcuam offshore hauv API 5L X70 PSL2 yog tib yam li cov kev cai rau cov yeeb nkab rau cov ntawv thov uas xav tau cov yas yas ntev ntev.Cov neeg txaus siab tuaj yeem tshawb xyuas API 5L Cov Ntawv Ntxiv N.

Mechanical Properties

API 5L X70 PSL1 Mechanical Properties

| Table 6—Yuav tsum muaj rau cov txiaj ntsig ntawm Tensile Test rau PSL 1 Pipe | ||||

| Qib Qib | Lub cev ntawm Seamless thiab Welded Yeeb Nkab | Weld Seam ntawm EW, LW, SAW, and COW Pipe | ||

| Yield zoga Rrau.5 MPa (psi) | Tensile zoga Rm MPa (psi) | Elongation (50mm lossis 2 nti) Af % | Tensile zogb Rm MPa (psi) | |

| min | min | min | min | |

| L485 los yog X70 | 485 (70,300) hnub | 570 (82,700) | c | 570 (82,700) |

Cov kev txwv tshwj xeeb tuaj yeem pom hauv API 5L Table 6.

API 5L X70 PSL2 txhua yam khoom

PSL2 raj rau cov ntawv thov tshwj xeeb yog hloov kho rau cov tshuaj muaj pes tsawg leeg, tab sis cov kev xav tau ntawm cov khoom siv kho tshuab yog tib yam.

| Table 7—Yuav tsum muaj rau cov txiaj ntsig ntawm Tensile Test rau PSL 2 Yeeb Nkab | |||||||

| Qib Qib | Lub cev ntawm Seamless thiab Welded Yeeb Nkab | Weld Seam ntawm HFW SAW thiab CoW tub | |||||

| Yield zoga Rrau.5 MPa (psi) | Tensile zoga Rm MPa (psi) | Piv txwvac Rt 0.5 / Rm | Elongation (ntawm 50 mm los yog 2 in.) Af % | Tensile Lub zogd Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L485Q or X70 Q L485M or X70M | 485 ib (70.300) Nws. | 6 35 (92.100) Nws. | 570 ib (82,700) | 760 ib (110.200) Nws. | 0.93 ua | f | 570 ib (82,700) |

Cov kev txwv tshwj xeeb tuaj yeem pom hauv API 5L Table 7.

Kev sim txoj kev

| Qeb xeem | Txoj Kev Xeem |

| Tshuaj muaj pes tsawg leeg | ISO 9769 lossis ASTM A751 |

| Mechanical Properties | ISO 6892-1 lossis ASTM A370 |

| Hydrostatic Test | API 5L 10.2.6 |

| Kev kuaj tsis raug | API 5L Appendix E |

| Bending Test | ISO 8491 lossis ASTM A370 |

| Guided Khoov Test | ISO 5173 lossis ASTM A370 |

| Flattening Test | ISO 8492 lossis ASTM A370 |

| CVN Impact Test (PLS2) | ASTM A370 Cov Lus Qhia Tshwj Xeeb |

| DWT Tests (PSL2) | API 5L3 |

Daim ntawv thov rau API 5L X70

Roj pipelines: siv rau kev thauj mus los ntawm cov roj crude los yog refined khoom, tshwj xeeb tshaj yog nyob rau hauv kev thauj mus los ntev nyob rau hauv lub cheeb tsam los yog underwater.

Gas pipelines: rau kev sib sau ua ke thiab faib cov roj av, suav nrog kev thauj mus los ntev thiab kev kub ntxhov.

Kev siv cov qauv: API 5L X70 steel yeeb nkab kuj tseem siv rau hauv cov haujlwm tshwj xeeb xws li offshore platforms lossis cov qauv kev txhawb nqa siab.

Cov ntawv thov kev lag luam: Cov kua dej thauj mus los hauv cov nroj tsuag tshuaj, refineries, thiab lwm yam.

Kev siv tshwj xeeb: Kev tiv thaiv corrosion ntawm API 5L X70 steel yeeb nkab ua rau nws tsim nyog siv rau ntau qhov chaw tshwj xeeb, tshwj xeeb tshaj yog nyob rau hauv acidic thiab offshore corrosive tej yam kev mob.

Peb cov khoom muaj feem xyuam

API 5L GR.B X60 X65 X70 PSL1 / PSL 2 LSAW Carbon Steel Pipe

Yeeb Nkab End Processing

Cov yeeb nkab txiav

Anti-corrosion txheej: galvanized, pleev xim rau, 3PE, FBE, thiab lwm yam.

Peb yog ib qho ntawm cov ua welded carbon steel yeeb nkab thiab seamless steel yeeb nkab manufacturers thiab cov neeg muag khoom los ntawm Tuam Tshoj, nrog rau ntau yam zoo steel yeeb nkab hauv Tshuag, peb tau cog lus los muab koj ntau yam kev daws teeb meem ntawm cov yeeb nkab steel.Xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb, peb tos ntsoov yuav pab koj nrhiav cov kev xaiv zoo tshaj plaws steel yeeb nkab rau koj cov kev xav tau!

Hot Tags: X70, API 5l x70, ai 5l, lwm tus neeg, manufacturers, hoobkas, stockists, tuam txhab, lag luam wholesale, yuav, nqe, hais, tej, muag, nqi.

Post lub sij hawm: Apr-14-2024