TS EN 10210 ọkpọkọ ígwèbụ akụkụ oghere na-ekpo ọkụ na-agwụ agwụ nke nchara na-adịghị mma na nke ọma maka ọtụtụ ngwa nhazi ụlọ na nhazi. Nwere akụkụ okirikiri, square, akụkụ anọ na akụkụ oval.

EN 10210 na BS EN 10210 bụ ụkpụrụ otu mana ha nwere otu dị iche iche.

Bọtịnụ igodo nsoroụzọ

BS EN 10210 nhazi ọkwa

Oke oke BS EN 10210

Ngwaọrụ

BS EN 10210 Steel aha

Ọnọdụ nnyefe nke BS EN 10210

Ihe mejupụtara kemịkalụ BS EN 10210

Njirimara akụrụngwa nke BS EN 10210

Nnwale mmetụta

Weldability

Ndidi n'akụkụ

Ọdịdị elu

Galvanized

Ndozi ntụpọ dị n'elu

BS EN 10210 akara

Ngwa

Ngwaahịa Anyị emetụtara

BS EN 10210 nhazi ọkwa

Site n'ụdị igwe

Igwe anaghị agba nchara na alloyed pụrụ iche nchara

Igwe anaghị agba nchara: S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH.

Alloyed pụrụ iche ígwèNdị a: S420NH, S420NLH, S460NH, S460NLH.

Ụzọ dị mfe nke njirimara bụ: n'aha nke ígwè, ma ọ bụrụ na ike mkpụrụ nke index malite na nọmba '4', maka alloy ígwè.

Site na usoro nrụpụta

Ekwesịrị imepụta akụkụ oghere arụpụtara site naenweghị nkebi ma ọ bụ welded usoro.

Enweghị nkebi na-agụnye: ekpocha ọkụ na oyi gwụchara

Welds ndị a na-ahụkarị gụnyere ịgbado ọkụ eletrik (ERW) na mgbado ọkụ Arc (SAW): LSAW, SSAW.

Akụkụ oghere ndị agbadoro ọkụ eletrik anaghị achọ mkpụcha weld n'ime.

Site Cross-ngalaba Ụdị

CHS: akụkụ oghere okirikiri;

RHS: akụkụ square ma ọ bụ akụkụ anọ oghere;

EHS: akụkụ oghere elliptical;

A na-ahazi akụkọ a site na okirikiri okirikiri (CHS) nke ọdịnaya dị mkpa.

Oke oke BS EN 10210

Ọkpụrụkpụ mgbidi: ≤120mm

Dayameta dị n'èzí:

Gburugburu (CHS): Dayameta nke mpụta≤2500 mm;

Square (RHS): dayameta dị n'èzí≤ 800 mm × 800 mm;

Rectangular (RHS): Dayameta mpụta≤750 mm × 500 mm;

Oval(EHS): Dayameta mpụta≤ 500 mm × 250 mm.

Ngwaọrụ

Igwe anaghị agba nchara na ezigbo ọka nchara.

A na-akọwapụta igwe anaghị agba nchara anọ JR, JO, J2, na K2.

Ngwongwo ọka dị mma: àgwà anọ N na NL ka akọwapụtara.

Ngwongwo ọka dị mma bụ nchara nwere ezigbo ọka, nwere nha ọka ferrite ≥ 6.

BS EN 10210 Steel aha

N'ihi na-abụghị alloy ígwè oghere ngalaba aha nchara mejupụtara

Ọmụmaatụ: BS EN 10210-S275J0H

nwere akụkụ anọ:S, 275, J0, na H.

1.S: na-egosi na structural ígwè.

2.Ọnụọgụgụ (275): ọkpụrụkpụ ≤ 16mm maka ike mkpụrụ kacha nta akọwapụtara, na MPa.

3.JR: na-egosi na na ụlọ okpomọkụ na kpọmkwem mmetụta Njirimara;

J0: na-egosi na na 0 ℃ na kpọmkwem mmetụta Njirimara;

J2 ma ọ bụ K2: gosiri na -20 ℃ nwere mmetụta mmetụta pụrụ iche;

4.H: na-egosi akụkụ oghere.

N'ihi na ezi ọka ígwè structural oghere ngalaba nke ígwè designing mejupụtara

Ọmụmaatụ: EN 10210-S355NLH

Ihe mejupụtara akụkụ ise:S, 355, N, L, na H.

1. S: na-egosi nchara nhazi.

2. Ọnụọgụ ọnụọgụgụ(355): ọkpụrụkpụ ≤ 16mm kacha nta kpọmkwem ike mkpụrụ, unit bụ MPa.

3. N: nhazigharị ma ọ bụ ahaziri ahazi.

4. L: Njirimara mmetụta pụrụ iche na -50 Celsius.

5.H: na-egosi ngalaba oghere.

Ọnọdụ nnyefe nke BS EN 10210

JR, J0, J2 na K2 - emechaala ọkụ.

N na NL - normalized. Haziri agụnye akpọrepu ahaziri nke ọma.

JR, J0, J2 na K2 - arụ ọrụ dị ọkụ

N na NL - Normalizing. Normalizing na-agụnye ịhazigharị ntụgharị.

Ọ nwere ike dị mkpa maka enweghị nkebi oghere ngalaba na a mgbidi ọkpụrụkpụ n'elu 10 mm, ma ọ bụ mgbe T / D karịrị 0,1, itinye accelerated jụrụ mgbe austenitizing iji nweta ihe owuwu, ma ọ bụ mmiri mmiri quenching na tempering iji nweta kpọmkwem n'ibu Njirimara.

N'ihi na enweghị nkebi oghere ngalaba na mgbidi ọkpụrụkpụ karịrị 10 mm, ma ọ bụ mgbe T / D bụ ukwuu karịa 0.1, accelerated jụrụ mgbe austenitization nwere ike chọrọ iji nweta chọrọ Ọdịdị, ma ọ bụ mmiri mmiri quenching na tempering iji nweta kpọmkwem n'ibu Njirimara.

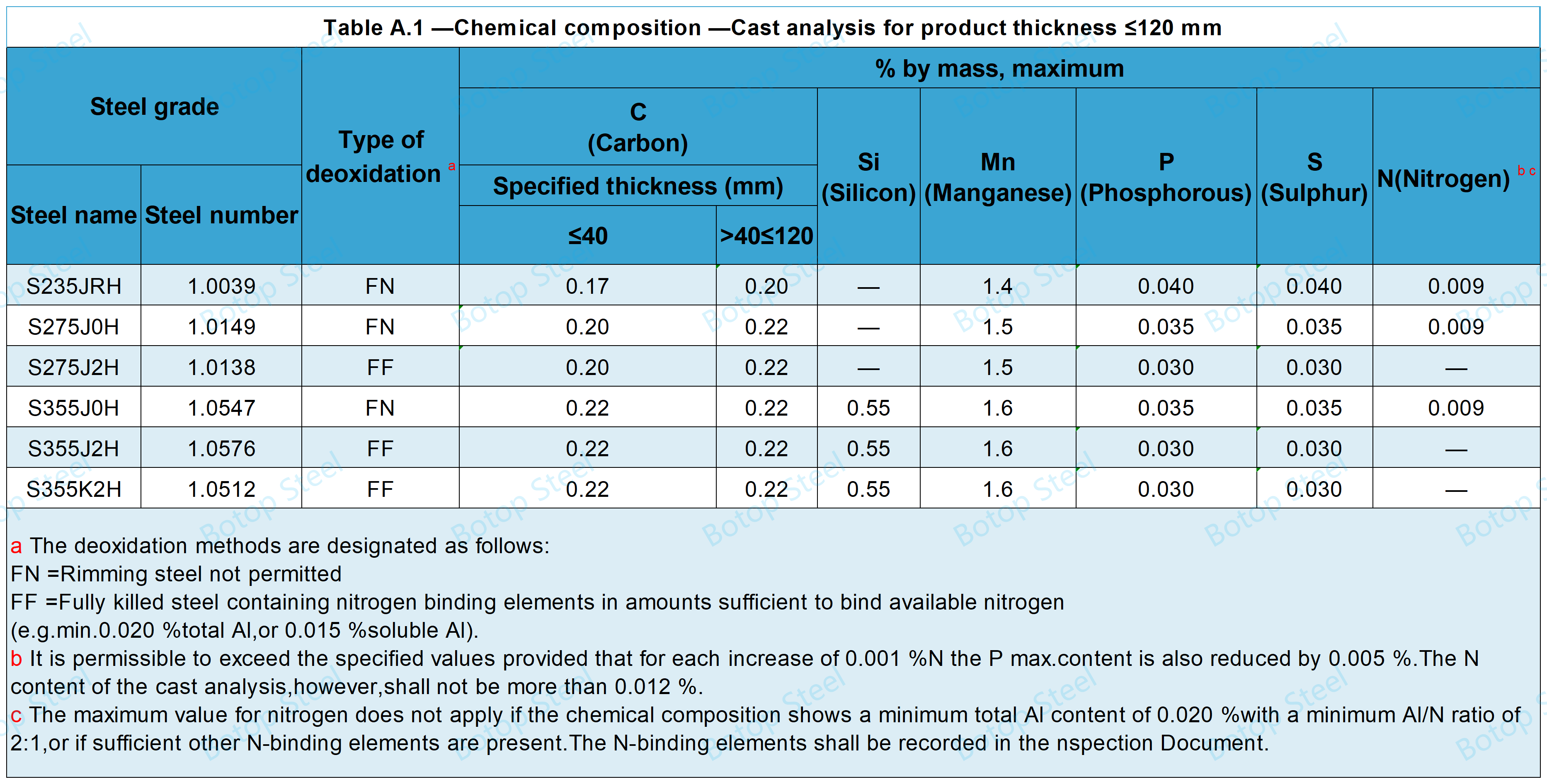

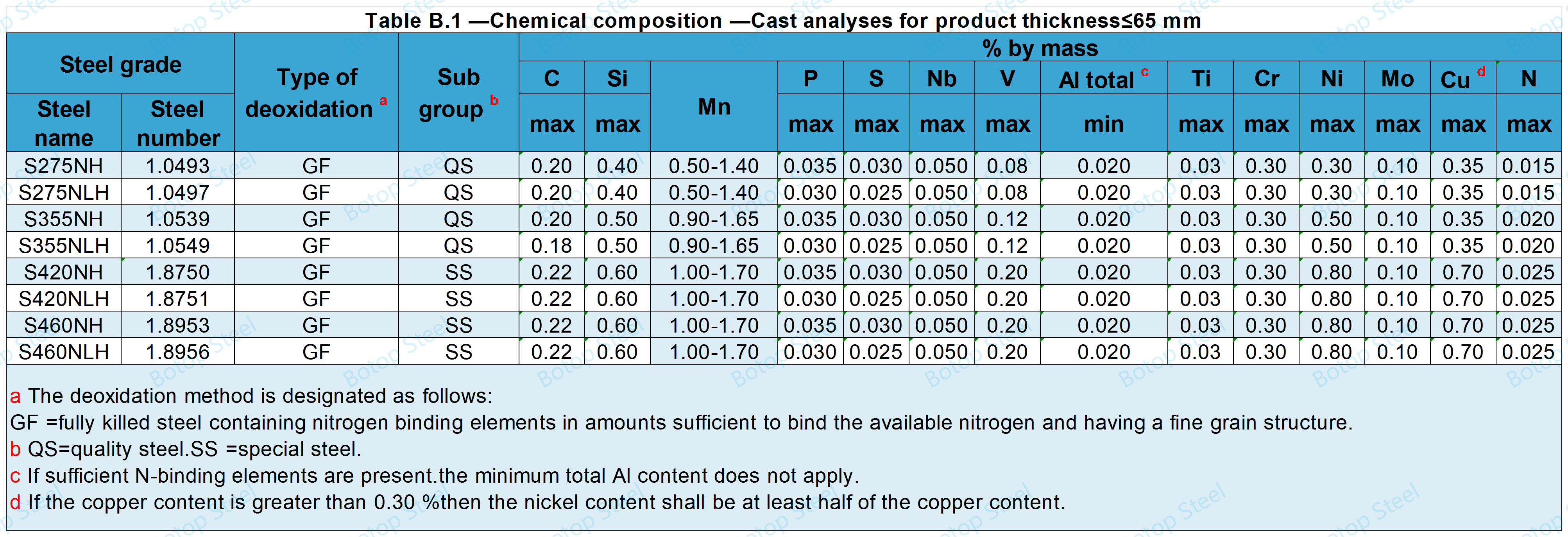

Ihe mejupụtara kemịkalụ BS EN 10210

Na-abụghị alloy Steels - Chemical mejupụtara

Ọmarịcha ọka Steels - Chemical mejupụtara

Mgbe ị na-ekpebi CEV, a ga-eji usoro a:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

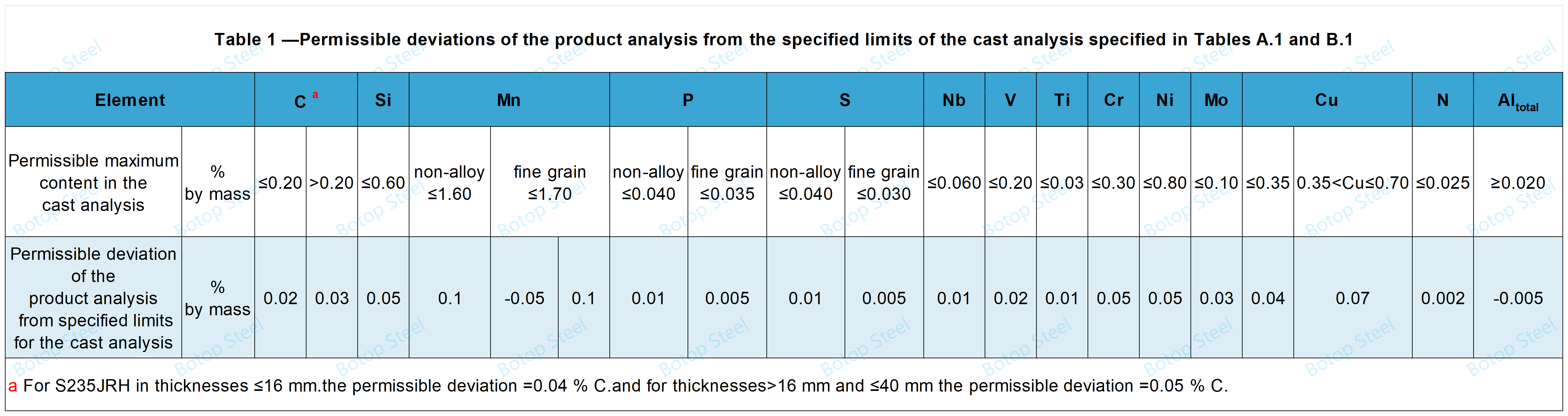

Ngbanwe na Chemical mejupụtara

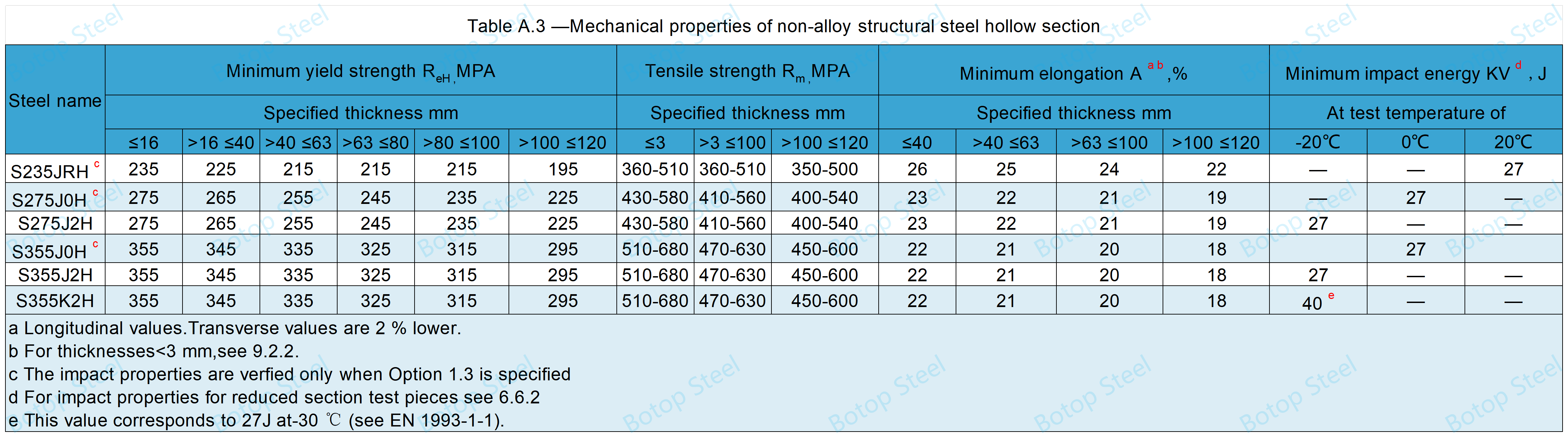

Njirimara akụrụngwa nke BS EN 10210

Mbelata nchekasị n'ihe karịrị 580 Celsius C ma ọ bụ ihe karịrị otu elekere nwere ike ibute mmebi nke akụrụngwa.

Igwe anaghị agba nchara - Njirimara arụrụ arụ

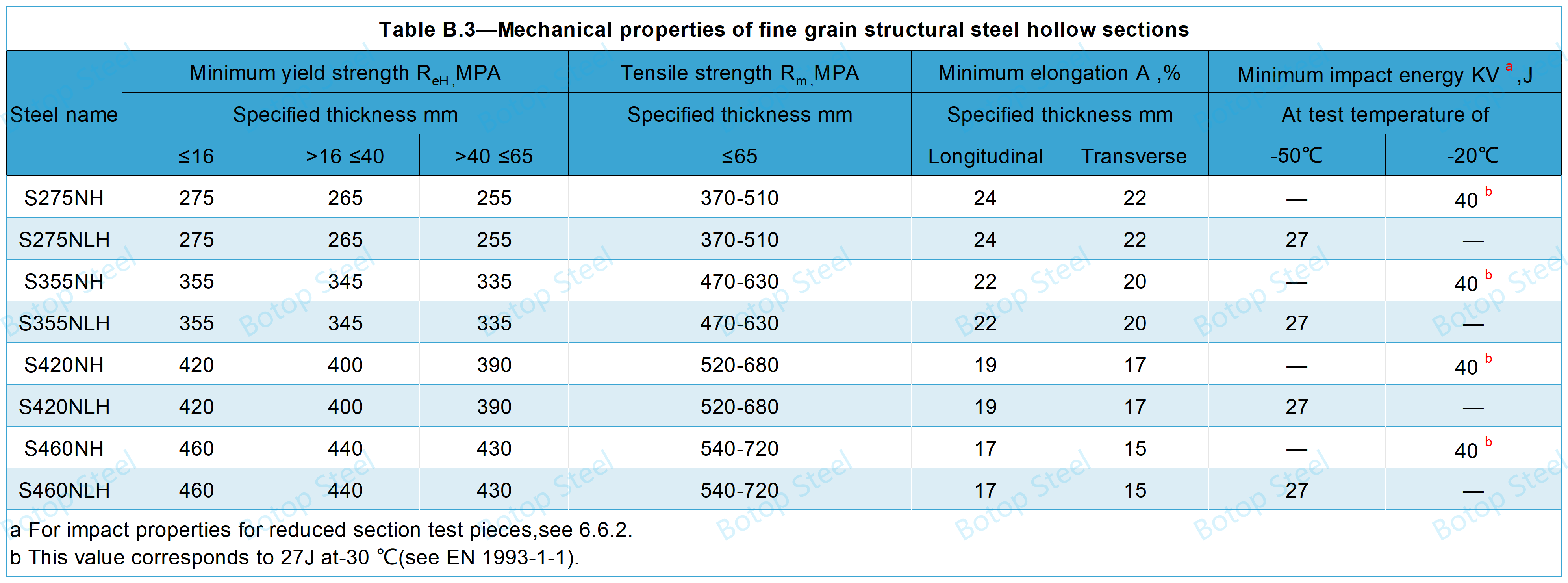

Steel ọka mara mma - Njirimara arụrụ arụ

Nnwale mmetụta

Achọghị nnwale mmetụta mgbe ọkpụrụkpụ akọwapụtara

A ga-eji ụdị ọkọlọtọ V-notched dị ka EN 10045-1.

Ọ bụrụ na ọkpụrụkpụ ngwaahịa aha ezughị ezu maka nkwadebe nke ụdị ahaziri ahazi, a ga-eme nyocha site na iji ụdị nke obosara na-erughị 10 mm, ma ọ bụghị ihe na-erughị 5 mm.

Weldability

Nchara ndị dị na BS EN 10210 nwere ike weldable.

EN 1011-1 na EN 1011-2 na-akọwapụta ihe niile achọrọ maka ngwaahịa welded.

Ntu oyi na mpaghara weld bụ isi ihe egwu dị ka ọkpụrụkpụ ngwaahịa, ọkwa ike na mmụba CEV.

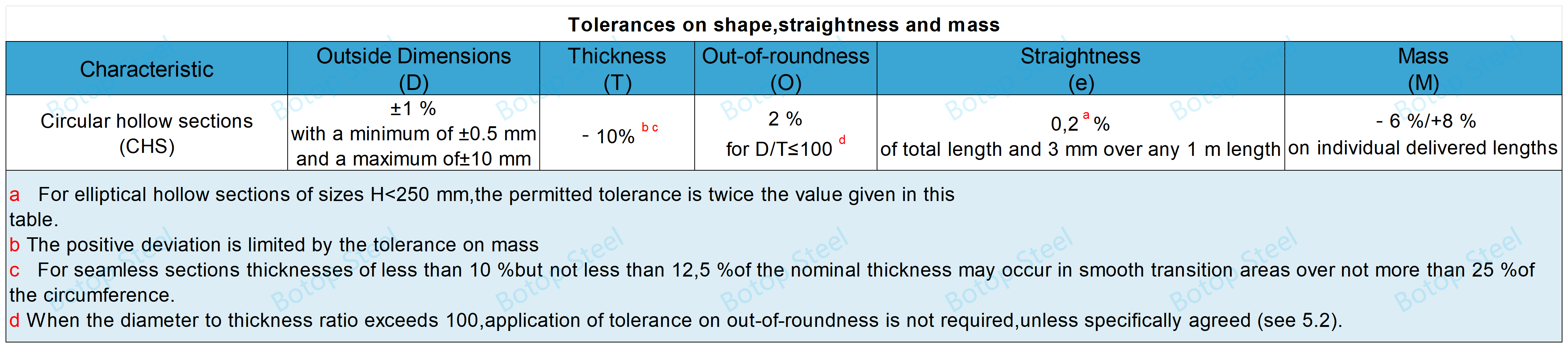

Ndidi n'akụkụ

Nkwenye na ọdịdị, kwụ ọtọ na Mass

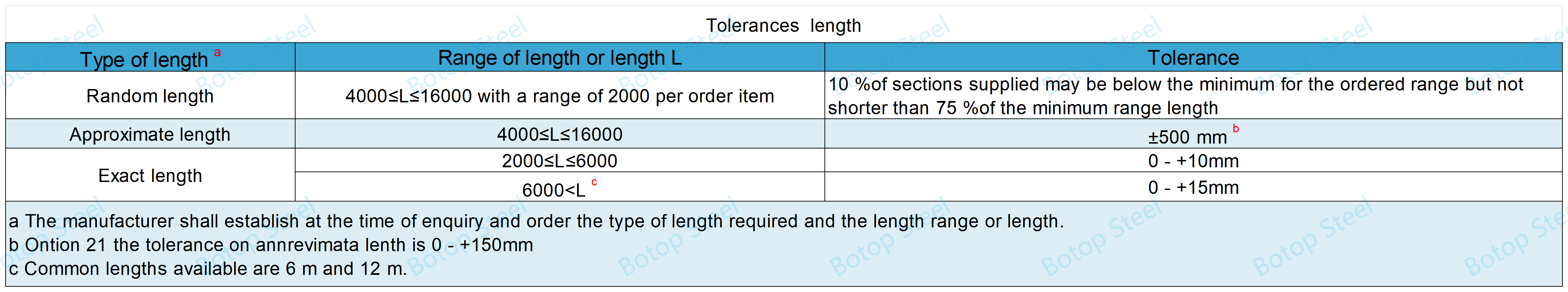

Nkwenye nke Ogologo

Seam Height nke SAW Weld

Nnade na elu nke esịtidem na mpụta weld onuete maka submerged aak welded oghere ngalaba.

| Ọkpụrụkpụ, T | Ogologo bead weld kacha, mm |

| ≤14,2 | 3.5 |

| > 14,2 | 4.8 |

Standardkpụrụ BS EN 10210 na-ekpuchi ngwaahịa ngalaba oghere na-ekpo ọkụ na-ekpo ọkụ. Isi ịgbado ọkụ usoro bụ iguzogide ịgbado ọkụ (RW) na submerged arc ịgbado ọkụ (SAW). Akpụkpọ anụ na ọkpọkọ ígwè ERW bụ nke a na-adịghị ahụ anya, ebe SAW welds na-adịkarị njọ ma na-ahụ anya n'ihi SAW.

Ọdịdị elu

Elu ga-enwe nkwụsị nke ọma kwekọrọ na usoro mmepụta ihe eji eme ihe;

Ọ bụrụ na ọkpụrụkpụ ahụ dị n'ime nnabata, a na-anabata mkpọmkpọ, oghere, ma ọ bụ oghere ogologo ogologo nke na-esite na usoro nrụpụta.

Galvanized

Ngwaahịa dị na BS EN 10210 dabara adaba maka ọgwụgwọ galvanizing na-ekpo ọkụ.

Ekwesịrị iji EN ISO 1461 kọwaa ihe mkpuchi mkpuchi.

A na-etinye ihe mkpuchi Zinc site na imikpu n'ime mmiri a wụrụ awụ nwere opekata mpe 98% zinc.

Ndozi ntụpọ dị n'elu

Enwere ike iwepụ ntụpọ dị n'elu site n'ịgweri site n'aka onye nrụpụta, ma ọ bụrụ na ọkpụkpụ arụziri erughị obere opekempe kwere ekwe.

Ọ bụrụ na ejiri usoro ịgbado ọkụ arụpụtara ya, anabataghị nrụzi weld ma ewezuga ịgbado ọkụ n'ime mmiri.

Enwere ike ịrụzi ọkpọkọ igwe anaghị agba nchara site na ịgbado ahụ ọkpọkọ. Enwere ike ghara ịrụzi ọkpọkọ nchara site na ịgbado ahụ.

BS EN 10210 akara

Ihe dị n'ime akara ọkpọkọ ígwè ga-enwe:

bụ aha igwe, dịka EN 10210-S275JOH.

bụ aha ma ọ bụ ụghalaahịa nke onye nrụpụta.

koodu njirimara, dịka nọmba iwu.

Enwere ike iji ụzọ dị iche iche akara TS EN 10210 ọkpọ ígwè ígwè iji hụ na ọ dị mfe njirimara na traceability, ma ọ bụ site na eserese, stampụ, akara nrapado, ma ọ bụ akara ndị ọzọ, nke enwere ike iji n'otu n'otu ma ọ bụ jikọtara ya.

Ngwa

N'ihi ike ya dị elu, ịdị mma siri ike na weldability, BS EN 10210 na-enwe ike iguzogide ọnọdụ dị iche iche na gburugburu ebe obibi ma na-eji ya eme ihe n'ọtụtụ ngwa nhazi.

Ihe owuwu ụlọ: dịka ọkpụkpụ maka ụlọ elu, ụlọ elu maka ámá egwuregwu, na ihe nkwado maka àkwà mmiri.

Mmụta mekanịkal injinịa: okpokolo agba na nkwado maka igwe na akụrụngwa dị arọ.

Mmụta sịvịl injinịa: dị ka nkwado ọwara, ogidi akwa na ihe ndị ọzọ na-ebu ibu.

akụrụngwa njem: gụnyere akụrụngwa maka okporo ụzọ na àkwà mmiri ụgbọ oloko.

Ngalaba ike: dịka ụlọ elu ikuku ikuku na ihe ndị ọzọ na-emepụta maka ụlọ ọrụ ike.

Anyị bụ onye na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-esi na China, nakwa onye na-emepụta ihe na-emepụta ihe na-adịghị mma, na-enye gị ihe ngwọta dị iche iche nke ígwè ígwè!

Tags: bs en 10210, en 10210,s275j2h,s275j0h,s355j2h.

Oge nzipu: Eprel-25-2024