Usoro nke imepụta Pipe Longitudinal Submerged-arc Welded(LSAW) bụ nke a:

Ultrasonic plate probing → ihu igwe → tupu ekwe → akpụ → tupu ịgbado ọkụ → Ime ịgbado ọkụ → Mpụga ịgbado ọkụ → Ultrasonic nnyocha → X-ray nnyocha → Ịbawanye → hydraulic ule →l. Chamfering → Nyocha Ultrasonic → Nyocha X-ray → nyocha ihe ndọta na njedebe tube.

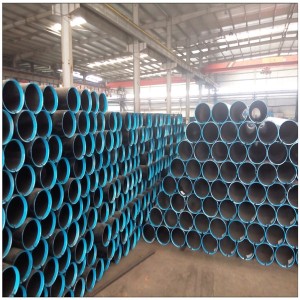

Mepụta: LSAW(JCOE) ígwè ọkpọkọ

Nha: OD: 406 ~ 1500mm WT: 6 ~ 40mm

Ọkwa: CB60,CB65, CC60,CC65, wdg.

Ogologo: 12M ma ọ bụ ogologo akọwapụtara ka achọrọ.

Akwụsị: Ọgwụgwụ Larịị, Ọgwụgwụ gbagọrọ agbagọ, Grood ;

| Ihe achọrọ kemịkalụmaka ASTM A672 B60/B70/C60/C65/C70LSAWCarbon Steel Pipe | |||||||||||||

| Ọkụ | Ọkwa | Ihe mejupụtara,% | |||||||||||

| C max | Mn | P max | S max | Si | Ndị ọzọ | ||||||||

| <=1 n'ime (25mm) | > 1 ~ 2 n'ime (25-50mm) | > 2 ~ 4in (50-100mm) | > 4 ~ 8 n'arọ (100-200mm) | >8 n'ime (200mm) | <= 1/2 n'ime (12.5mm) | > 1/2 n'arọ (12.5mm) | |||||||

| CB | 60 | 0.24 | 0.21 | 0.29 | 0.31 | 0.31 | 0.98 kacha | 0,035 | 0,035 | 0.13–0.45 | ... | ||

| 65 | 0.28 | 0.31 | 0.33 | 0.33 | 0.33 | 0.98 kacha | 0,035 | 0,035 | 0.13–0.45 | ... | |||

| 70 | 0.31 | 0.33 | 0.35 | 0.35 | 0.35 | 1.30 kacha | 0,035 | 0,035 | 0.13–0.45 | ... | |||

| CC | 60 | 0.21 | 0.23 | 0.25 | 0.27 | 0.27 | 0.55–0.98 | 0.79–1.30 | 0,035 | 0,035 | 0.13–0.45 | ... | |

| 65 | 0.24 | 0.26 | 0.28 | 0.29 | 0.29 | 0.79–1.30 | 0.79–1.30 | 0,035 | 0,035 | 0.13–0.45 | ... | ||

| 70 | 0.27 | 0.28 | 0.30 | 0.31 | 0.31 | 0.79–1.30 | 0.79–1.30 | 0,035 | 0,035 | 0.13–0.45 | ... | ||

| Ihe eji arụ ọrụ | |||||

| Ọkwa | |||||

|

| CB65 | CB70 | CC60 | CC65 | CC70 |

| Ike nkwụsịtụ, min: | |||||

| ksi | 65 | 70 | 60 | 65 | 70 |

| Mpa | 450 | 485 | 415 | 450 | 485 |

| Mpụta ike, min: | |||||

| ksi | 35 | 38 | 32 | 35 | 38 |

| MPa | 240 | 260 | 220 | 240 | 260 |

1. N'èzí dayameta-Dabere na nha okirikiri ±0.5% nke dayameta mpụga akọwapụtara.

2. Ọpụpụ-Roundness-iche n'etiti isi na obere n'èzí dayameta.

3. Nhazi- Iji 10 ft (3m) kwụ ọtọ na-etinye ka njedebe abụọ ahụ na-ejikọta ya na ọkpọkọ, 1/8 na. (3mm).

4. Ọkpụrụkpụ-Opekempe mgbidi mgbidi n'ebe ọ bụla n'ime ọkpọkọ agaghị abụ ihe karịrị 0.01 in. (0.3mm) n'okpuru ọnụ ọgụgụ a kapịrị ọnụ.

5. Ogologo na njedebe na-enweghị isi ga-adị n'ime -0 + 1 / 2 in. (-0 + 13mm) nke akọwapụtara. Ogologo nwere ngwụcha igwe ga-adị ka ekwenyero n'etiti onye nrụpụta na onye zụrụ ya.

Nnwale mgbakasị ahụ—Ngwongwo ntụgharị ntụgharị nke nkwonkwo welded ga-ezute ihe kacha nta chọrọ maka ike tensile kacha nke ihe efere akọwapụtara.

Transverse-guided-weld-bent tests — A ga-anabata ule gbagọọ agbagọ ma ọ bụrụ na enweghị mgbawa ma ọ bụ ntụpọ ndị ọzọ gafere 1/8 in. (3mm) n'akụkụ ọ bụla dị na igwe weld ma ọ bụ n'etiti weld na metal ntọala mgbe agbachara.

Nyocha nyocha redio-A ga-enyocha ogologo ogologo nke weld ọ bụla nke klaasị X1 na X2 n'ụzọ redio dabere ma mezuo ihe achọrọ nke ASME Boiler and Pressure Code Code, Nkebi nke asaa, paragraf UW-51.

Aha ma ọ bụ akara onye nrụpụta

Nọmba nkọwapụta (ụbọchị afọ ma ọ bụ achọrọ)

Nha (OD, WT, ogologo)

Ọkwa (A ma ọ bụ B)

Ụdị ọkpọkọ (F, E, ma ọ bụ S)

Nnwale nrụgide (naanị ọkpọkọ nchara enweghị nkebi)

Nọmba okpomọkụ

Ozi mgbakwunye ọ bụla akọwapụtara n'usoro ịzụrụ.

Ọnụọgụ (ụkwụ, mita ma ọ bụ ọnụ ọgụgụ ogologo)

Aha ihe (nchara anwụrụ, electric fusion welded)

Nọmba nkọwapụta

Ngosipụta na ọkwa klas

Size (n'èzí ma ọ bụ n'ime dayameta, nkịtị ma ọ bụ nke kacha nta mgbidi ọkpụrụkpụ)

Ogologo (kpọmkwem ma ọ bụ enweghị usoro)

Ngwucha agwụ

Nhọrọ ịzụta

Ihe mgbakwunye chọrọ, ọ bụrụ na ọ bụla.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) ígwè ọkpọkọ

ASTM A671/A671M LSAW Steel Pipe

ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Ọkwa X70 LSAW Ọkụ ígwè

EN10219 S355J0H Ọdịdị LSAW(JCOE) Ọkụ ígwè