API 5L X70 bụ ọkwa ihe API 5L maka ọkpọkọ ahịrị nwere ike mkpụrụ kacha nta nke 70,000 psi.A na-ejikarị ya eme njem dị elu nke gas, mmanụ, na mmiri.

Iji mụtakwuo maka API 5L-46th, ị nwere ikepịa ebe a!

Atụmatụ API 5L X70

Ike mkpụrụ dị elu: ike mkpụrụ kacha nta nke 70,000 psi (ihe dị ka 485 MPa), dabara maka nrụgide dị n'ime.

Ike siri ike: na-arụ ọrụ na obere okpomọkụ maka mpaghara oyi na ngwa mmiri miri emi.

Ọkachamara weldability: Ike dị elu ka ị na-ejigide weldability dị mma, yana welds dabara na njirimara nke metal ntọala.

Nguzogide corrosion: enwere ike ịkwalite ya site na njikwa ihe mejupụtara kemịkalụ na ọgwụgwọ mgbe emechara (dịka mkpuchi mkpuchi), dabara adaba maka oke osimiri na gburugburu corrosive.

Kwesịrị ekwesị maka gburugburu ebe obibi: Enwere ike ịhazi ya maka ojiji n'ime ala ọkọlọtọ, oke osimiri, na gburugburu ọrụ acid.

Njigide: Mbelata mmetụta gburugburu ebe obibi yana nkwalite mgbasa ozi dị mma dịka ihe enwere ike ịmegharị.

API Nhazi 5L X70

Ụdị ọkpọkọ: Ọkụ ígwè welded na enweghị nkebi

Ọkwa nkọwapụta ngwaahịa: API 5L X70 PSL1 na API 5L X70 PSL2

Pipe n'ichepụta usoro: SMLS, LFW, HFW, LW, SAWL, SAWH, ehi, COWH

Ụdị njedebe ọkpọkọ: Ngwunye agba agba, njedebe dị larịị

Ngwaọrụ

Ingots, billlets, billlets, ibe (coils), ma ọ bụ efere dị ka akụrụngwa maka imepụta ọkpọkọ ígwè.

Ngwa ngwa maka ọkpọkọ ígwè PSL2 ga-abụ ezigbo ọka sedimented ígwè.

Ọzọkwa, eriri igwe (coil) ma ọ bụ efere eji arụpụta ọkpọkọ ígwè PSL2 agaghị ebu welds ọ bụla.

Usoro nrụpụta ọkpọkọ API 5L X70

| Ụdị ọkpọkọ | SMLS | LFW | HFW | LW | SAWLc | SAWHd | Ehic | COWHd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | - | X | - | X | X | X | X |

cỌkpụkpọ nke nwere okpukpu abụọ dị ma ọ bụrụ na ekwenyero, mana enwere oke na ọkpọkọ nwere D ≥ 914 mm.

dHelical onuete ọkpọkọ na-ejedebeghị na ọkpọkọ na D ≥ 114.3 mm.

Ụdị ngwụcha ọkpọkọ maka API 5L X70

| Ọgwụgwụ ọkpọkọ | Nkwụsị mgbịrịgbae | Ọgwụgwụ nkịtị |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | - | X |

eỌkpụkpọ mgbanaka nwere oke na ọkpọkọ nwere D ≤219.1 mm na t≤ 3.6 mm.

Ọkwa nnyefe ikpeazụ

API 5L X70 ikpeazụ nnyefe steeti (ọgwụgwọ okpomọkụ ikpeazụ nke okokụre ígwè ọkpọkọ) nwere ike kewaa: Rolling, normalizing rolling, thermo-mechanical rolling, thermo-mechanical forming, normalizing akpụ, normalizing, normalizing na tempering ma ọ bụ quenching na tempering.

| PSL | Ọnọdụ nnyefe | Ọkwa ọkpọkọ/ọkwa ígwè | |

| PSL1 | Dị ka-akpọrela, normalizing akpọrepu, thermomechanical akpọrepu, thermomechanical kpụrụ, na-eme ka ọ dị mma, na-eme ka ọ dị mma, na-eme ka ọ dị mma ma na-ewe iwe ma ọ bụ na-emenyụ na iwe | X70 | L485 |

| PSL 2 | Emenyụ na iwe | X70Q | L485Q |

| Thermomechanical akpọrepu ma ọ bụ thermomechanical kpụrụ | X70M | L485M | |

Nkwupụta nnyefe ndị a na-ahụ na tubing API 5L X70 na-arụ ọrụ nke ọma na ngwa dị iche iche dị iche iche, dị ka iji na oke nrụgide, obere okpomọkụ, ma ọ bụ gburugburu ebe na-emebi emebi.

Ngwakọta kemịkalụ

Ihe mejupụtara API 5L X70 PSL1

Ngwakọta kemịkalụ nke API 5L X70 PSL1 ọkpọ ígwè na-agụnye carbon dị ala, manganese na-agafeghị oke, yana obere phosphorus, sọlfọ, na silicon.Tụkwasị na nke ahụ, a na-agbakwunye ihe ndị na-emepụta ihe dị ka chromium, nickel na ọla kọpa iji kwalite ike na nguzogide corrosion.Ihe ndị na-eme ka micro-alloying dị ka vanadium, molybdenum na titanium na-ebuli ịdịte aka ma na-emepụta ihe, na-eme ka arụmọrụ dị na gburugburu ebe dị egwu.

| Ihe mejupụtara kemịkalụ maka PSL 1 Pipe nwere t≤25.0 mm (0.984 in.) | |||||||||

| Ọkwa ígwè (Aha igwe) | Iberibe Mass, dabere na nyocha ọkụ na ngwaahịaag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | min | max | max | max | max | max | ||

| Pipe enweghị nkebi | |||||||||

| L485 | X70 | 0.28 | 1.40 | - | 0.03 | 0.03 | f | f | f |

| Ọkpọkpọ welded | |||||||||

| L485 | X70 | 0.26e | 1.65e | - | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50%;Ni≤0.50%;Cr≤0.50% na Mo≤0.15 %. b Maka mbelata ọ bụla nke 0.01% n'okpuru mkpokọta kachasị maka carbon, mmụba nke 0.05% n'elu ọkwa kachasị maka Mn kwere omume, ruo kacha nke 1.65% maka akara ule ≥L245 ma ọ bụ B, ma ≤L360 ma ọ bụ X52;ruo kacha nke 1.75% maka akara ule>L360 ma ọ bụ X52, mana na ihe ruru 2.00% kacha maka ọkwa L485 ma ọ bụ X70. e Ọ gwụla ma ekwetaghị f Ọ gwụla ma ekwetaghị, Nb+V+Ti≤0.15 %. g Ọnweghị ụma gbakwụnye nke B anabataghị yana nke fọdụrụ B≤0.001 %. | |||||||||

Ihe mejupụtara API 5L X70 PSL2

Ngwakọta kemịkalụ nke API 5L X70 PSL2 gụnyere carbon, manganese, sọlfọ, na phosphorus, yana oke nha nke silicon, chromium, nickel, na ọla kọpa.Njikwa elementrị siri ike ọ bụghị naanị na-akwalite ike mkpụrụ na ike nke ọkpọkọ kamakwa ọ na-eme ka nguzogide corrosion dị n'okpuru ọnọdụ dị oke egwu.Tụkwasị na nke ahụ, a na-emegharị ihe ndị dị ka vanadium, molybdenum, na titanium iji mee ka arụmọrụ dịkwuo elu, na-eme ka X70 PSL2 dị mma maka ịlụso gburugburu ebe dị ize ndụ ọgụ.

| Ihe mejupụtara kemịkalụ maka PSL 2 Pipe nwere t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| Ọkwa ígwè (Aha igwe) | Iberibe Mass, dabere na nyocha ọkụ na ngwaahịa % kacha | Carbon Dakọtaraa % kacha | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Ndị ọzọ | CEllw | CEpcm | ||

| Ọkpụkpọ enweghị nkebi na Welded | ||||||||||||

| L485Q | X70Q | 0.18 f | 0.45 f | 1.80f | 0.025 | 0.015 | g | g | g | h, I | 0.43 | 0.25 |

| Ọkpọkpọ welded | ||||||||||||

| L485M | X70M | 0.12 f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h, I | 0.43 | |

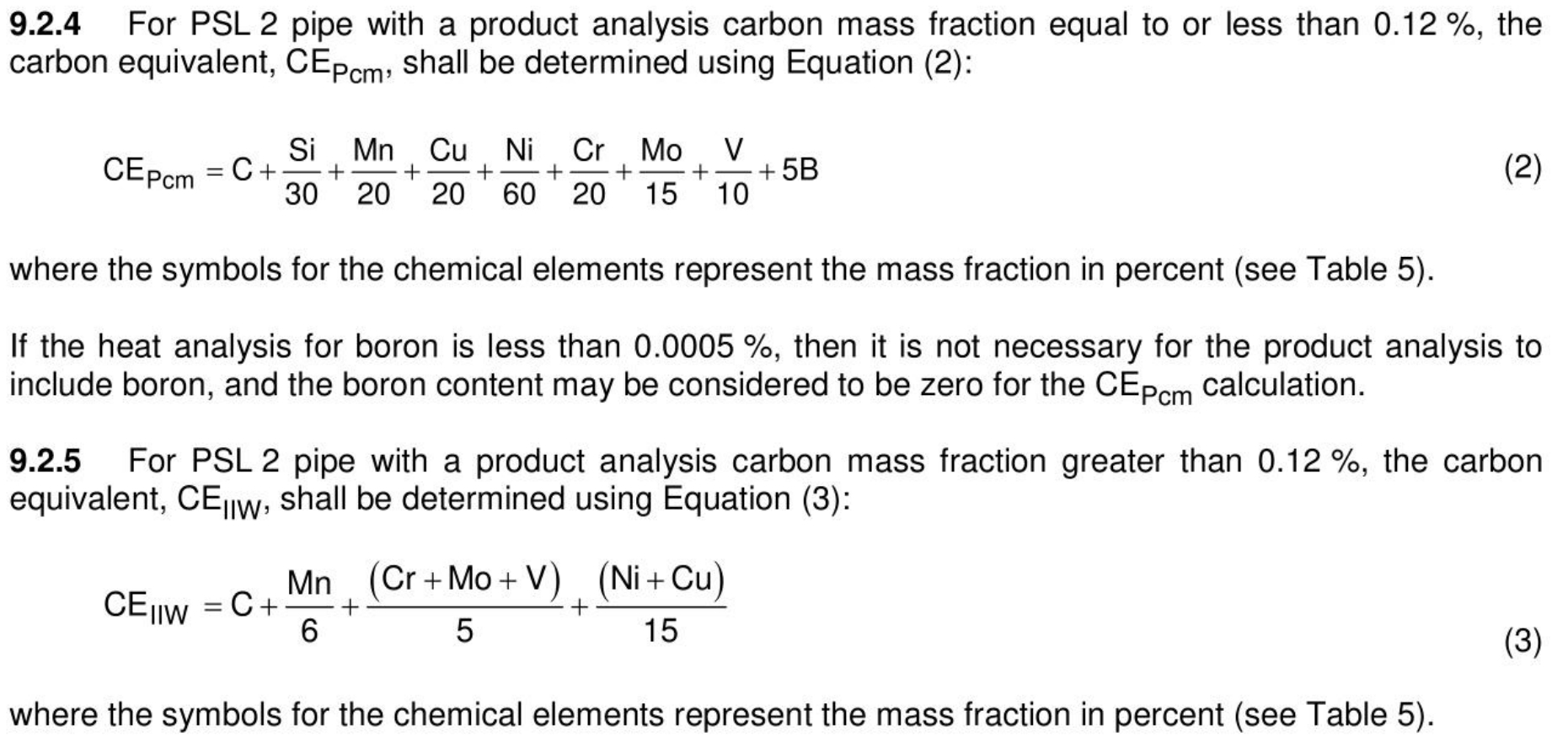

| a Dabere na nyocha ngwaahịa, maka ọkpọkọ enweghị nkebi nwere t>20.0 mm (0.787 in.), oke CE ga-adị ka ekwenyero;Oke CEllw na-emetụta ma ọ bụrụ C> 0.12%, na oke CEpcm na-emetụta ma ọ bụrụ C≤0.12%. b Maka mbelata ọ bụla nke 0.01 % n'okpuru oke akọwapụtara maka C, mmụba nke 0.05 % karịa nke akọwapụtara maka Mn na-agaghị ekwe omume, ruo na kacha nke 1.65 % maka akara ule≥L245 ma ọ bụ B, ma ≤L360 ma ọ bụ X52;ruo kacha nke 1.75% maka akara ule>L360 ma ọ bụ X52, manaL555 ma ọ bụ X80. c Ọ gwụla ma ekwetaghị, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ,Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 % na Mo≤0.15 %. f Ọ gwụla ma ekwetaghị. g Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ, Nb+V+Ti≤0.15 %. h Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ,Cu≤0.50%;Ni≤0.50%;Cr≤0.50 % na Mo≤0.50%. i Ọ gwụla ma ekwetaghị,Cu≤0.50%;Ni≤1.00%;Cr≤0.50% na Mo≤0.50% j B≤0.004 %. k Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ,Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 % na Mo≤0.80 %. l Maka akara ule PSL 2 ma ewezuga akara ule ndị akara ala j) na-etinyelarị, ihe a na-emetụta: ọ gwụla ma ekwenyeghị na mgbakwunye B≤0.001 n'amaghị ama na 5. | ||||||||||||

Ihe mejupụtara kemịkalụ maka ọnọdụ ọrụ utoojoo API 5L X70 PSL2

Ọnọdụ ọrụ utoojoo na-ezo aka karịsịa na iji pipeline na gburugburu nwere hydrogen sulfide (H₂S), nke nwere ike iduga hydrogen sulfide stress corrosion cracking (HIC) na sulfide stress corrosion cracking (SSCC).

Ndozi nke ihe mejupụtara kemịkalụ: N'okpuru ọnọdụ ndị a, a ga-edozi ihe mejupụtara kemịkalụ nke nchara pipeline nke ọma iji meziwanye nguzogide corrosion ha.Ọtụtụ mgbe, nke a na-agụnye ibelata ọdịnaya carbon nke ihe ahụ na ịgbakwunye ihe ndị na-emepụta ihe dị ka molybdenum (Mo) na nickel (Ni), nke na-eme ka nkwụsị nke corrosion na ike nke ihe ahụ dịkwuo elu.

| Tebụl H.1—Ihe mejupụtara kemịkal maka ọkpọkọ nwere t≤25.0 mm (0.984 in.) | |||||||||||

| Ọkwa ígwè | Iberibe Mass dabere na nyocha ọkụ na ngwaahịa% max | Carbon Dakọtaraa % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Ndị ọzọc,d | CEllw | CEpcm | |

| SMLS na ọkpọkọ welded | |||||||||||

| L485QS ma ọ bụ X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0,003e | 0.09 | 0.05 | 0.06 | g, m,k | 0.42 | 0.22h |

| Ọkpọkpọ welded | |||||||||||

| L485MS ma ọ bụ X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0,002e | 0.10 | 0.08 | 0.06 | g, i,j | - | 0.22 |

Enwere ike ịhụ ozi zuru ezu na API 5L Ihe mgbakwunye H.

Ngwakọta kemịkalụ nke API 5L X70 PSL2 maka ọnọdụ ọrụ Offshore

Ọnọdụ ọrụ dị n'ikpere mmiri gụnyere gburugburu mmiri, gụnyere ikpughe na mmiri nnu na ọnọdụ ihu igwe dị oke egwu.Ọnọdụ ndị a chọrọ ọkpọkọ nwere nnukwu nguzogide corrosion na ike zuru oke iji guzogide mmebi mmiri nnu na mmetụta okpomọkụ dị ala.

Ndozi nke ihe mejupụtara kemịkalụ: Maka ọrụ dị n'ụsọ osimiri, a na-abawanye alloy nke ọkpọkọ na chromium (Cr), nickel (Ni) na molybdenum (Mo) iji kwalite nguzogide ya na corrosion mmiri osimiri.Enwere ike gbanwee ọnụọgụ nke micro-alloying dị ka vanadium (V) na niobium (Nb) iji kwalite ike na obere okpomọkụ.

| Tebụl J.1—Ihe mejupụtara kemịkal maka ọkpọkọ nwere t≤25.0 mm (0.984 in.) | ||||||||||||

| Ọkwa ígwè | Iberibe Mass dabere na nyocha ọkụ na ngwaahịa max % | Carbon Dakọtara max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Ndị ọzọc | CElw | CEPC | ||

| SMLS na ọkpọkọ welded | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | e,h | 0.42 | 0.23g |

| Ọkpọkpọ welded | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | e,h | - | 0.22 |

Enwere ike ịhụ ozi zuru ezu na API 5L Ihe mgbakwunye J.

Na mgbakwunye, ihe mejupụtara kemịkalụ nke ọkpọkọ nchara maka ọnọdụ ọrụ dị n'ụsọ mmiri na API 5L X70 PSL2 bụ otu ihe achọrọ maka ọkpọkọ maka ngwa chọrọ ikike eriri ogologo ogologo.Ndị nwere mmasị nwere ike ịlele API 5L Ihe mgbakwunye N.

Ihe eji arụ ọrụ

Njirimara akụrụngwa API 5L X70 PSL1

| Tebụl 6 - Ihe ndị chọrọ maka nsonaazụ nke ule nkwụsị maka PSL 1 Pipe | ||||

| Ọkwa ọkpọkọ | Ahụ ọkpọkọ nke ọkpọkọ enweghị nkebi na welded | Weld Seam nke EW, LW, SAW, na COW Pipe | ||

| Mpụta Ikea Rka.5 MPa (psi) | Ike ọdụdọa Rm MPa (psi) | Ogologo oge (na 50 mm ma ọ bụ 2 inch) Af % | Ike ọdụdọb Rm MPa (psi) | |

| min | min | min | min | |

| L485 ma ọ bụ X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

Enwere ike ilele paramita dị iche iche na API 5L Tebụl 6.

Njirimara igwe API 5L X70 PSL2

A na-edozi tubes PSL2 maka ngwa pụrụ iche maka ihe mejupụtara kemịkalụ, mana ihe achọrọ maka akụrụngwa akụrụngwa bụ otu.

| Tebụl 7 - Ihe ndị chọrọ maka nsonaazụ nke ule nkwụsị maka PSL 2 Pipe | |||||||

| Ọkwa ọkpọkọ | Ahụ ọkpọkọ nke ọkpọkọ enweghị nkebi na welded | Weld Seam nke HFW SAW na CoW Pipe | |||||

| Mpụta Ikea Rka.5 MPa (psi) | Ike ọdụdọa Rm MPa (psi) | Okeac Rt0.5/Rm | Ogologo oge (na 50 mm ma ọ bụ 2 in.) Af % | Ịkwụsị Iked Rm MPa (psi) | |||

| min | max | min | max | max | min | min | |

| L485Q ma ọ bụ X70Q L485M ma ọ bụ X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

Enwere ike ilele paramita dị iche iche na API 5L Tebụl 7.

Ụzọ nnwale

| Udi nwale | Usoro ule |

| Ngwakọta kemịkalụ | ISO 9769 ma ọ bụ ASTM A751 |

| Ihe eji arụ ọrụ | ISO 6892-1 ma ọ bụ ASTM A370 |

| Nnwale Hydrostatic | API 5L 10.2.6 |

| Nyocha na-adịghị emebi emebi | API 5L Ihe Mgbakwunye E |

| Nnwale ịgbagọ | ISO 8491 ma ọ bụ ASTM A370 |

| Nnwale Bend eduzi | ISO 5173 ma ọ bụ ASTM A370 |

| Nnwale ire ọkụ | ISO 8492 ma ọ bụ ASTM A370 |

| Nnwale mmetụta CVN(PLS2) | ASTM A370 |

| Nnwale DWT(PSL2) | API 5L3 |

Ngwa maka API 5L X70

pipeline mmanụ: eji maka ibufe mmanụ crude ma ọ bụ ngwaahịa a nụchara anụcha, ọkachasị n'ụgbọ njem dị anya gafee mpaghara ala ma ọ bụ n'okpuru mmiri.

pipeline gas: maka nchịkọta na nkesa nke gas, gụnyere njem dị anya na gburugburu ebe nrụgide dị elu.

Ngwa nhazi: API 5L X70 ọkpọkọ na-ejikwa ya na ọrụ pụrụ iche dị ka ikpo okwu dị n'ụsọ osimiri ma ọ bụ ihe nkwado dị elu.

Ngwa ụlọ ọrụ: Usoro njem mmiri mmiri na osisi kemịkalụ, ụlọ nrụpụta, wdg.

Ebe eji eme ihe pụrụ iche: Nguzogide corrosion nke API 5L X70 ígwè ọkpọkọ na-eme ka ọ dị mma maka ojiji na gburugburu ebe dị iche iche pụrụ iche, karịsịa na ọnọdụ acidic na nke dịpụrụ adịpụ.

Ngwaahịa Anyị emetụtara

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Carbon Steel Pipe

Nhazi ngwụcha ọkpọkọ

Ịcha ọkpọkọ

Ihe mkpuchi mgbochi corrosion: galvanized, esere, 3PE, FBE, wdg.

Anyị bụ otu n'ime ndị na-eduzi welded carbon steel pipe na ndị na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na ndị na-ebubata ya site na China, na-eji ihe dị iche iche nke ígwè dị elu dị elu na ngwaahịa, anyị na-agba mbọ inye gị ihe ngwọta zuru oke nke ígwè ígwè.Maka nkọwa ngwaahịa ndị ọzọ, biko nweere onwe gị ịkpọtụrụ anyị, anyị na-atụ anya inyere gị aka ịchọta nhọrọ ọkpọkọ ígwè kacha mma maka mkpa gị!

Tags: X70, API 5l x70, ai 5l, suppliers, emepụta, ụlọ ọrụ, stockists, ụlọ ọrụ, N'ogbe, ịzụrụ, price, nhota, nnukwu, maka ire ere, na-eri.

Oge nzipu: Eprel-14-2024