Hom E steel yeeb nkabyog tsim nyob rau hauv raws liASTM A53thiab yog tsim los ntawm Electric-Resistance-Vuam (ERW) txheej txheem.

Cov yeeb nkab no feem ntau yog siv rau kev siv tshuab thiab kev siv siab tab sis kuj tsim nyog siv los ua cov kav dej dav dav rau kev thauj mus los ntawm chav dej, dej, roj, thiab huab cua.

Qhov luaj li cas ntawmASYM A53 yog DN 6-650.

Qhov ntau lawm ntawmHom E yog DN 20-650 DN.

Cov yeeb nkab diameters hauv qab DN 20 tsawg dhau rau Hom E. Rau cov laj thawj kev ua haujlwm tsis muaj txoj hauv kev los tsim lawv, yog li Hom S, uas yog ib qhoseamless manufacturing txheej txheem, yog feem ntau siv.

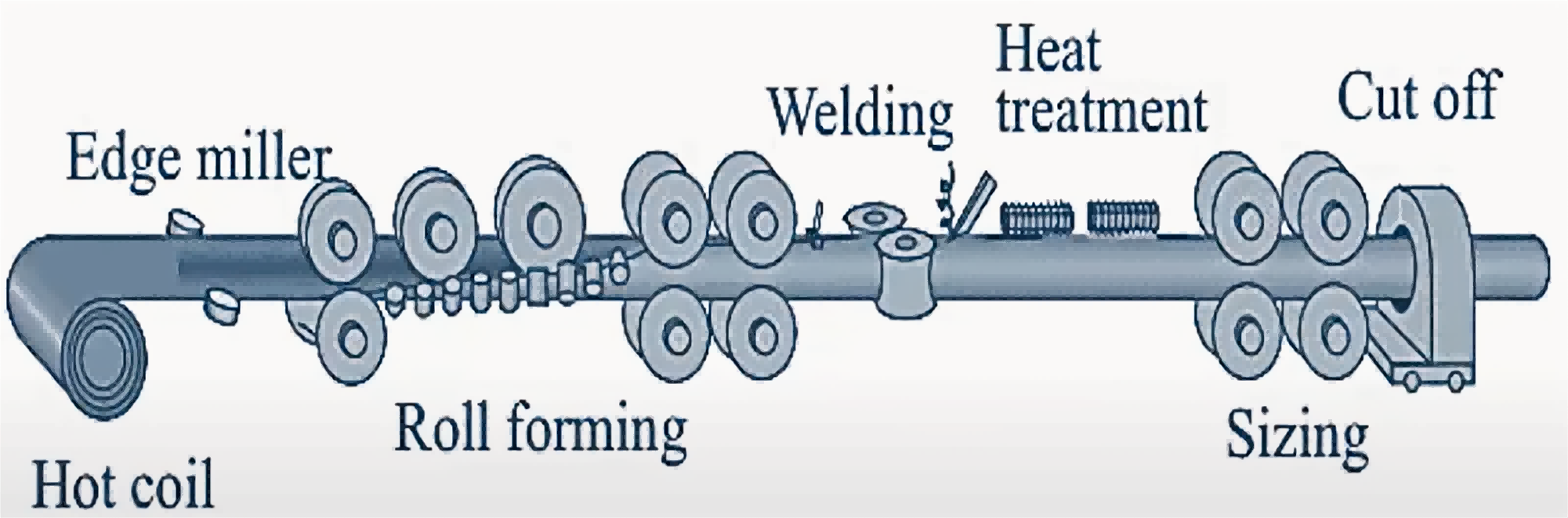

Kev tsim cov txheej txheem rau ASTM A53 Hom E

Cov txheej txheem ntau lawm suav nrog kev tsim cov hlau coils los ntawm yob, vuam npoo los ntawm cov cua kub tsis kam, deburring welds, thiab sizing thiab straightening los ua cov raj.

Cov yam ntxwv ntawm ASTM A53 Hom E Hlau Yeeb Nkab

Nws muaj ob longitudinal taub qab welds sab hauv thiab sab nraud.Cov npoo ntawm cov hlau phaj yog welded rau ob sab hauv thiab sab nraud ntawm cov yeeb nkab thaum lub sij hawm tsim cov txheej txheem los xyuas kom meej lub zog thiab sealing.

Sab hauv thiab sab nrauv welds tsis pom.Cov welds sab hauv thiab sab nraud raug ntxuav kom txog qhov siab tib yam li cov yeeb nkab nto thaum lub sij hawm tsim khoom, uas ua rau tag nrho cov tsos thiab ua tau hydrodynamic zog ntawm cov yeeb nkab.

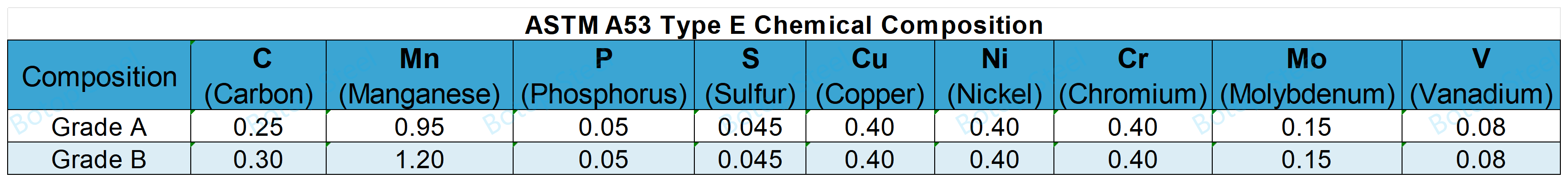

ASTM A53 Hom E Cov Khoom Siv Tshuaj

Rau txhua qhov kev txo qis ntawm 0.01% qis dua cov pa roj carbon siab tshaj plaws, qhov nce ntawm 0.06% ntawm manganese saum toj no qhov siab tshaj plaws yuav raug tso cai mus txog qhov siab tshaj ntawm 1.65%.

Cu, Ni, Cr, Mo, thiab V, yog tsib yam ua ke tsis pub tshaj 1.00%.

ASTM A53 Hom E Mechanical Properties

Kev Ntsuas Siab

Kev tiv thaiv welded kav DN ≥ 200 yuav tsum tau sim siv ob qhov kev hloov pauv, ib qho hla lub vuam thiab lwm qhov tawm ntawm qhov vuam.

| Sau npe | kev faib tawm | Qib A | Qib B |

| Tensile zog, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Yield zog, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation nyob rau hauv 50 mm (2 nyob rau hauv) | Nco tseg | A, B | A, B |

Nco tseg A: Qhov tsawg kawg nkaus elongation hauv 2 hauv [50 mm] yuav tsum tau txiav txim siab los ntawm cov kab zauv hauv qab no:

e = 625000 [1940] A0.2/U0.9

e = yam tsawg kawg nkaus elongation nyob rau hauv 2 nyob rau hauv los yog 50 mm nyob rau hauv feem pua, sib npaug mus rau qhov ze feem pua

A = qhov tsawg dua ntawm 0.75 in2[500 hli2] thiab qhov chaw seem ntawm qhov ntsuas qhov nro, suav nrog qhov ntsuas sab nraud ntawm cov yeeb nkab, lossis qhov dav ntawm qhov ntsuas qhov nro thiab qhov ntsuas phab ntsa tuab ntawm cov yeeb nkab, suav nrog tus nqi sib npaug mus rau qhov ze tshaj 0.01 hauv2 [1 hli2].

U = qhov tsawg kawg nkaus tensile zog, psi [MPa].

Nco tseg B: Saib Table X4.1 lossis Table X4.2, qhov twg yog siv tau, rau qhov tsawg kawg nkaus elongation qhov tseem ceeb uas yuav tsum tau muaj rau ntau yam kev sib txuas ntawm qhov nro ntsuas qhov loj me thiab teev qhov tsawg kawg nkaus tensile lub zog.

Khoov Test

Rau cov yeeb nkab, DN ≤50, qhov ntev txaus ntawm cov yeeb nkab yuav tsum muaj peev xwm khoov txias los ntawm 90 ° nyob ib ncig ntawm lub cylindrical mandrel, lub cheeb ntawm kaum ob npaug ntawm qhov teev sab nraud ntawm cov yeeb nkab, tsis muaj kev tawg ntawm ib feem thiab tsis qhib qhov vuam.

Ob chav-ntxiv-muaj zog yeeb nkab tshaj DN 32 yuav tsum tsis txhob raug rau qhov khoov xeem.

"Double-extra-strong", feem ntau hu ua XXSyog cov yeeb nkab uas muaj cov phab ntsa tshwj xeeb, feem ntau yog siv rau hauv cov ntawv thov kev lag luam kom tiv taus kev kub ntxhov siab dua thiab hnyav dua. Phab ntsa tuab ntawm cov yeeb nkab no yog tuab dua li cov yeeb nkab ib txwm muaj, yog li nws muab ntau lub zog thiab ua haujlwm zoo dua.

Flattening Test

Kev ntsuas flattening yuav tsum tau ua rau ntawm cov yeeb nkab welded tshaj DN 50 hauv qhov hnyav ntxiv (XS) lossis sib dua.

Cov txheej txheem kev sim hauv qab no siv rau Hom E, Qib A thiab B.

Thaum lub sij hawm tiaj tiaj, lub vuam yuav tsum tau muab tso rau ntawm 0 ° los yog 90 ° rau txoj kab ntawm kev quab yuam, nyob ntawm seb qhov yuav tsum tau ua.

Kauj ruam 1: Kuaj qhov ductility ntawm qhov vuam. Yuav tsum tsis txhob muaj cov kab nrib pleb lossis tawg rau hauv qhov chaw sab hauv lossis sab nraud ntawm lub vuam kom txog rau thaum qhov kev ncua deb ntawm cov phaj tiaj yog tsawg dua li ob feem peb ntawm cov kab sab nraud ntawm cov yeeb nkab.

Kauj ruam 2: Txuas ntxiv mus nias lub tiaj thiab sim rau ductility nyob rau hauv cheeb tsam sab nraum lub vuam. Yuav tsum tsis txhob muaj cov kab nrib pleb lossis tawg ntawm sab hauv lossis sab nraud ntawm cov yeeb nkab dhau ntawm qhov vuam kom txog rau thaum qhov kev ncua deb ntawm cov phaj tiaj tiaj yog tsawg dua li ib feem peb ntawm sab nraud txoj kab uas hla ntawm cov yeeb nkab, tab sis tsis pub tsawg tshaj tsib npaug ntawm cov yeeb nkab phab ntsa.

Kauj ruam 3: Ntsuam xyuas qhov kev ncaj ncees ntawm cov khoom los ntawm kev txuas ntxiv mus rau lub tiaj tus kom txog thaum cov khoom kuaj tawg lossis cov yeeb nkab phab ntsa tuaj yeem sib cuag. Qhov no yog siv los kuaj cov khoom siv rau cov teeb meem xws li cov txheej txheem tawg, tsis zoo, lossis tsis tiav welds.

Hydrostatic Test

Kev ntsuas hydrostatic yuav tsum tau siv, tsis muaj qhov xau los ntawm cov vuam seam lossis lub cev yeeb nkab.

Plain-end yeeb nkab yuav tsum tau kuaj hydrostatically rau lub siab siv tau muab rau hauv Table X2.2,

threaded-thiab-coupled yeeb nkab yuav tsum tau kuaj hydrostatically rau lub siab siv tau muab rau hauv Table X2.3.

Rau cov kav hlau steel nrog DN ≤ 80, qhov ntsuas siab yuav tsum tsis pub tshaj 17.2MPa;

Rau cov kav hlau steel nrog DN >80, qhov ntsuas siab yuav tsum tsis pub tshaj 19.3MPa;

Nondestructive Electric Test

Rau Hom E thiab Hom F Class B kav DN ≥ 50, cov welds yuav tsum raug kuaj xyuas hluav taws xob tsis zoo.

Kev ntsuas hluav taws xob tsis muaj kev puas tsuaj yuav tsum ua raws li Cov Lus Qhia E213, E273, E309 lossis E570.

Yog tias qhov ntsuas hluav taws xob tsis muaj kev puas tsuaj tau ua tiav, cov yeeb nkab yuav tsum raug cim "NDE".

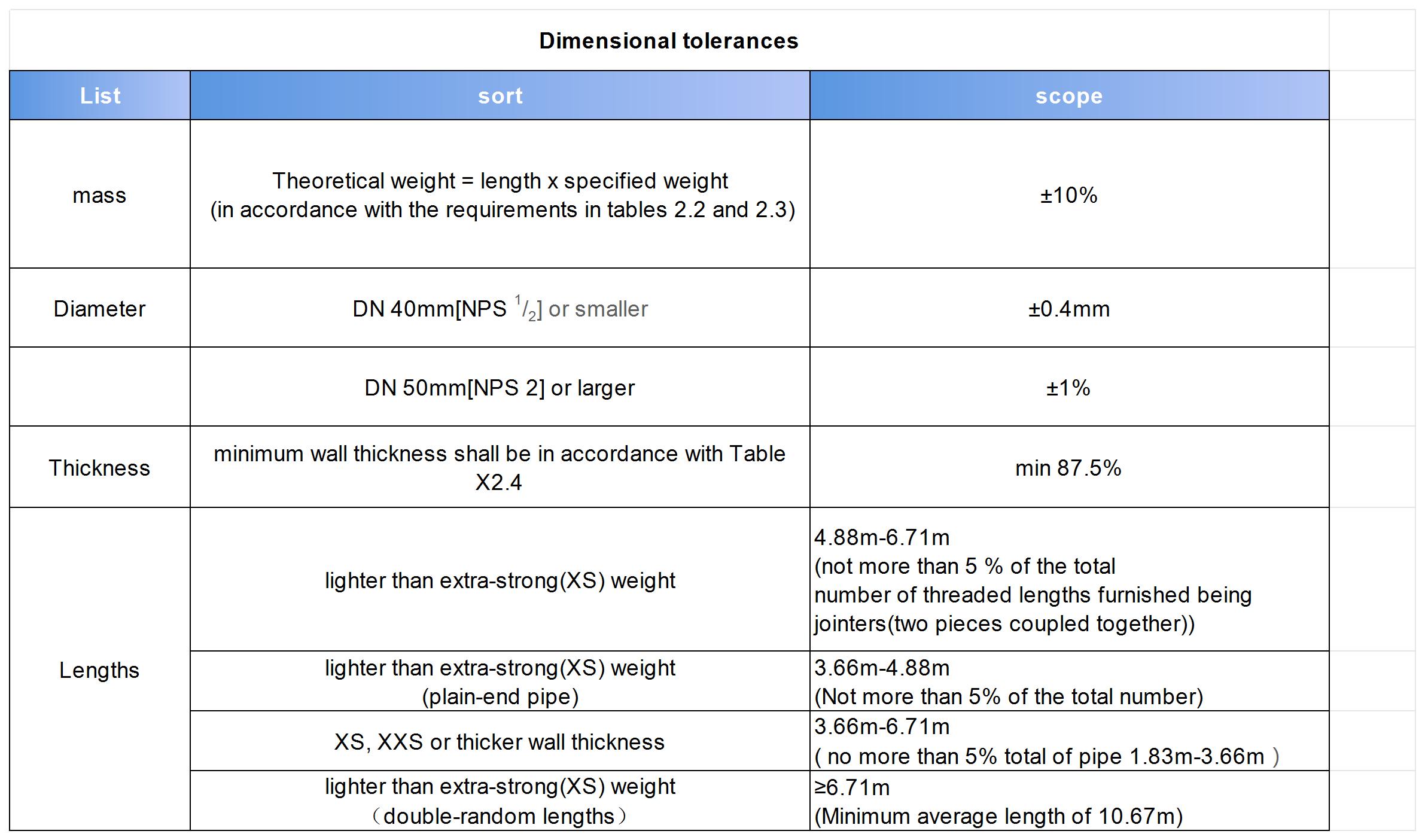

ASTM A53 Dimensional kam rau ua

Pipe Weight Charts thiab Pipe Schedules

Qhov zoo ntawm ASTM A53 Hom E Yeeb Nkab

Resistance welding yog ib txoj kev vuam uas tsis tshua muaj nqi, ua rau hom E cov raj kuj pheej yig los tsim thiab tsim rau ntau lawm.

Cov txheej txheem vuam tsis kam yog ceev thiab tuaj yeem tsim tawm tsis tu ncua, uas ua rau kom muaj txiaj ntsig thiab txo cov sij hawm txhuas.

Vim nws cov khoom siv zoo thiab kev tiv thaiv corrosion, hom yeeb nkab no tau siv dav hauv ntau yam kev siv rau kev thauj cov kua dej, xws li dej, roj, thiab chav.

Cov welds tuaj yeem ua rau pom tsis pom los ntawm kev kho kom zoo ntawm cov welds, uas tsis tsuas yog txhim kho cov yeeb nkab, tab sis kuj tseem tuaj yeem txo qhov tsis kam ntawm cov kua dej los ntawm cov welds..

Daim ntawv thov ntawm ASTM A53 Hom E Hlau Yeeb Nkab

Kev siv tus qauv: Hauv kev tsim kho, A53 Hom E steel yeeb nkab yog siv los ua cov khoom siv hauv tsev xws li kev txhawb nqa lub tsev thiab truss systems.

Cov kav dej: Siv nyob rau hauv cov khoom siv dej rau cov tsev, nrog rau cov tshuab tua hluav taws.

Chav systems: Hauv cov chaw tsim khoom, cov yeeb nkab steel no feem ntau siv rau hauv cov tshuab xa hluav taws xob, tshwj xeeb tshaj yog hauv cov ntawv siv hluav taws xob tsawg.

Gas kis tau tus mob: Siv rau kev thauj mus los ntawm ntuj lossis lwm yam roj av, tshwj xeeb tshaj yog nyob rau hauv nroog thiab thaj chaw siv roj av.

Cov nroj tsuag tshuaj: rau kev xa cov pa qis, dej, thiab lwm yam tshuaj.

Ntawv thiab qab zib mills: xa cov khoom siv raw thiab cov khoom tiav, nrog rau kev pov tseg cov txheej txheem pov tseg.

Cua sov thiab cua txias tshuab: Dav siv rau cov kav dej hauv cov cua sov, qhov cua, thiab cua txias (HVAC).

Kev kho dej khib nyiab: Rau kev xa dej khib nyiab lossis dej kho.

Irrigation systems: Cov kav dej siv rau cov dej ua liaj ua teb.

Mining: Siv rau kev thauj mus los hauv dej thiab roj hauv mines.

Peb cov khoom muaj feem xyuam

Txij li thaum nws tsim nyob rau hauv 2014, Botop Steel tau dhau los ua tus xa khoom ntawm carbon steel yeeb nkab nyob rau sab qaum teb Tuam Tshoj, paub txog kev pabcuam zoo, cov khoom zoo, thiab cov kev daws teeb meem.

Lub tuam txhab muaj ntau yam carbon steel kav thiab lwm yam khoom,

suav nrog seamless, ERW, LSAW, thiab SSAW steel yeeb nkab, nrog rau cov kab tiav ntawm cov yeeb nkab fittings thiab flanges.

Nws cov khoom tshwj xeeb kuj suav nrog cov qib high-qib alloys thiab austenitic stainless hlau, tsim kom tau raws li qhov xav tau ntawm ntau lub raj xa dej.

Hot Tags: ASTM a53, hom e, qib a, qib b, erw.

Post lub sij hawm: May-12-2024