ASTM A333maka ọkpọkọ igwe anaghị agba nchara na welded;

A na-eji ASTM A333 maka ọrụ obere okpomọkụ yana ngwa ndị ọzọ chọrọ ike siri ike.

Bọtịnụ igodo nsoroụzọ

ASTM A333 Ọkwa na Okpomọkụ Ọrụ kacha nta

Ọgwụgwọ okpomọkụ

Nnwale ASTM A333

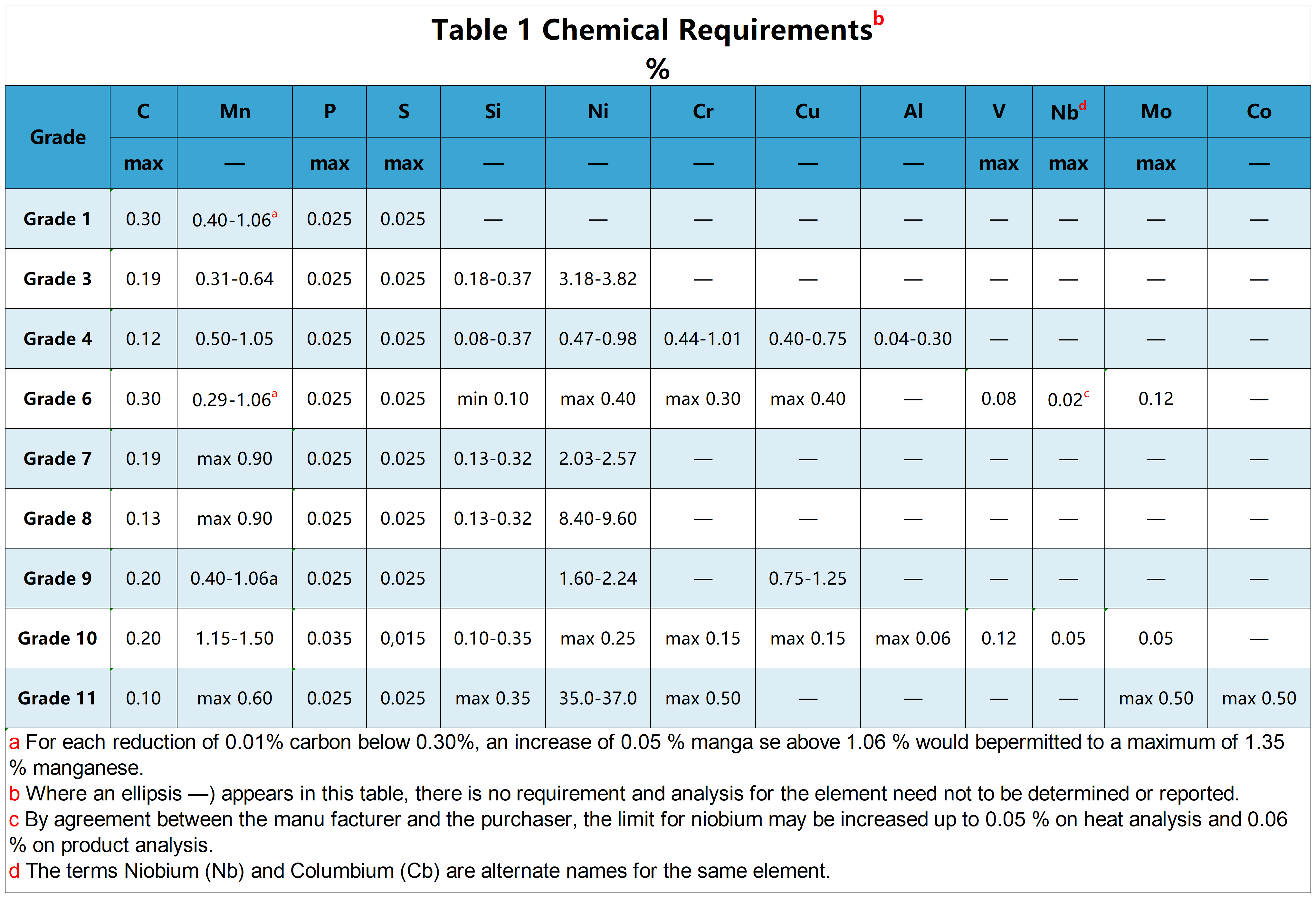

Ngwa kemịkalụ

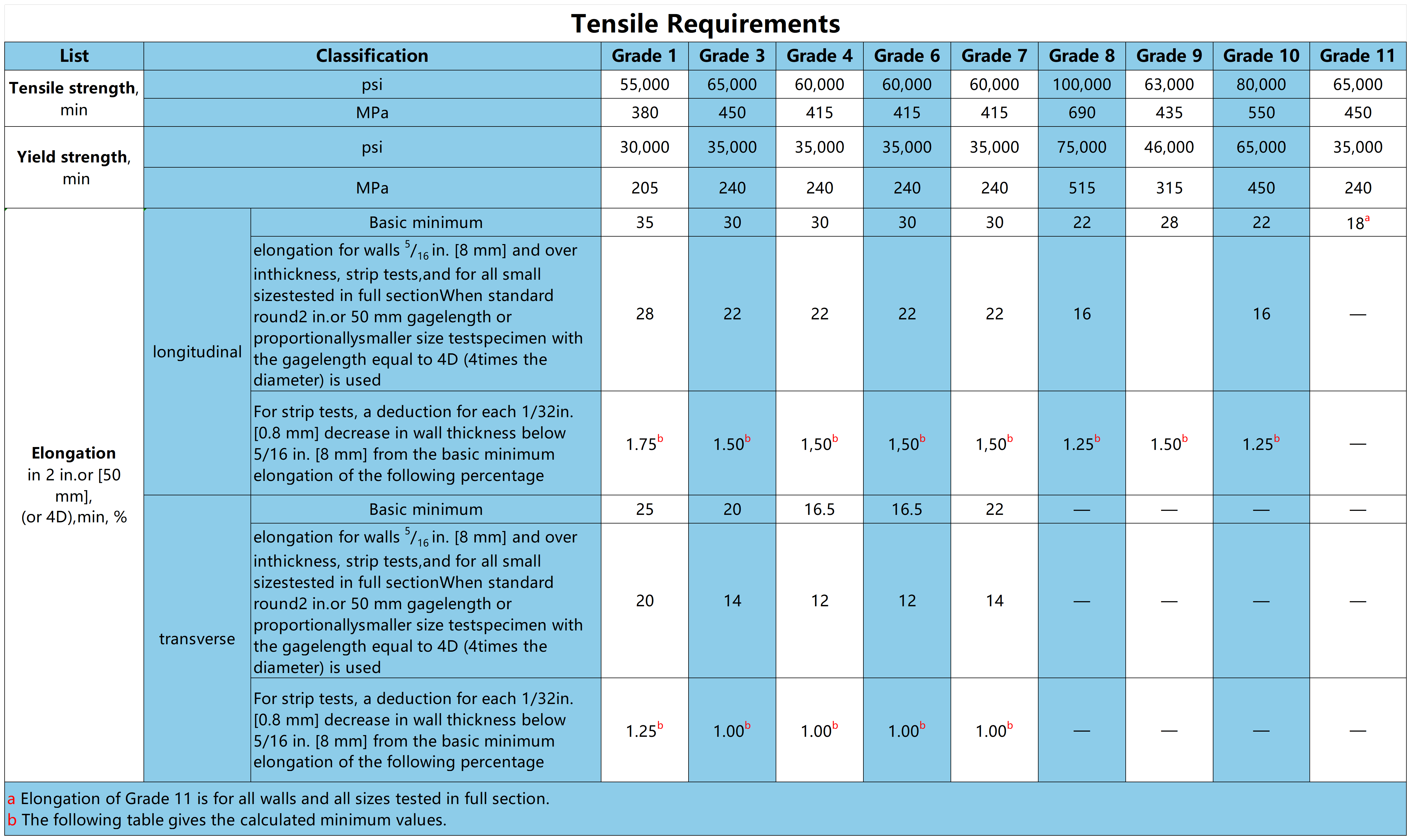

Chọrọ tensile

Nnwale mmetụta

Ule eletriki Hydrostatic ma ọ bụ Nodestructive

ASTM A333 nha na ngbanwe

Dayameta dị n'èzí

Ọkpụrụkpụ mgbidi

Ibu

Ogologo, kwụ ọtọ na njedebe

Mmejọ na njikwa

ASTM A333 akara

Ụkpụrụ ASTM A333 dị mkpa

ASTM A333 Ọkwa na Okpomọkụ Ọrụ kacha nta

ASTM A333Nkeji 1:-50°F (-45°C)

ASTM A333Nkeji 3:-150°F (-100°C)

ASTM A333Nkeji 4:-150°F (-100°C)

ASTM A333Nkeji 6:-50°F (-45°C)

ASTM A333Nkeji 7:-100°F (-75°C)

ASTM A333Nkeji 8:-320°F (-195°C)

ASTM A333Nkeji 9:-100°F (-75°C)

ASTM A333Nkeji 10:-75°F (-60°C)

ASTM A333Nkeji 11:-320°F (-195°C)

Mara: ASTM A333 Grade 4 nwere ike ịbụ naanị tubes enweghị nkebi.

Enwere ike imepụta ọkpọkọ ASTM A333 Grade 11 site na ịgbado ọkụ yana ma ọ bụ na-enweghị mgbakwunye nke ọla filler.

Ọgwụgwọ okpomọkụ

Ntụaka na ASTM A333 Nkebi 4.3.

Nnwale ASTM A333

Ngwa kemịkalụ

Chọrọ tensile

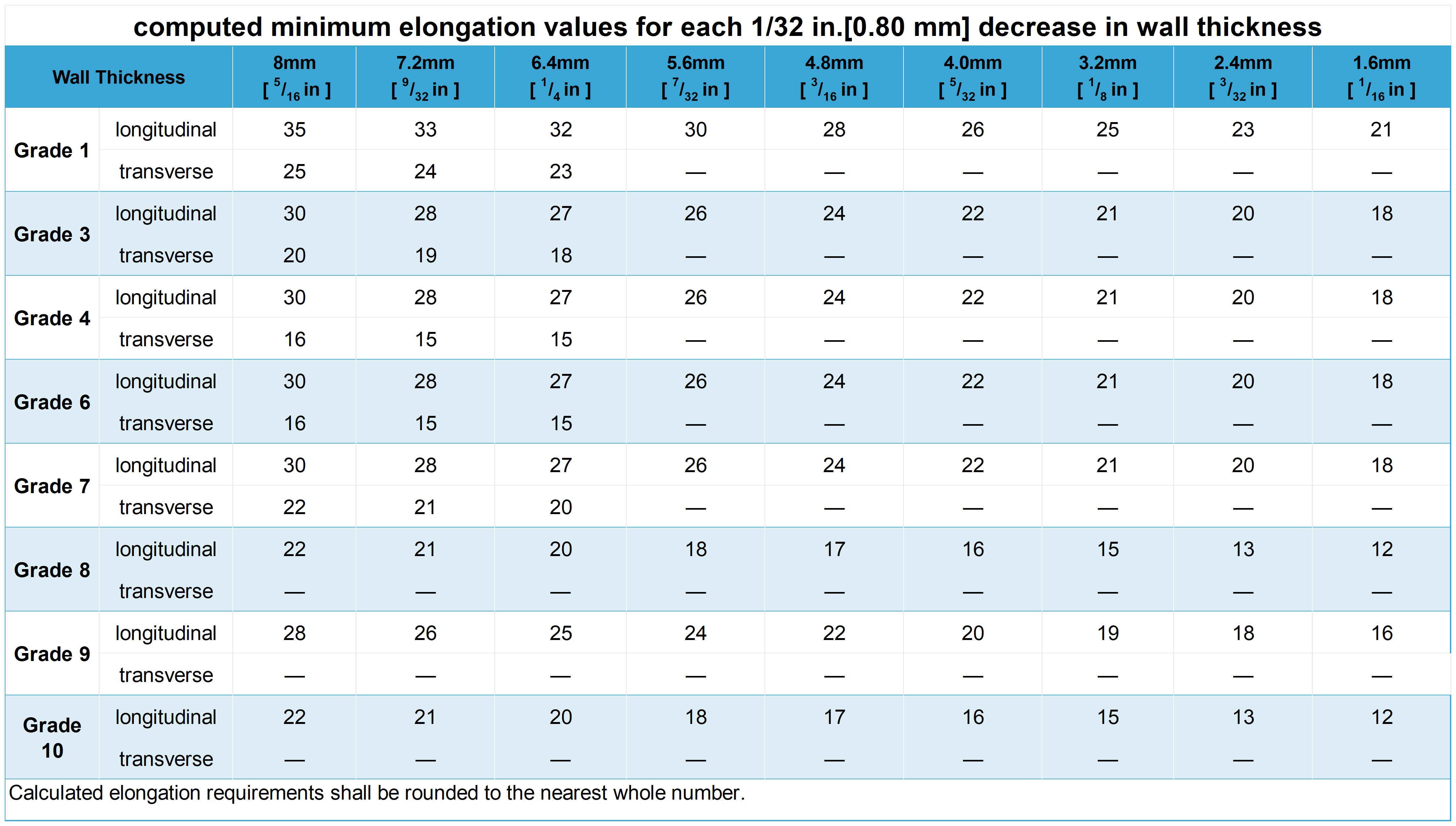

ASTM A333na-akọwapụtakwa uru elongation kacha nta maka mbelata 1/32 inch (0.80 mm) ọ bụla na ọkpụrụkpụ mgbidi.

Nnwale mmetụta

| Ihe achọrọ mmetụta TABLE 3 maka klaasị 1, 3, 4, 6, 7, 9, 10, na 11 | ||||

| Nha ihe atụ, mm | Uru Mmetụta Ogwe Opekempe kacha nta nke Ntụpọ atọ nke ọ bụla | Uru Mbelata Mmetụta Opekempe nke Otu ihe atụ naanị nke Ntọala | ||

| ft.lbf | J | ft.lbf | J | |

| 10 nke 10 | 13 | 18 | 10 | 14 |

| 10 site na 7.5 | 10 | 14 | 8 | 11 |

| 10 site na 6.67 | 9 | 12 | 7 | 9 |

| 10 nke 5 | 7 | 9 | 5 | 7 |

| 10 site na 3.33 | 5 | 7 | 3 | 4 |

| 10 site na 2.5 | 4 | 5 | 3 | 4 |

Ule eletriki Hydrostatic ma ọ bụ Nodestructive

Ule ule: ASTM A999/A999M.

A ga-edobe ọkpọkọ ọ bụla na ule eletrik na-adịghị emebi emebi ma ọ bụ ule hydrostatic.

ASTM A333 nha na ngbanwe

Dayameta dị n'èzí

| Tebụl 3 Mmetụta mmetụta chọrọ maka klaasị 1, 3, 4, 6, 7, 9, 10, na 11 | ||||

| Nha ụdịdị, mm | Uru Mmetụta Ogwe Opekempe kacha nta nke Ntụpọ atọ nke ọ bụla | Uru Mbelata Mmetụta Opekempe nke Otu ihe atụ naanị nke Ntọala | ||

| ft.lbf | J | ft.lbf | J | |

| 10 nke 10 | 13 | 18 | 10 | 14 |

| 10 site na 7.5 | 10 | 14 | 8 | 11 |

| 10 site na 6.67 | 9 | 12 | 7 | 9 |

| 10 nke 5 | 7 | 9 | 5 | 7 |

| 10 site na 3.33 | 5 | 7 | 3 | 4 |

| 10 site na 2.5 | 4 | 5 | 3 | 4 |

Ọkpụrụkpụ mgbidi

| Ndịiche ekwenyere na ọkpụrụkpụ mgbidi | ||

| ụdị | Ndịiche ekwenyere na ọkpụrụkpụ mgbidi | Ndịiche anabatara na ịdị arọ mgbidi maka obere mgbidi |

| 1/8 [DN 6] ruo 2 1/2[DN 65] gụnyere, niile t/D ruru | 87.5% ~ 120% | 100% ~ 132.5% |

| 3 [DN 80] ruo 18 [DN 450] gụnyere, t/D ruo 5% gụnyere. | 87.5% ~ 122.5% | 100% ~ 135% |

| 3 [DN 80] ruo 18 [DN 450] gụnyere, t/D> 5% gụnyere. | 87.5% ~ 115% | 100% ~ 127.5% |

| 20 [DN 500] na ibu, welded, niile t/D ruru | 87.5% ~ 117.5% | 100% ~ 130% |

| 20 [DN 500] na ibu, enweghị nkebi, t/D ruo 5% gụnyere. | 87.5% ~ 122.5% | 100% ~ 135% |

| 20 [DN 500] na ibu, enweghị nkebi, t/D>5% | 87.5% ~ 115% | 100% ~ 127.5% |

Ibu

Tebụl dị arọ na nhazi oge maka akọwapụtara n'èzí dayameta yana ọkpụrụkpụ mgbidi akọwapụtara maka iji ọkpọkọ ígwèASME B36.10.

Ogologo, kwụ ọtọ na njedebe

| Ndepụta | Hazie | Oke |

| Ogologo a | Ogologo ≤ 24 ft [7.3m] | 1/4 nke anụ ọhịa [6mm] |

| Ogologo: 24 ft (7.3m) | nkwekọrịta | |

| Izi ezi | Ọkụ emechara ga-abụ nke ziri ezi kwụ ọtọ. | |

| Akwụsị | Ọ gwụla ma akọwapụtara n'ụzọ ọzọ, a ga-eji ọkpọkọ rụọ ya. A ga-ewepụ ihe niile burrs na nsọtụ ọkpọkọ. | |

| a Ọ bụrụ na achọrọghị ogologo ogologo. 1. nye iwu otu ogologo ọkpọkọ na-enweghị usoro site na 16 ruo 22 ụkwụ, na oke nke 5% nke ogologo n'etiti 12 na 16 ụkwụ; 2. Nye iwu ogologo ọkpọkọ na-enweghị usoro okpukpu abụọ nwere opekempe ogologo nke 35 ụkwụ yana ogologo kacha nta nke 22 ụkwụ, yana oke 5% nke ogologo n'etiti 16 na 22 ụkwụ. | ||

Mmejọ na njikwa

Mmejọ

A ga-ewere ezughị okè dị n'elu nke na-abanye karịa 12% nke ọkpụrụkpụ mgbidi ọnụ ma ọ bụ karịa opekempe mgbidi dị ka ntụpọ,

na ntụpọ anya hụrụ na ọ karịrị 5% dị omimi karịa ọkpụrụkpụ mgbidi ọnụ ka a na-akpọkarị skabs, seams, laps, anya mmiri, ma ọ bụ iberi.

Ijikwa ntụpọ

Enwere ike ikpochapụ ntụpọ site n'igweri, ma ọ bụrụhaala na ọkpụrụkpụ mgbidi fọdụrụ n'ime oke a kapịrị ọnụ ma na-edobe elu gbagọrọ agbagọ.

Enwere ike belata akụkụ nke ọkpọkọ nwere ntụpọ n'ime oke ogologo achọrọ.

ASTM A333 akara

Aha ma ọ bụ akara onye nrụpụta, nọmba nkọwapụta (afọ nke mbipụta anaghị achọ), yana ọkwa kwesịrị ka achọpụtara nke ọma.

O kwesịkwara ịgụnye okpomọkụ nke a na-eme nyocha mmetụta mgbe arụ ọrụ ọkụ gasịrị, eserese oyi, enweghị nkebi ma ọ bụ welded, nọmba mmemme, na mkpụrụedemede "LT".

A ga-amalite akara n'ihe dịka sentimita 300.

Maka ọkpọkọ na-erughị NPS 2 na ọkpọkọ na-erughị otu mita n'ogologo, a pụrụ ịkanye ozi achọrọ n'ihe e debere n'ùkwù ma ọ bụ igbe a na-ebufe ọkpọkọ ahụ.

Ụkpụrụ ASTM A333 dị mkpa

TS EN 10216-4 ọkọlọtọ European na-ekpuchi ọnọdụ teknụzụ maka tubes na-abụghị alloyed na alloyed maka ọrụ cryogenic.

TS EN ISO 9329-3 International Organisation for Standardization Standard maka tubes steel enweghị nkebi maka ọrụ cryogenic.

TS EN 10216-4 ọkọlọtọ European nke Germany nakweere, yiri EN 10216-4 maka ọkpọkọ igwe anaghị agba nchara maka ebumnuche nrụgide na ọrụ cryogenic.

JIS G3460: Alloy ígwè tubes maka ọrụ cryogenic.

GB/T 18984: Igwe nchara na-enweghị nkebi maka ọrụ cryogenic si -45°C ruo -195°C.

BS 3603: Carbon na alloy ígwè tubes emebere maka ọrụ cryogenic.

CSA Z245.1: Standard maka tubes ígwè na ọkpọkọ nke Canadian Standards Association mepụtara, gụnyere nkọwa maka ojiji na ọrụ cryogenic.

GOST 8731: tubes ígwè na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na ọkpọkọ maka ọrụ cryogenic.

Botop Steel bụ onye China Ọkachamara Welded Carbon Steel Pipes Manufacturer & Onye na-eweta ihe karịrị afọ 16 nwere 8000+ tọn nke Linepipe enweghị nkebi na ngwaahịa kwa ọnwa.

Anyị nwere ike inye gị ezigbo mma na ọnụ ala carbon ígwè ọkpọkọ ngwaahịa, na-enye gị ọtụtụ ụdị ígwè ọkpọkọ ngwọta, Ọ bụrụ na ị nwere ihe ọ bụla chọrọ, biko kpọtụrụ anyị!

mkpado: astm A333, astm a333 ọkwa, astmA333 ọkwa 6,suppliers, emepụta, ụlọ mmepụta ihe, stockists, ụlọ ọrụ, N'ogbe, ịzụrụ, price, nhota, nnukwu, maka ire ere, efu.

Oge nzipu: Mar-28-2024