ISO 21809-1 applies to buried or submerged pipeline systems in the oil and gas industry and specifies the requirements for the external corrosion protection coatings 3LPE and 3LPP for welded and seamless steel pipes.

There are three classes of surfacing materials, depending on the type of surfacing material:

A: LDPE (low-density polyethylene);

B: MDPE/HDPE (medium-density polyethylene)/(high-density polyethylene);

C: PP (Polypropylene).

The density requirements for each material are described in detail in the following subsection on the requirements for the three raw materials.

| Coating class | Top layer material | Design temperature (°C) |

| A | LDPE | -20 to + 60 |

| B | MDPE/HDPE | -40 to + 80 |

| C | PP | -20 to + 110 |

The coating system shall consist of three layers:

1st layer: epoxy(liquid or powder);

2nd layer: adhesive;

3rd layer: PE/PP top layer applied by extrusion.

If required, a rough coat can be applied to increase slip resistance. Especially where improved grip and reduced risk of sliding are required.

Epoxy Resin Layer Thickness

Maximum 400 um

Minimum: Liquid epoxу: minimum 50um; FBE: minimum125um.

Adhesive Layer Thickness

Minimum 150um on pipe body

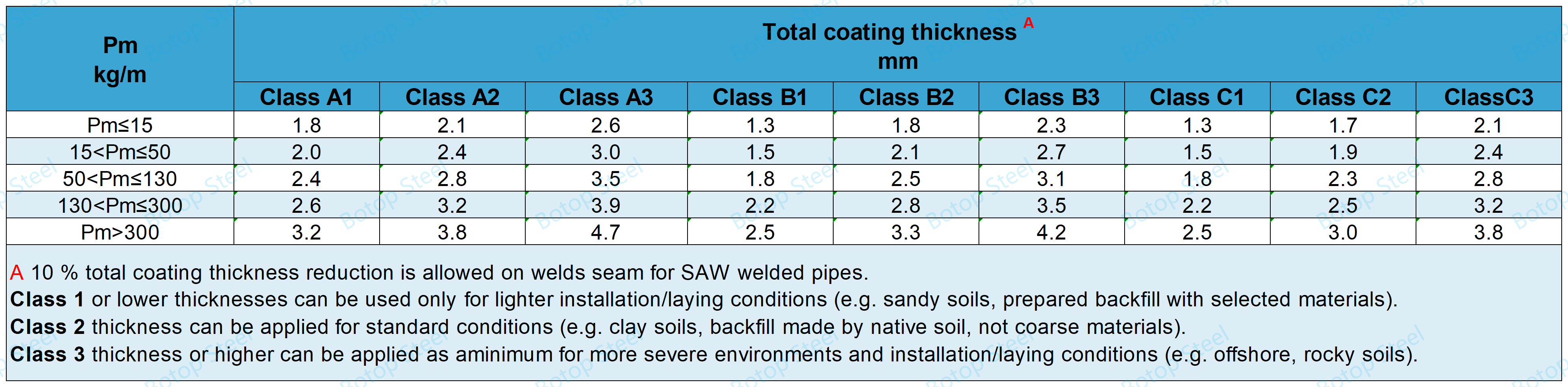

Total Coating Thickness

The thickness level of the anti-corrosion layer is changed with the site load and the pipe's weight, and the anti-corrosion layer's thickness level should be selected according to the construction conditions, pipe laying method, use conditions, and pipe size.

Pm is the weight of the steel pipe per meter.

which can be queried by consulting the corresponding weight table of the steel pipe standard, or by the formula:

Pm=(D-T)×T×0.02466

D is the specified outside diameter, expressed in mm;

T is the specified wall thickness, expressed in mm;

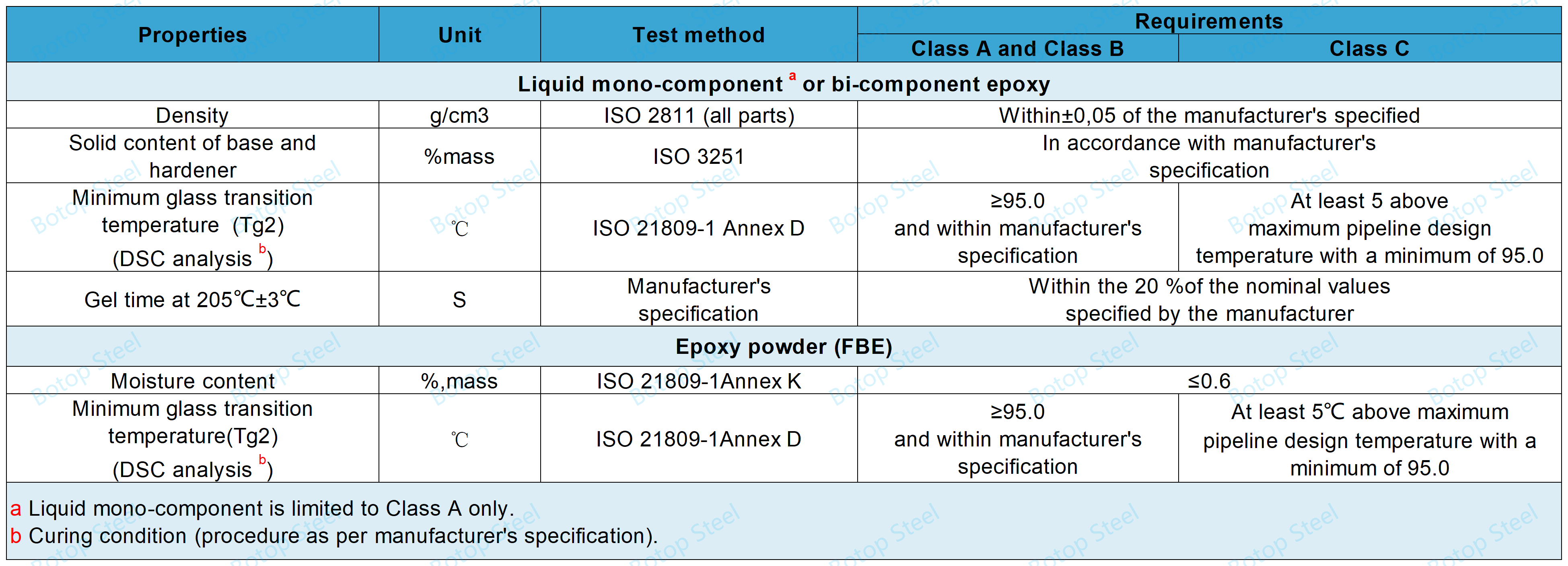

Requirements for the Epoxy Material

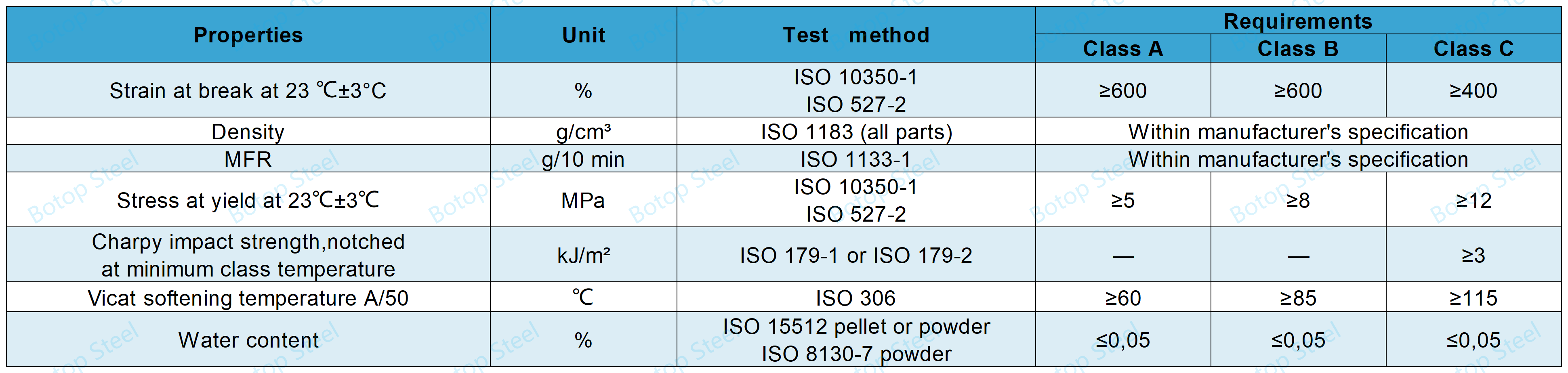

Requirements for the Adhesive Material

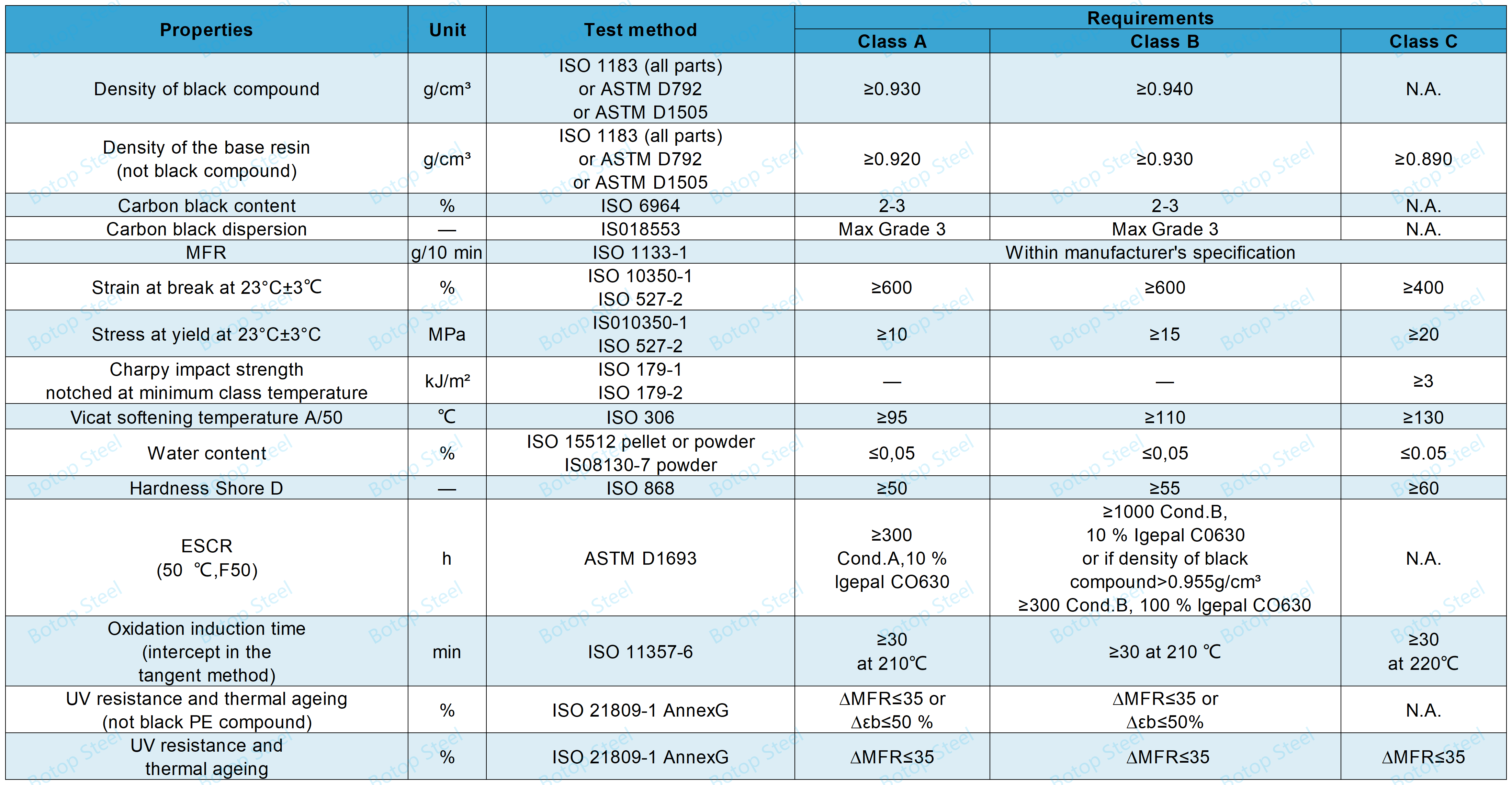

Requirements for PE/PP Top Layer

The anti-corrosion process can be roughly divided into:

1. Surface preparation;

2. Coating application

3. Cooling

4. Cutback

5. Marking

6. Finished product inspection

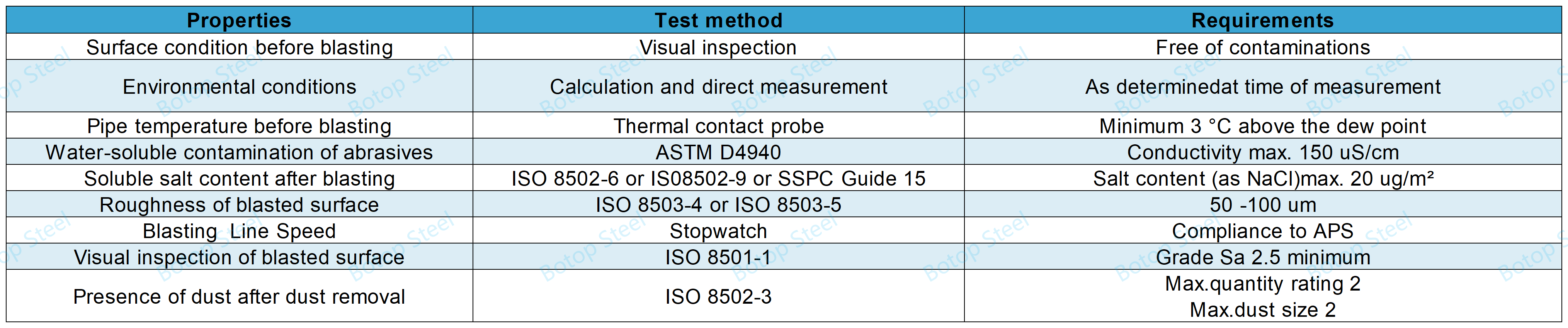

1. Surface Preparation

Similar requirements are found in the SSPC and NACE standards, and the following is a general correspondence:

| ISO 8501-1 | NACE | SSPC-SP | Designation |

| Sa 2.5 | 2 | 10 | Near-white metal blast cleaning |

| Sa 3 | 1 | 5 | White metal blast cleaning |

Please note that the effect of Sa 2.5 is not fixed depending on the corrosion grade of the steel pipe, which is categorized as A, B, C, and D, corresponding to 4 effects.

2. Coating Application

Ensure that the preheating temperature and line speed of the steel pipe in the coating process are appropriate to achieve full curing of the powder coating and to ensure the adhesion of the coating as well as to control the thickness of the coating.

The thickness of the corrosion protection layer is also related to the parameters of the coating equipment.

3. Cooling

The applied coating shall be cooled to a temperature that prevents handling damage during finishing and final inspection.

Generally, the cooling temperature of 3LPE is no more than 60℃, and the cooling temperature of 3LPP will be a little higher.

4. Cutback

A certain length of coating should be removed from both ends of the pipe and the corrosion protection layer should not be beveled at an angle of more than 30° to prevent possible damage to the corrosion protection coating during welding.

5. Marking

Compliance with standards and customer requirements.

These markings should be stenciled or painted to ensure that the lettering is clear and does not fade.

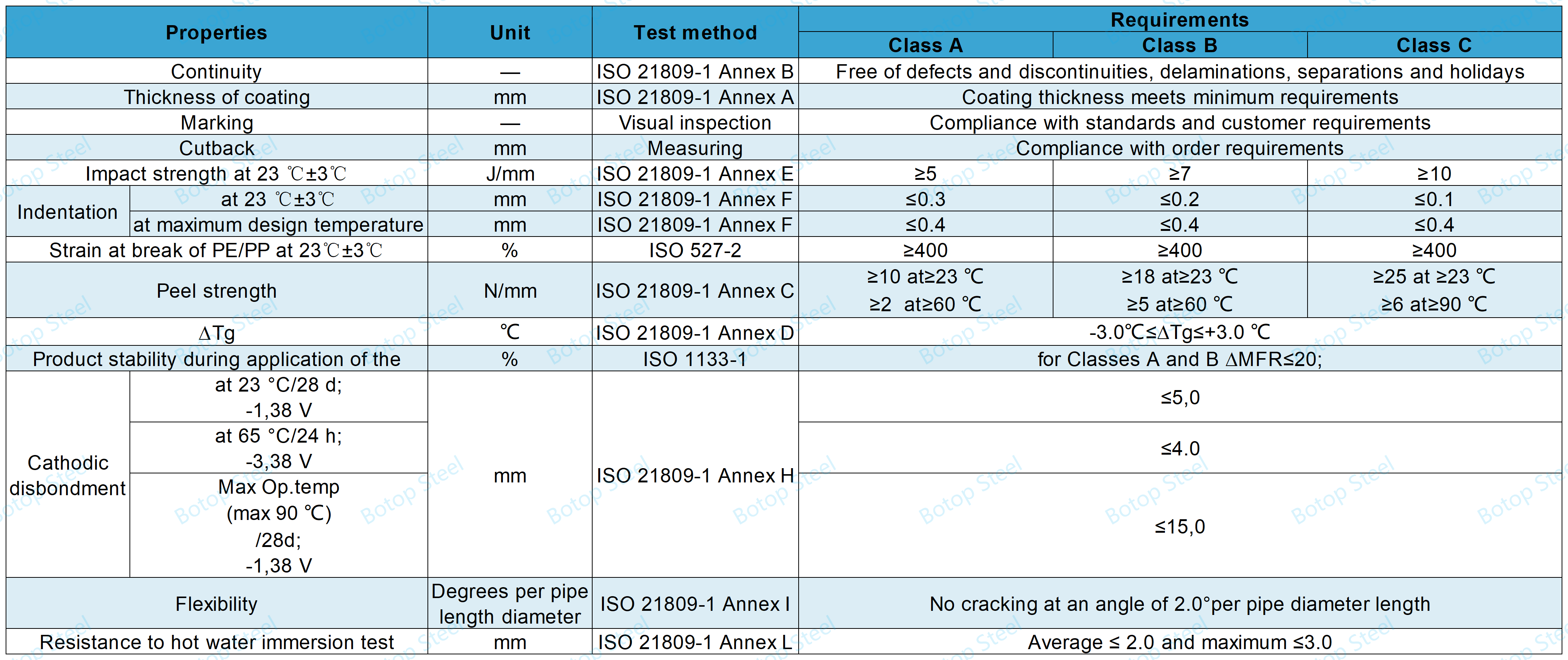

6. Finished Product Inspection

Comprehensive inspection of finished anti-corrosion pipes to meet the requirements of ISO 21809-1.

3LPE Applications

3LPE coatings offer high chemical resistance, excellent mechanical protection as well as good durability, and low maintenance costs.

It is suitable for buried or underwater pipelines that require high corrosion resistance and mechanical protection in soil and water environments.

Commonly used in piping systems for the transportation of oil, gas, and water.

3LPP Applications

3LPP coatings have higher temperature resistance and excellent chemical stability than polyethylene. However, it can become brittle at low temperatures.

Suitable for higher temperatures and more demanding environments, such as piping in hotter areas or near chemical processing plants.

Typically used in oil and gas piping systems where high-temperature performance is required.

DIN 30670: Polyethylene coatings of steel pipes and fittings.

This is a German industry standard specifically for polyethylene coatings for steel pipes and their fittings.

DIN 30678: Polypropylene coatings on steel pipes.

Polypropylene coating system specifically for steel pipes.

GB/T 23257: Polyethylene coating technology standards on buried steel pipeline.

This is a national standard in China covering polyethylene coating technology for buried steel pipelines.

CSA Z245.21: Plant-applied external coatings for steel pipe.

This is a Canadian Standards Association (CSA) standard that specifies requirements for external polyethylene coatings used to protect steel pipe.

Comprehensive product coverage: We offer a wide selection of carbon steel pipes from basic to advanced alloys to meet your diversified needs.

High-quality assurance: All products comply with international quality standards, such as ISO 21809-1, which are specifically designed for the anti-corrosion requirements of the oil and gas industry.

Customized service: Not only do we offer standard products, but depending on the project requirements and environmental conditions, anti-corrosion coatings and steel pipes can be customized to ensure optimum performance and cost-effectiveness.

Technical support and customer service: Our team of experts provides technical advice and support to help customers select the most appropriate steel pipe and anti-corrosion solutions to ensure the successful implementation of their projects.

Rapid response and delivery: With a large inventory and efficient logistics system, we are able to respond quickly to customer needs and ensure timely delivery.

We are looking forward to cooperating with you to provide the best quality steel pipe and anti-corrosion coating solutions for your projects. Please feel free to contact us for more product details, we are happy to help you find the best steel pipe option for your needs!