ASTM A106 Qib B yog seamless carbon steel yeeb nkab raws li tus qauv ASTM A106 thiab tsim los tiv thaiv qhov kub thiab txias ib puag ncig.

Nws yog tsuas yog siv nyob rau hauv cov roj, roj, thiab tshuaj industries rau tsim piping systems thiab lwm yam chaw.

Navigation Khawm

ASTM A106 Qib

ASTM A106 yog tus qauv kev qhia tshwj xeeb rau seamless carbon steel yeeb nkab rau kev siv kub kub tsim los ntawm ASTM International. Qhov kev qhia tshwj xeeb txhais tau peb qib ntawm seamless carbon steel yeeb nkab, Qib A, Qib B, thiab Qib C. Ntawm cov no, Qib B yog cov feem ntau siv.

Qib "B" sawv cev rau cov tshuaj muaj pes tsawg leeg thiab cov cuab yeej cuab tam ntawm cov khoom siv rau qee qhov kub thiab txias.

Yog tias koj xav paub ntau ntxiv txog ASTM A106 koj tuaj yeem nyem:ASTM A106 txhais li cas?

Cov yam ntxwv tseem ceeb

Seamless Manufacturing

ASTM A106 Qib B tubing yog tsim los ntawm cov txheej txheem tsim seamless uas ua kom muaj kev sib haum xeeb thiab lub zog siv rau hauv ib puag ncig uas muaj kev ntxhov siab.

High-temperature Performance

Cov yeeb nkab no tshwj xeeb yog tsim rau kev ua haujlwm nyob rau hauv qhov kub thiab txias, xws li hauv cov kav dej hauv cov chaw nres tsheb fais fab, refineries, thiab cov nroj tsuag tshuaj.

Tshuaj muaj pes tsawg leeg

Cov tshuaj muaj pes tsawg leeg ntawm Qib B yog tsim los muab nws cov cua sov ua haujlwm zoo thiab ua haujlwm tau zoo. Nws feem ntau muaj cov ntsiab lus tsis tshua muaj carbon thiab nruab nrab ntawm manganese, phosphorus, sulfur, thiab silicon.

Mechanical Properties

ASTM A106 Qib B steel yeeb nkab muab lub zog tensile zoo thiab muaj zog tawm los zoo rau cov ntawv thov uas xav tau cov cuab yeej zoo.

Ntau yam kev siv

Vim tias nws cov cua sov ua haujlwm thiab cov khoom siv kho tshuab, ASTM A106 Qib B tubing yog siv rau ntau yam kev siv xws li roj thiab roj, petrochemicals, boilers, thiab tshav kub exchangers.

Tshuaj muaj pes tsawg leeg

| Kev sib xyaw | C (Carbon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) | Si (Silicon) | Cr (Chromium) | Cu (Xov tooj) | Mo (Molybdenum) | Ni (Nickel) | V (Vanadium) |

| max | — | max | max | min | max | max | max | max | max | |

| kom muaj nuj nqis | 0.30% | 0.29 - 1.06% | 0.035% | 0.035% | 0.10% | 0.40% | 0.40% | 0.15% | 0.40% | 0.08% |

Tshwj tsis yog txwv tsis pub teev los ntawm tus neeg yuav khoom, rau txhua qhov txo qis ntawm 0.01% qis dua cov pa roj carbon siab tshaj plaws, qhov nce ntawm 0.06% ntawm manganese saum toj kawg nkaus yuav raug tso cai mus txog qhov siab tshaj ntawm 1.65%.

Cr, Cu, Mo, Ni, thiab V: tag nrho ntawm tsib lub ntsiab lus yuav tsum tsis pub tshaj 1%.

Mechanical Properties

| Sau npe | Tensile zog, min | Yield zog, min | ||

| kev faib tawm | psi | MPa | psi | MPa |

| ASTM A106 Qib b | 60,000 | 415 | 35,000 | 240 |

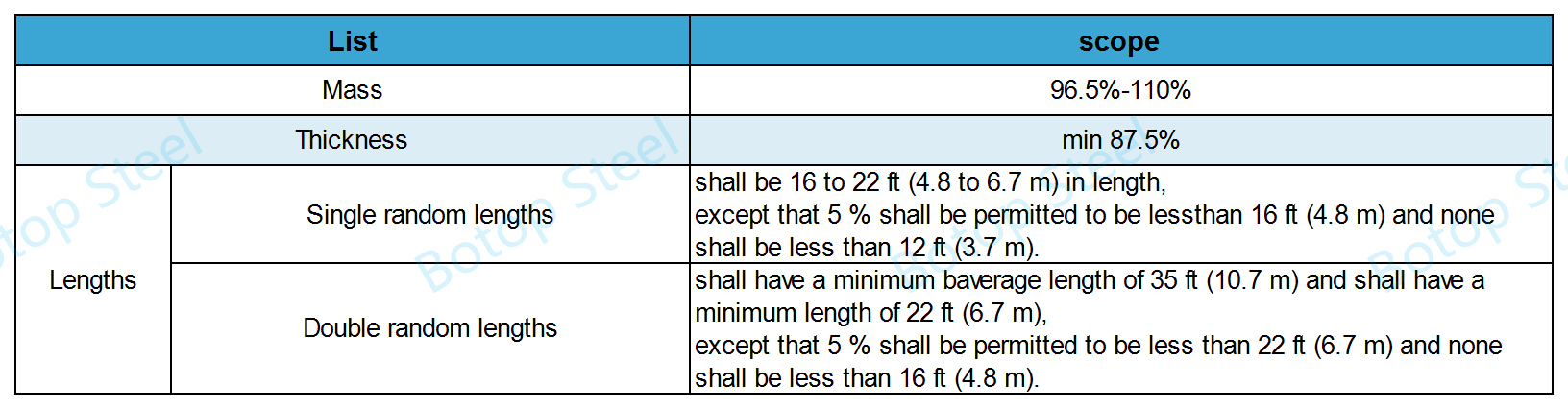

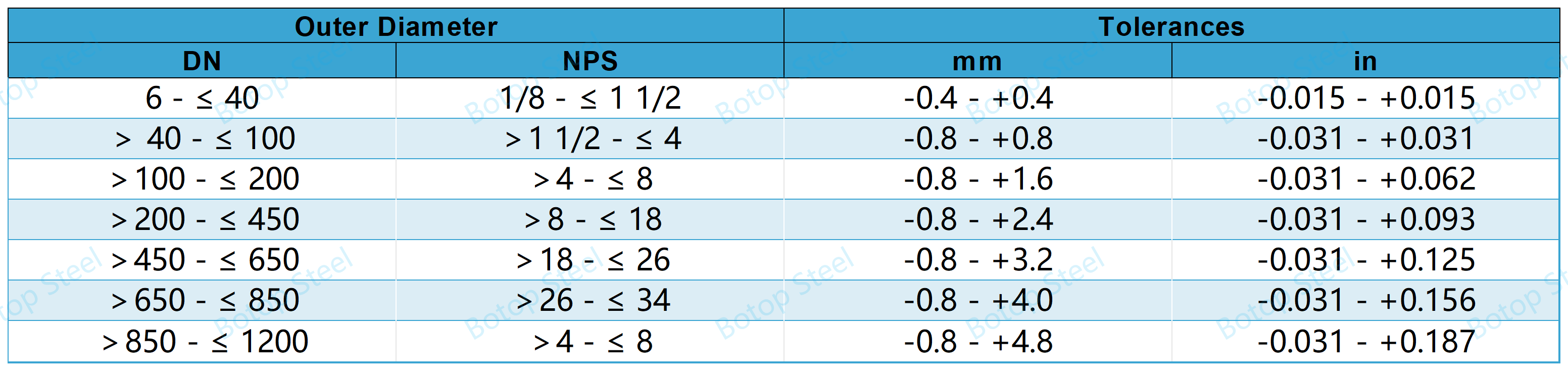

Dimensional Tolerances

Mass, Thickness, thiab Lengths

Sab nraud

Kev xeem thiab ntawv pov thawj

Chemical Composition Analysis

Txiav txim siab cov tshuaj muaj pes tsawg leeg ntawm cov yeeb nkab, suav nrog cov pa roj carbon, manganese, phosphorus, sulfur, thiab silicon kom ntseeg tau tias cov khoom ua tau raws li cov txheej txheem tshuaj lom neeg uas tau teev tseg hauv tus qauv.

Kev Ntsuas Tensile

Ntsuas lub zog tensile, tawm lub zog, thiab elongation ntawm cov yeeb nkab steel. Cov kev ntsuam xyuas no pab ntsuam xyuas cov khoom ua tau zoo thiab toughness nyob rau hauv tensile stress.

Bending Test

Kev ntsuam xyuas kev khoov yog ua los ntawm welded thiab seamless yeeb nkab los ntsuas nws cov yas deformation muaj peev xwm thiab kev ncaj ncees ntawm cov pob qij txha welded.

Flattening Test

Kev ntsuam xyuas flattening yog ua rau cov hlab ntsha los ntsuas lawv cov deformation thiab rupture yam ntxwv nyob rau hauv siab.

Kev Xeem Hardness

Lub hardness ntawm cov khoom yog soj ntsuam los ntawm txoj kev ntawm Brinell los yog Rockwell hardness test. Qhov kev ntsuam xyuas no tseem ceeb hauv kev txiav txim siab txog kev ua thiab kev siv cov yam ntxwv ntawm cov khoom.

Hydrotesting

Txhua cov yeeb nkab yuav tsum tau kuaj xyuas hydrostatically kom paub tseeb tias nws tsis muaj qhov xau ntawm lub siab uas tau teev tseg los xyuas kom meej qhov nruj thiab kev nyab xeeb ntawm cov kav dej.

Kev kuaj tsis muaj kev puas tsuaj

Xws li Ultrasonic Testing (UT), Sib Nqus Particle Testing (MT) thiab/los yog Radiographic Testing (RT) rau kev kuaj pom ntawm sab hauv thiab saum npoo tsis xws li tawg, inclusions thiab porosity.

Impact Testing (raws li kev thov)

Qee zaum, kev sim cuam tshuam (xws li Charpy V-notch test) yuav tsum tau ntsuas qhov tawg ntawm cov khoom ntawm qhov kub thiab txias.

Daim ntawv thov tseem ceeb ntawm ASTM A106 Qib B

Kev thauj roj thiab roj: rau high-pressure thiab high-temperature ib puag ncig.

Kev ua tshuaj lom neeg: rau corrosion thiab kub-resistant piping systems.

Chaw nres tsheb fais fab: rau chav ua noj thiab boiler qhov hluav taws xob.

Kev tsim khoom lag luam: rau cov kav dej siab thiab cov khoom siv siab.

Kev tsim kho thiab nkoj tsim: rau lub tsev cua sov thiab cua txias tshuab thiab boiler thiab chav tshuab rau nkoj.

Automotive kev lag luam: rau kev tsim cov khoom siv tsheb uas tiv taus qhov kub thiab txias.

Hloov mus rau ASTM A106 GR.B

Thaum xaiv lwm cov ntaub ntawv, xav txog yuav tsum tau muab rau cov neeg kho tshuab cov khoom, qhov kub thiab txias tsis kam, siab tsis kam, thiab corrosion kuj ntawm cov khoom kom ua tau raws li cov kev cai tshwj xeeb thiab cov kev cai thiab cov qauv.

| Standard Name | Scope ntawm daim ntawv thov |

| ASTM A53 Qib B | Tsis tshua muaj siab thiab Mechanical Structure Applications |

| API 5L Qib B | Roj thiab roj pipelines |

| ASTM A333 Qib 6 | Rau kev pabcuam kub-kub |

| ASTM A335 P11 thiab P22 | Rau qhov kub siab xws li boilers hauv cov chaw nres tsheb fais fab |

| ASTM A312 TP304 thiab TP316 | Cov ntawv thov yuav tsum muaj kev tiv thaiv corrosion siab |

| ASME SA106 | High-temperature thiab high-pressure ib puag ncig |

| AS/NZS 1163 C350L0 | Lub hom phiaj ntawm kev tsim thiab tshuab |

| wb 3087 | Seamless steel raj rau qis thiab nruab nrab-siab boilers |

| wb 5310 | Seamless steel raj rau high-pressure boilers |

| wb 9948 | Seamless steel raj rau roj tawg |

Kev tiv thaiv txheej rau ASTM A106 GR.B

Galvanized

Galvanizing yog ib txoj hauv kev muab kev tiv thaiv corrosion los ntawm kev siv zinc txheej rau saum npoo ntawm cov hlau.

Cov txheej txheem galvanizing feem ntau yog kub dip galvanizing, nyob rau hauv uas cov yeeb nkab steel yog dipped rau hauv molten zinc los ua ib txheej tuab ntawm zinc ntawm nws qhov chaw.

Zinc txheej no tsis tsuas yog lub cev insulates cov hlau substrate los ntawm huab cua thiab dej, tiv thaiv oxidation, tab sis kuj slows tus nqi ntawm steel corrosion los ntawm sacrificial anodic tiv thaiv (zinc yog active dua hlau).

Kub-dip galvanized kho steel yeeb nkab yog tsim rau siv sab nraum zoov lossis hauv qhov chaw ntub dej, xws li cov chaw kho dej thiab cov vaj tsev sab nraum zoov.

Txheej

Txheej yog ib txoj hauv kev tiv thaiv corrosion los ntawm kev siv ib lossis ntau txheej ntawm cov txheej txheem tiv thaiv corrosion rau saum npoo ntawm cov yeeb nkab steel.

Cov txheej no tuaj yeem yog epoxy, polyurethane, polyethylene, lossis lwm yam khoom siv hluavtaws.

Epoxy txheej yog dav siv nyob rau hauv industrial piping vim lawv zoo heev tshuaj stability thiab adhesion.

Lub luag haujlwm tseem ceeb ntawm txheej txheej yog los thaiv cov dej noo thiab cov tshuaj corrosive, tiv thaiv lawv los ntawm kev sib cuag nrog cov hlau. Cov txheej txheem kev kho mob yog tsim rau ntau qhov chaw xws li cov nroj tsuag tshuaj, marine ib puag ncig thiab cov kav dej hauv nroog.

Txheej Txheej

Kev kho hauv ob sab phlu yog siv cov txheej txheem los tiv thaiv corrosive, xws li epoxy resin, ceramics, lossis roj hmab, hauv cov yeeb nkab steel los tiv thaiv corrosion ntawm cov khoom nruab nrab ntawm cov yeeb nkab hauv phab ntsa.

Txoj kev no tshwj xeeb tshaj yog tsim rau kev xa cov kua dej corrosive (xws li acids, alkalis, ntsev tov, thiab lwm yam).

Epoxy resin hauv ob sab phlu muab cov txheej txheem tiv thaiv corrosion uas tuaj yeem tiv taus qee qhov kev tawm tsam tshuaj lom neeg thiab lub cev puas.

Lub hauv ob sab phlu tsis tsuas yog txuas lub neej ntawm cov yeeb nkab, tab sis kuj tseem tswj kev huv ntawm cov kua dej thiab tiv thaiv kev sib kis.

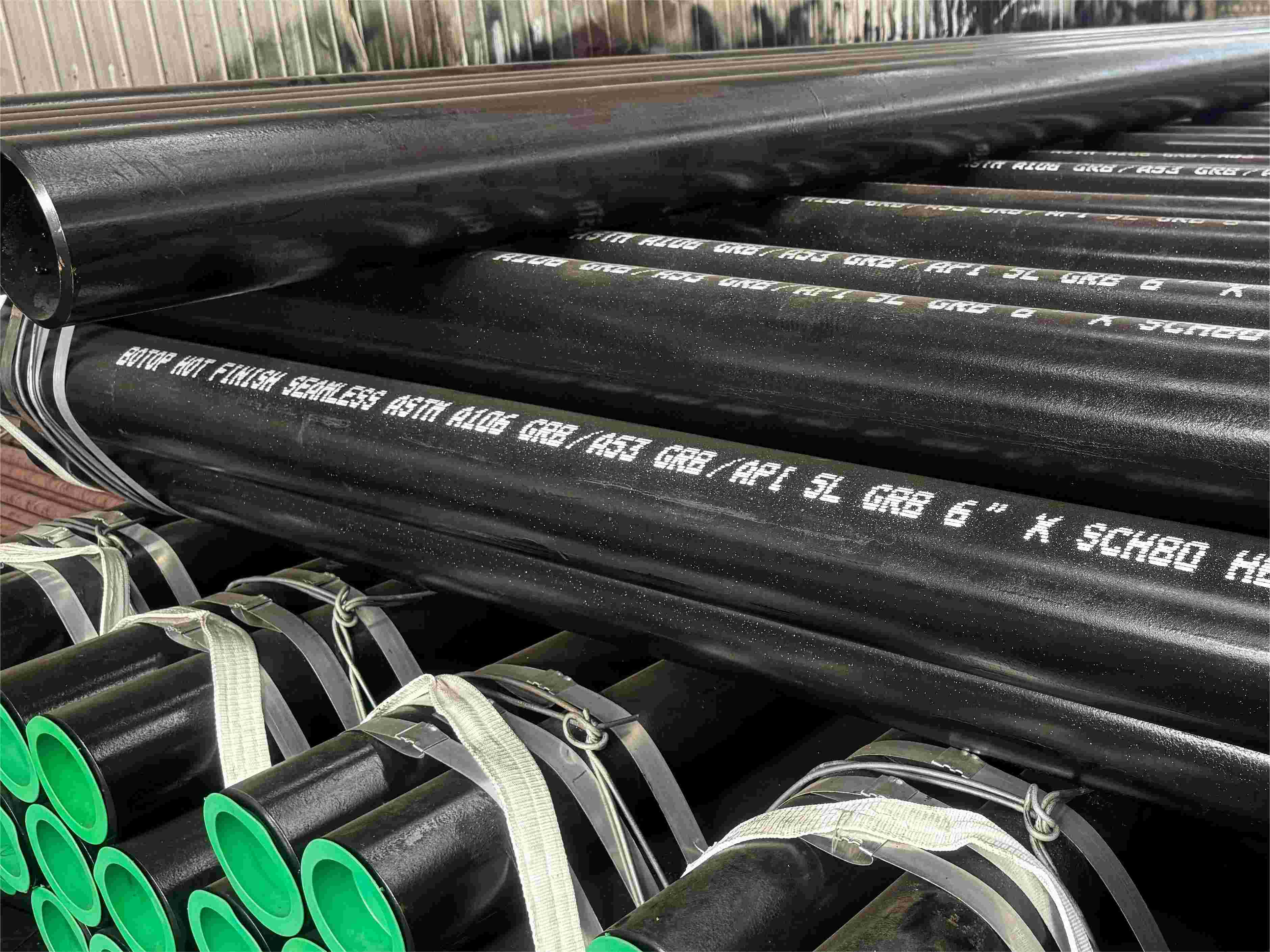

Peb cov khoom muaj feem xyuam

Peb yog ib qho ntawm cov ua welded carbon steel yeeb nkab thiab seamless steel yeeb nkab manufacturers thiab cov neeg muag khoom los ntawm Tuam Tshoj, nrog rau ntau yam zoo steel yeeb nkab hauv Tshuag, peb tau cog lus los muab koj ntau yam kev daws teeb meem ntawm cov yeeb nkab steel. Xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb, peb tos ntsoov yuav pab koj nrhiav cov yeeb nkab steel zoo tshaj plaws rau koj cov kev xav tau!

Hot Tags: a106 qib b, a106, seamless, lwm tus neeg, manufacturers, hoobkas, stockists, tuam txhab, lag luam wholesale, yuav, nqe, hais, tej, kev muag, nqi.

Post lub sij hawm: Mar-01-2024