ASTM A178ígwè tubes bụ eletriki na-eguzogide welded (ERW) tubes nkecarbon na carbon-manganese ígwèeji dị ka ọkpọkọ mmiri ọkụ, anwụrụ ọkụ ọkụ, flues superheater, na njedebe nchekwa.

Ọ dabara maka tubes nchara na dayameta dị n'èzí nke 12.7-127mm na ọkpụrụkpụ mgbidi n'etiti 0.9-9.1mm.

Ọkụ ASTM A178 dabara adaba maka iguzogide welded tubes naDayameta n'èzí n'etiti 1/2 - 5 na [12.7 - 127 mm] na ọkpụrụkpụ mgbidi n'etiti 0.035 - 0.360 na [0.9 - 9.1 mm], ọ bụ ezie na nha ndị ọzọ dị n'ezie dị ka achọrọ, ma ọ bụrụhaala na tubes ndị a na-emezu ihe ndị ọzọ niile chọrọ maka nkọwa a.

Enwere akara ule atọ iji nagide gburugburu ojiji dị iche iche.

Ọkwa A, Ọkwa C na Ọkwa D.

| Ọkwa | Ụdị Carbon Steel |

| Ọkwa A | Obere Carbon Steel |

| Ọkwa C | Ọkara-Carbon Steel |

| Ọkwa D | Carbon-Manganese ígwè |

Ihe enyere n'okpuru nkọwapụta a ga-adaba n'ihe achọrọ nke mbipụta nkọwapụta A450/A450M dị ugbu a. ọ gwụla ma enyereghị ya ebe a.

Ọkwa AnaỌkwa Cakọwapụtala ígwè a kapịrị ọnụ; họrọ akụrụngwa kwesịrị ekwesị ka achọrọ.

The ígwè makaỌkwa Da ga-egbu.

A na-emepụta ígwè e gburu egbu site n'ịgbakwụnye deoxidizers (dịka, silicon, aluminum, manganese, wdg) na-agbaze ígwè n'oge usoro mmepụta ígwè, si otú ahụ belata ma ọ bụ wepụ ikuku oxygen nke ígwè ahụ.

Ọgwụgwọ a na-eme ka homogeneity na nkwụsi ike nke ígwè ahụ dịkwuo mma, na-eme ka ihe ndị na-arụ ọrụ ya dịkwuo mma, na-eme ka nkwụsị nke corrosion dịkwuo mma.

Ya mere, a na-eji ígwè ndị e gburu egbu eme ihe na ngwa ebe a na-achọ nnukwu ogo homogeneity na ihe ndị magburu onwe ya, dị ka ịmepụta arịa nrụgide, ndị na-ekpo ọkụ, na nnukwu ihe nhazi.

A na-emepụta tubes ígwè site na ijiERWusoro mmepụta ihe.

ERW (Electric Resistance Welded)bụ usoro dabara adaba maka nrụpụta carbon steel pipe.

Na uru nke elu ịgbado ọkụ ike, ezigbo esịtidem na mpụga na-ebupụta, ngwa ngwa mmepụta ọsọ, na ala price, ọ na ọtụtụ-eji na ọtụtụ ulo oru na-ewu ubi.

ASTM A178ígwè ọkpọkọa ga-agwọrịrị okpomọkụn'oge usoro mmepụta ihe. A na-eji ya emeziwanye ihe eji arụ ọrụ na nkwụsi ike nke ọkpọkọ, yana ikpochapụ nrụgide ndị nwere ike ịmalite n'oge usoro ịgbado ọkụ.

Mgbe ịgbado ọkụ, ọkpọkọ niile ga-ekpo ọkụ na okpomọkụ nke 1650°F [900°C] ma ọ bụ karịa ma na-esote ya site na oyi na ikuku ma ọ bụ n'ọnụ ụlọ jụrụ oyi nke ọkụ ikuku na-achịkwa.

Ọkpụkpọ oyi na-adọtaA ga-edozi okpomọkụ ka ọ gafechara nfe oyi ikpeazụ na okpomọkụ nke 1200°F [650°C] ma ọ bụ karịa.

Mgbe a na-eme nyocha ngwaahịa, a na-ekpebi ugboro nyocha dị ka ndị a.

| Nhazi | Ugboro nyocha |

| Dayameta mpụta ≤ 3in [76.2mm] | 250 pcs / oge |

| Dayameta mpụta | 3in [76.2mm] | 100 pcs / oge |

| Jiri nọmba ọkụ tube mara ọdịiche | Kwa okpomọkụ nọmba |

Ihe achọrọ maka akụrụngwa anaghị emetụta tubing na-erughị 1/8 inch [3.2 mm] n'ime dayameta ma ọ bụ 0.015 in. [0.4 mm] n'ọkpụrụkpụ.

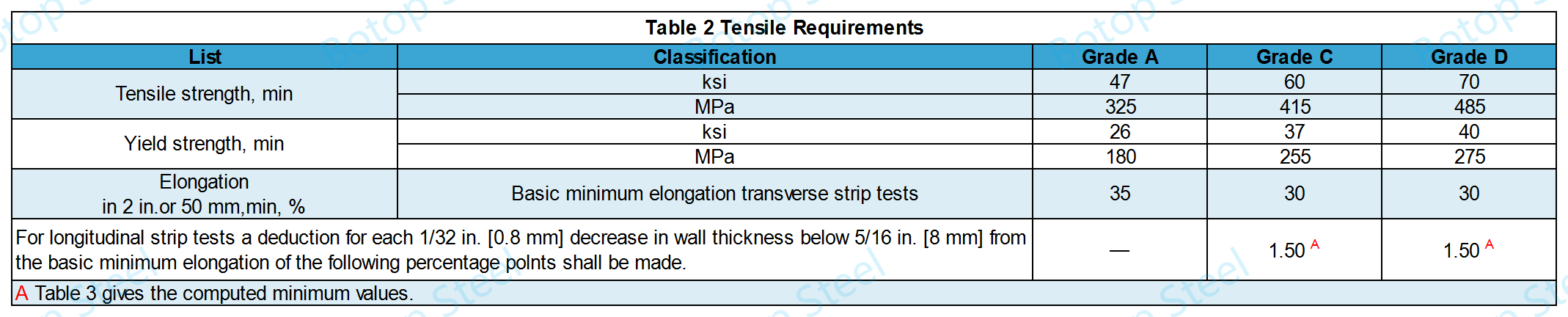

1. Ihe onwunwe tensile

Maka klaasị C na D, a ga-eme ule tensile na tube abụọ na nza ọ bụla.

Maka Ọkwa A tubing, a naghị achọkarị nnwale tensile. Nke a bụ n'ihi na a na-ejikarị tubing Grade A maka obere nrụgide na ngwa okpomọkụ.

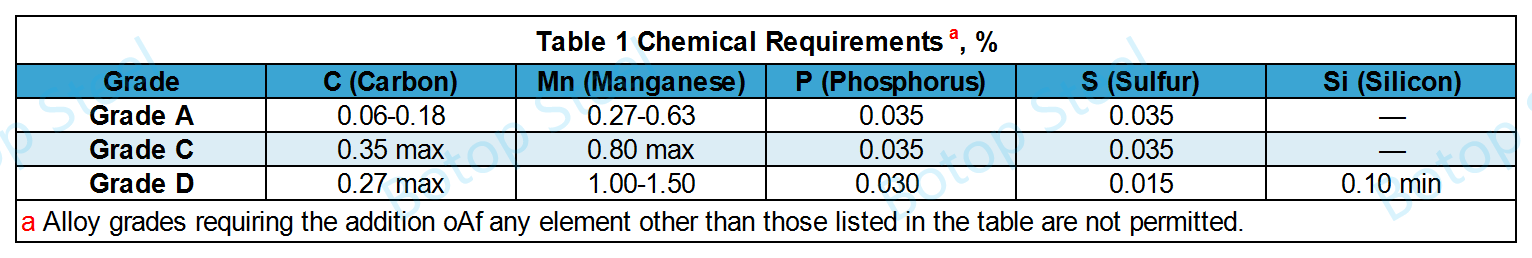

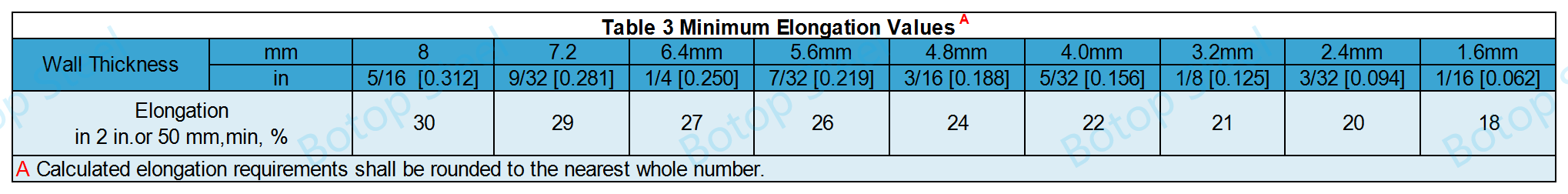

Tebụl 3 na-enye ụkpụrụ elongation kacha nta agbakọtara maka 1/32 inch [0.8 mm] mbelata na ọkpụrụkpụ mgbidi.

Ọ bụrụ na mgbidi mgbidi nke ọkpọkọ ígwè abụghị otu n'ime mgbidi mgbidi ndị a, a pụkwara ịgbakọ ya site na usoro.

Nkeji inch: E = 48t + 15.00ma ọ bụNkeji ISI: E = 1.87t + 15.00

E = elongation na 2 in. ma ọ bụ 50 mm,%,

t= ọkpụrụkpụ ihe atụ n'ezie, n'ime. [mm].

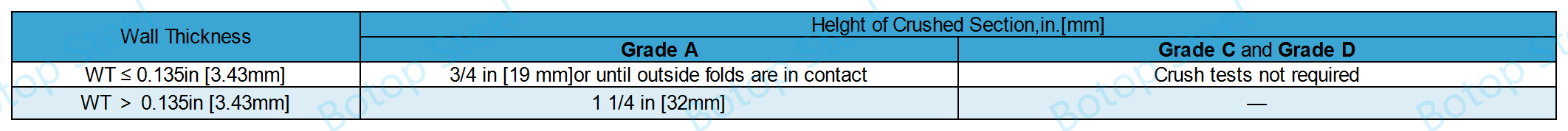

2. Ntụpịa ule

A na-eme nnwale extrusion na mpaghara ọkpọkọ 2 1/2 sentimita n'ogologo nke ga-anagide extrusion ogologo na-enweghị mgbawa, kewaa, ma ọ bụ kewaa na welds.

Maka tubing na-erughị 1 inch [25.4 mm] na dayameta dị n'èzí, ogologo ihe atụ ahụ ga-abụ 2 1/2 ugboro n'obosara n'èzí nke tube ahụ. Obere nlele elu agaghị abụ ihe kpatara ajụ.

3. Nnwale ire ọkụ

Usoro nnwale ahụ kwekọrọ n'ihe achọrọ ASTM A450 Nkebi 19.

4. Nnwale flange

Usoro nnwale ahụ kwekọrọ n'ihe achọrọ ASTM A450 Nkebi 22.

5. Laghachi azụ n'ule

Usoro nnwale ahụ kwekọrọ n'ihe achọrọ ASTM A450, Nkebi 20.

A na-eme nnwale eletriki hydrostatic ma ọ bụ nke na-adịghị emebi emebi na ọkpọkọ ígwè ọ bụla.

Ihe achọrọ dabere na ASTM A450, Nkeji 24 ma ọ bụ 26.

A na-enweta data ndị a site na ASTM A450 wee mezuo ihe achọrọ maka naanị ọkpọkọ ígwè welded.

Ngbanwe ibu

0 - +10%.

Mgbawa nke ịdị arọ mgbidi

0 - +18%.

Ngbanwe dayameta dị n'èzí

| Dayameta dị n'èzí | Ọdịiche ekwenyere | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1 OD ≤1½ | 25.4 OD ≤38.4 | ±0.006 | ±0.15 |

| 1½ OD2 | 38.1 OD.50.8 | ±0.008 | ±0.2 |

| 2≤ OD2½ | 50.8≤ OD | 63.5 | ±0.010 | ±0.25 |

| 2½≤ OD3 | 63.5≤ OD.76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4 OD ≤7½ | 101.6 OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5 OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Mgbe etinyere n'ime ọkụ ọkụ, tube ahụ ga-enwe ike iguzogide mgbasawanye na ịgbagọ na-enweghị ntụpọ ma ọ bụ mgbawa na welds.

Ọkpụkpọ ọkụ dị elu ga-enwe ike ikwado akpụ akpụ, ịgbado ọkụ na ịgbado ọrụ na-enweghị ntụpọ.

A na-ejikarị ya na tubes ji esi mmiri ọkụ, anwụrụ ọkụ, flues superheater, na nsọtụ nchekwa.

ASTM A178 Ọkwa AỌdịnaya carbon dị ala nke tubing na-enye ya ezigbo weldability na ike siri ike maka ngwa ndị na-anaghị etinye nrụgide dị elu.

A na-eji ya eme ihe maka ngwa nrụgide dị ala na nke na-ekpo ọkụ dị ka igwe ọkụ ọkụ dị ala (dịka ọmụmaatụ, igwe ọkụ ụlọ, obere ụlọ ọrụ, s ma ọ bụ ụlọ mmepụta ihe) na ndị ọzọ na-ekpo ọkụ na-ekpo ọkụ na gburugburu ebe okpomọkụ dị ala.

ASTM A178 Ọkwa Cnwere elu carbon na manganese ọdịnaya na-enye tube a mma ike na okpomọkụ na-eguzogide maka ndị ọzọ na-achọ ọrụ ọnọdụ.

Kwesịrị ekwesị maka ngwa nrụgide ọkara na ọkara okpomọkụ dị ka ụlọ ọrụ mmepụta ihe na mmiri ọkụ, nke na-achọkarị nrụgide na okpomọkụ karịa ọkụ ụlọ.

ASTM A178 Ọkwa Dtubes nwere nnukwu ọdịnaya manganese na ọdịnaya silicon kwesịrị ekwesị iji nye ike dị mma na nguzogide okpomọkụ, na-eme ka ha guzosie ike na oke okpomọkụ na gburugburu ebe dị elu ma dị mma maka iguzogide ọnọdụ ọrụ dị oke egwu.

A na-ejikarị ya na gburugburu oke nrụgide na oke okpomọkụ, dị ka igwe ọkụ ọdụ ụgbọ mmiri na ụlọ ọrụ mmepụta ihe.

1. ASTM A179 / ASME SA179: Igwe ọkụ na-ekpo ọkụ nchara dị nro na-enweghị ntụpọ na tubes condenser maka ọrụ cryogenic. A na-ejikarị ya na mpaghara nrụgide dị ala, ọ dị na kemịkalụ na akụrụngwa na ASTM A178.

2. ASTM A192 / ASME SA192: Igwe ọkụ ọkụ carbon na-enweghị ntụpọ na ọrụ nrụgide dị elu. A na-ejikarị eme mgbidi mmiri, ndị na-ahụ maka akụ na ụba na ihe nrụgide ndị ọzọ maka ndị na-ekpo ọkụ ọkụ.

3. ASTM A210 / ASME SA210: Na-ekpuchi carbon na-enweghị ihe ọ bụla na-esi na mmiri ọkụ na-ekpo ọkụ na-ekpo ọkụ na tubes maka okpomọkụ dị elu na usoro mmiri ọkụ ọkụ.

4. DIN 17175: tubes ígwè na-enweghị ntụpọ na ọkpọkọ maka iji mee ihe na nrụgide dị elu na gburugburu okpomọkụ dị elu. A na-ejikarị na-emepụta ọkpọkọ uzuoku maka ndị na-ekpo ọkụ na arịa nrụgide.

5. EN 10216-2: Na-edepụta ọnọdụ nkà na ụzụ maka tubes na-enweghị ntụpọ na ọkpọkọ nke ndị na-abụghị alloy na alloy steels nwere kpọmkwem okpomọkụ dị elu maka ngwa n'okpuru nrụgide.

6. JIS G3461: Na-ekpuchi tubes ígwè carbon maka ndị na-ekpo ọkụ na ndị na-ekpo ọkụ. Ọ dabara adaba maka ọnọdụ mgbanwe okpomọkụ dị ala na nke ọkara.

Anyị bụ onye na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-esi na China, nakwa onye na-emepụta ihe na-emepụta ihe na-adịghị mma, na-enye gị ihe ngwọta dị iche iche nke ígwè ígwè!

Maka ajụjụ ọ bụla ma ọ bụ ka ịmatakwu gbasara onyinye anyị, egbula oge ịkpọtụrụ anyị. Ngwọta ọkpọkọ ígwè gị dị mma bụ naanị ozi pụọ!