ASTM A 672 Cov Lus Qhia Tshwj Xeebyog steel yeeb nkab ua los ntawm lub siab lub nkoj zoo phaj,Hluav taws xob-Fusion-Welded (EFW)rau high-pressure kev pab cuam nyob rau hauv nruab nrab kub.

Navigation Khawm

ASTM A672 Qib Classification

ASTM A672 Kev faib tawm chav kawm

ASTM A672 Loj Ntau Yam

Vuam ceev faj

Kev kho cua sov

Chemical Cheebtsam

Kev Ntsuas Siab

Transverse-Guided-Weld-Bend Tests

Kev ntsuas siab

Radiographic Examination

Dimensional kam rau ua rau ASTM A672

ASTM A672 Kev Ntsuas

Kev kho thiab kho

ASTM A672 Daim Ntawv Pom Zoo

Daim ntawv thov ntawm ASTM A672 Steel Pipe

Peb cov khoom muaj feem xyuam

ASTM A672 Qib Classification

Muab faib raws li hom phaj siv los tsim cov raj steel.

Cov qib sib txawv sawv cev rau cov tshuaj sib txawv thiab cov khoom siv kho tshuab rau qhov sib txawv siab thiab qhov kub thiab txias.

| Qib Qib | Hom Hlau | ASTM Specification | |

| Tsis muaj. | Qib | ||

| A 45 | carbon dawb | A285 / A285M | A |

| A50 | carbon dawb | A285 / A285M | B |

| A 55 | carbon dawb | A285 / A285M | C |

| B 60 | carbon dawb, tua | A515 / A515M | 60 |

| B 65 | carbon dawb, tua | A515 / A515M | 65 |

| B 70 | carbon dawb, tua | A515 / A515M | 70 |

| C 55 | carbon dawb, tua, nplua nplej | A516 / A516M | 55 |

| C 60 | carbon dawb, tua, nplua nplej | A516 / A516M | 60 |

| C 65 | carbon dawb, tua, nplua nplej | A516 / A516M | 65 |

| C 70 | carbon dawb, tua, nplua nplej | A516 / A516M | 70 |

| D 70 | manganese-silicon, normalized | A537 / A537M | 1 |

| D 80 | manganese-silicon, Q&TA | A537 / A537M | 2 |

| H 75 | manganese-molybdenum, normalized | A302 / A302M | A |

| H 80 | manganese-molybdenum, normalized | A302 / A302M | B, C, los yog D |

| J 80 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-3B |

| lwj 65 | molybdenum | A204 / A204M | A |

| lwj 70 | molybdenum | A204 / A204M | B |

| l75 ua | molybdenum | A204 / A204M | C |

| N 75 | manganese-silicon | A299 / A299M | A |

AQ&T = quenched thiab tempered.

ВTxhua qib tuaj yeem muab tau.

Peb tuaj yeem pib txiav txim siab hom yeeb nkab steel los ntawm cov ntawv hauv qib.

Cov qib pib nrog cov tsiaj ntawv A, B, thiab C feem ntau qhiacarbon steel yeeb nkab.

Cov qib pib nrog cov ntawv D, H, J, L, thiab N qhiaalloy steel yeeb nkab.

ASTM A672 Kev faib tawm chav kawm

Cov raj raug cais raws li hom kev kho cua sov uas lawv tau txais thaum lub sijhawm tsim khoom thiab seb lawv puas tau kuaj xyuas hluav taws xob thiab ntsuas siab.

| Chav kawm | Kev kho cua sov ntawm cov yeeb nkab | Radiography, saib daim ntawv: | Kev ntsuas siab, saib daim ntawv: |

| 10 | tsis muaj | tsis muaj | tsis muaj |

| 11 | tsis muaj | 9 | tsis muaj |

| 12 | tsis muaj | 9 | 8.3 |

| 13 | tsis muaj | tsis muaj | 8.3 |

| 20 | kev ntxhov siab, saib 5.3.1 | tsis muaj | tsis muaj |

| 21 | kev ntxhov siab, saib 5.3.1 | 9 | tsis muaj |

| 22 | kev ntxhov siab, saib 5.3.1 | 9 | 8.3 |

| 23 | kev ntxhov siab, saib 5.3.1 | tsis muaj | 8.3 |

| 30 | normalized, saib 5.3.2 | tsis muaj | tsis muaj |

| 31 | normalized, saib 5.3.2 | 9 | tsis muaj |

| 32 | normalized, saib 5.3.2 | 9 | 8.3 |

| 33 | normalized, saib 5.3.2 | tsis muaj | 8.3 |

| 40 | normalized thiab tempered, saib 5.3.3 | tsis muaj | tsis muaj |

| 41 | normalized thiab tempered, saib 5.3.3 | 9 | tsis muaj |

| 42 | normalized thiab tempered, saib 5.3.3 | 9 | 8.3 |

| 43 | normalized thiab tempered, saib 5.3.3 | tsis muaj | 8.3 |

| 50 | quenched thiab tempered, saib 5.3.4 | tsis muaj | tsis muaj |

| 51 | quenched thiab tempered, saib 5.3.4 | 9 | tsis muaj |

| 52 | quenched thiab tempered, saib 5.3.4 | 9 | 8.3 |

| 53 | quenched thiab tempered, saib 5.3.4 | tsis muaj | 8.3 |

Kev saib xyuas tshwj xeeb yuav tsum tau them rau qhov ntsuas kub ntawm qhov kev pabcuam thaum xaiv cov khoom siv tsim nyog.Xa mus rau qhov tshwj xeeb ASTM A20 / A20M.

ASTM A672 Loj Ntau Yam

Pom zoo qhov loj me: DN≥400mm [16 nyob rau hauv] thiab WT≤75mm [3 nyob rau hauv].

Rau lwm qhov ntau thiab tsawg ntawm cov yeeb nkab, muab nws ua tau raws li tag nrho lwm cov kev cai ntawm qhov kev qhia no, nws kuj tseem siv tau.

Vuam ceev faj

Seams yuav tsum tau muab ob npaug rau-welded, puv-ntev welded.

Cov welds yuav tsum tau ua manually lossis txiav los ntawm cov txheej txheem hluav taws xob uas cuam tshuam nrog kev tso tawm ntawm cov hlau muab tub lim.

Welds yuav raug tshuaj xyuas siv hluav taws xob thiab yuav tsum ua raws li cov kev cai hauv Tshooj VII UW-51 ntawm ASME Boiler thiab Pressure Vessel Code.

Qhov siab ntawm qhov vuam yuav tsum tsis pub tshaj 3 hli [1/8 hauv].

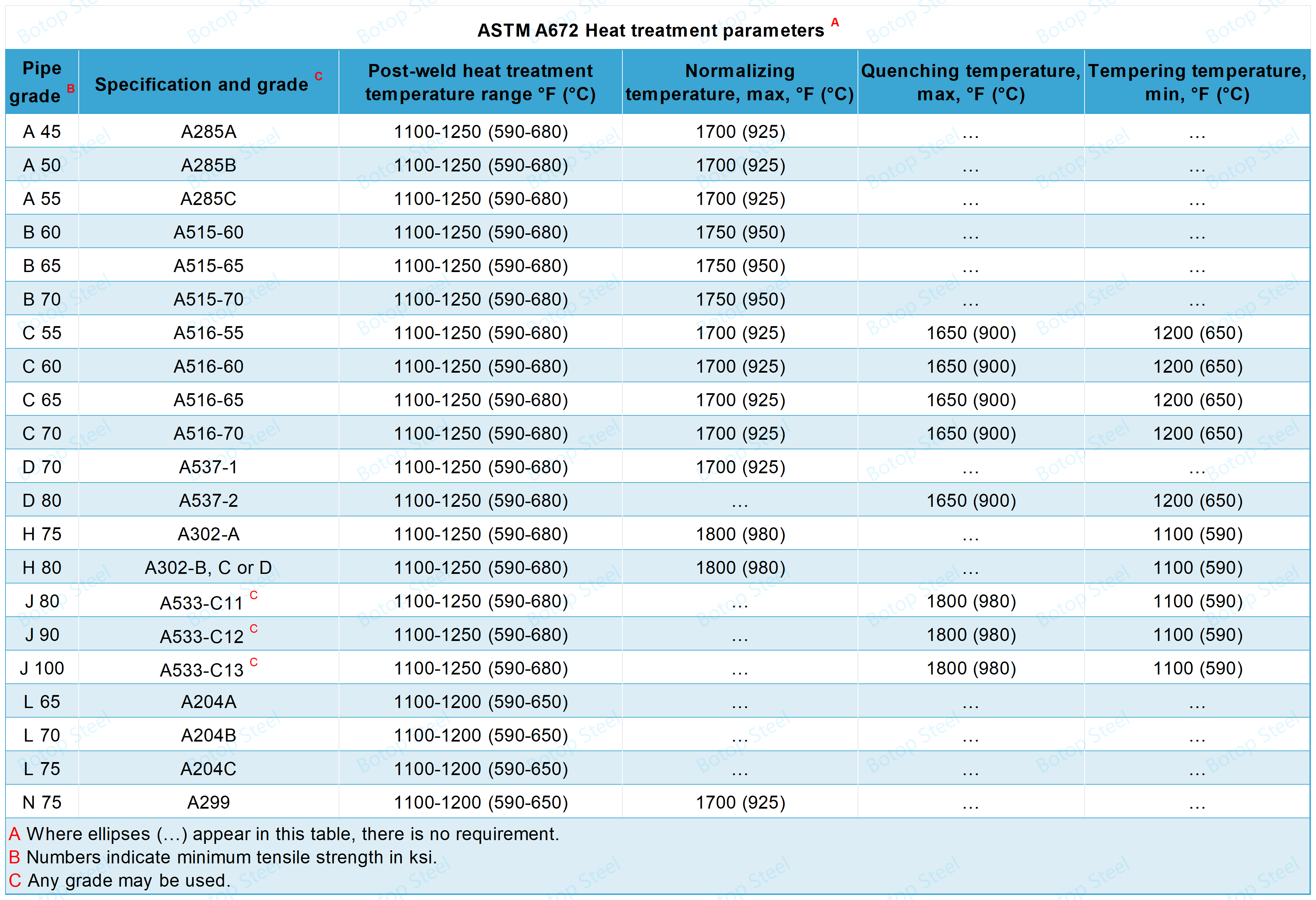

Kev kho cua sov

Tag nrho cov chav kawm uas tsis yog 10, 11, 12, thiab 13 yuav tsum tau kho cua sov hauv qhov cub tswj kom ± 25 ° F [± 15 ° C]:

Qib 20, 21, 22, thiab 23

Cov yeeb nkab yuav tsum tau muab tso rau hauv qhov ntsuas kub tom qab vuam kub-kho qhov ntsuas kub uas tau teev tseg hauv Table 2 rau qhov tsawg kawg nkaus ntawm 1 h / hauv.[0.4 h / cm] ntawm thickness los yog rau 1 h, qhov twg ntau dua.

Chav kawm 30, 31, 32, thiab 33

Cov yeeb nkab yuav tsum tau ua kom sov zoo ib yam rau qhov kub ntawm qhov ntsuas austenitizing thiab tsis pub tshaj qhov siab tshaj plaws normalizing kub qhia hauv Table 2 thiab tom qab txias hauv huab cua ntawm chav tsev kub.

Chav Kawm 40, 41, 42, thiab 43

Cov yeeb nkab yuav tsum normalized.

Cov yeeb nkab yuav tsum tau rov ua kom sov rau qhov ntsuas kub uas tau teev tseg hauv Table 2 raws li qhov tsawg kawg nkaus thiab tuav ntawm qhov kub ntawm qhov tsawg kawg nkaus ntawm 0.5 h / hauv.[0.2 h / cm] ntawm tuab lossis rau1/2h, qhov twg ntau dua, thiab cua txias.

Chav kawm 50, 51, 52, thiab 53

Cov yeeb nkab yuav tsum tau sib npaug rau qhov kub thiab txias nyob rau hauv lub austenitizing ntau yam thiab tsis pub tshaj qhov siab tshaj plaws quenching kub qhia nyob rau hauv Table 2.

Tom qab ntawd, quench nyob rau hauv dej los yog roj.Tom qab quenching, cov yeeb nkab yuav tsum reheated rau qhov tsawg kawg nkaus tempering kub qhia nyob rau hauv Table 2 thiab tuav ntawm qhov ntawd.

kub rau qhov tsawg kawg nkaus ntawm 0.5 h / nti [0.2 h / cm] ntawm tuab los yog 0.5 h, qhov twg yog qhov ntau dua, thiab cua txias.

Chemical Cheebtsam

Nws yuav tsum yog lub luag hauj lwm ntawm cov chaw tsim tshuaj paus los ntsuam xyuas cov tshuaj muaj pes tsawg leeg ntawm cov phaj thiab welds rau ua raws li cov kev cai ntawm lub phaj specification rau cov khoom txiav txim thiab cov txheej txheem welding rau depositing lub weld hlau, raws li.

Kev Ntsuas Siab

Kev sim zaus: ib qho qauv rau ib qho ntau.

Txoj Kev Xeem: Cov qauv kuaj yuav tsum tau ua raws li QW-150 hauv Tshooj IX ntawm ASME Boiler thiab Pressure Vessel Code.Cov qauv yuav tsum raug kuaj nyob rau hauv chav tsev kub raws li Test Methods thiab txhais A370.

Ntxiv rau Qib Dxx, Hxx, Jxx, thiab Nxx hauv Chav Kawm 3x, 4x, thiab 5x transverse tensile zog ntawm lub hauv paus phaj, yuav tsum tau txiav txim siab ntawm cov qauv txiav los ntawm cov yeeb nkab uas muaj cua sov.

Kev xav tau rau cov txiaj ntsig: Transverse tensile zog ntawm cov welded sib koom yuav tsum tau raws li qhov tsawg kawg nkaus yuav tsum tau rau qhov kawg tensile lub zog ntawm cov ntaub ntawv phaj.

Transverse-Guided-Weld-Bend Tests

Tus lej xeem: Kev sim ntau zaus: ib zaug rau ib pawg, ob qho qauv

Txoj kev sim: Cov kev cai xeem ntawm Test Methods and Definitions A370, paragraph A2.5.1.7 yuav tsum ua kom tau raws li.

Rau phab ntsa thickness tshaj3/ 8hauv. [10 mm] tab sis tsawg dua3/4nyob rau hauv. [19 mm] Kev ntsuam xyuas sab-khoov tej zaum yuav ua los ntawm kev ntsuam xyuas lub ntsej muag thiab cov cag-khoov.

Rau phab ntsa thicknesses3/4nyob rau hauv. [19 mm] thiab tshaj ob tus qauv yuav tsum raug kuaj rau sab-khoov.

Kev xav tau rau cov txiaj ntsig: Kev ntsuas khoov yuav tsum tau txais yog tias tsis muaj qhov tawg lossis lwm yam tsis xws luag dhau1/8nyob rau hauv. [3 mm] nyob rau hauv ib qho kev taw qhia muaj nyob rau hauv lub weld hlau los yog nruab nrab ntawm lub weld thiab lub hauv paus hlau tom qab khoov.

Cov kab nrib pleb uas tshwm sim los ntawm cov npoo ntawm cov qauv thaum kuaj, thiab qhov ntawd tsawg dua1/4hauv [6 mm] ntsuas nyob rau hauv ib qho kev taw qhia yuav tsum tsis txhob muab xam.

Kev ntsuas siab

Hoob X2 thiab X3 yeeb nkab yuav tsum raug kuaj raws li Specification A530/A530M, Hydrostatic Test Requirements.

Radiographic Examination

Tag nrho ntev ntawm txhua qhov vuam ntawm Chav Kawm X1 thiab X2 yuav tsum tau kuaj xyuas hluav taws xob raws li thiab ua tau raws li qhov yuav tsum tau ua ntawm ASME Boiler thiab Pressure Vessel Code, Tshooj VIII, Nqe Lus UW-51.

Kev kuaj radiographic tuaj yeem ua ua ntej kev kho cua sov.

Dimensional kam rau ua rau ASTM A672

| Kev ua kis las | Tolerance tus nqi | Nco tseg |

| Sab nraud txoj kab uas hla | ± 0.5% | Raws li qhov ntsuas qhov ntsuas |

| Out-of-Roundness | 1%. | Qhov sib txawv ntawm qhov loj thiab me me sab nraud diameters |

| Kev sib tw | 1/8 nyob rau hauv. [3 mm] | Siv 10 ft [3 m] ncaj ntug muab tso kom ob qhov kawg nyob rau hauv kev sib cuag nrog cov yeeb nkab |

| Thickness | 0.01 hli [0.3 hli] | Qhov tsawg kawg nkaus phab ntsa thickness tsawg tshaj li qhov teev nominal thickness |

| Ntev | 0-+ 0.5 hli [0-+ 13mm] | unmachined xaus |

ASTM A672 Kev Ntsuas

Cov yeeb nkab tiav yuav tsum tsis muaj qhov raug mob thiab yuav tsum muaj cov neeg ua haujlwm tiav.

Cov kev cai tib yam li hauv specification ASTM A20/A20M rau nto tiav ntawm steel daim hlau.

Kev kho thiab kho

Kev txiav txim siab tsis raug

ASTM A672 tus qauv tsis qhia meej txog qib kev ua tau zoo thiab kev txiav txim siab rau cov kav dej thiab feem ntau yog hais txog cov qauv tsim engineering thiab kev coj ua hauv kev lag luam.

Internal defects: Internal defects yuav muaj xws li porosity, slag, inclusions, thiab lwm yam.

Sab nraud tsis xws luag: Sab nraud tsis xws luag muaj xws li tawg, dents, khawb, thiab lwm yam.

Kev tshem tawm los ntawm Regrinding

Deg tsis xws luag yuav raug tshem tawm los ntawm overgrinding los yog machining nrog ib tug residual thickness ntawm tsis tsawg tshaj li 0.3 hli hauv qab tus qauv thickness.

Lub regrind kev nyuaj siab yuav tsum tau uniformly blended rau hauv ib puag ncig nto.

Vuam Kho

Qhov tsis xws luag yuav tsum raug tshem tawm los ntawm kev siv tshuab lossis thermal txiav los yog dicing txoj kev thiab npaj los kho cov kab noj hniav welded.

thiab kuaj hluav taws xob raws li ASME Boiler thiab Pressure Vessel Code, Seem VIII, Paragraph UW-51.

Tag nrho qhov ntev ntawm cov yeeb nkab kho yuav tsum tau kho cua sov tom qab kho raws li cov txheej txheem teev cov kav dej.

ASTM A672 Daim Ntawv Pom Zoo

Lub marking yuav tsum muaj cov hauv qab no:

Tus neeg tsim khoom tus cim, xws li lub cim lag luam lossis lub logo.

Specification ntawm cov yeeb nkab (qhov loj, phab ntsa thickness, thiab lwm yam).

Cov ntaub ntawv qib lossis hom yeeb nkab.Piv txwv li: C60-22 (cov ntawv luv rau qib: C60 thiab chav kawm 22).

Cov qauv tsim ntawm cov yeeb nkab yog ASTM A672.

Hnub tsim khoom lossis ntau ntau tus lej.

Daim ntawv thov ntawm ASTM A672 Steel Pipe

Hauv kev lag luam hluav taws xob hluav taws xob, ASTM A672 Electric Welded Steel Pipe feem ntau yog siv los xa cov pa hauv cov tshuab boiler.

Hauv kev lag luam tshuaj, ASTM A672 welded steel yeeb nkab feem ntau yog siv los thauj ntau yam tshuaj, kua qaub, thiab alkali daws, thiab lwm yam xov xwm.

Hauv kev lag luam roj thiab roj, ASTM A672 welded steel yeeb nkab feem ntau yog siv los thauj cov roj av, roj av, thiab lwm yam kua lossis roj.

Peb yog ib tug zoo welded carbon steel yeeb nkab chaw tsim tshuaj paus thiab tsum los ntawm Tuam Tshoj, thiab kuj yog ib tug seamless steel yeeb nkab stockist, muab koj ib tug ntau yam ntawm cov yeeb nkab steel kev daws teeb meem!

Hot Tags: ASTM a672, efw, carbon steel yeeb nkab, qib.

Post lub sij hawm: Apr-23-2024