API (American Petroleum Institute Standard) 5L bụ ọkọlọtọ mba ụwa maka ọkpọkọ ígwè ejiri na sistemu ụgbọ njem pipeline.

API 5L na-ekpuchi ọkpọkọ ígwè maka ngwa dị iche iche maka ibufe gas, mmanụ na mmiri mmiri ndị ọzọ.Ụbọchị dị irè nke mbipụta 46: dị irè na Nọvemba 1, 2018.

Ọ bụrụ na ịchọrọ ịnweta echiche izugbe nke API 5L, biko pịaNkọwa nkọwapụta ọkpọkọ API 5L.

Bọtịnụ igodo nsoroụzọ

Ihe emelitere na API 5L 46th

Mmalite nke API 5L PSL

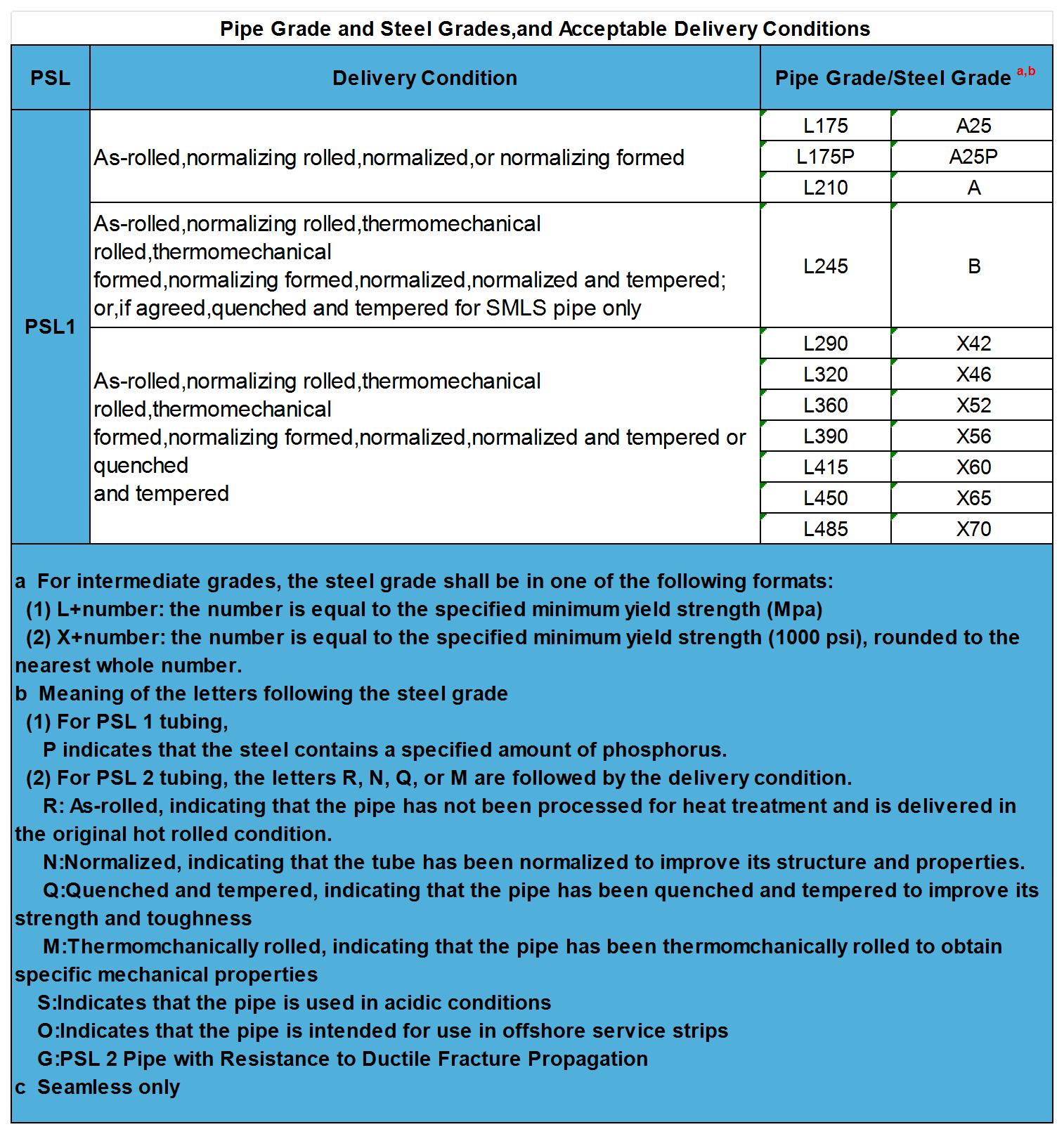

Nhazi ọkwa ọkwa igwe na ọkwa ọkpọkọ

Steeti Nnyefe anabatara

Ngwa akụrụngwa maka ọkpọkọ igwe

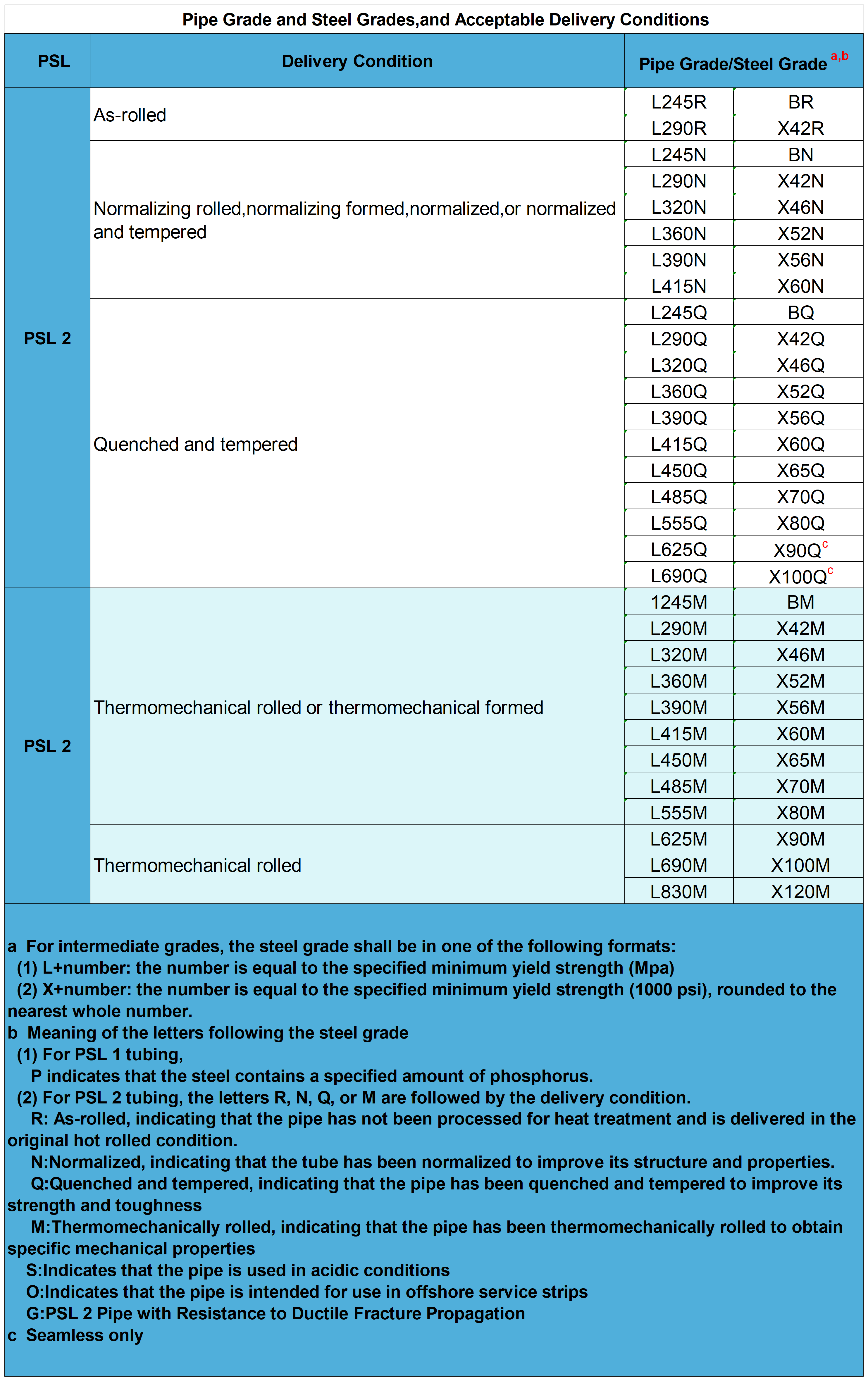

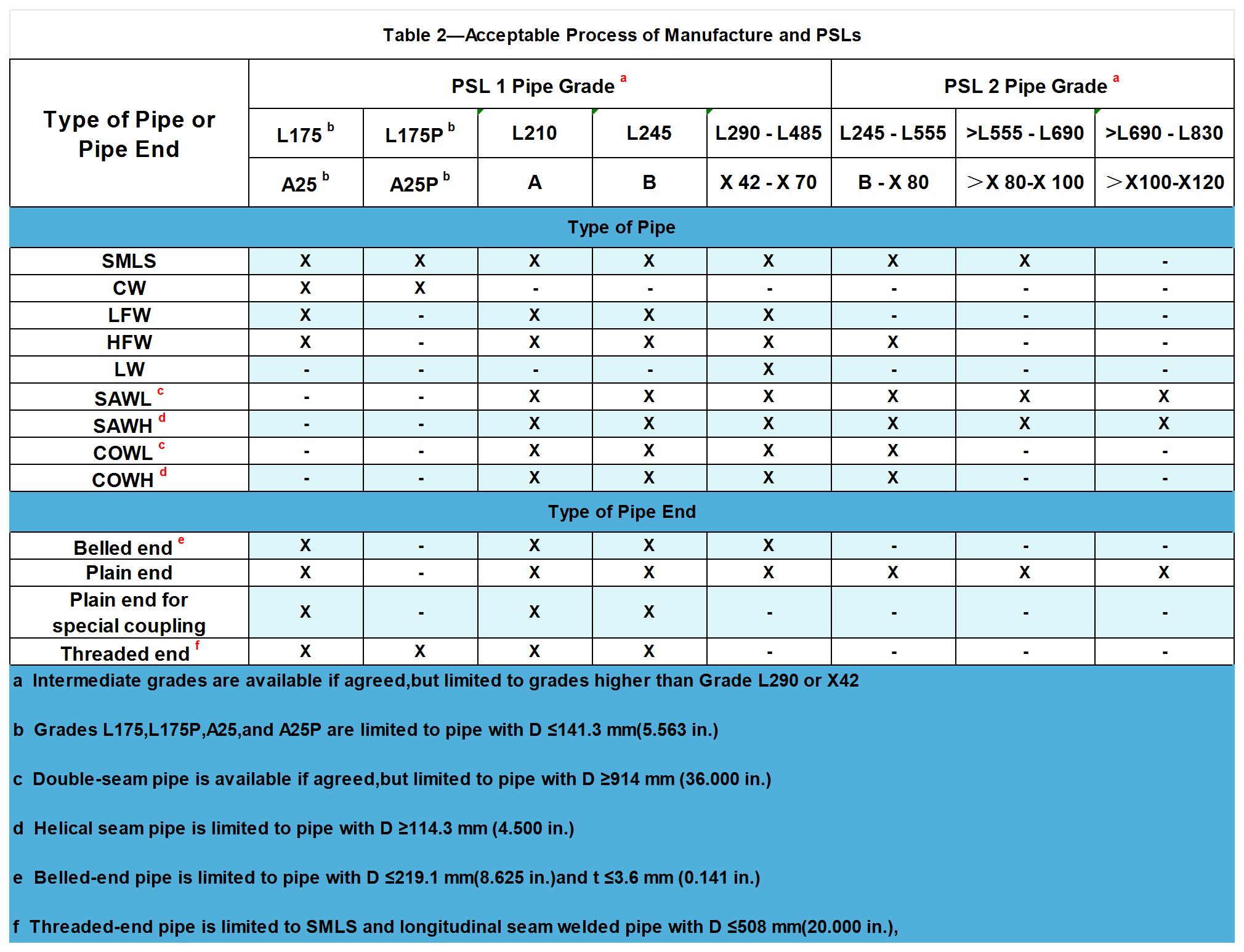

Ụdị ọkpọ ígwè na nkwụsị tube nke API 5L kpuchiri

Usoro nrụpụta anabatara maka PSL2 Steel tubing

Nnyocha ọdịdị na ntụpọ nkịtị nke API 5L

Nyocha akụkụ (Ngbanwe akụkụ)

Ihe Nnwale API 5L

Akara ọkpọkọ na ebe

Ụkpụrụ nhata

Ngwaahịa Anyị emetụtara

Ihe emelitere na API 5L 46th

Mmelite

Ihe emelitere na gbasaa chọrọ maka nkwonkwo igwe igwe;

Emelitere chọrọ maka njedebe ọkpọkọ perpendicularity;

Ihe nnwale ule ike emelitere maka ọkpọkọ API 5LPSL 2 maka gburugburu utoojoo yana ọkpọkọ API 5L PSL 2 maka gburugburu oke osimiri;

Ọhụrụ

API 5L PSL 2 ọkpọkọ maka ngwa chọrọ ike eriri plastik ogologo.

Mmalite nke API 5L PSL

PSL: Mpempe akwụkwọ nkọwapụta pipeline ;

Kewara na: API 5L PSL 1 na API 5L PSL 2.

Nhazi ọkwa ọkwa igwe na ọkwa ọkpọkọ

L + nọmba(a na-esote mkpụrụedemede L na ike mkpụrụ kacha nta akọwapụtara na MPa):

L175,L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485,L555,L625,L683,L690.

Nọmba X +(nọmba na-eso leta X na-akọwapụta ike mkpụrụ kacha nta na 1000 psi):

X42,X46,X52,X56,X60,X65,X70,X80,X90,X100,X120.

Na ọkwa a na ọkwa b.Ọkwa A=L210 Ọkwa B=L 2459

Steeti nnyefe anabatara

Cheta na: E kwesịghị iji L415/X60 ma ọ bụ karịa akara ule n'ọnọdụ L360/X52 ma ọ bụ obere akara ule na-enweghị nkwekọrịta nke onye zụrụ ya.

Ngwa akụrụngwa maka ọkpọkọ igwe

Ingot, billet, billet, strip (coil) ma ọ bụ efere.

Mara:

1. The raw material makaAPI 5L PSL2ọkpọkọ ígwè ga-abụ ezigbo ọka sedimented ígwè.

2. Steel strip (coil) ma ọ bụ efere eji emepụta API 5L PSL2 ígwè ọkpọkọ agaghị ebu ihe ọ bụla tack welds.

Ụdị ọkpọ ígwè na nkwụsị tube nke API 5L kpuchiri

Ọkpụkpọ ígwè welded

Ọkụ CW:Usoro nke akpụ a onuete site kpo oku nke warara n'ime ọkụ na mechanically na-pịa kpụrụ n'ọnụ ọnụ, bụ ebe sochiri coils nke warara na-ejikọta ọnụ iji nye a na-aga n'ihu eruba nke strip maka ịgbado ọkụ igwe igwe.

COWHPipe:Ngwaahịa Tubular nwere otu seam helical mepụtara site na ngwakọta nke gas metal arc na ịgbado ọkụ n'okpuru mmiri, ebe a na-ewepụghị bead metal arc weld kpamkpam site na ngafe ịgbado ọkụ n'okpuru mmiri.

Ehi Pipe:Ngwaahịa Tubular nwere otu eriri ogologo ma ọ bụ abụọ na-emepụta site na nchikota gas metal arc na ịgbado ọkụ n'okpuru mmiri, ebe a na-ewepụghị bead metal arc weld kpamkpam site na ngafe ịgbado ọkụ n'ime mmiri.

EW ọkpọkọ:Ngwaahịa Tubular nwere otu eriri ogologo ogologo nke welding eletrik dị ala ma ọ bụ dị elu na-emepụta.

Ọkụ HFW:EWpipe emepụtara' na oge ịgbado ọkụ ugbu a hà ma ọ bụ karịa 70 kHz.

Ọkụ LFW:A na-emepụta ọkpọkọ EW na oge ịgbado ọkụ ugbu a na-erughị 70 kHz.

Ọkụ LW:Ngwaahịa Tubular nwere otu eriri ogologo ogologo nke welding laser mepụtara.

Ọkụ SAWH:Ngwaahịa Tubular nwere otu ihe nkedo helical nke usoro ịgbado ọkụ nke arc mekpuru emepụtara.

SAWLPipe:Ngwaahịa Tubular nwere otu eriri ogologo ogologo ma ọ bụ abụọ nke welding arc kpuru mmiri na-emepụta.

Igwe anaghị agba nchara

SMLS ọkpọkọ:Igwe ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, e nwere ụfọdụ ụzọ nhazi ndị ọzọ, dị ka ịbịaru oyi, ịbịaru oyi, akpụ akpụ, wdg.

Ụdị ụdị API 5L PSL2 maka ngwa pụrụ iche

Iguzogide Mgbasa Ọkpụkpụ Ductile (G)

Ụtọ Service Ọnọdụ Pipe (S)

Ọkpọkpọ ọnọdụ ọrụ Offshore (O)

Na-achọ ike ọkpọkọ ogologo eriri ogologo

Ụdị njedebe ọkpọkọ

Ọgwụgwụ sọket, ewepụghị ọnụ, Ọgwụ mgbochi ọpụrụiche, ngwụcha eriri.

Mara:

1. Ngwunye oghere, ọkpọkọ ọkpọkọ maka clamps pụrụ iche, na eriri eriri eriri bụ maka API 5L PSL1 naanị.

2. L175 P / A25 P ígwè ọkwa API 5L PSL1 ọkpọkọ ígwè ga-eji eriri eri eme ihe, na API 5L PSL1 ọkpọkọ ígwè nke ọkwa ígwè ndị ọzọ ga-eji njedebe dị larịị.

3. API 5L PSL 2 tubes ga-enyefe ya na njedebe dị larịị.

Usoro nrụpụta anabatara maka PSL2 Steel tubing

| Tebụl 3-Ụzọ nrụpụta anabatara maka PSL 2 Pipe | ||||

| Ụdị ọkpọkọ | Mmalite ihe | Ịkpụpụta ọkpọkọ | Ọkụ Ọkụ Ọgwụgwọ | Nnyefe Ọnọdụ |

| SMLS | Ingot, oge ntoju, ma ọ bụ billet | Dị ka-akpọrela | - | R |

| Normalizing akpụ | - | N | ||

| Na-ekpo ọkụ akpụ | Na-emezigharị | N | ||

| Na-ekpo ọkụ na iwe ọkụ | Q | |||

| Na-ekpo ọkụ na-akpụ na oyi imecha | Na-emezigharị | N | ||

| Na-ekpo ọkụ na iwe ọkụ | Q | |||

| HFW | Igwe mmiri a na-akpọgharị nkịtị | Oyi akpụ | Ọgwụgwọ okpomọkụa nke weld ebe naanị | N |

| Thermomechanical-akpọrela igwe igwe | Oyi akpụ | Ọgwụgwọ okpomọkụa nke weld ebe naanị | M | |

| Ọgwụgwọ okpomọkụa nke mpaghara weld na nkwụsị nrụgide nke ọkpọkọ dum | M | |||

| Dị ka-akpọrela ma ọ bụ Igwe ọkụ ọkụ thermomechanical akpọrepu | Oyi akpụ | Na-emezigharị | N | |

| Na-emenyụ na iwe iwe | Q | |||

| Oyi akpụ sochiri ọkụ ibelata n'okpuru nchịkwa okpomọkụ na-akpata ọnọdụ nkịtị | - | N | ||

| Oyi akpụ sochiri ya thermomechanical akpụ nke ọkpọkọ | - | M | ||

| SAW ma ọ bụ Ehi | Normalized ma ọ bụ normalizes - eriri igwe akpọrepu ma ọ bụ efere | Oyi akpụ | - | N |

| Dị ka-akpọrela thermomechanical - akpọrepu normalizing-akpọrela, ma ọ bụ normalized | Oyi akpụ | Na-emezigharị | N | |

| Thermomechanical-akpọrela eriri igwe ma ọ bụ efere | Oyi akpụ | - | M | |

| Emenyụ na iwe efere | Oyi akpụ | - | Q | |

| Dị ka-akpọrela thermomechanical - akpọrepu normalizing-akpọrela, ma ọ bụ eriri igwe nkịtị ma ọ bụ efere | Oyi akpụ | Na-emenyụ na iwe iwe | Q | |

| Dị ka-akpọrela thermomechanical - akpọrepu normalizing-akpọrela, ma ọ bụ eriri igwe nkịtị ma ọ bụ efere | Normalizing akpụ | - | N | |

| aLee ISO 5L 8.8 maka ọgwụgwọ okpomọkụ dị | ||||

Nnyocha ọdịdị na ntụpọ nkịtị nke API 5L

Ọdịdị

N'elu elu nke ọkpọkọ ga-adị mma na enweghị ntụpọ nke nwere ike imetụta ike na akara akara nke ọkpọkọ.

Nnukwu ntụpọ

Akụkụ ndị a kpara akpa:Enwere ike idobe ọnụ ọnụ ebe a na-ahụ anya site na nlele anya.

Arc na-ere ọkụ:A ga-ekpe ikpe ọkụ ọkụ dị ka ntụpọ.

Arc na-ere ọkụ bụ ọtụtụ ntụpọ ntụpọ na-etolite site na agbaze nke elu igwe nke arc dị n'etiti electrode ma ọ bụ ala electrode na elu nke ọkpọkọ ígwè.

Ebe kọntaktị bụ ntụpọ na-adịte aka n'akụkụ ahịrị weld nke ọkpọkọ EW, nke sitere na kọntaktị dị n'etiti electrode na-enye ịgbado ọkụ ugbu a na elu nke ọkpọkọ.

Delamination:Delamination ọ bụla ma ọ bụ nsonye nke gbatịrị n'elu ọkpọkọ ma ọ bụ ihu gbagọrọ agbagọ yana> 6.4 mm (0.250 in) n'ogologo okirikiri na nlele anya ka a ga-ewere dị ka ntụpọ.

Ndịiche geometric:Ngbanwe geometric (dịka ọmụmaatụ, ngọngọ dị larịị ma ọ bụ pout, wdg), na-abụghị olulu dobe, nke usoro ịkpụ tube kpatara ma ọ bụ ọrụ nrụpụta.A ga-ewere ebe dị anya n'etiti ebe dị oke egwu na mgbatị nke contour nkịtị nke tube ahụ, ya bụ, omimi karịa 3.2 mm (0.125 na), dị ka ntụpọ.

olulu mmiri ga-abụ ≤ 0.5 D n'akụkụ ọ bụla.

Isi ike: Mgbe nlele anya na-ekpughe ihe ndị a na-enyo enyo na o siri ike, a ga-eji onye na-anwale ike ike na-ebugharị mee ule siri ike, na ntinye otu ihe nwere uru siri ike karịa 35 HRC, 345 HV10, ma ọ bụ 327 HBW ka a ga-ewere dị ka onye nwere nkwarụ mgbe nha ya. nke indentation dị ukwuu karịa 50 mm (2.0 in) n'akụkụ ọ bụla.

Ijikwa ntụpọ

Biko rụtụ aka na ihe ndị dị mkpa dị na API 5L Ihe mgbakwunye C maka njikwa.

Nyocha akụkụ (Ngbanwe akụkụ)

Chart ibu arọ na ngbanwe ịdị arọ

Ụdị ịdị arọ

M=(DT)×T×C

M bụ uka kwa nkeji ogologo;

D bụ dayameta n'èzí akọwapụtara nke ọma, gosipụtara na millimeters (inch);

T bụ ọkpụrụkpụ mgbidi akọwapụtara, gosipụtara na millimeters (inch);

C bụ 0.02466 maka mgbako na nkeji SI yana 10.69 maka mgbako na nkeji USC.

CHATỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWỤKWASỊ".

A na-ezo aka na tebụl ịdị arọ ọkpọkọ na API 5LISO 4200naASME B36.10M, nke na-enye ụkpụrụ ọkọlọtọ maka ọkpọkọ na dayameta n'èzí akọwapụtara na ọkpụrụkpụ mgbidi akọwapụtara.

Usoro 40 na Usoro nke 80agbakwunyere n'okpuru, ọ bụrụ na ịchọrọ ịhụ usoro pipụ zuru ezu,biko pịa ebe a!

Ngbanwe ibu

Ogo nke ọkpọkọ ọ bụla metụtara usoro iwu: arọ: 95% ≤ theoretical arọ ≤ 110;

Ntugharị na ọkpọkọ nkọwapụta nke dị mkpa: 5% ≤ 110% nke ibu usoro;

L175, L175P, A25, na A25P ígwè akara ule: 95% ≤ 110% nke theoretical arọ.

Dayameta dị n'elu na oke mgbidi

| Tebụl 9-Ekwere ka akọwapụtara n'èzí dayameta yana ọkpụrụkpụ mgbidi akọwapụtara | ||

| Oke dayameta dị n'èzí akọwapụtara D mm (n'ime) | Ọkpụrụkpụ mgbidi akọwapụtara t mm (n'ime) | |

| Nha Ọkụ Pụrụ Ichea | Nha oge niile | |

| ≥10.3 (0.405) ruo <13.7 (0.540) | - | ≥1.7 (0.068) ruo≤2.4 (0.094) |

| ≥13.7 (0.540) ruo <17.1 (0.675) | - | ≥2.2 (0.088) ruo≤3.0 (0.118) |

| ≥17.1 (0.675) ruo <21.3 (0.840) | - | ≥2.3 (0.091) ruo≤3.2 (0.125 |

| ≥21.3 (0.840) ruo <26.7 (1.050) | - | ≥2.1 (0.083) ruo≤7.5 (0.294) |

| ≥26.7 (1.050) ruo <33.4 (1.315) | - | ≥2.1 (0.083) ruo≤7.8 (0.308) |

| ≥33.4 (1311}5) ruo <48.3 (1.900) | - | ≥2.1 (0.083) ruo≤10.0 (0.394) |

| ≥48.3 (1.900) ruo <60.3 (2.375) | - | ≥2.1 (0.083) ruo≤12.5 (0.492) |

| ≥60.3 (2.375) ruo <73.0 (2.875) | ≥2.1 (0.083) ruo≤3.6 (0.141) | > 3.6 (0.141) ruo≤14.2 (0.559) |

| ≥73.0 (2.875) ruo <88.9 (3.500) | ≥2.1 (0.083) ruo≤3.6 (0.141) | > 3.6 (0.141) ruo≤20.0 (0.787) |

| ≥88.9 (3.500) ruo <101.6 (4.000) | ≥2.1 (0.083) ruo≤4.0 (0.156) | > 4.0 (0.156) ruo ≤22.0 (0.866) |

| ≥101.6 (4.000) ruo <168.3 (6.625) | ≥2.1 (0.083) ruo≤4.0 (0.156) | > 4.0 (0.156) ruo ≤25.0 (0.984) |

| ≥168.3 (6.625) ruo <219.1 (8.625) | ≥2.1 (0.083) ruo≤4.0 (0.156 | > 4.0 (0.156) ruo ≤40.0 (1.575) |

| ≥219.1 (8.625) ruo <273.1 (10.750) | ≥3.2 (0.125) ruo≤4.0 (0.156 | > 4.0 (0.156) ruo≤40.0 (1.575 |

| ≥273.1 (10.750) ruo <323.9 (12.750) | ≥3.6 (0.141) ruo≤5.2 (0.203) | > 5.2 (0.203) gaa ≤45.0 (1.771) |

| ≥323.9 (12.750) ruo <355.6 (14.000) | ≥4.0 (0.156) ruo≤5.6 (0.219) | > 5.6 (0.219) ruo≤45.0 (1.771 |

| ≥355.6 (14.000) ruo <457 (18.000) | ≥4.5 (0.177) ruo≤7.1 (0.281) | > 7.1 (0.281) ruo≤45.0 (1.771 |

| ≥457 (18.000) ruo <559 (22.000) | ≥4.8 (0.188) ruo≤7.1 (0.281) | > 7.1 (0.281) gaa ≤45.0 (1.771) |

| ≥559 (22.000) ruo <711 (28.000) | ≥5.6 (0.219) ruo≤7.1 (0.281) | > 7.1 (0.281) gaa ≤45.0 (1.771) |

| ≥711 (28.000) ruo <864 (34.000) | ≥5.6 (0.219) ruo≤7.1 (0.281) | > 7.1 (0.281) ruo ≤52.0 (2.050) |

| ≥864 (34.000) ruo <965 (38.000) | - | ≥5.6 (0.219) ruo≤52.0 (2.050) |

| ≥965 (38.000) ruo <1422 (56.000) | - | ≥6.4 (0.250) ruo≤52.0 (2.050) |

| ≥1422 (56.000) ruo <1829 (72.000) | - | ≥9.5 (0.375) ruo≤52.0 (2.050) |

| ≥1829 (72.000) ruo <2134 (84.000) | - | ≥10.3 (0.406) ruo≤52.0 (2.050) |

| aPipe inwe nchikota nke kpọmkwem n'èzí dayameta na kpọmkwem mgbidi ọkpụrụkpụ a kọwara dị ka a pụrụ iche ìhè-size ọkpọkọ;A na-akọwa nchikota ndị ọzọ e nyere na tebụl a dị ka ọkpọkọ nke na-emekarị. | ||

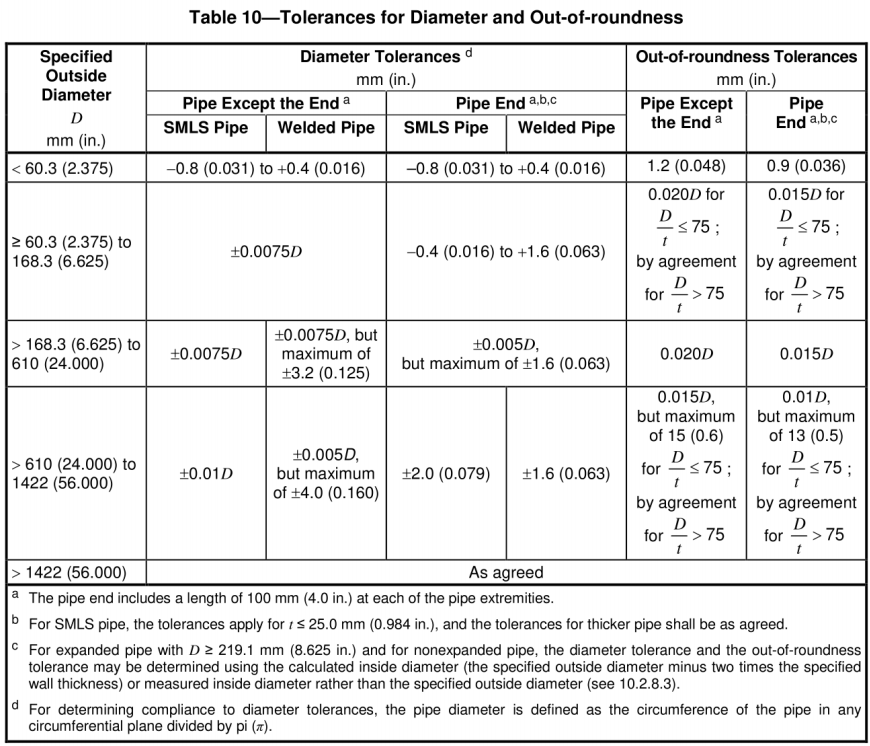

Dayameta na Roundness Deviation

Mgbawa nke ịdị arọ mgbidi

| Tebụl 11-Nkwenye maka Ọkpụrụkpụ mgbidi | |

| Ọkpụrụkpụ mgbidi t mm (n'ime) | Nkwenyea mm (n'ime) |

| SMLS Pipeb | |

| ≤4.0 (0.157) | +0.6 (0.024) -0.5 (0.020) |

| > 4.0 (0.157) ruo <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146) ma ọ bụ + 0.1t, nke ọ bụla dị ukwuu -3.0 (0.120) ma ọ bụ-0.1t, nke ọ bụla bụ nke ukwuu |

| Ọkpọkpọ weldedcd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| > 5.0 (0.197) ruo <15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ± 1.5 (0.060) |

| aỌ bụrụ na iwu ịzụrụ akọwapụta mwepu ntachi obi maka ọkpụrụkpụ mgbidi dị obere karịa uru ọdabara enyere na tebụl a, a ga-abawanye nnabata maka ọkpụrụkpụ mgbidi site na ego zuru oke iji dokwaa oke nnabata ọdabara. bMaka ọkpọkọ nwere D2 355.6 mm (14.000 in.) na 1 2 25.0 mm (0.984 in.), ntachi obi nke mgbidi na mpaghara nwere ike karịa gbakwunyere ndidi maka ọkpụrụkpụ mgbidi site na 0.05t ọzọ, ma ọ bụrụhaala na gbakwunyere ndidi maka oke (lee anya). 9.14) agafebeghị. cMgbakwunye nnabata maka ọkpụrụkpụ mgbidi anaghị emetụta mpaghara weld. dLee 9.13.2 maka mgbochi ndị ọzọ. | |

Ngbanwe Ogologo

Nkwekọrịta tubing ogologo: Ngbanwe ogologo kwesịrị ịbụ 500 mm (inch 20).

Nnade ogologo ọkpọkọ enweghị usoro:

| Tebụl 12 - Nkwenye maka ọkpọkọ ogologo ogologo | |||

| Ogologo random Nhọpụta m(ft) | Ogologo kacha nta m (ft) | Ogologo Ogologo kacha nta Maka ihe ọ bụla ịtụ m (ft) | Ogologo kachasị m (ft) |

| Ọkpọkpọ eriri na-ejikọta ọnụ | |||

| 6 (20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72 (45.0 |

| Ọkụ dị larịị | |||

| 6 (20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72 (45.0) |

| 15 (50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18 (60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24 (80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Ngbanwe nke kwụ ọtọ

Mkpokọta nkewa site na ahịrị kwụ ọtọ n'ogologo dum nke ọkpọkọ ga-abụ <0.2% nke ogologo ọkpọkọ;

Ntugharị mpaghara site na ahịrị kwụ ọtọ ga-abụ <3.2 mm (0.125 in) karịa ogologo 1.5 m (5.0 ft) nke njedebe ọkpọkọ ọ bụla.

Ngbanwe Angle Bevel

Tube nwere t> 3.2 mm (0.125 in) njedebe dị larịị ka a ga-eji akwa weld bevel nwere akụkụ bevel nke 30°-35°.

Obosara elu Mgbọrọgwụ E Mepụtara

1.6 mm (0.063 in) na ntụgharị nke ± 0.8 mm (0.031 na).

Oke nke Inner Cone Angle (naanị maka ọkpọkọ nchara enweghị nkebi)

| Tebụl 13- Kachasị akụkụ nke Taper esịtidem maka ọkpọkọ SMLS | |

| Ọkpụrụkpụ mgbidi akọwapụtara t mm (n'ime) | Akụkụ Taper kacha elu ogo |

| <10.5 (0.413) | 7.0 |

| 10.5 (0.413) ruo <14.0 (0.551) | 9.5 |

| 14.0 (0.551) ruo <17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

Pipe End Squareness (nke na-adịghị n'okirikiri)

A na-atụpụta ihe na-apụ apụ dị ka ọdịiche dị n'etiti njedebe nke ọkpọkọ na ọkpọkọ ọkpọkọ, nke ga-abụ 1.6 mm (0.063 in.).

Welding Seam Deviation

Mpempe akwụkwọ / mpempe akwụkwọ adịghị mma:

Maka ọkpọkọ elektrọn-welded (EW) na laser-welded (LW), ngbanwe ahụ ekwesịghị ime ka ọkpụkpụ mgbidi fọdụrụ na weld nke na-erughị opekempe mgbidi kwere ekwe.

Maka Submerged Arc Welded (SAW) na Nchikota Welded (COW) ọkpọkọ, ihe na-ezighị ezi ekwesịghị ịgafe ụkpụrụ kwekọrọ ekwekọ nyere na Tebụl 14 nke API 5L.

Burrs (Electro-welded (EW) na laser-welded (LW) tubes):

A ga-ewepụ ihe mgbawa dị n'èzí gaa n'ọnọdụ na-ekpochapụ nke ukwuu (ya na ihe ndabere).

Burrs dị n'ime agaghị agbatị 1.5 mm (0.060 in) gafere contour nke tube ahụ, na ọkpụrụkpụ mgbidi n'ebe a na-ewepụ burr agaghị abụ ihe na-erughị opekempe a na-ekwe ka mgbidi mgbidi.

Weld elu(Submerged Arc Welding (SAW) na Ngwakọta Welding (COW) Pipe):

Wepu ihe fọdụrụ n'ịdị elu nke eriri ime n'ime opekempe 100 mm (4.0 in) nke njedebe ọkpọkọ na njedebe ọ bụla nke ọkpọkọ, ma gwerie weld ka ọ ghara ibili karịa 0.5 mm (0.020 in) n'elu elu. nke ọkpọkọ dị n'akụkụ.

Ihe Nnwale API 5L

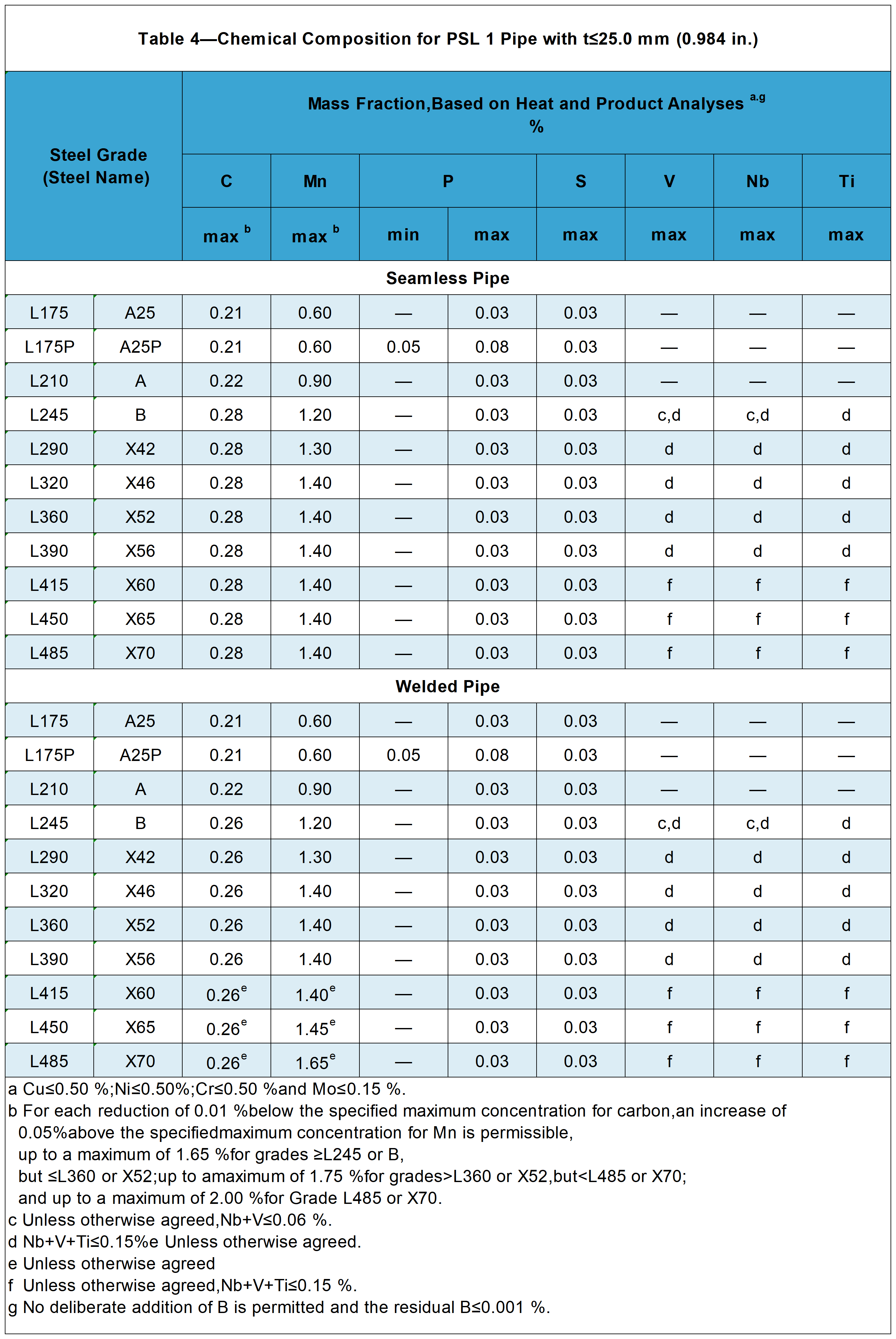

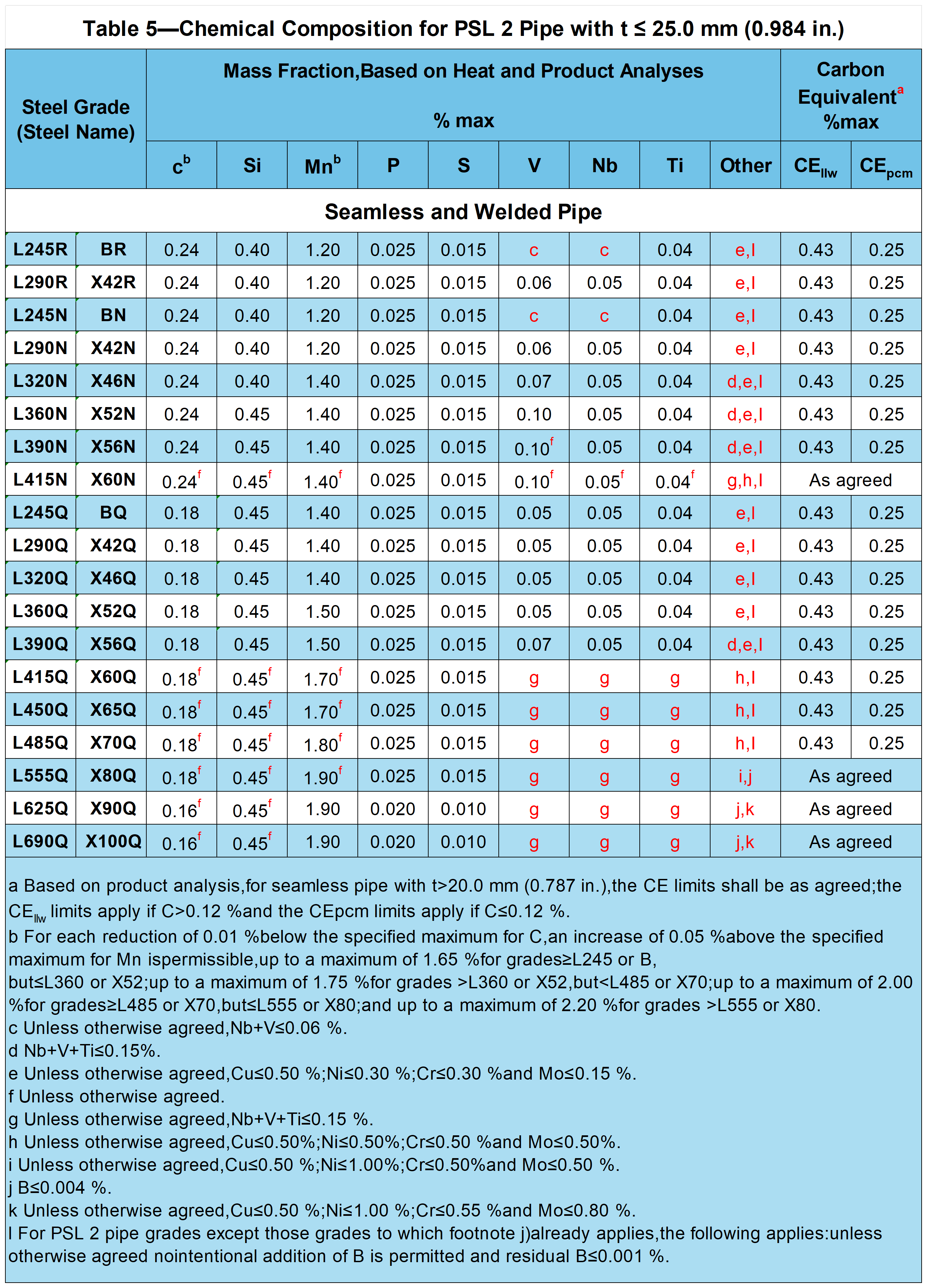

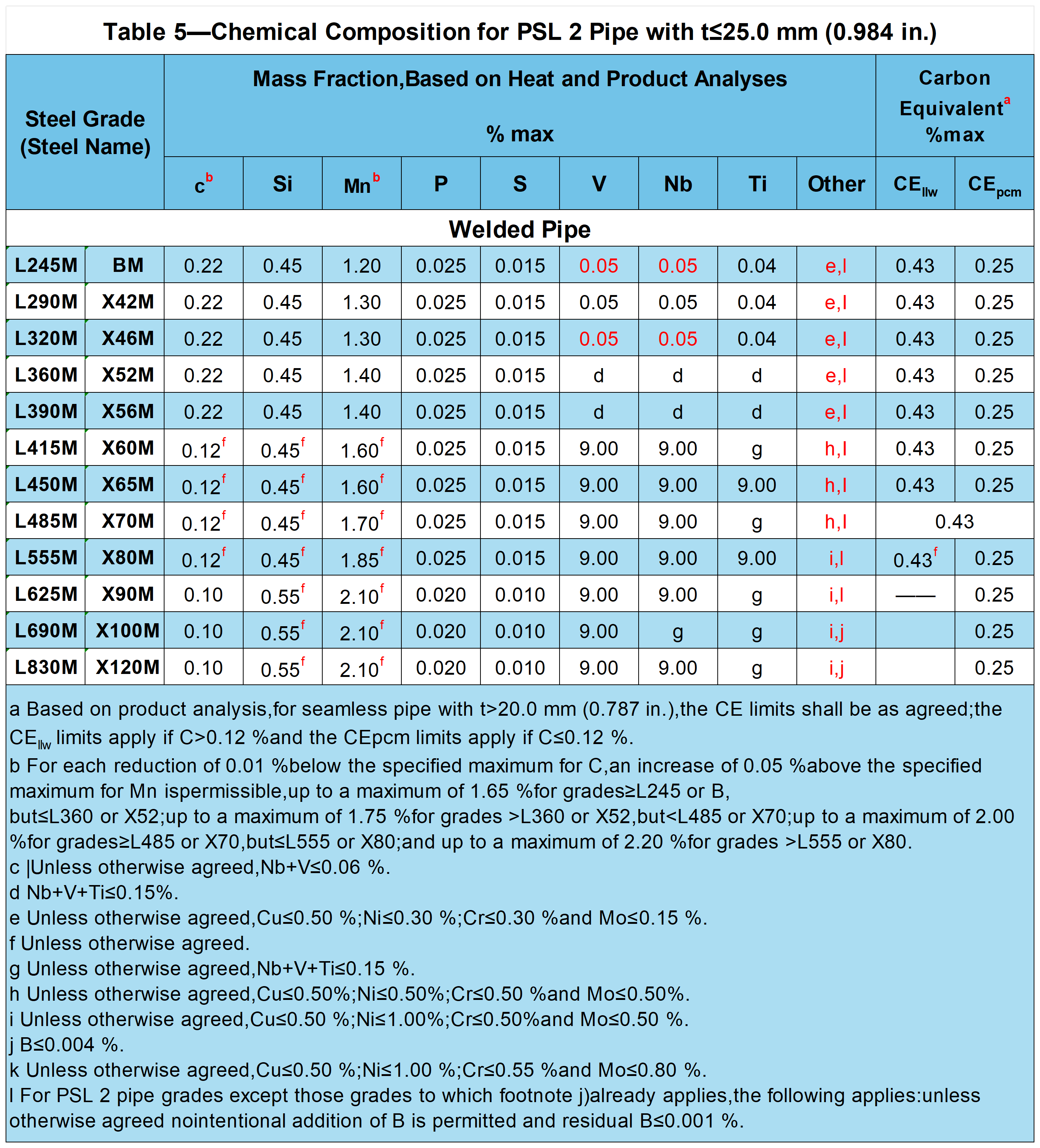

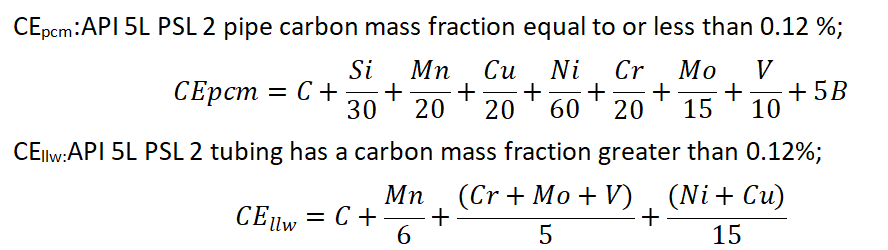

Ngwakọta kemịkalụ

Ule ule: rụtụ aka na ISO 9769 ma ọ bụ ASTM A751.

Ngwakọta kemịkalụ nke API 5L PSL1 na API 5L PSL2 ígwè ọkpọkọ t> 25.0 mm (0.984 na) ga-ekpebi site na mkparita uka dabere na ihe mejupụtara kemịkalụ na tebụl kwekọrọ.

Ihe mejupụtara kemịkalụ maka PSL 1 Pipe nwere t≤25.0 mm (0.984 in.)

Ihe mejupụtara kemịkalụ maka PSL 2 Pipe nwere t≤25.0 mm (0.984 in.)

Njirimara tensile

Ule ule: A ga-eme ya dabere na ISO 6892-1 ma ọ bụ ASTM A370.

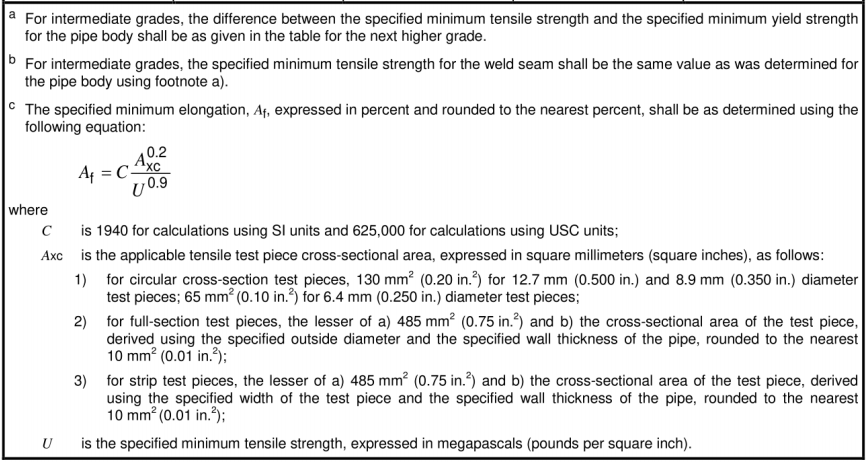

Ihe ndị achọrọ maka nsonaazụ nke ule tensile maka PSL 1 Pipe

| Tebụl 6 - Ihe ndị chọrọ maka nsonaazụ nke ule nkwụsị maka PSL 1 Pipe | ||||

| Ọkwa ọkpọkọ | Ahụ ọkpọkọ nke ọkpọkọ enweghị nkebi na welded | Weld Seam nke EW, LW, SAW, na COW Pipe | ||

| Mpụta Ikea Rka.5 MPa (psi) | Ike ọdụdọa Rm MPa (psi) | Ogologo oge (na 50 mm ma ọ bụ 2 inch) Af % | Ike ọdụdọb Rm MPa (psi) | |

| min | min | min | min | |

| L175 ma ọ bụ A25 | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L175P ma ọ bụ A25P | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L210 ma ọ bụ A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 ma ọ bụ B | 245 (35,500) | 415 (60,200) | c | 415 (60,200) |

| L290 ma ọ bụ X42 | 290 (42,100) | 415 (60,200) | c | 415 (60,200) |

| L320 ma ọ bụ X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 ma ọ bụ X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| L390 ma ọ bụ X56 | 390 (56,600) | 490 (71,100) | c | 490 (71,100) |

| L415 ma ọ bụ X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| L450 ma ọ bụ X65 | 450 (65,300) | 535 (77,600) | c | 535 (77,600) |

| L485 ma ọ bụ X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

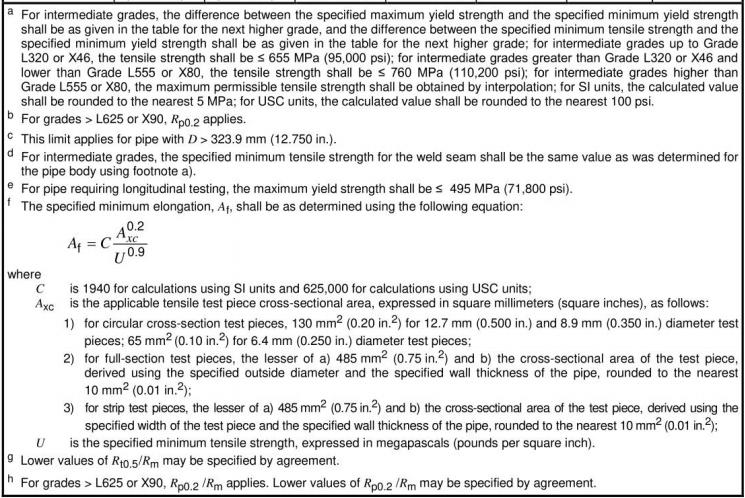

Ihe ndị a chọrọ maka nsonaazụ ule tensile maka PSL 2 Pipe

| Tebụl 7 - Ihe ndị chọrọ maka nsonaazụ nke ule nkwụsị maka PSL 2 Pipe | |||||||

| Ọkwa ọkpọkọ | Ahụ ọkpọkọ nke ọkpọkọ enweghị nkebi na welded | Weld Seam nke HFW SAW na CoW Pipe | |||||

| Mpụta Ikea Rto.5 MPa (psi) | Ike ọdụdọa Rm MPa (psi) | Okeac Rt0.5/Rm | Ogologo oge (na 50 mm ma ọ bụ 2 in.) Af % | Ịkwụsị Iked Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L245R ma ọ bụ BR L245N ma ọ bụ BN L245Q ma ọ bụ BQ L245M ma ọ bụ BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95,000) | 0.93 | f | 415 (60.200) |

| L290R ma ọ bụ X42R L290N ma ọ bụ X42N L290Q ma ọ bụ X42Q L290M ma ọ bụ X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95,000) | 0.93 | f | 415 (60.200) |

| L320N ma ọ bụ X46N L320Q ma ọ bụ X46Q L320M ma ọ bụ X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95,000) | 0.93 | f | 435 (63.100) |

| L360N ma ọ bụ X52N L360Q ma ọ bụ X52Q L360M ma ọ bụ X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N ma ọ bụ X56N L390Q ma ọ bụ X56Q L390M ma ọ bụ X56M | 390 (56.600) | 545 (79,000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N ma ọ bụ X56N L390Q ma ọ bụ X56Q L390M ma ọ bụ X56M | 390 (56.600) | 545 (79,000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N ma ọ bụ X60N L415Q ma ọ bụ X60Q L415M ma ọ bụ X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q ma ọ bụ X65Q L450M ma ọ bụ X65M | 450 (65.300) | 600 (87,000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q ma ọ bụ X70Q L485M ma ọ bụ X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q ma ọ bụ X80Q L555M ma ọ bụ X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M ma ọ bụ X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q ma ọ bụ X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M ma ọ bụ X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q ma ọ bụ X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M ma ọ bụ X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

A ga-akọpụta elongation pasent na nkwụsịtụ maka ihe atụ nwere ogologo nlele nke 50 mm (2 in).

Maka ihe atụ nwere ogologo nlele nke na-erughị 50 mm (2 in), elongation na ezumike ga-agbanwe na elongation na 50 mm (2 in) dị ka ISO 2566-1 ma ọ bụ ASTM A370 si dị.

Nnwale nrụgide Hydrostatic

Usoro nnwale: API 5L 10.2.6.

Ogo niile nke ọkpọkọ (SMLS) na ọkpọkọ welded nwere D ≤ 457 mm (18.000 in) ga-enwe oge nkwụsi ike nke na-erughị 5 sekọnd.ọkpọkọ welded na D> 457 mm (18.000 in) ga-enwe oge nkwụsi ike nke na-erughị 10 sekọnd.

Bend Test

Ule ule: Nnwale na-ehulata ga-agbaso ụkpụrụ ISO 8491 ma ọ bụ ASTM A370.

Ọ dịghị akụkụ nke ihe atụ a ga-agbawa na weld agaghị agbawa.

Ọkwa L175P/A25P bụ ígwè emelitere site na phosphorus nke na-enye ịrụ ọrụ ntanetị ka mma karịa L175/A25 ígwè mana ọ na-esi ike ịgbagọ.

Nnwale ire ọkụ

Ule ule: Nnwale mkpakọ ga-agbaso ihe achọrọ nke ISO 8492 ma ọ bụ ASTM A370.

Ebe dị n'etiti efere abụọ ahụ ga-abụ nke na ọ dịghị mgbawa nke weld ga-eme ruo mgbe a ga-erute ebe a kapịrị ọnụ.

Nnwale ịgbagọ eduzi

Ule ule: Nnwale ịgbagọ eduzi ga-agbaso ụkpụrụ ISO 5173 ma ọ bụ ASTM A370.

Ule isi ike

Usoro nnwale: Nnwale ike dị ka ISO 6506, ISO 6507, ISO 6508, ma ọ bụ ASTM A370.

Mgbe achọpụtara mkpụkpọ siri ike na-enyo enyo na nleba anya n'ọdịdị, a ga-eji ihe nleba anya ike siri ike mee nnwale ike.

Nnwale mmetụta CVN maka API 5L PSL2 Steel Pipe

Ule ule: Nnwale mmetụta charpy ga-emezu ihe ASTM A370 chọrọ.

Nnwale DWT maka API 5L PSL2 Welded Pipe

Usoro nnwale: Nnwale DWT ga-adị na API5L3.

Nleba macro na nyocha meta

A ga-enyocha ngbanwe nke ime na mpụta nke arc welded submerged (SAW) na ọkpọkọ welded (COW) site na nyocha macroscopic.

Maka tubes chọrọ ọgwụgwọ ikpo ọkụ weld, a ga-eme nyocha metallurgical iji chọpụta na a na-emeso HAZ dum nke ọma n'ụzọ zuru oke na mgbidi mgbidi.

Maka tubes nke na-achọghị ọgwụgwọ okpomọkụ weld, a ga-eme nyocha metallographic iji chọpụta na ọ dịghị ihe fọdụrụnụ na-adịghị agwụ agwụ martensite.

Nnwale na-adịghị emebi emebi (naanị maka ọkpọkọ API 5L PSL2 pụrụ iche atọ)

Ule ule: API 5L Annex E.

Akara ọkpọkọ na ebe

Ihe akara a na-ahụkarị maka tubes ígwè:

Aha ma ọ bụ akara onye nrụpụta ọkpọkọ;

Na-akara "API Spec 5L".(A na-akpọkarị API 5L.) Ngwaahịa ndị kwekọrọ na ihe karịrị otu ọkọlọtọ dakọtara nwere ike iji aha ọkọlọtọ ọ bụla nwere akara.

Oke dayameta dị n'èzí akọwapụtara

Ọkpụrụkpụ mgbidi akọwapụtara

Ọkwa ọkpọkọ (aha igwe)

Ụdị ọkpọkọ

Ogologo (ogologo ọkpọkọ na m ruo 0.01 m kacha nso (na ft ruo otu ụzọ n'ụzọ iri nke ụkwụ))

Ebe akara ọkpọkọ ígwè

D ≤ 48.3 mm (1.900 na) ọkpọkọ ígwè: Taabụ ndị a na-emepụta mgbe niile n'ogologo nke ọkpọkọ ígwè ma ọ bụ nke a ga-echekwa na ngwugwu ígwè ígwè.

Ọkpọụ nwere D> 48.3 mm (1.900 in):

N'èzí: Malite n'ebe dị n'èzí nke ọkpọkọ n'etiti 450 mm na 760 mm (1.5 ft na 2.5 ft) site na otu njedebe nke ọkpọkọ.

N'ime elu: Malite akara n'ime ime ọkpọkọ ma ọ dịkarịa ala 150 mm (6.0 in) site na njedebe nke ọkpọkọ.

Ụkpụrụ nhata

Ọkọlọtọ mba ụwa na mpaghara tube nke API 5L bụ otu ma ọ bụ, n'ọnọdụ ụfọdụ, nhọrọ ọzọ, yana ọtụtụ ụkpụrụ akọwapụtara ngwa:

Ụkpụrụ mba ụwa na mpaghara

1. ISO 3183 - ọkọlọtọ pipeline zuru ụwa ọnụ maka ụlọ ọrụ mmanụ na gas nke International Organisation for Standardization bipụtara yana njikọ chiri anya na API 5L.

2. EN 10208 - Ụkpụrụ European maka ọkpọkọ ígwè maka ibufe gas mmanụ na mmiri mmiri.

3. GB / T 9711 - ọkọlọtọ mba China maka usoro ụgbọ njem pipeline na ụlọ ọrụ mmanụ na gas.

4. CSA Z245.1 - Canadian Standard ekpuchi eriri eriri maka njem nke mmanụ na gas.

5. GOST 20295 - Russian Standard for steel line pipe maka njem mmanụ na ngwaahịa mmanụ.

6. IPS (Iranian Petroleum Standards) - Ụkpụrụ mmanụ ụgbọ ala nke Iran maka ọkpọkọ eriri maka ụlọ ọrụ mmanụ na gas.

7. JIS G3454, G3455, G3456 - Japanese Industrial Standards maka nnyefe ọkpọkọ nke dị iche iche nrụgide klas.

8. DIN EN ISO 3183 - German Industrial Standard dabere na ISO 3183 maka ọkpọkọ ahịrị.

9. AS 2885 - Standard Australian maka usoro ọkpọkọ ahịrị maka njem mmanụ na gas.

Ụkpụrụ akọwapụtara ngwa

1. API 5CT - American Petroleum Institute Standard for oil well casing and tubing, nke, ọ bụ ezie na a na-ejikarị eme ihe n'olulu mmanụ, dịkwa mkpa na ụlọ ọrụ mmanụ na gas.

2. ASTM A106 - American Society for Testing and Materials Standard maka enweghị nkebi na welded carbon steel pipe maka ọrụ okpomọkụ dị elu.

3. ASTM A53 - National Institute for Testing and Materials Standard maka enweghị nkebi na welded carbon steel pipe, nke a na-ejikarị eme njem mmiri na ụlọ okpomọkụ ma ọ bụ obere okpomọkụ.

4. ISO 3834 - International Organisation for Standardization Standards for quality chọrọ, na-elekwasị anya na mma nkwa usoro maka welded ọla.

5. dnv-os-f101 - Norwegian nhazi ọkwa ọha ọkọlọtọ maka sistemụ ọkpọkọ ụgbọ mmiri maka mmanụ na-ebufe mmanụ na gas.

6. MSS SP-75 - Manufacturers Standards Society standard na-elekwasị anya na ike dị elu, nnukwu dayameta okirikiri welded ígwè ọkpọkọ ọkpọkọ.

Njikwa ogo na ụkpụrụ ndabara gburugburu

1. NACE MR0175 / ISO 15156 - Ihe ndị a chọrọ maka ihe ndị a na-eji na mmanụ na gas na-emepụta ihe na gburugburu ebe obibi nke sọlfọ nwere hydrocarbon, bụ nke, n'agbanyeghị na nhọrọ ihe, dị mkpa iji hụ na nguzogide corrosion nke ihe eji eme mmanụ na gas.

Ngwaahịa Anyị emetụtara

API 5L PSL1&PSL2 GR.B Ọkụ Welded Ọdụdọ n'Enyochiri Submerged-arc

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Carbon Steel Pipe

API 5L GR.B Ọkpụrụkpụ Mgbidi Dị Elu Ọkụ Na-adịghị Anya Maka Nrụ Ọrụ

API 5L Gr.X52N PSL 2 Igwe anaghị agba nchara ACC.To IPS-M-PI-190(3) & NACE MR-01-75 maka ọrụ utoojoo

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Mmanụ na Gas Carbon enweghị ntụpọ

API 5L GR.B Ọkụ na-enweghị ntụpọ maka nrụgide na nhazi

API 5L/ASTM A106/ASTM A53 Gr.B Igwe anaghị agba nchara Carbon

BotopSteel bụ ọkachamara ChinaOnye na-emepụta ọkpọkọ Carbon Steel welded & ndị na-eweta yaIhe karịrị afọ 16 nwere 8000+ tọn nke Linepipe enweghị nkebi na ngwaahịa kwa ọnwa.Anyị dị njikere ịzaghachi gị n'ime awa iri abụọ na anọ n'oge na-adịghị anya mgbe ị nwetasịrị otu arịrịọ yana ịzụlite uru na nhazi na-enweghị oke n'etiti onwe ha.

mkpado: API 56 46th, Akụkụ akụkụ, PSL1, PSL2,suppliers, emepụta, ụlọ mmepụta ihe, stockists, ụlọ ọrụ, N'ogbe, ịzụrụ, price, nhota, nnukwu, maka ire ere, efu.

Oge nzipu: Mar-22-2024