JIS G 3454bụ ọkọlọtọ ụlọ ọrụ ndị Japan maka ọkpọkọ ígwè carbon maka sistemu nrụgide nwere oke arụ ọrụ nke 350°C. Ọkọlọtọ na-agụnye akara ule abụọ:STPG 370naSTPG 410. Ọ na-emetụta electric iguzogide welded (ERW) ma ọ bụ enweghị nkebi ọkpọkọ na a nominal dayameta nke 10.5 mm ka 660.4 mm (ie 6A ka 650A, ma ọ bụ 1/8B ka 26B).

JIS G 3454 ọkpọkọ ígwè ga-arụ ọrụ site na iji nchikota kwesịrị ekwesị nke ígwè ọkpọkọ ụzọ na-emecha usoro na tebụl n'okpuru.

| Akara ọkwa | Akara nke usoro nrụpụta | ||

| Usoro nrụpụta ọkpọkọ | Usoro mmecha | Nhazi nke mkpuchi zinc | |

| STPG370 STPG410 | Akwụsịghị: S Mgbado ọkụ eletrik: E | Emechara ọkụ: H Oyi emechara: C Dị ka ọkụ eletrik welded: G | Ọkpụkpọ ojii: ọkpọkọ enyeghị zinc- mkpuchi Ọcha ọcha: ọkpọkọ nyere zinc- mkpuchi |

Kpọmkwem, e nwere ụzọ nrụpụta ise:

SH: Ọkụ nchara na-ekpo ọkụ na-agwụcha;

SC: Ọkpụkpụ ígwè na-enweghị ntụpọ oyi gwụchara;

EH: ọkụ na-agwụcha ọkụ eletrik na-eguzogide welded ígwè ọkpọkọ;

EC: Igwe ọkụ eletrik na-eguzogide oyi welded ígwè ọkpọkọ;

EG: Igwe ọkụ na-eguzogide welded ígwè ọkpọkọ na-abụghị ndị na-ekpo ọkụ na oyi na-agwụ.

Steel akpụkpọ ụkwụbụ onye na-emepụta ihe na onye na-ebubata ọkpọkọ carbon ígwè welded dị elu nke sitere na China, yana onye na-azụ ahịa nke ọkpọkọ nchara. Ọ bụrụ na ị nwere mkpa ọ bụla, biko nweere onwe gị ịkpọtụrụ anyị na anyị ga-enye gị nkwado teknụzụ n'efu.

| Akara ọkwa | C | Si | Mn | P | S |

| max | max | - | max | max | |

| STPG 370 | 0.25% | 0.35% | 0.30-0.90% | 0.040% | 0.040% |

| STPG 410 | 0.30% | 0.35% | 0.30-1.00% | 0.040% | 0.040% |

Na-enye ohere ịgbakwunye ihe ndị ọzọ alloying.

Ike tensile, Isi Mpụta ma ọ bụ ihe mgbakasị ahụ, yana ịgbatị

| Akara nke ọkwa | Ike ọdụdọ | Ebe mpụta ma ọ bụ egosi nrụgide | Ogologo oge min,% | |||

| Ibe ule tensile | ||||||

| Nke 11 ma ọ bụ No.12 | Nke 5 | Nọmba.4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Ntuziaka ule tensile | ||||

| min | min | Yiri na axis ọkpọkọ | Perpendicular na axis ọkpọkọ | Yiri na axis ọkpọkọ | Perpendicular na axis ọkpọkọ | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Nnwale ire ọkụ

Mgbe ebe dị n'etiti efere abụọ ahụ ruru ebe a kapịrị ọnụ H, ọ gaghị enwe ntụpọ ma ọ bụ mgbawa n'elu ọkpọ ígwè.

Maka tubes nchara na-enweghị nkebi: H = (1+e) t/(e + t/D);

Maka ọkpọkọ ígwè ERW: H = 1/3 D (maka weld) ma ọ bụ H = 2/3 D (maka akụkụ na-enweghị weld);

H: ebe dị anya n'etiti efere ndị na-adaba adaba (mm);

е: akọwapụta n'otu n'otu maka ọkwa ọ bụla nke ọkpọkọ, 0.08 maka STPG 370, 0.07 maka STPG 410;

t: ọkpụrụkpụ mgbidi nke ọkpọkọ (mm);

D: n'èzí dayameta nke ọkpọkọ (mm);

Nnwale flattening na-adabara na ọkpọkọ igwe nwere dayameta ọnụ karịa 40A (48.6mm).

Bendability

Bendability na-emetụta ọkpọkọ nwere dayameta aha nke 40 A (48.6) ma ọ bụ karịa.

Ekwesịrị ịgbatị ọkpọkọ ahụ 90° na radius ugboro isii n'obosara ya. Mgbidi ọkpọkọ aghaghị ịbụ nke enweghị ntụpọ ma ọ bụ mgbawa.

Ọkụ ígwè ọ bụla ga-enwerịrị ule nrụgide hydrostatic ma ọ bụ ule na-adịghị emebi emebi.

Nnwale Hydrostatic

Jikwaa ụfọdụ nrụgide ma ọ dịkarịa ala 5 sekọnd na-enweghị ntapu.

Ọnụ ego nrụgide na-ejikọta na nhazi oge Nọmba nke ọkpọkọ ígwè.

| Ọkpụrụkpụ mgbidi ọnụ | Nọmba usoro: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Nrụgide ule hydraulic kacha nta, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Nnwale na-adịghị emebi emebi

Ọ bụrụ na ejiri nyocha ultrasonic, ọ ga-adabere na ọkọlọtọ siri ike karịa akara UD klas na JIS G 0582.

Ọ bụrụ na a na-eji ule eddy ugbu a, ọ ga-adabere na ọkọlọtọ nke siri ike karịa akara akara EY na JIS G 0583.

| Dayameta aha aha | Dayameta dị n'èzí | Ọkpụrụkpụ mgbidi | Uka nke otu | Nọmba nhazi oge (Sch No.) | |

| A | B | mm | mm | n'arọ/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0,369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0,450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0,479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0,629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0,675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0,799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0,851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

JIS G 3454 gụnyerenhazi oge 10, nhazi oge 20, usoro 30, usoro 40, usoro 60, nausoro 80.

Ị nwere ike pịa nhazi oge Mba. ịchọrọ ilele; anyị ahazila ụdị PDF kwekọrọ maka ịdị mma gị.

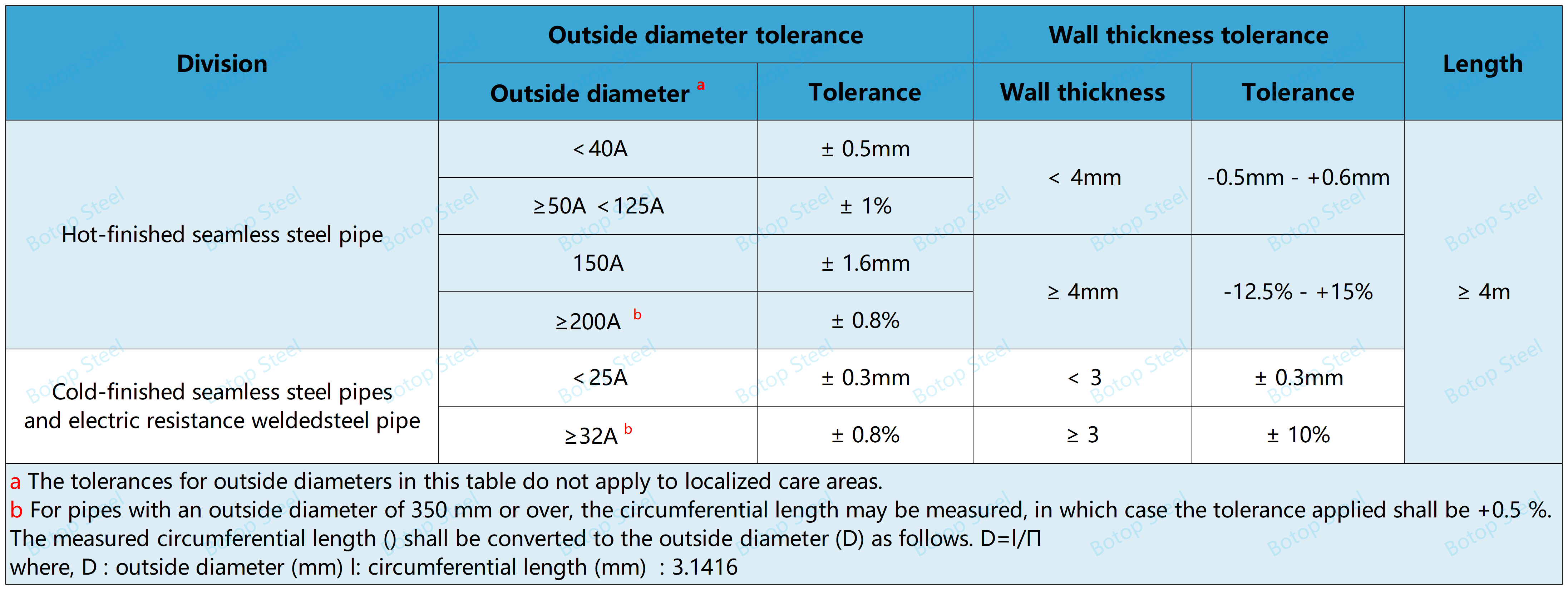

JIS G 3454 Nkwenye maka dayameta mpụta, ọkpụrụkpụ mgbidi, eccentricity, na ogologo ga-ezute ihe ndị a.

Ebe ọ bụ na e guzobere ya na 2014, Botop Steel aghọwo onye na-ebute ụzọ nke ọkpọkọ carbon ígwè na Northern China, mara maka ọrụ magburu onwe ya, ngwaahịa dị elu, na ngwọta zuru oke.

Ụlọ ọrụ ahụ na-enye ụdị ọkpọkọ carbon carbon dị iche iche na ngwaahịa ndị metụtara ya, gụnyere enweghị nkebi, ERW, LSAW, na SSAW ọkpọkọ ígwè, yana nchịkọta zuru ezu nke ọkpọkọ na flanges.

Ngwaahịa ya ọpụrụiche gụnyekwara alloys dị elu na igwe anaghị agba nchara austenitic, ahaziri iji gboo ihe achọrọ nke ọrụ pipeline dị iche iche.

Biko kpọtụrụ anyị, anyị ga-enye gị ezigbo mma, ọkọlọtọ ígwè ọkpọkọ na ọrụ ọkachamara na nke ọma. Botop na-atụ anya ijere gị ozi.