JIS G 3444 ígwè ọkpọkọbụ ọkpọkọ carbon nchara arụpụtara site na usoro enweghị nkebi ma ọ bụ welded, nke a na-ejikarị na injinia obodo na ihe owuwu.

Bọtịnụ igodo nsoroụzọ

Oke Oke

Ebumnuche izugbe n'obosara elu: 21.7-1016.0mm;

Okpokoro ntọala na ikpo maka mkpochapụ ala OD: n'okpuru 318.5mm.

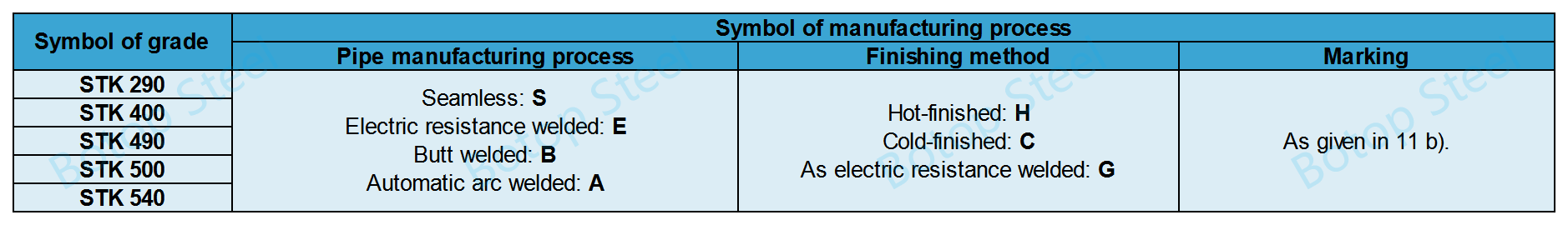

JIS G 3444 Usoro nrụpụta

A ga-emepụta tubes site na nchikota nke usoro mmepụta tube na usoro njedebe nke egosiri.

Enwere ike ịgwọ tubes nke ọma okpomọkụ ma ọ bụrụ na achọrọ ya.

Ọ bụrụ na onye na-azụ ahịa chọrọ, enwere ike ịmepụta ọkpọkọ site na mpempe akwụkwọ nchara ma ọ bụ ihe mkpuchi nchara. N'okwu a, ụdị mkpuchi na ịdị mma nke mkpuchi ga-agbaso ihe ndị JIS G 3444 chọrọ, Ihe Mgbakwunye A.

Ụdị ihe mkpuchi nke nwere ike itinye ya bụ mkpuchi zinc na-ekpo ọkụ, mkpuchi zinc electrolytic, mkpuchi aluminum na-ekpo ọkụ, ihe mkpuchi na-ekpo ọkụ na-ekpo ọkụ-5% aluminum alloy cover, hot-dip 55% aluminum-zinc alloy cover, ma ọ bụ na-ekpo ọkụ zinc-aluminium-magnesium alloy mkpuchi.

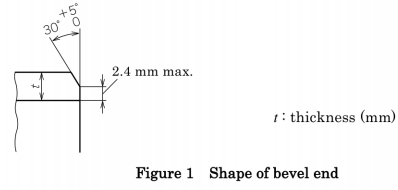

Ụdị njedebe tube

Ngwunye ọkpọkọ ígwè ga-adị larịị.

Ọ bụrụ na a na-achọ ka a na-edozi ọkpọkọ ahụ n'ime njedebe nke beveled, akụkụ nke bevel bụ 30-35 °, obosara nke oghere nchara nchara: bụ max 2.4mm.

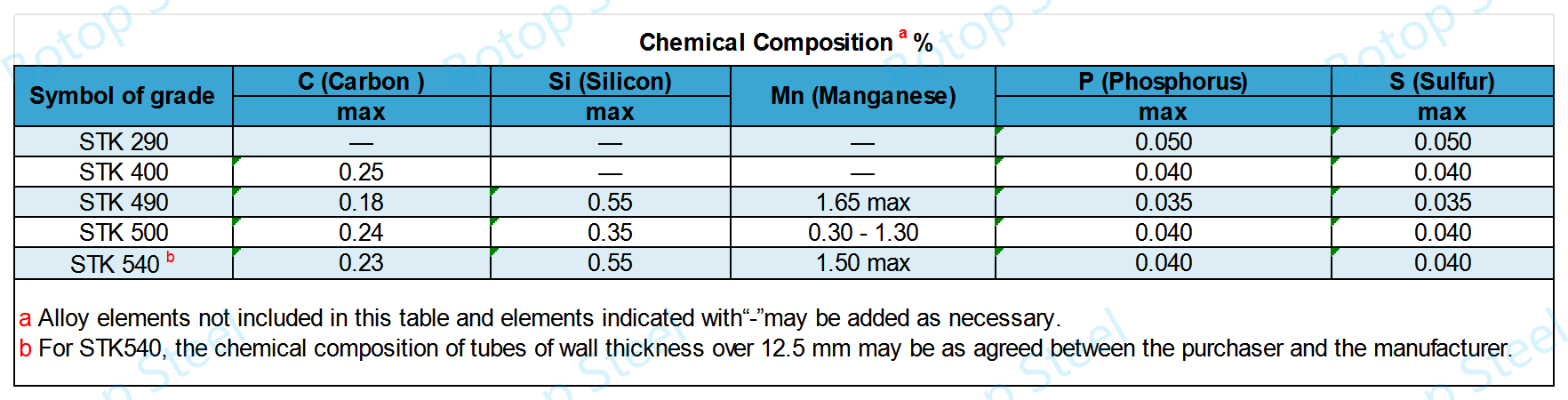

Ngwakọta kemịkalụ nke JIS G 3444

Usoro nyocha nke okpomọkụ ga-adị ka ihe achọrọ na JIS G 0320.

Usoro nyocha ngwaahịa ga-adị ka ihe achọrọ na JIS G 0321.

Ngwongwo igwe nke JIS G 3444

Ihe achọrọ maka nnwale igwe ga-adị na ngalaba 7 na 9 nke JIS G 0404.

Agbanyeghị, usoro nlele maka nnwale igwe ga-adaba n'ihe achọrọ nke klaasị A na ngalaba 7.6 nke JIS G 0404.

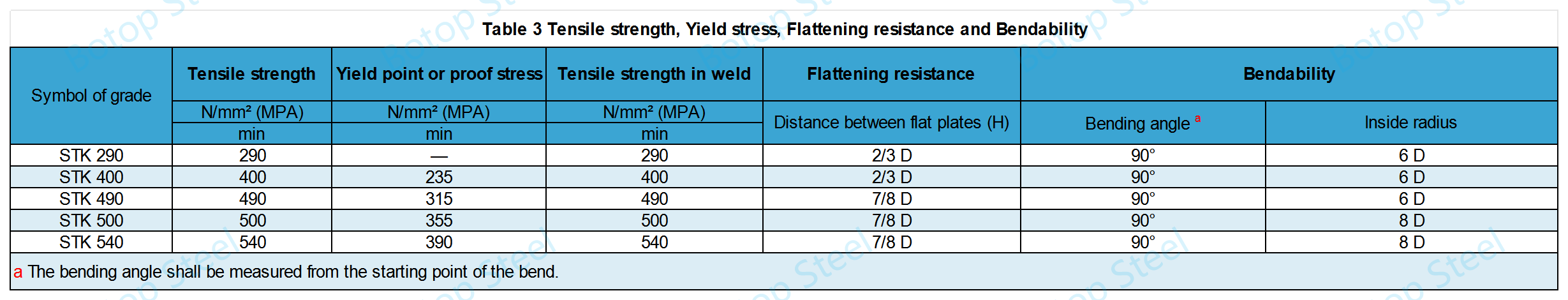

Ike tensile na ihe mpụta ma ọ bụ ihe mgbakasị ahụ

Ike tensile na ebe mkpụrụ ma ọ bụ ihe mgbakasị mgbanaka yana ike tensile na weld ga-eju ụkpụrụ akọwapụtara na Tebụl 3.

Ike ike nke weld na-adabara na tubes welded arc akpaka.

Ike nke weld bụ otu ihe achọrọ maka ahụ ọkpọkọ. Akụkụ welded na-abụkarị njikọ na-adịghị ike na nhazi ahụ, ya mere inwe otu ike nkwụsị ahụ na-eme ka a ghara ịdabere na nhazi nke welded.

Tebụl 3 nwekwara ihe dị anya chọrọ maka nguzogide Flattening na ihe ndị a chọrọ maka akụkụ bend na radius na-ehulata na njedebe bendability.

Ogologo oge

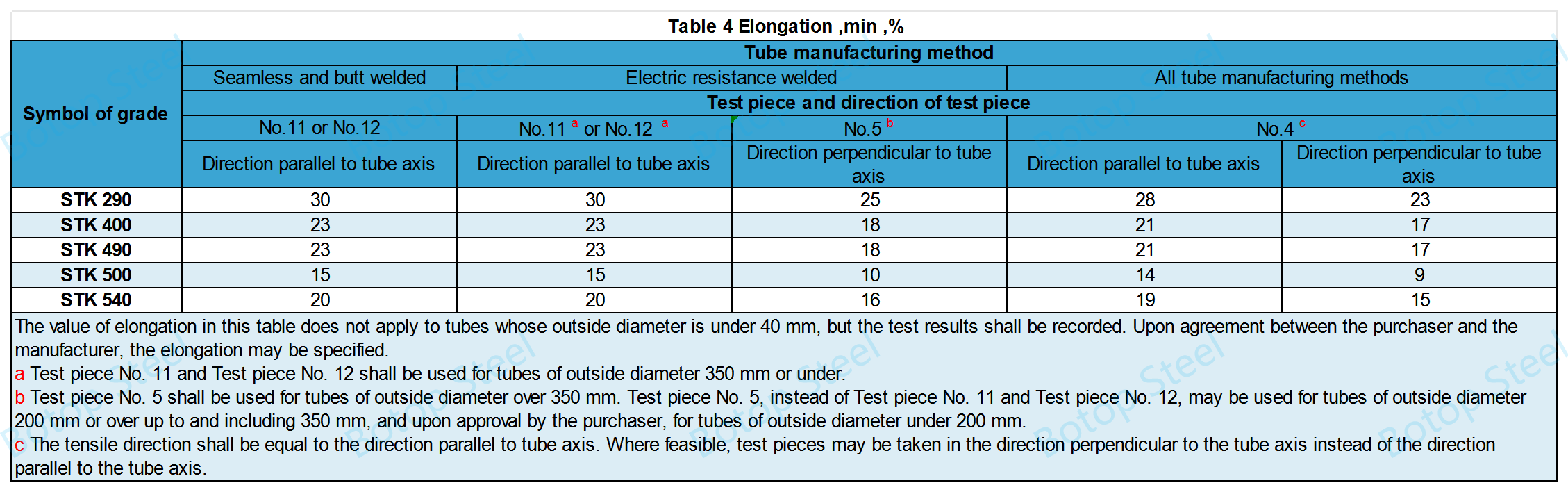

E gosipụtara elongation kwekọrọ na usoro nrụpụta tube na tebụl 4.

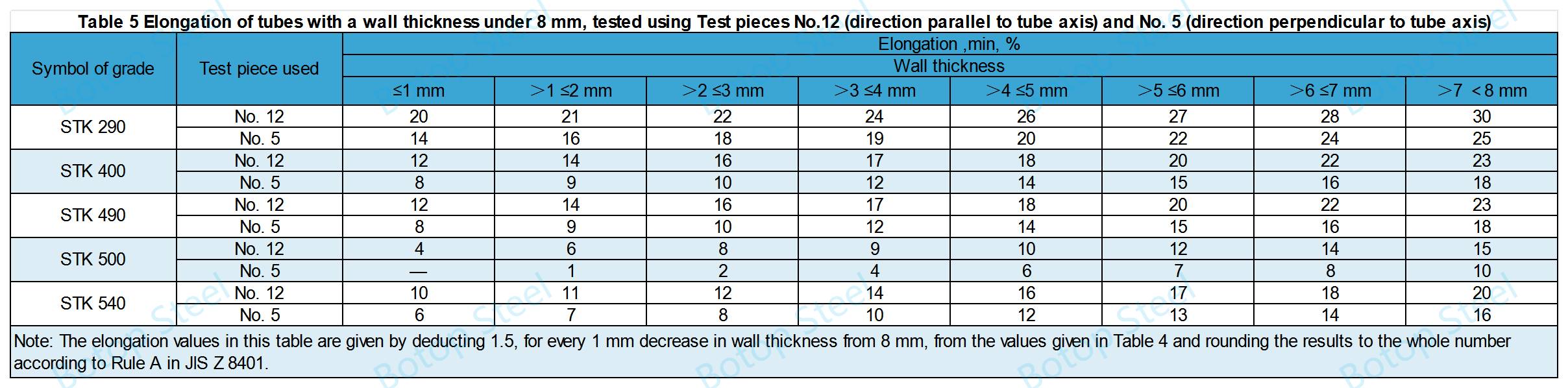

Otú ọ dị, mgbe a na-eme ule nkwụsịtụ na Nnwale Nleba Nleba 12 ma ọ bụ Nnwale Nleba nke 5 nke e si na tube n'okpuru 8 mm na mgbidi mgbidi, elongation ga-adị na tebụl 5.

Nguzogide ire ụtọ

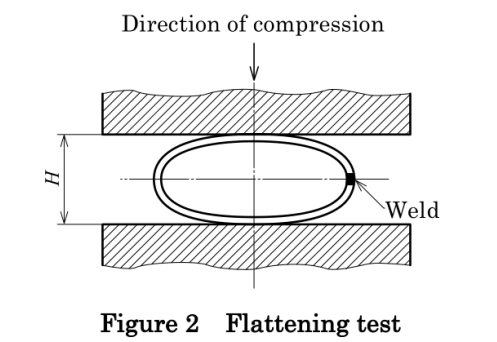

Debe ihe nlele ahụ na okpomọkụ nkịtị (5 Celsius C ruo 35 Celsius) n'etiti efere abụọ dị larịị ma pịgharịa ka ọ gbasaa ruo mgbe ebe dị n'etiti efere H ga-adaba ma ọ bụ dị ntakịrị karịa uru akọwapụtara na Tebụl 3, wee nyochaa maka mgbawa na mpempe ule.

Debe welds nke iguzogide welded ígwè ọkpọkọ na butt welded ígwè ọkpọkọ nke mere na akara n'etiti etiti ọkpọkọ na weld bụ perpendicular na ntụziaka nke mkpakọ.

Bend Test

Tụgharịa mpempe ule ahụ gburugburu cylinder na okpomọkụ nkịtị (5 Celsius C ruo 35 Celsius) n'akụkụ nkuku na-ehulata ọ bụghị ihe na-erughị opekempe na-ehulata nke akọwapụtara na Tebụl 3, yana n'ime radius n'ime radius na-adịghị karịa nke kachasị n'ime radius akọwapụtara na Tebụl 3, wee nyochaa mpempe ule maka mgbawa.

N'ihi na-anwale eletriki na-eguzogide welded ígwè tube na butt-welded ígwè tube, tinye ule ibe dị otú ahụ weld bụ 90 Celsius C si mpụta ọnọdụ nke ekwe.

Nlele ndị ọzọ

Nnwale hydrostatic, ule na-adịghị emebi emebi nke weld, ma ọ bụ ule ndị ọzọ ka a ga-ekwenye tupu oge eruo na ihe ndị dị mkpa.

Okpokoro ibu ibu nke JIS G 3444

Ngụkọta ọnụ ọgụgụ ígwè ọkpọkọ

W=0.02466 t (Dt)

W: unit uka nke tube (kg/m)

t: mgbidi ọkpụrụkpụ nke tube (mm)

D: n'èzí dayameta nke tube (mm)

0,02466: ihe ngbanwe otu maka inweta W

Usoro a dabere n'eziokwu na njupụta nke ígwè bụ 7.85 g / cm³.

Nlere anya akụkụ nke JIS G 3444

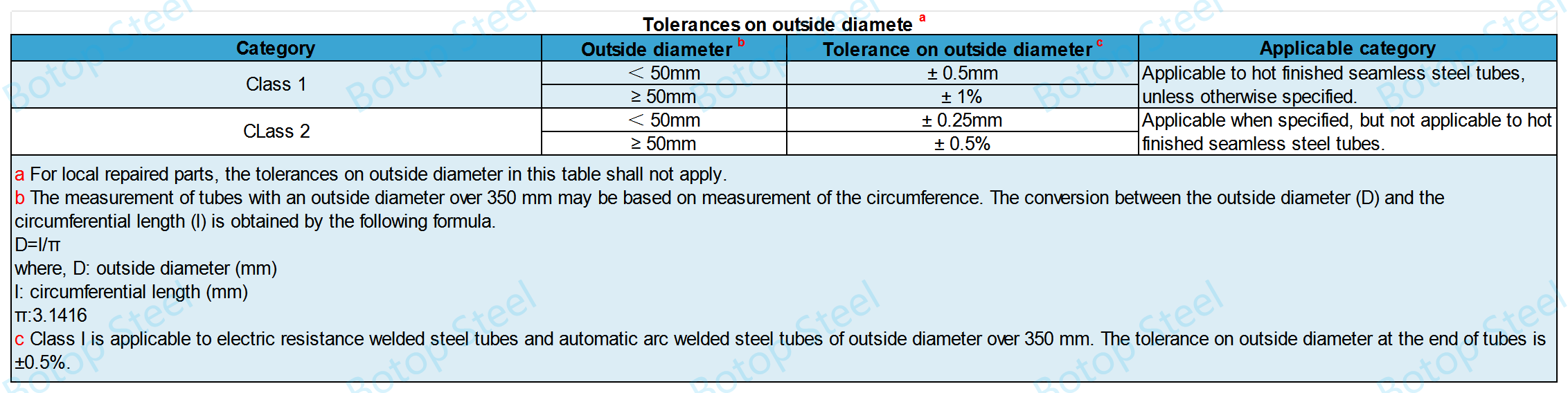

Ntachie dayameta n'èzí

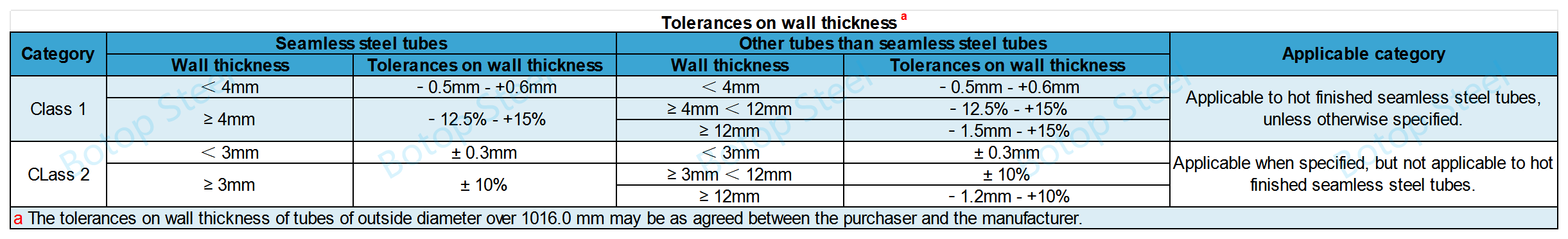

Nlegide Ọkpụrụkpụ mgbidi

Ogologo ndidi

Nkwenye nke ogologo nke ọkpọkọ ígwè, nkwụsị na-adịghị mma bụ efu, nkwụsị dị mma adịghị mkpa n'ụzọ doro anya, onye na-azụ ahịa na onye na-emepụta ihe na-ekpebi site na nkwekọrịta nkwekọrịta.

Ọdịdị

Ihe dị n'ime na mpụga nke ọkpọkọ ígwè ga-adị mma na enweghị ntụpọ na-adịghị mma iji.

A na-etinye ihe mkpuchi mgbochi corrosion dị ka ihe mkpuchi zinc-ọgaranya, mkpuchi epoxy, mkpuchi agba, wdg nwere ike tinye ya na mpụga ma ọ bụ n'ime.

Ịka akara

A ga-edobe ọkpọkọ ígwè ọ bụla na ozi ndị a.

a)Akara ọkwa.

b) Akara maka usoro nrụpụta.Akara maka usoro nrụpụta ga-abụ nke a. Enwere ike iji oghere dochie nhịahụ.

1) Ọkụ nchara na-ekpo ọkụ mechaa: -SH

2) Oyi mechapụrụ enweghị nkebi ígwè tube: -SC

3) Dị ka ọkụ eletrik na-eguzogide welded ígwè tube: -EG

4) Igwe ọkụ eletrik na-ekpo ọkụ na-ekpo ọkụ welded ígwè tube: -EH

5) Oyi mechapụrụ ọkụ eletrik na-eguzogide welded ígwè tube: -EC

6) butt-welded ígwè tubes -B

7) Akpaaka arc welded ígwè tubes -A

c) Akụkụ.A ga-akara dayameta dị n'èzí na ọkpụrụkpụ mgbidi.

d) Aha onye nrụpụta ma ọ bụ ndebiri.

Mgbe akara na tube siri ike n'ihi na dayameta dị n'èzí dị ntakịrị ma ọ bụ mgbe onye zụrụ ya rịọrọ ya, enwere ike ịnye akara ahụ na ngwugwu tubes ọ bụla site na ụzọ dabara adaba.

Ụzọ dị ka iji akara, wdg.

Ngwa JIS G 3444

A na-eji ha maka injinia obodo na ihe owuwu dị ka ụlọ elu igwe, ihe mkpuchi, ikpo ụkwụ, ikpo ntọala, na ikpo maka mkpochapụ ala.

Ụkpụrụ emetụtara

JIS G 3452: Na-akọwapụta ọkpọkọ nchara carbon maka ebumnuche izugbe (dị iche na ebumnuche nhazi yana itinye uche na mbufe mmiri ma ọ bụ gas).

JIS G 3454: Na-akọwapụta ụkpụrụ maka ọkpọkọ ígwè carbon maka ọkpọkọ nrụgide.

ASTM A500: ekpuchi oyi-kpụrụ welded na enweghị nkebi carbon ígwè structural tubes na yiri JIS G 3444 na ụfọdụ nke ya chọrọ.

EN 10219: Na-ekpuchi akụkụ oghere welded emebere oyi maka ebumnuche nhazi, gụnyere gburugburu, square, na profaịlụ akụkụ anọ.

Uru anyị

Ebe ọ bụ na e guzobere ya na 2014, Botop Steel aghọwo onye na-ebute ụzọ nke ọkpọkọ carbon ígwè na Northern China, mara maka ọrụ magburu onwe ya, ngwaahịa dị elu, na ngwọta zuru oke.

Ụlọ ọrụ ahụ na-enye ụdị ọkpọkọ carbon carbon dị iche iche na ngwaahịa ndị metụtara ya, gụnyere enweghị nkebi, ERW, LSAW, na SSAW ọkpọkọ ígwè, yana nchịkọta zuru ezu nke ọkpọkọ na flanges.

Ngwaahịa ya ọpụrụiche gụnyekwara alloys dị elu na igwe anaghị agba nchara austenitic, ahaziri iji gboo ihe achọrọ nke ọrụ pipeline dị iche iche.

Tags: jis g 3444, carbon ígwè ọkpọkọ, stk, ígwè tube, Ọdịdị anwụrụ.

Oge nzipu: Mee-10-2024