Klas ak Konpozisyon Chimik (%)

| Klas | C≤ | Mn | P≤ | S≤ | Si≥ | Cr≤ | Ki ≤ | Mo≤ | Ni≤ | V≤ |

| A | 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| B | 0.30 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15

| 0.40 | 0.08 |

| C | 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

Pwopriyete mekanik:

|

|

|

| Yon% |

|

| A | ≥330 | ≥205 | 20 | Rekwit |

| B | ≥415 | ≥240 | 20 | Rekwit |

| C | ≥485 | ≥275 | 20 | Rekwit |

| Non pwodwi | Tiyo asye san pwoblèm |

| Materyèl | Asye kabòn ak asye alyaj |

| Estanda | ASTMA53, ASTMA106, ASTMA179, ASTMA192, ASTMA210, ASTM A213, ASTM A335, DIN2391-2, DIN1629, DIN2448, DIN17175.DIN17176,EN10219,EN10210 |

| Klas | Kalite asye kabòn tankou A53 Gr.B, A106 GrA, B, C, A210 GrA1.Gr.C. API 5L Gr.B.X42, X52. X56, elatriye; klas asye alyaj tankou T5, T9, T11, T12, T22, T23, T91, P1, P2, P5, P9.P11, P12 P22.P91, P92, 25CrMo4.34CrMo4, 42CrMo4SAE4130, SAE4140, SAE4145, SAE4340, elatriye |

| Gwosè ranje | 10 * 1-810 * 25, pwa jiska 120mm maksimòm |

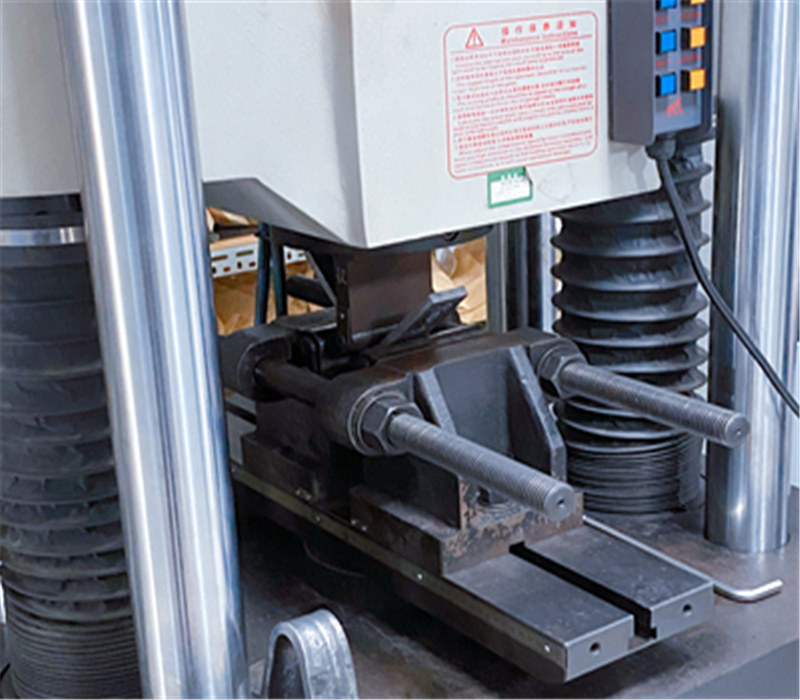

| Metòd fabrikasyon | Trase a frèt, woule a frèt, trase a frèt idwolik, woule a cho, elaji a cho |

| Kondisyon livrezon | Jan li woule, soulaje estrès, rkwit, nòmalize, trempe + apeze |

| Fini fen | Bout plenn ak koupe suqare, bout bizote, bout file |

| Itilizasyon/Aplikasyon | Veso presyon, transpò likid, itilizasyon estriktirèl. Machin. Lwil ak gaz transpò, eksplorasyon ak perçage, elatriye |

| Kalite tib | Tib chodyètib presizyon, tib mekanik. tib silenn.tiyo liyelatriye. |

-

-

Tolerans dimansyon:

Kalite tiyo

Gwosè tiyo Tolerans Desine a frèt

OD ≤48.3mm ±0.40mm ≥60.3mm ±1%mm Pwa ±12.5%

-