JIS G 3452 steel yeeb nkabyog tus txheej txheem Japanese rau carbon steel yeeb nkab siv nrog kev ua haujlwm qis rau kev thauj mus los ntawm chav, dej, roj, roj, cua, thiab lwm yam.

Nws yog tsim rau cov kav dej nrog ib txoj kab uas hla sab nraud ntawm 10.5 mm-508.0 mm.

Navigation Khawm

Lub cim ntawm qib thiab kev tsim khoom ntawm JIS G 3452

Cov yeeb nkab kawg hom JIS G 3452

Tshuaj muaj pes tsawg leeg ntawm JIS G 3452

Mechanical Properties ntawm JIS G 3452

Flattening Property

Kho tau

Hydraulic Test lossis Nondestructive Test (NDT)

Pipe Weight Chart thiab Dimensional Tolerances

Hlau Yeeb Nkab Zoo

Galvanized ntawm JIS G 3452

Kev ntsuas ntawm JIS G 3452

Cov ntawv thov tseem ceeb ntawm JIS G 3452

Cov qauv tsim nyog

Peb cov khoom muaj feem xyuam

Lub cim ntawm qib thiab kev tsim khoom ntawm JIS G 3452

Cov kav dej yuav tsum tau tsim nrog kev sib xyaw ua ke ntawm cov yeeb nkab tsim cov txheej txheem thiab cov txheej txheem tiav xaiv.

| Lub cim ntawm qib | Lub cim ntawm kev tsim khoom | Classification ntawm zinc-coating | ||

| Kev tsim cov yeeb nkab | Txoj kev ua tiav | Kos npe | ||

| SGP | Hluav taws xob kuj welded:E Lub taub hau welded:B | Kub tiav:H Cold-ua tiav:C Raws li hluav taws xob kuj welded:G | Raws li muab rau hauv13 b). | Cov kav dej dub: cov kav dej tsis muab zinc-txheej Cov kav dej dawb: pipes muab zinc-coating |

Cov kav dej yuav tsum tau muab xa raws li tsim. Cov yeeb nkab ua haujlwm txias yuav tsum tau muab tshem tawm tom qab kev tsim tiav.

Yog tias siv cov txheej txheem welding tsis kam, welds yuav tsum tau muab tshem tawm ntawm qhov chaw sab hauv thiab sab nraud ntawm cov yeeb nkab kom tau txais ib qho kev sib txuas ntawm cov yeeb nkab. Weld hlaws rau hauv qhov chaw sab hauv yuav tsis raug tshem tawm yog tias qhov no yog vim cov khoom siv lossis cov yeeb nkab txoj kab uas hla.

Cov yeeb nkab kawg hom JIS G 3452

Yeeb Nkab Xaus Xaiv

Hom yeeb nkab kawg rau DN≤300A / 12B: threaded lossis ca kawg.

Hom yeeb nkab kawg rau DN≤350A / 14B: tiaj tus kawg.

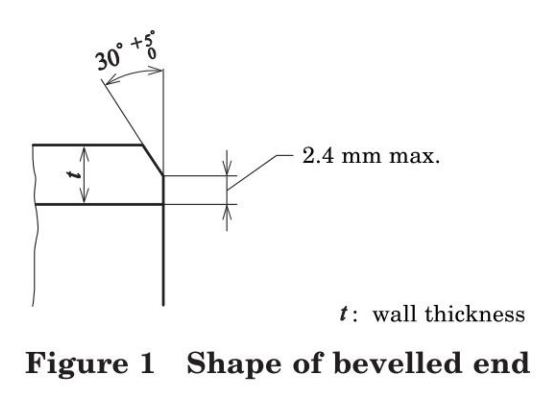

Yog tias tus neeg yuav khoom xav tau beveled kawg, lub kaum sab xis ntawm bevel yog 30-35 °, bevel dav ntawm steel yeeb nkab ntug: max 2.4mm.

Lus Cim: Hauv JIS G 3452, muaj A series thiab B series ntawm nominal txoj kab uas hla DN. Qhov twg A yog sib npaug rau DN, chav tsev yog mm; B yog sib npaug rau NPS, chav tsev nyob hauv.

Kev xav tau rau Threaded Pipe Ends

Threaded kav yuav tsum tau tsim los ntawm muab cov yeeb nkab xaus cov taper threads raws li teev nyob rau hauv JIS B 0203, thiab haum ib tug threaded xaus nrog ib tug screwed hom haum (tom qab no hu ua lub qhov (socket) conforming rau JIS B 2301 los yog JIS B 2302.

Cov yeeb nkab kawg uas tsis muaj lub qhov (socket) yuav tsum muaj kev tiv thaiv nrog lub nplhaib tiv thaiv xov los yog lwm txoj kev tsim nyog.

Threaded kav tej zaum yuav muab tau yam tsis muaj qhov (socket) yog hais tias tus neeg yuav khoom tau teev tseg. Kev soj ntsuam ntawm taper threads yuav tsum ua raws li JIS B 0253.

Tshuaj muaj pes tsawg leeg ntawm JIS G 3452

Cov kev cai dav dav rau kev tshuaj xyuas tshuaj thiab cov qauv kev ntsuas cua sov yuav tsum ua raws li JIS G 0404 clause 8. Cov txheej txheem ntawm thermal tsom xam yuav tsum ua raws li cov qauv hauv JIS G 0320.

| Lub cim ntawm qib | P (phosphorus) | S (Sulfur) |

| SGP | max 0.040% | max 0.040% |

Cov qib siab ntawm phosphorus thiab sulfur txo qhov kev ua haujlwm thiab kev ua haujlwm ntawm cov hlau thiab tshwj xeeb tshaj yog ua rau brittleness thaum vuam. Yog li ntawd, qhov zoo thiab weldability ntawm carbon steel kav yuav ua kom ntseeg tau los ntawm kev txwv phosphorus thiab sulfur cov ntsiab lus.

Lwm yam alloying ntsiab kuj tuaj yeem ntxiv raws li xav tau.

Mechanical Properties ntawm JIS G 3452

Cov kev cai dav dav rau kev ntsuas kev siv tshuab yuav tsum ua raws li nqe lus 7 thiab 9 ntawm JIS G 0404. Txawm li cas los xij, ntawm cov qauv qauv muab hauv 7.6 ntawm JIS G 0404, tsuas yog cov qauv qauv A yog siv tau.

Tensile test: Txoj kev xeem yuav tsum ua raws li cov qauv hauv JIS Z 2241.

| Lub cim ntawm qib | Tensile zog | Elongationa min,% | ||||||

| Kuaj daim | Kuaj kev taw qhia | Phab ntsa thickness, mm | ||||||

| N / mm² (MPA) | 3 ≤ 4 | 4 ≤ 5 | 5 ≤ 6 | 6 ≤ 7 | > 7 | |||

| SGP | 290 nqi | No.11 | Parallel rau yeeb nkab axis | 30 | 30 | 30 | 30 | 30 |

| No.12 | Parallel rau yeeb nkab axis | 24 | 26 | 27 | 28 | 30 | ||

| No.5 | Perpendicular rau cov yeeb nkab axis | 19 | 20 | 22 | 24 | 25 | ||

| aRau cov kav dej ntawm nominal txoj kab uas hla 32A lossis qis dua, qhov elongation qhov tseem ceeb hauv cov lus no tsis siv, txawm hais tias lawv cov txiaj ntsig elongation yuav tsum tau sau tseg. Hauv qhov no, qhov kev xav tau elongation tau pom zoo ntawm tus neeg yuav khoom thiab cov chaw tsim khoom tuaj yeem siv. | ||||||||

Flattening Property

Nyob rau hauv chav tsev kub (5 ℃ ~ 35 ℃), lub weld yog perpendicular mus rau compression kev taw qhia. Nthuav cov qauv ntawm ob lub platform kom txog rau thaum qhov kev ncua deb H ntawm lub platforms ncav cuag ob feem peb ntawm cov kab sab nraud ntawm lub hauv paus steel yeeb nkab, thiab tom qab ntawd xyuas cov kab nrib pleb.

Kho tau

Thaum DN≤50A, ua qhov kev sim khoov.

Thaum khoov rau sab hauv lub vojvoog ntawm 90 ° ntawm 6 npaug ntawm txoj kab uas hla ntawm cov yeeb nkab, cov ntawv xeem yuav tsum tsis txhob muaj cov kab nrib pleb. Ua ntej khoov, ntsuas lub kaum sab xis ntawm txoj haujlwm ncaj.

Hydraulic Test lossis Nondestructive Test (NDT)

Txhua lub yeeb nkab yuav tsum yog Kev Ntsuas Hydraulic lossis Kev Ntsuas Tsis Zoo.

Kev Ntsuas Hydraulic

Cov yeeb nkab yuav tsum tiv taus 2.5MPa rau tsawg kawg yog 5 s, tsis muaj qhov xau.

Kev kuaj tsis raug

Cov yam ntxwv tsis zoo yuav siv tau rau kev soj ntsuam ultrasonic lossis eddy tam sim no, thiab cov yeeb nkab yuav tsum ua raws li cov yam ntxwv hauv qab no tsis muaj kev puas tsuaj.

Rau kev soj ntsuam ultrasonic, cov qauv siv tau teev tseg hauv JIS G 0582 uas muaj cov qauv siv hauv chav kawm UE yuav tsum siv raws li lub tswb; txhua lub teeb liab los ntawm cov yeeb nkab uas sib npaug los yog ntau dua li lub tswb yuav tsum raug siv raws li qib tswb. teeb liab yuav tsum tau siv raws li lub tswb theem; ib qho teeb liab los ntawm lub raj xa dej sib npaug los yog ntau dua li lub tswb ntsuas yuav ua rau tsis lees paub.

Rau kev tshuaj xyuas tam sim no, cov cim qhia los ntawm cov qauv siv uas muaj cov qauv siv ntawm qeb EZ raws li tau teev tseg hauv JIS G 0583 yuav tsum raug siv ua lub tswb theem; ib qho teeb liab sib npaug los yog siab tshaj qhov ceeb toom ntawm lub raj xa dej yuav yog qhov laj thawj rau kev tsis lees paub. yuav tsum ua raws li lub tswb theem; ib qho teeb liab los ntawm lub raj xa dej sib npaug los yog ntau dua li lub tswb ntsuas yuav ua rau tsis lees paub. Ntawm qhov chaw tsim khoom qhov kev txiav txim siab, yuav siv lub tswb nrov hauv qab lub teeb liab ntawm tus qauv siv tau hais tseg.

Lwm txoj kev kuaj tsis muaj kev puas tsuaj kuj tuaj yeem siv tau, piv txwv li rau kev kuaj pom cov dej ntws tsis siv neeg raws li tau teev tseg hauv JIS G 0586.

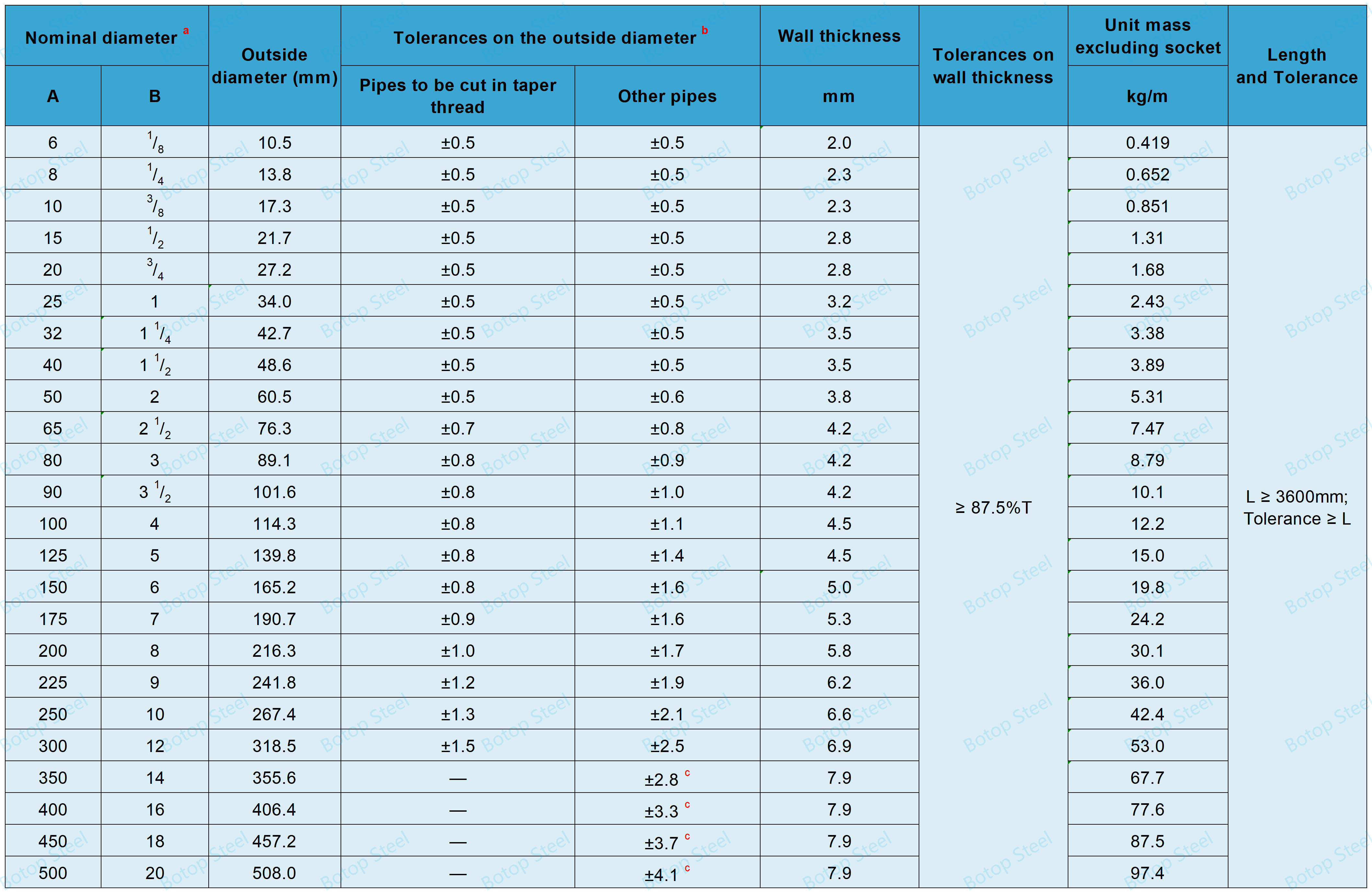

Pipe Weight Chart thiab Dimensional Tolerances

Hlau Yeeb Nkab Qhov Ntsuas Cov Qauv

Piv txwv li 1 cm3 ntawm hlau yog 7.85g hauv qhov hnyav

W = 0.02466t(Dt)

Wunit loj ntawm cov yeeb nkab (kg / m);

t: phab ntsa thickness ntawm cov yeeb nkab (mm);

D: sab nraud txoj kab uas hla ntawm cov yeeb nkab (mm);

0.02466 ib: kev hloov pauv kom tau txais W;

Hloov mus rau peb qhov tseem ceeb raws li JIS Z 8401, txoj cai A.

Pipe Weight Chart thiab Dimensional Tolerances

aQhov nominal txoj kab uas hla yuav tsum yog raws li ib tug ntawm cov npe A los yog B thiab qhia los ntawm kev txuas nrog tsab ntawv A los yog B, qhov twg los xij yog siv, tom qab tus lej ntawm txoj kab uas hla.

bRau cov khoom kho hauv zos, kev kam rau siab hauv cov lus no tsis siv.

cRau cov kav dej ntawm nominal txoj kab uas hla 350A lossis tshaj, kev ntsuas sab nraud tuaj yeem hloov tau los ntawm kev ntsuas qhov ntev, nyob rau hauv rooj plaub uas qhov kam rau ua yuav tsum yog 0.5%. Qhov ntsuas qhov ntev (I) yuav tsum hloov mus rau sab nraud (D) siv cov qauv hauv qab no.

D = l/Π

D: sab nraud txoj kab uas hla (mm);

l: circumferential length (mm);

Π3, 1416 : kuv.

Hlau Yeeb Nkab Zoo

Qhov tshwm sim

Sab hauv thiab sab nrauv ntawm cov yeeb nkab yuav tsum du thiab tsis muaj qhov tsis zoo siv.

Cov yeeb nkab yuav tsum ncaj, nrog rau qhov kawg ntawm txoj cai kaum rau lub axis ntawm cov yeeb nkab.

Kho qhov tsis xws luag

Cov yeeb nkab dub (steel yeeb nkab yam tsis muaj kev kho corrosion) tuaj yeem kho los ntawm kev sib tsoo, machining, lossis lwm txoj hauv kev, thiab kho qhov chaw yuav tsum du raws cov yeeb nkab contour.

Txawm li cas los xij, kho cov phab ntsa tuab yog khaws cia nyob rau hauv qhov kev pom zoo.

Nto Txheej

Ob tog los yog ob qho tib si ntawm cov yeeb nkab tuaj yeem coated xws li zinc-nplua nuj txheej, epoxy txheej, primer txheej, 3PE, FBE, thiab lwm yam.

Galvanized ntawm JIS G 3452

Kub Dip Galvanizing

Hlau kav, yog galvanized, threaded kav thiab sockets yuav tsum tau coated nrog zinc ua ntej zawm cov xov.

Txhuam steel nto tu los ntawm sandblasting, pickling, thiab lwm yam., ua raws li kub dip galvanizing.

Rau zinc-txheej txheem, cov distilled zinc ingot Class 1 teev nyob rau hauv JIS H 2107 los yog zinc nrog yam tsawg kawg nkaus zoo rau qhov no yuav tsum tau siv.

Lwm cov kev cai dav dav rau zinc txheej tau teev tseg hauv JIS H 8641.

Kev sim Galvanization

Test Method Raws li txoj kev xeem tau teev tseg nyob rau hauv Tshooj 6 ntawm JISH0401, cov qauv yog immersed nyob rau hauv tooj liab sulfate tov, rau 1 min 5 zaug, thiab cov hnoos qeev raug kuaj xyuas seb nws mus txog qhov kawg.

Kev ntsuas ntawm JIS G 3452

Cov ntsiab lus ntawm lub logo muaj tsawg kawg yog cov ntsiab lus hauv qab no, qhov kev txiav txim uas tuaj yeem npaj tau dawb.

a) Lub cim ntawm qib (SGP)

b) Lub cim ntawm kev tsim khoom

Lub cim ntawm kev tsim khoom yuav tsum yog raws li hauv qab no.Cov dash(es) tuaj yeem hloov nrog qhov khoob.

Raws li hluav taws xob kuj welded steel yeeb nkab: -EG

Kub-tiav hluav taws xob kuj welded steel yeeb nkab: -EH

Txias-tiav hluav taws xob tiv thaiv welded steel yeeb nkab: -EC

Butt-welded steel yeeb nkab: -B

c) Dimensions, qhia los ntawm nominal txoj kab uas hla

d) Tus neeg tsim khoom lub npe lossis txheeb xyuas lub npe

Piv txwv: BOTOP JIS G 3452-EG SGP 500A * 7.9 * 12000MM PIPE NO.001

Cov ntawv thov tseem ceeb ntawm JIS G 3452

JIS G 3452 steel kav yog siv rau kev thauj mus los ntawm dej, roj, roj, chav, thiab lwm yam kev siv dav dav. Cov kav dej no feem ntau yog siv rau hauv kev tsim kho, tshuab, tsheb, nkoj, thiab lwm yam.

Kev lag luam roj thiab roj: siv nyob rau hauv piping systems rau kev thauj mus los ntawm cov roj, natural gas liquefied petroleum gas, thiab lwm yam.

Kev tsim kho kev lag luam: siv rau cov tshuab hydraulic, kav dej, cua sov, tshuab cua txias, thiab lwm yam hauv kev tsim vaj tsev.

Machinery manufacturing: Siv nyob rau hauv hydraulic systems, pneumatic systems, conveying pipelines ntawm txhua yam khoom, thiab lwm yam.

Kev tsim kho tsheb: siv nyob rau hauv cov pa system, roj system, hydraulic system, thiab lwm yam ntawm tsheb.

Shipbuilding: siv nyob rau hauv piping systems, cabin qauv ntawm nkoj, thiab lwm yam.

Kev lag luam tshuaj: siv nyob rau hauv tshuaj nroj tsuag rau kev thauj mus los kav, reactors, thiab lwm yam.

Municipal engineering: siv nyob rau hauv piping systems rau hauv nroog cov dej, kua, dej phwj kho, thiab lwm yam.

Cov qauv tsim nyog

ASTM A53 / A53M / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / A53M / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53 / ASTM A53) thiab ASTM A53 / A53MDIN 2440, EN 10255, GB / T 3091, BS 1387, ISO 65, NFA 49-146,AS/NZS 1163API 5L, ASTM A106 / A106M, EN 10216-1, GB 8163.

Peb cov khoom muaj feem xyuam

Peb yog ib qho ntawm cov ua welded carbon steel yeeb nkab thiab seamless steel yeeb nkab manufacturers thiab cov neeg muag khoom los ntawm Tuam Tshoj, nrog rau ntau yam zoo steel yeeb nkab hauv Tshuag, peb tau cog lus los muab koj ntau yam kev daws teeb meem ntawm cov yeeb nkab steel. Xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb, peb tos ntsoov yuav pab koj nrhiav cov yeeb nkab steel zoo tshaj plaws rau koj cov kev xav tau!

Hot Tags: jis g 3452, sgp, erw, lwm tus neeg, manufacturers, hoobkas, stockists, tuam txhab, lag luam wholesale, yuav, nqe, hais, tej, muag, nqi.

Lub sij hawm xa tuaj: Plaub Hlis-28-2024