Pwovizyon pou asye BotopTiyo asye ERWsoti nanGR.B,X42,X46,GR.1,GR.2,S355J0H,S275JRH,SGP, elatriye

| Stil | Estanda | Klas | Itilizasyon |

| Tiyo asye ERW | API 5L PSL1 ak PSL2 | GR.B, X42, X46, X52, X60, X65, X70, elatriye | Transpò lwil oliv ak gaz |

| ASTM A53 | GR.A, GR.B | ||

| ASTM A252 | GR.1, GR.2, GR.3 | Pou Estrikti (Pilotaj) | |

| BS EN10210 | S275JRH, S275J0H, S355J0H, S355J2H, elatriye | ||

| BS EN10219 | S275JRH, S275J0H, S355J0H, S355J2H, elatriye | ||

| JIS G3452 | SGP, elatriye | Transpò nan Likid ki ba presyon | |

| JIS G3454 | STPG370, STPG410, elatriye | Transpò nan Likid anba gwo presyon | |

| JIS G3456 | STPG370, STPG410, STPG480, elatriye | Tiyo asye tanperati ki wo |

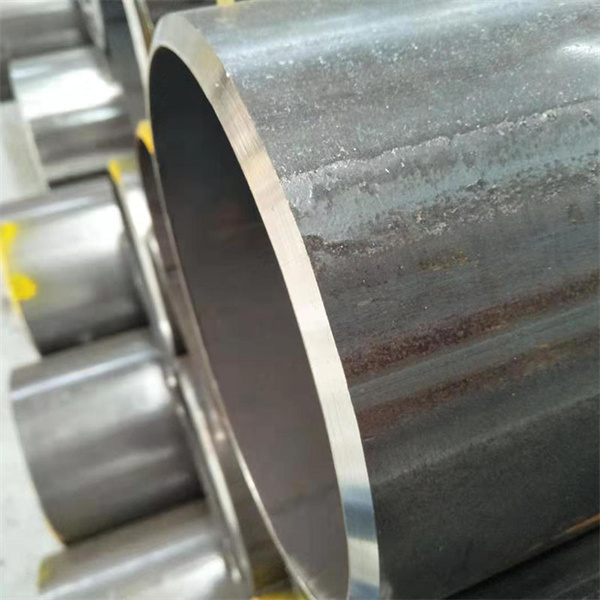

Bizote Fen Tiyo

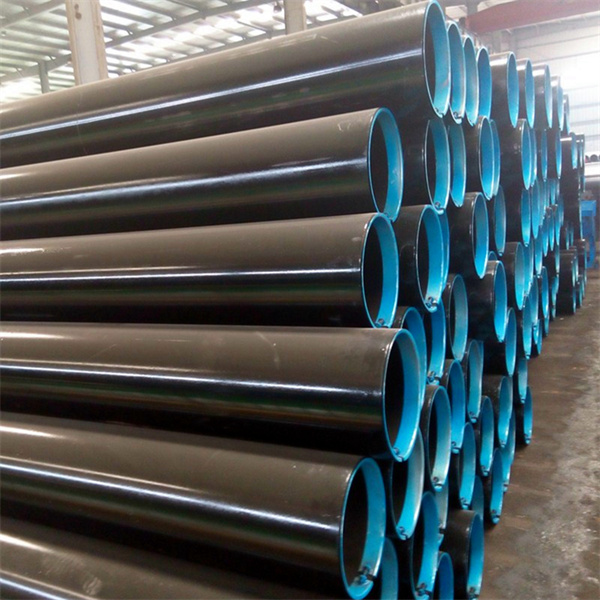

Penti Nwa ak Make

Gwoupman ak Sling

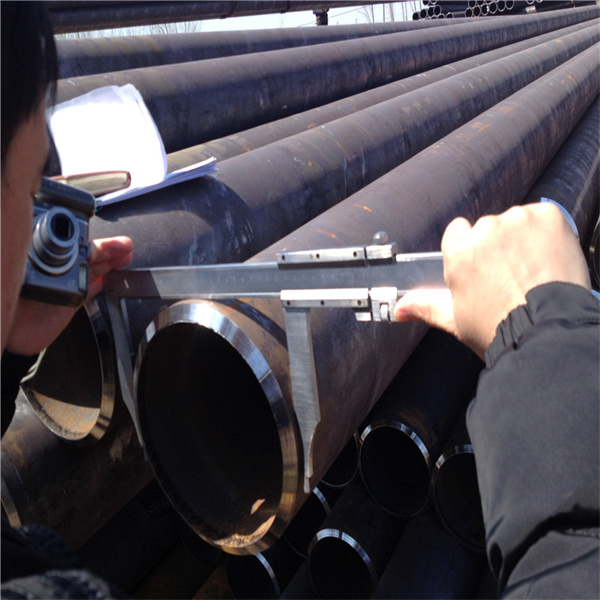

Enspeksyon Dyamèt Eksteryè

Enspeksyon epesè miray

Fen Enspeksyon an

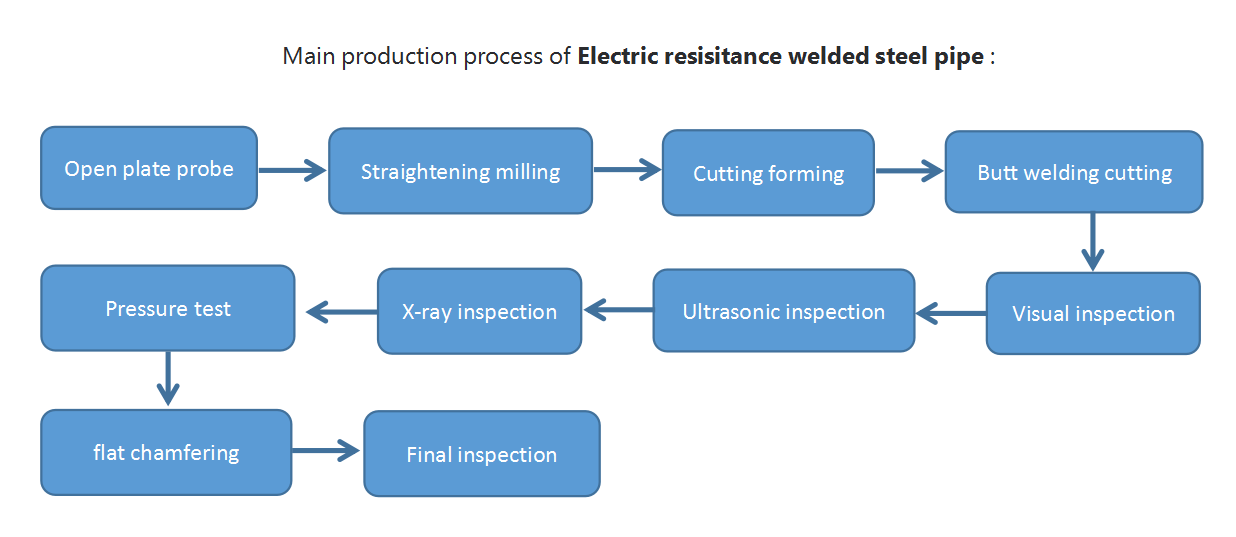

Soude ak rezistans elektrik (Metòd fabrikasyon an se soude ak rezistans elektrik oswa soude bout. Metòd fini an ka fini cho oswa fini frèt. Tiyo fini frèt yo dwe rkui apre fabrikasyon.)

Tolerans OD ak WT

| Divizyon | Tolerans sou OD | Tolerans sou WT | |

| Tiyo asye ERW | 10.5mm≤D≤48.6mm | ±0.5 milimèt | -12.5% + Pa espesifye |

| D = 60.5mm | ±0.5 milimèt | ||

| D = 76.3mm | ±0.7 milimèt | ||

| 89.1mm≤D≤139.8mm | ±0.8 milimèt | ||

| D = 165.2mm | ±0.8 milimèt | ||

| D = 190.7mm | ±0.9 milimèt | ||

| D = 216.3mm | ±1.0 milimèt | ||

| D = 241.8mm | ±1.2 milimèt | ||

| D = 267.4mm | ±1.3 milimèt | ||

| D = 318.5mm | ±1.5mm | ||

| 355.6mm≤D≤508.0mm | - | ||

| Tiyo Astm A252 ERW | Tiyo wonn ERW |

| Tiyo Astm A53 B ERW | Tiyo asye soude ERW |

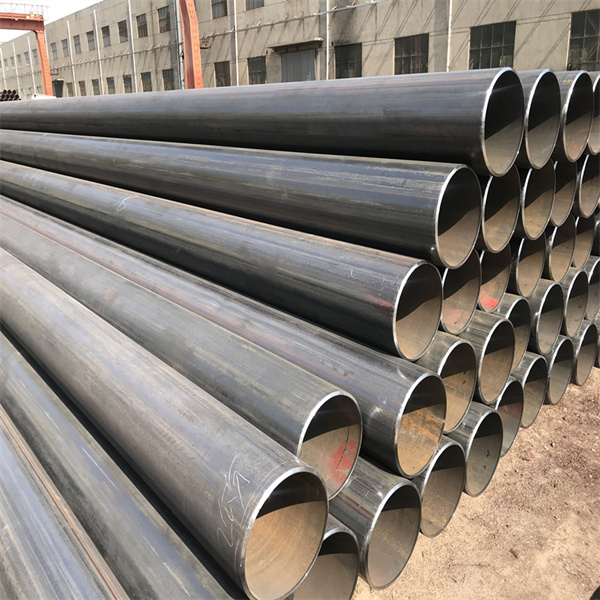

| Pil tiyo asye ERW | Tiyo asye nwa ERW |

| Tiyo ERW an asye mou | Tiyo asye kabòn ERW |

Tiyo asye ASTM A53 Gr.A ak Gr. B Kabòn ERW pou tanperati ki wo

EN10210 S355J2H TIYO ASYE ESTRIKTIRAL ERW

JIS G3454 Kabòn ERW Tiyo Asye Presyon Sèvis

Tiyo asye kabòn JIS G3452 ERW pou tiyo òdinè

EN10219 S275J0H S275J2H / S275JRH Tiyo pou pil asye estriktirèl ERW