API 5L Ọkwa BA na-emepụta ọkpọkọ ígwè dị ka ihe ndị dị mkpa chọrọ nkeAPI 5La na-ejikwa ya na usoro ụgbọ njem pipeline na ụlọ ọrụ mmanụ na gas.

Ọkwa Benwere ike ịkpọ yaL245. Ihe e ji mara bụ na kacha nta mkpụrụ ike nke ígwè ọkpọkọ bụ245 MPa.

Ọkpụkpọ ahịrị API 5L dị n'ọkwa abụọ nkọwapụta ngwaahịa:PSL1bụ isi eji na ọkọlọtọ njem usoro, mgbePSL2dabara adaba maka ọnọdụ ndị siri ike nwere ike igwe dị elu yana ụkpụrụ nnwale siri ike.

Usoro nrụpụta nwere ike enweghị nkebi (SMLS), ọkụ eletrik welded (ERW), ma ọ bụ arc welded miri emi (SAW) iji kwado nrụnye dị iche iche na mkpa ọrụ.

Steel akpụkpọ ụkwụbụ ọkachamara emeputa nke nnukwu mgbidi nnukwu dayameta nwere akụkụ abụọ submerged arc LSAW ígwè ọkpọkọ dị na China.

Ebe: Cangzhou City, Hebei Province, China;

Mkpokọta ntinye ego: 500 nde RMB;

Mpaghara ụlọ ọrụ: 60,000 square mita;

Ike mmepụta kwa afọ: 200,000 tọn JCOE LSAW ígwè ọkpọkọ;

Akụrụngwa: Ngwá ọrụ mmepụta na ule dị elu;

Ọpụrụiche: LSAW mmepụta ọkpọkọ ígwè;

Asambodo: API 5L kwadoro.

API 5L Ọkwa B nhazi ọkwa

E kewara ya n'ụdị dị iche iche dabere na ọkwa nkọwapụta ngwaahịa dị iche iche (PSL) yana ọnọdụ nnyefe.

Nkewa a na-eme ka nhọrọ nke ọkpọkọ ahịrị ziri ezi dịkwuo mkpa iji gboo mkpa nke otu ọrụ na ihe ndị chọrọ na gburugburu ebe ọrụ.

PSL1: B.

PSL2: BR;BN;BQ;BM

A na-eji ọtụtụ ọkpọkọ ígwè PSL 2 pụrụ iche maka gburugburu ọrụ pụrụ iche.

gburugburu ọrụ utoojoo: BNS; BQS; BMS.

Mpaghara ọrụ ndị dị n'ụsọ osimiri: BNO; BQO; BMO.

Ngwa na-achọ ikike eriri plastik ogologo: BNP; BQP; BMP.

Ọnọdụ nnyefe

| PSL | Ọnọdụ nnyefe | Ọkwa ọkpọkọ/ọkwa ígwè | |

| PSL1 | Dị ka-akpọrela, normalizing akpọrepu, thermomechanical akpọrepu, thermomechanical kpụrụ, normalize kpụrụ, normalized, normalized na iwe; ma ọ bụ, ọ bụrụkwenye, menyụọ na iwe maka naanị ọkpọkọ SMLS | B | L245 |

| PSL 2 | Dị ka-akpọrela | BR | L245R |

| Normalizing akpọrela, na-eme ka ọ dị mma etolite, emebere ya ka ọ dị mma, ma ọ bụ mee ka ọ dị mma na iwe ọkụ | BN | L245N | |

| Emenyụ na iwe | BQ | L245Q | |

| Thermomechanical akpọrepu ma ọ bụ thermomechanical kpụrụ | BM | L245M | |

Ọnọdụ nnyefe nke ọkpọkọ ígwè na-ezo aka na ọgwụgwọ okpomọkụ ma ọ bụ ọgwụgwọ ndị ọzọ a na-eme na njedebe nke usoro mmepụta nke ọkpọkọ ígwè, na ọgwụgwọ ndị a nwere mmetụta dị mkpa na ihe ndị na-emepụta ihe, nguzogide corrosion, na nkwụsi ike nhazi nke ọkpọkọ ígwè.

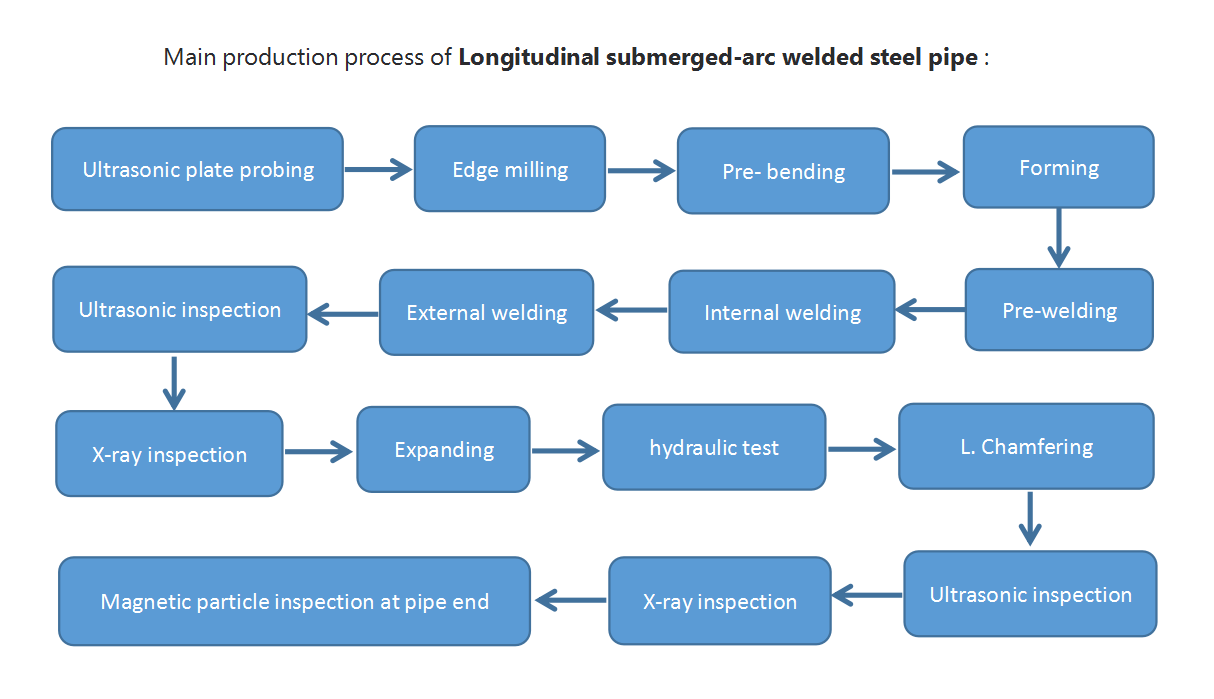

API 5L GR.B Usoro nrụpụta ọkpọkọ igwe

Na API 5L ọkọlọtọ ọkwa B nwere ike ịmepụta site na iji otu n'ime usoro mmepụta na tebụl na-esonụ.

| API 5L PSL1 Ọkwa B | SMLS | LFW | HFW | SAWL | SAWH | Ehi | COWH |

| API 5L PSL2 Ọkwa B | SMLS | - | HFW | SAWL | SAWH | Ehi | COWH |

Iji chọpụta ihe ndị ọzọ gbasara usoro mkpọpụta okwu acronym pụtara,pịa ebe a.

LSAWbụ ihe ngwọta kachasị mma maka ọkpọkọ ígwè buru ibu, nke nwere mgbidi.

Ihe dị iche iche dị n'ọdịdị bụ ọnụnọ nke weld na ntụgharị ogologo nke ọkpọkọ.

Ụdị njedebe ọkpọkọ

Ụdị njedebe njedebe API 5L nke ọkwa B nwere ike ịdị iche na PSL1 na PSL2.

PSL 1 Steel Pipe Ọgwụgwụ

Nkwụsị mgbịrịgba; Ọgwụgwụ nkịtị;Ọgwụgwụ dị larịị maka njikọta pụrụ iche; Ọgwụgwụ eriri.

Ọgwụgwụ mgbawa: Oke na tubes nwere D ≤ 219.1 mm (8.625 in) na t ≤ 3.6 mm (0.141 na) na njedebe oghere.

Ọgwụgwụ eriri: Ọkụ nwere eriri nwere oke na SMLS yana ọkpọkọ ogologo welded nwere D <508 mm (20 in).

PSL 2 Steel Pipe Ọgwụgwụ

Ọgwụgwụ nkịtị.

Maka ngwụcha ọkpọkọ nkịtị, a ga-agbaso ihe ndị a:

Ihu njedebe nke t ≤ 3.2 mm (0.125 in) ọkpọkọ njedebe dị larịị ga-abụ akụkụ anọ.

Tubọ dị larịị nwere t> 3.2 mm (0.125 in) ga-agbado maka ịgbado ọkụ. Oghere bevel kwesịrị ịbụ 30-35 ° na obosara nke ihu mgbọrọgwụ nke bevel kwesịrị ịbụ 0.8 - 2.4 mm (0.031 - 0.093 na).

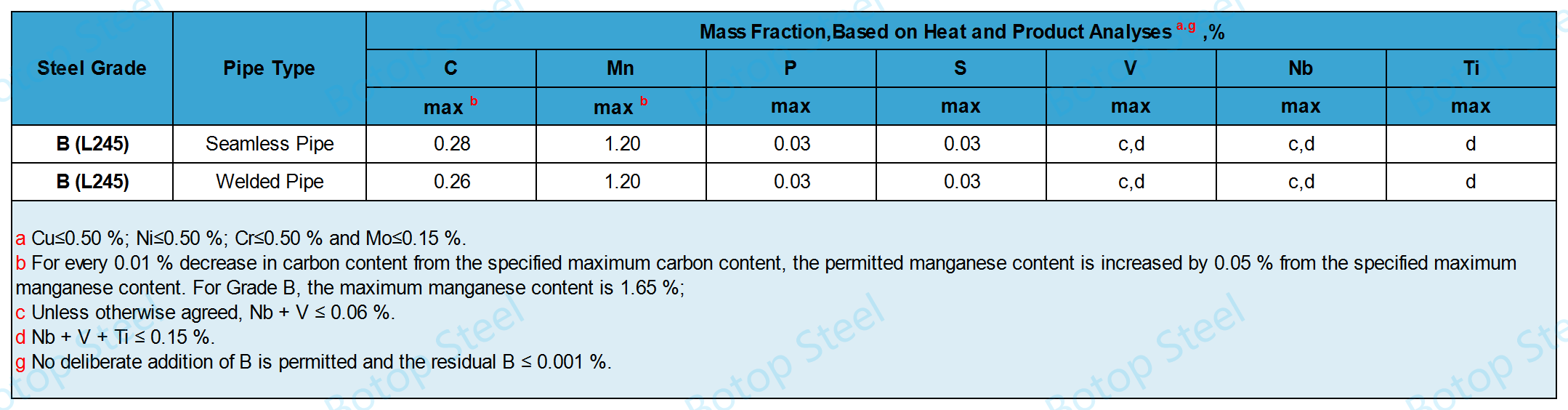

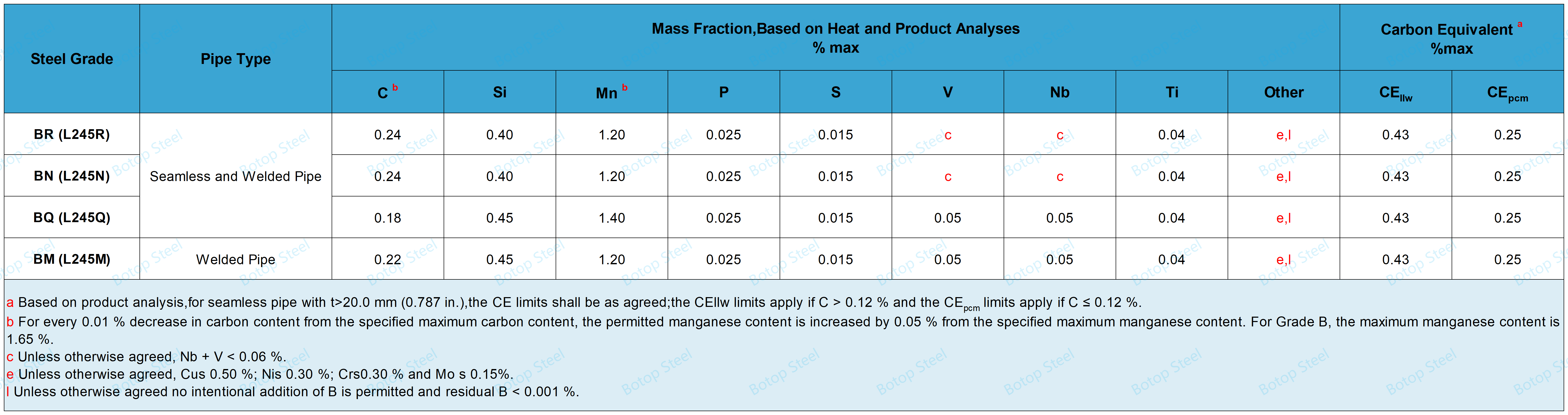

API 5L Ọkwa B Ngwakọta kemịkalụ

Ngwakọta kemịkalụ nke PSL1 na PSL2 ígwè ọkpọkọ t> 25.0 mm (0.984 na) ga-ekpebi site na nkwekọrịta.

Ihe mejupụtara kemịkalụ maka PSL 1 Pipe nwere t ≤ 25.0 mm (0.984 in.)

Ihe mejupụtara kemịkalụ maka PSL 2 Pipe nwere t ≤ 25.0 mm (0.984 in.)

N'ihi na PSL2 ígwè anwụrụ ngwaahịa nyochara na acarbon ọdịnaya nke ≤0.12%, carbon kwekọrọ CEpcmenwere ike gbakọọ site na iji usoro a:

CEpcm= C + Si/30 + Mn/20 + Cu/20 + Ni/60 + Cr/20 + Mo/15 + V/15 + 5B

N'ihi na PSL2 ígwè anwụrụ ngwaahịa nyochara na acarbon ọdịnaya> 0.12%, carbon kwekọrọ CElwenwere ike gbakọọ site na iji usoro dị n'okpuru:

CElw= C + Mn/6 + (Cr + Mo + V)/5 + (Ni +Cu)/15

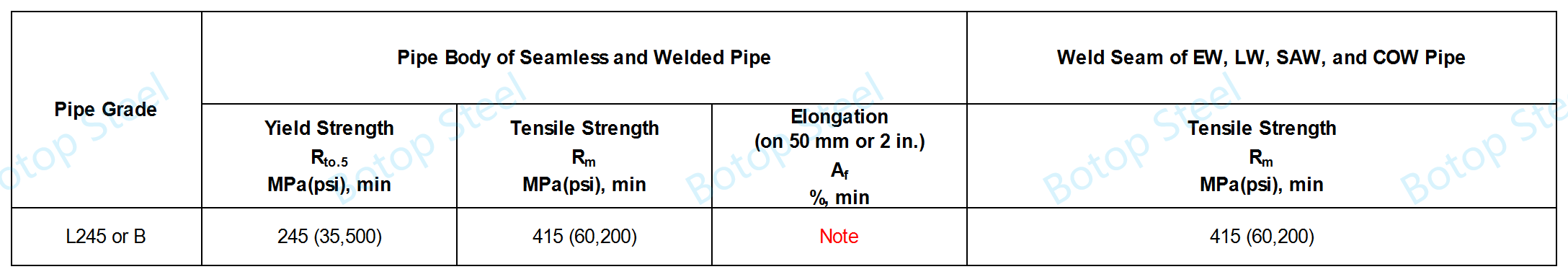

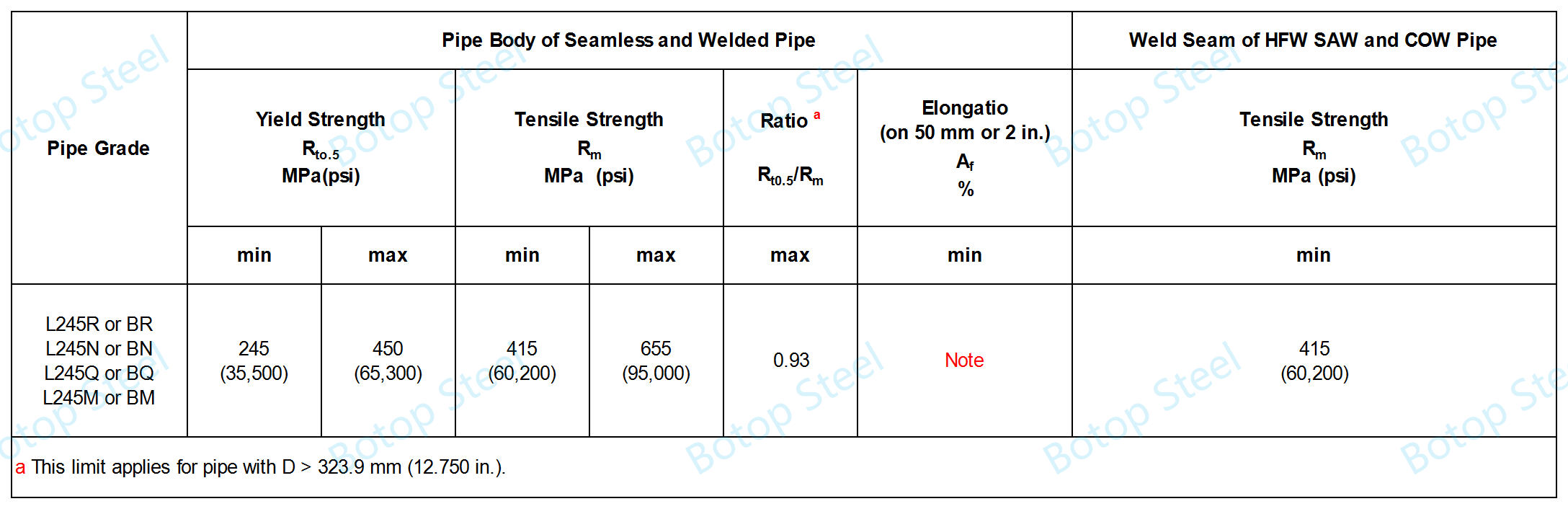

API 5L Ọkwa B Mechanical Property

Ihe onwunwe tensile

PSL1 GR.B Njirimara Tensile

PSL2 GR.B Tensile Njirimara

Rịba ama: Nke kacha nta elongation akọwapụtara, Afa ga-ekpebi site na iji nha nhata:

Af= C × (Axc0.2/U0.9)

Cbụ 1940 maka mgbako site na iji nkeji SI na 625,000 maka mgbako site na iji nkeji USC;

Axc bụ mpaghara ebe a na-agafe agafe, nke egosipụtara na square millimeters (square inches), dị ka ndị a:

1) maka mpempe ule obe okirikiri okirikiri, 130 mm2(0.20 nke anụ ọhịa)2) maka 12.7 mm (0.500 in.) na 8.9 mm (0.350 in.) mpempe ule dayameta; 65 mm2(0.10 n'arọ.2) maka 6.4 mm (0.250 in.) mpempe ule dayameta;

2) maka mpempe ule zuru oke, nke pere mpe nke a) 485 mm2(0.75 nke anụ ọhịa)2) na b) mpaghara obe nke mpempe ule, T ewepụtara site na iji dayameta dị n'èzí akọwapụtara na ọkpụrụkpụ mgbidi a kapịrị ọnụ nke ọkpọkọ, gbakọtara na 10 mm kacha nso.2(0.01 n'arọ.2);

3) maka mpempe ule warara, nke pere mpe nke a) 485 mm2(0.75 nke anụ ọhịa)2) na b) mpaghara obe nke mpempe ule, nke a na-enweta site na iji obosara a kapịrị ọnụ nke mpempe ule na mgbidi a kapịrị ọnụ nke ọkpọkọ, gbakọrọ na 10 mm kacha nso.2(0.01 n'arọ.2);

Ubụ ike tensile kacha nta akọwapụtara, egosipụtara na megapascals (paụnd kwa square inch).

Bend Test

Ọ dịghị akụkụ nke ihe atụ a ga-agbawa na weld agaghị agbawa.

Nnwale ire ọkụ

Ọ bụghị na ọdabara na LSAW ígwè ọkpọkọ.

Kwesịrị ekwesị makaEW, LW, naCWmmepụta ụdị tubes.

Nnwale eduzi-ehulata

Gosi mgbape ma ọ bụ mgbawa ọ bụla na igwe weld ogologo karịa 3.2 mm (0.125 in), n'agbanyeghị omimi.

Gosi mgbawa ma ọ bụ mgbawa ọ bụla na metal nne na nna, HAZ, ma ọ bụ njikọ njikọ ogologo karịa 3.2 mm (0.125 in) ma ọ bụ miri karịa 12.5 % nke ọkpụrụkpụ mgbidi akọwapụtara.

Nnwale Mmetụta CVN maka PSL 2 Pipe

Nnwale mmetụta CVN (Charpy V-Notch), usoro nnwale ahaziri ahazi maka ịlele ịdị ike nke ihe mgbe etinyere ibu mmetụta ngwa ngwa.

Ihe ndị a chọrọ na-emetụta akara ule ≤ X60 ma ọ bụ L415.

| Achọrọ ike ike nke CVN maka ahụ ọkpọkọ nke PSL 2 Pipe | |

| Oke dayameta dị n'èzí akọwapụtara D mm (n'ime) | Nha zuru oke CVN Absorbed Energy min Kv J (ft.lbf) |

| 762 (30) | 27 (20) |

| 762 (30) ruo 2134 (84) | 40 (30) |

Nnwale DWT maka PSL 2 Welded Pipe

Nkezi mpaghara shiee kwa ule ga-abụ ≥ 85 % na 0 Celsius C (32 Celsius F) nnwale nnwale.

Maka tubes nwere ọkpụrụkpụ mgbidi> 25.4 mm (1 in.), a ga-emekọrịta ihe nnabata chọrọ maka ule DWT.

Nnwale Hydrostatic

Oge ule

Nha niile nke tubes ígwè enweghị nkebi na welded nwere D ≤ 457 mm (18 in.):oge ule ≥ 5s;

Ọkụ ígwè welded D> 457 mm (18 in.):oge ule ≥ 10s.

Ugboro ule

Ọkpụkpọ ígwè ọ bụla.

Nwale nrụgide

Nrụgide ule hydrostatic P nke aọkpọkọ ígwè dị larịịenwere ike gbakọọ site na iji usoro.

P = 2st/D

Sbụ nrụgide hoop. uru ya ruru ka ike mkpụrụ kacha nta nke igwe nchara xa, na MPa (psi);

Maka API 5L Ọkwa B, pasent bụ 60% maka ule ule ọkọlọtọ na 70% maka nrụgide ule nhọrọ.

Maka D <88.9 mm (3.500 in.), ọ dịghị mkpa na nrụgide ule gafere 17.0 MPa (2470 psi);

Maka D> 88.9 mm (3.500 in.), ọ dịghị mkpa na nrụgide ule gafere 19.0 MPa (2760 psi).

tbụ ọkpụrụkpụ mgbidi a kapịrị ọnụ, gosipụtara na millimeters (inch);

Dbụ dayameta dị n'èzí akọwapụtara nke akọwapụtara na millimeters (inch).

Nyocha na-adịghị emebi emebi

Maka tubes SAW, ụzọ abụọ,UT(nnwale ultrasound) ma ọ bụRT(nnwale redio), na-ejikarị.

ET(Nnwale elektrọnịk) adịghị etinye aka na tubes SAW.

welded seams na welded ọkpọkọ nke akara ule ≥ L210 / A na diameters ≥ 60.3 mm (2.375 in) ga-nondestructively enyocha maka zuru ọkpụrụkpụ na ogologo (100%) dị ka akọwapụtara.

Nyocha UT na-adịghị emebi emebi

Nyocha RT na-adịghị emebi emebi

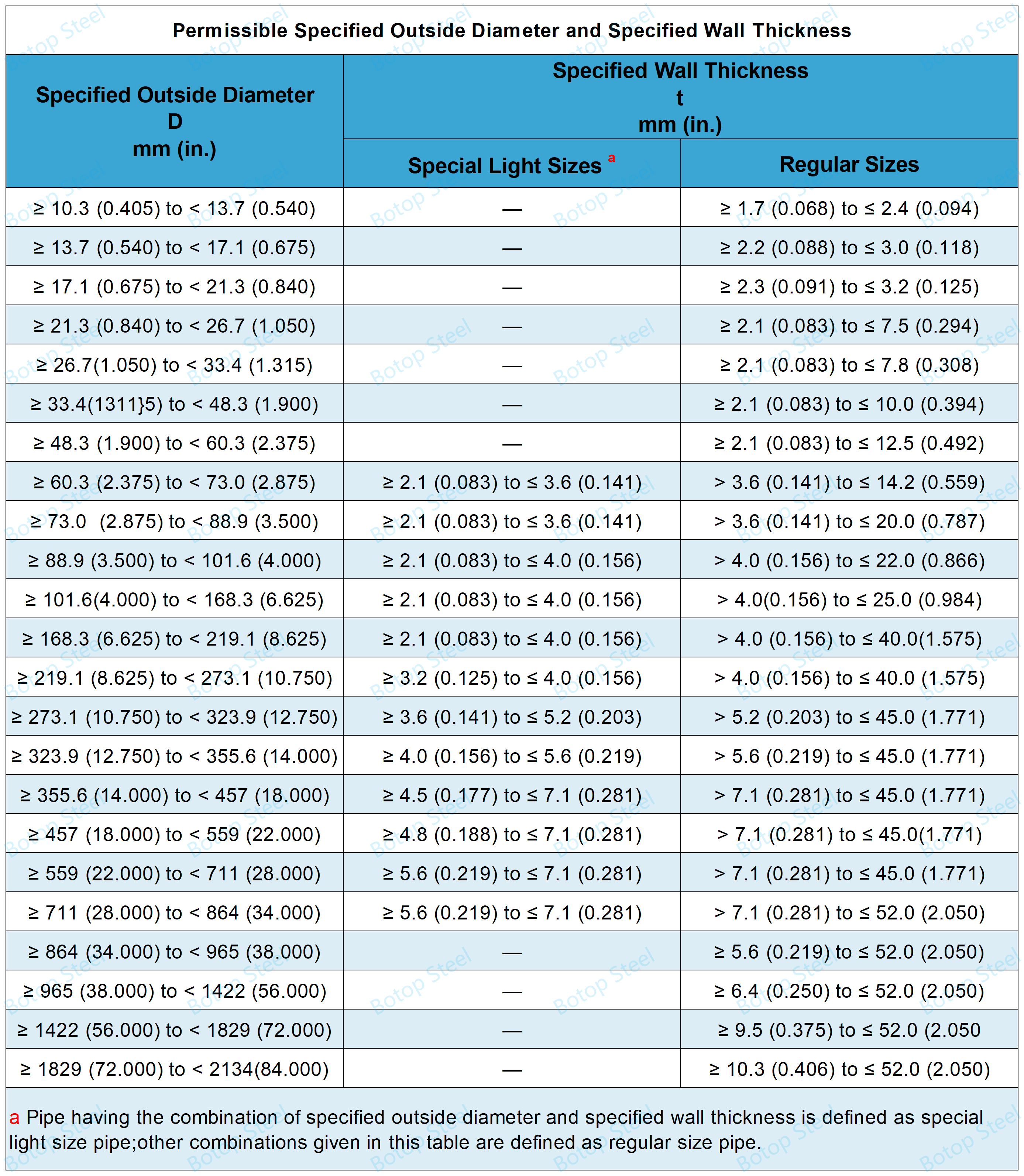

Kọwaa dayameta dị n'èzí na ịdị arọ nke mgbidi

A na-enye ụkpụrụ ọkọlọtọ maka akọwapụtara n'èzí dayameta yana ọkpụrụkpụ mgbidi akọwapụtara nke ọkpọkọ ígwèISO 4200naASME B36.10M.

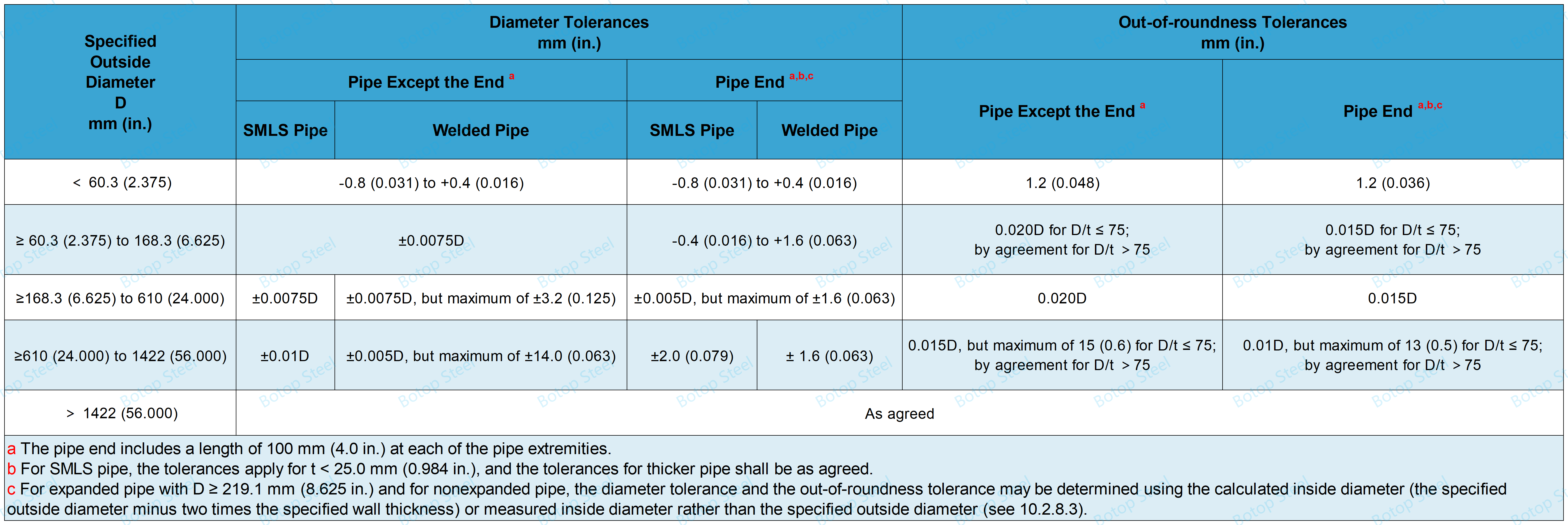

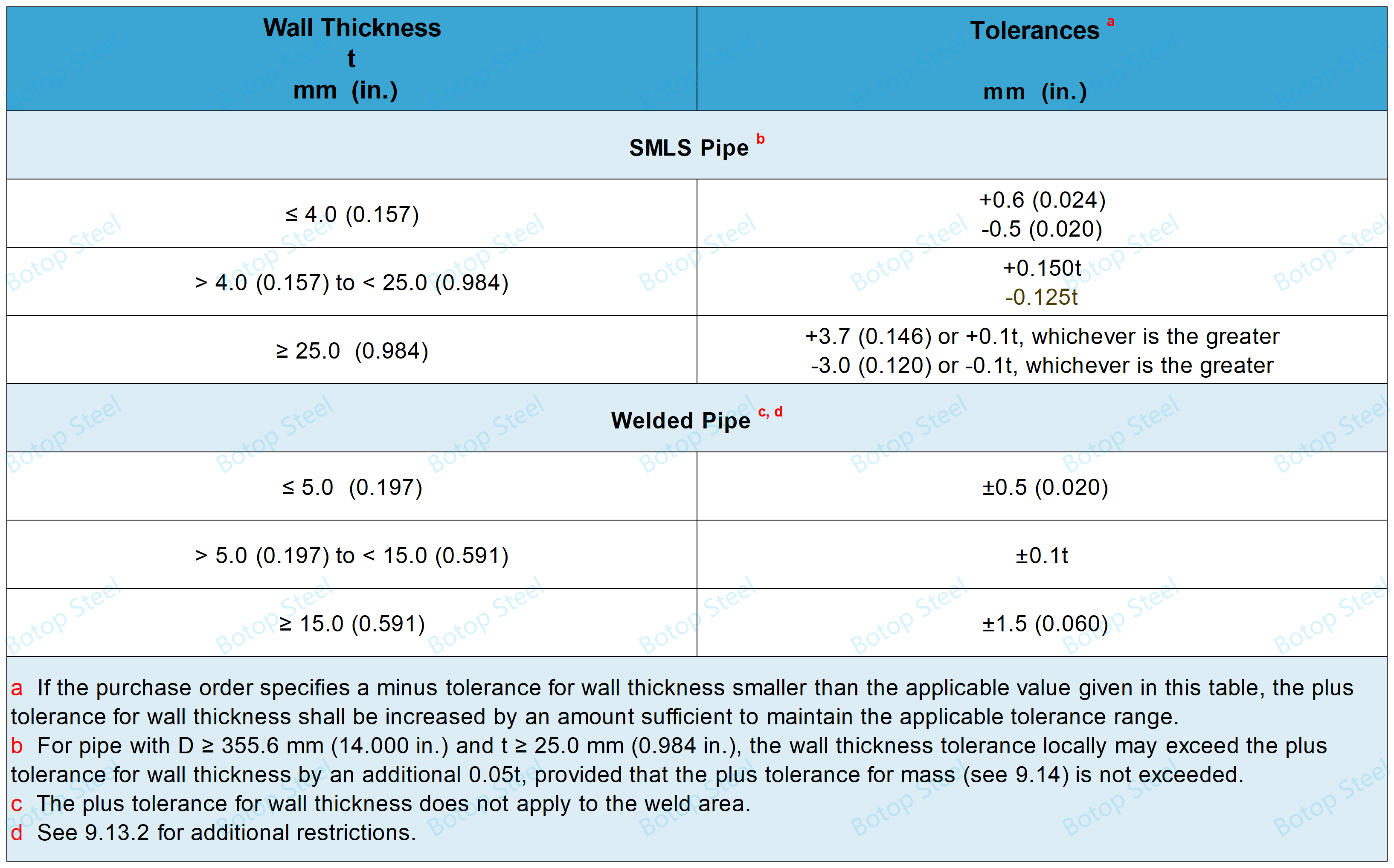

Oke ndidi

Nkwenye maka dayameta na mpụga okirikiri

Akọwapụtara dayameta nke ọkpọkọ nchara dịka okirikiri nke ọkpọkọ n'ime ụgbọ elu okirikiri ọ bụla kewara site na π.

Nkwenye maka ịdị arọ mgbidi

Nkwenye maka Ogologo

Ogologo ogologoa ga-anapụta n'ime nnabata nke ± 500 mm (20 in.).

Nkwenye makarandom ogologo

| Nhọpụta Ogologo Random m (ft) | Ogologo kacha nta m (ft) | Ogologo Opekempe kacha nta maka ihe ọ bụla nyere iwu m (ft) | Ogologo kachasị m (ft) |

| Ọkpọkpọ eriri na-ejikọta ọnụ | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0) |

| Ọkụ dị larịị | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5) | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0) | 10.67 (35.0) | 13.72 (45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0) | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Ndidi maka Izi ezi

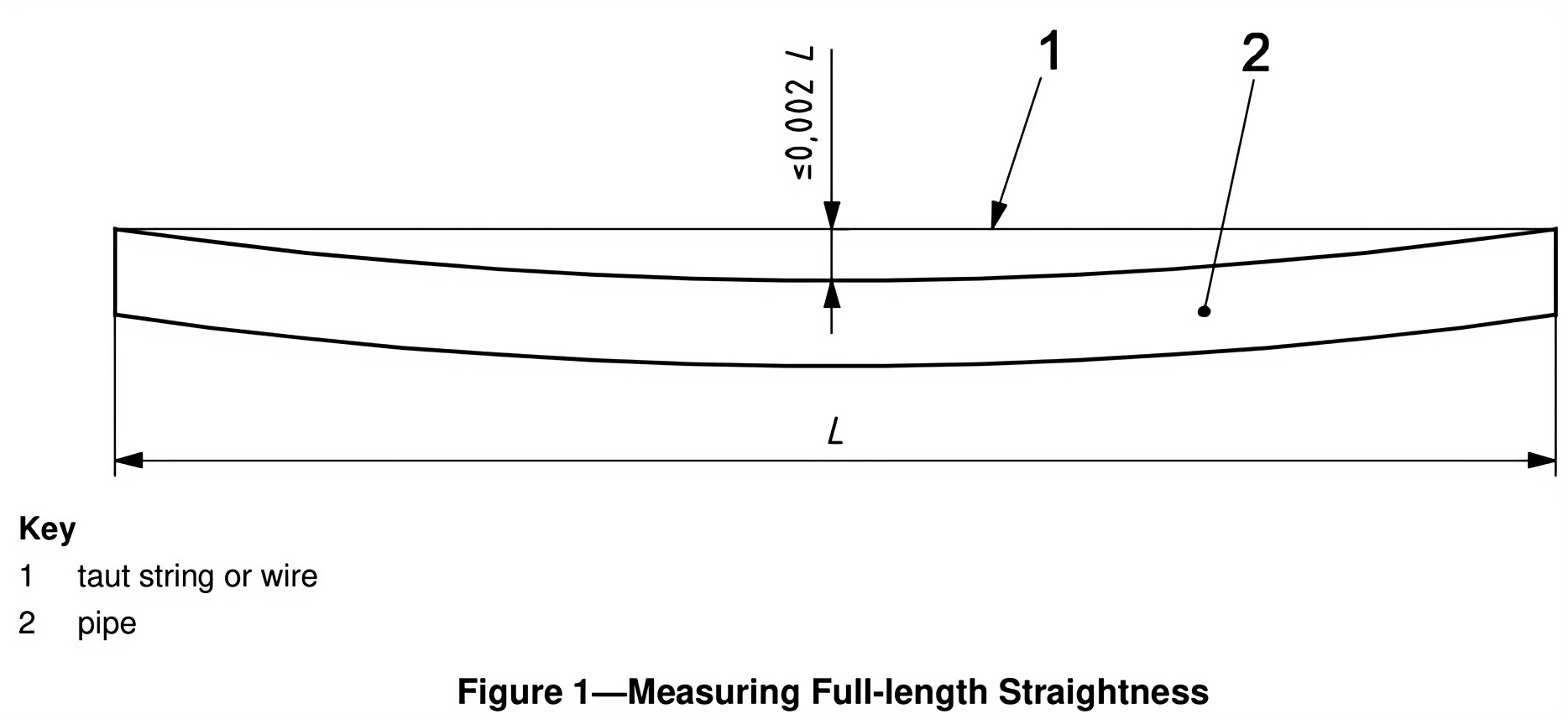

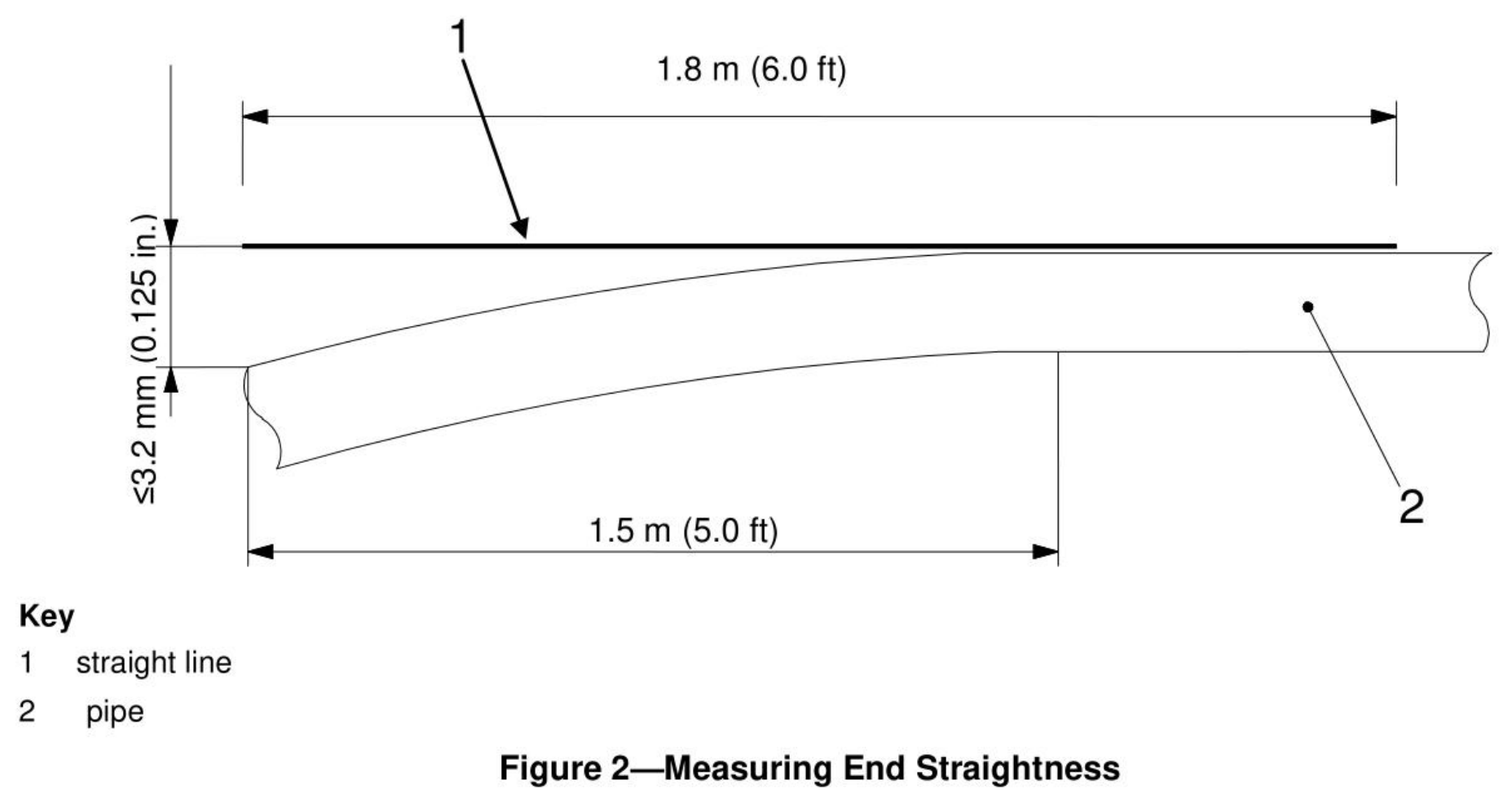

Mgbanwe ziri ezi n'eludum ogologo nke tube: ≤ 0.200 L;

Izi ezi ndiiche nke1.5 m (5.0 ft) ọkpọkọ ọkpọkọ ígwè: ≤ 3.2mm (0.125 in.).

Ndidi maka Izi ezi

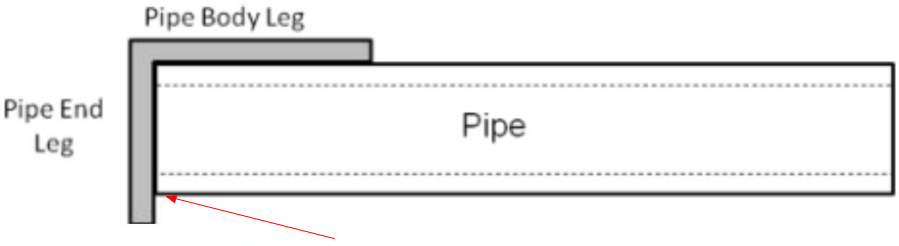

A na-akọwa njedebe njedebe dị ka square ruo na njedebe nke ọkpọkọ.

Mpụpụ-squareness ga-abụ <1.6 mm (0.063 in.). A na-atụpụta ihe na-apụ apụ dị ka ọdịiche dị n'etiti njedebe nke ọkpọkọ na ọkpọkọ ọkpọkọ.

Nkwenye maka Weld Seam

Mgbasa Radial kacha anabatamaka SAW na COW Pipe.

| Ọkpụrụkpụ mgbidi akọwapụtara t mm (n'ime) | Mgbasa Radial kacha anabataamm (n'ime) |

| ≤ 15.0 (0.590) | 1.5 (0.060) |

| > 15.0 (0.590) ruo 25.0 (0.984) | 0.1t |

| > 25.0 (0.984) | 2.5 (0.098) |

| aOke ndị a na-emetụtakwa na warara / efere njedebe welds | |

Ogologo Bead Weld kacha anabatamaka SAW na COW Pipe (Ewezuga na Pipe Ends).

| Ọkpụrụkpụ mgbidi akọwapụtara mm (n'ime) | Weld Bead Height mm (n'ime) maxim | |

| Ime bead | Mpụga Bead | |

| ≤13.0 (0.512) | 3.5 (0.138) | 3.5 (0.138) |

| > 13.0 (0.512) | 3.5 (0.138) | 4.5 (0.177) |

Weld ga-enwe mgbanwe dị mma na elu nke ọkpọkọ ígwè dị n'akụkụ.

A ga-akụtu eriri ngwụcha n'ogologo ruo 100 mm (4.0 in.) na ogologo weld fọdụrụ nke ≤ 0.5 mm (0.020 in.).

Nkwenye maka Mas

Ọkpụkpọ ígwè ọ bụla:

a) maka ọkpọkọ ọkụ pụrụ iche: -5.0% - + 10.0%;

b) maka ọkpọkọ na ọkwa L175, L175P, A25, na A25P: -5.0% - + 10.0%;

c) maka ọkpọkọ ndị ọzọ niile: -3.5% - + 10.0%.

Pipe kwa otutu(≥ 18 tọn (ton 20) maka ịtụ nza):

a) maka akara ule L175, L175P, A25, na A25P: -3.5 %;

b) maka akara ule ndị ọzọ niile: -1.75%.

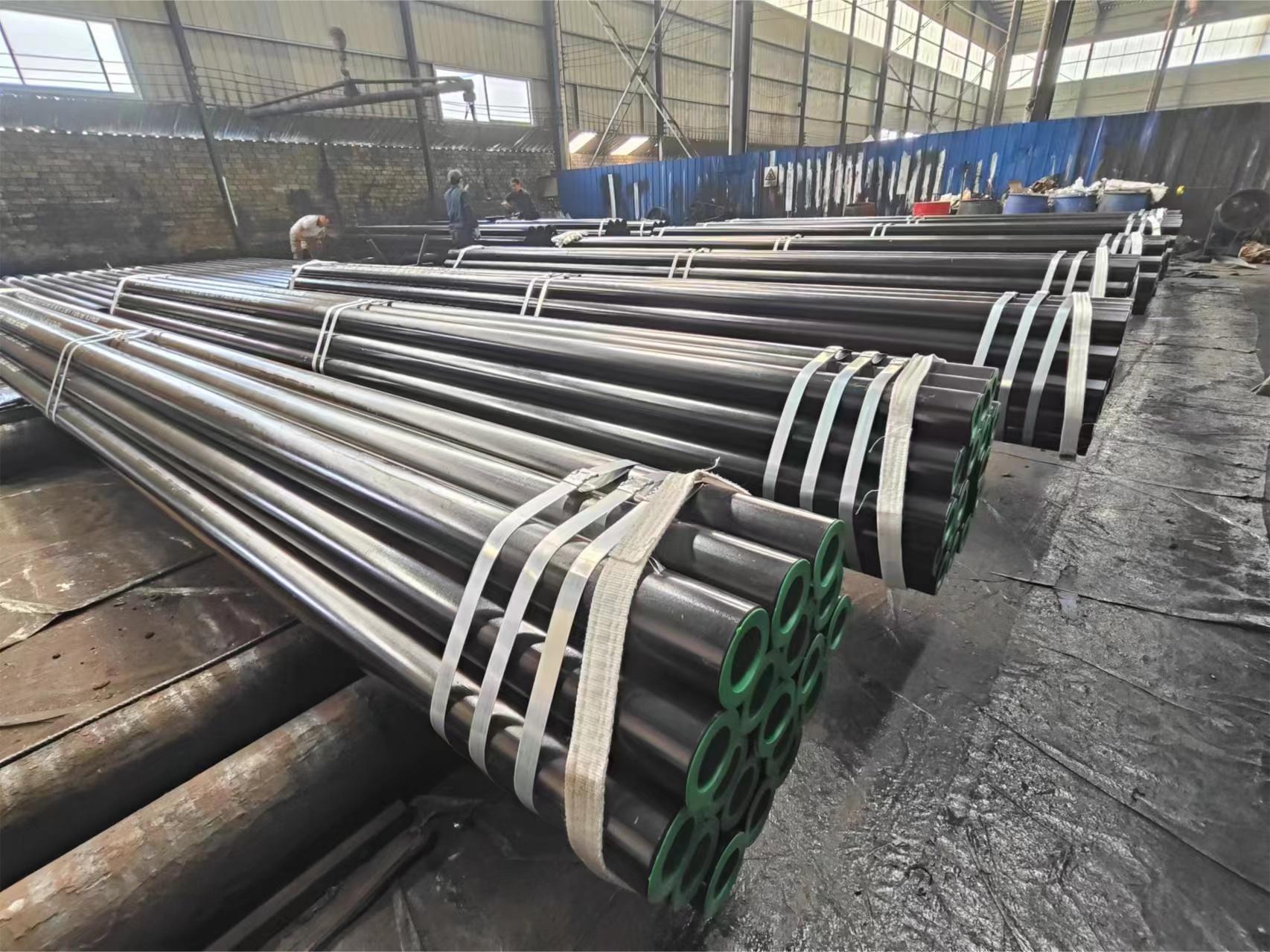

Ngwa API 5L GR.B

API 5L Ọkwa B ígwè ọkpọkọ bụ ụdị ọkpọkọ ahịrị, nke a na-ejikarị ebufe mmiri dị ka mmanụ, gas, na mmiri, ma bụrụ otu n'ime ihe ndị a na-ejikarị eme ihe na ụlọ ọrụ mmanụ na gas.

Usoro nnyefe mmanụ na gas: API 5L Ọkwa B ígwè ọkpọkọ na-ejikarị na mmanụ na gas ubi mmịpụta na nhazi ụlọ ọrụ ibufe crude mmanụ na eke gas na-achịkọta usoro ma ọ bụ nhazi ụlọ ọrụ.

pipeline mmiri: Enwere ike itinye ọgwụgwọ ndị ọzọ dị n'elu, dị ka mkpuchi ma ọ bụ mkpuchi, iji melite nguzogide corrosion ha maka iji na-ebufe mmiri, gụnyere mmiri na usoro mmiri.

Ụlọ nrụpụta: Na refineries, API 5L ọkwa B ígwè ọkpọkọ na-ebufe dị iche iche nke kemịkalụ na intermediates ewepụtara site fractional distillation nke crude mmanụ.

Ihe owuwu na akụrụngwa: N'ime ụlọ ọrụ na-ewu ụlọ, maka ịmepụta àkwà mmiri, ihe nkwado, ma ọ bụ ọrụ akụrụngwa ndị ọzọ dị mkpa, karịsịa ebe a na-achọ ụgbọ mmiri dị anya.

API 5L Ọkwa B Dakọtara

ASTM A106 Ọkwa B: Ọkpụkpụ carbon steel tubing enweghị nkebi nke a na-ejikarị maka ọrụ okpomọkụ dị elu, yana ihe mejupụtara kemịkalụ na ihe eji arụ ọrụ yiri API 5L Grade B. ASTM A106 Grade B bụ nke a na-ejikarị eme ihe maka ibufe ikuku mmiri dị elu, kemịkalụ, na ngwaahịa mmanụ ala.

ASTM A53 Ọkwa B: Nke a bụ ụdị ọzọ nke carbon ígwè ọkpọkọ, nke nwere ike welded ma ọ bụ enweghị nkebi, na ọtụtụ ebe na-eji n'ibu, ewu, na ndị ọzọ engineering ngwa. Ọ bụ ezie na a na-eji ya eme ihe maka obere nrụgide na ngwa okpomọkụ, ụfọdụ n'ime usoro ihe onwunwe ya yiri API 5L Grade B.

EN 10208-2 L245NB: Ejiri ya maka imepụta pipeline maka ibufe gas na-ere ọkụ na mmiri mmiri ndị ọzọ. L245NB (1.0457) bụ ọkpọkọ ọkpọkọ siri ike nwere ihe eji arụ ọrụ yiri API 5L Grade B.

ISO 3183 L245: A na-eji usoro ụgbọ njem pipeline na mmanụ na gas.

Ọrụ ndị ọzọ anyị nwere ike inye

Steel akpụkpọ ụkwụọ bụghị naanị na-enye API 5L ọkwa B dị elu nke ọkpọkọ ígwè, ma na-enyekwa gị usoro ọrụ nkwado, gụnyere ọtụtụ nhọrọ mkpuchi mgbochi corrosion, ngwọta ngwugwu ahaziri iche, na nkwado ngwa ngwa zuru ezu iji hụ na anyị nwere ike izute mkpa gị dị iche iche.

Anyị na-agba mbọ imepụta ikpo okwu ị nweta otu nkwụsị na-enye gị ohere ịnweta ngwaahịa na ọrụ niile ị chọrọ. Site na ọrụ ndị ọkachamara na ndị a pụrụ ịdabere na ya, ị nwere ike mezue nzọụkwụ ọ bụla nke ọrụ gị nke ọma na enweghị nsogbu, na-eme ka ọ dị mma na ọganihu. Ebumnuche anyị bụ ịbụ onye mmekọ ntụkwasị obi kacha ntụkwasị obi.

Mkpuchi mgbochi corrosion

Steel akpụkpọ ụkwụna-enye ọtụtụ nhọrọ mkpuchi mkpuchi corrosion, gụnyereagba, galvanized,3 LPE (HDPE), 3LPP,FBE, na cementitious counterweights, iji gboo mkpa ojiji dị iche iche nke ọrụ gị.

nkwakọ ngwaahịa

Anyị na-enye nhọrọ nkwakọ ngwaahịa dị iche iche, gụnyere bales, tarps, crates, na ọkpọkọ ọkpọkọ, nke enwere ike ịhazi ya iji gboo mkpa gị.

Nkwado ndị teknuzu

Ụlọ ọrụ anyị na-agba mbọ ịnye ọrụ nkwado teknụzụ zuru oke na-ekpuchi ọkwa niile nke ọrụ. Site na nkwadebe dị nro tupu arụ ọrụ ruo n'etiti ịzụ ahịa na nhazi njem ụgbọ njem, na-arụzi ọrụ post-project na nchọpụta nsogbu, ndị ọkachamara anyị nwere ike inye gị ndụmọdụ na nkwado ọkachamara.

Ebumnuche anyị bụ inyere gị aka ịzụta ngwaahịa dị elu na ọnụ ala na China, hụ na ọrụ gị na-aga nke ọma na ọnụ ahịa. Anyị na-atụ anya ka gị na gị rụọ ọrụ iji mepụta ọdịnihu mmeri.