STPT 370 is a grade of the Japanese standard JIS G 3456 for carbon steel pipes, which is used for pressure pipes in environments with temperatures above 350°C. It can be either seamless or welded pipes using the electric resistance welding (ERW) process. The mechanical properties of STPT 370 material are a minimum tensile strength of 370 MPa and a minimum yield strength of 215 MPa.

If you are looking for a manufacturer and supplier of steel pipes that meet the JIS G 3456 standard, then we are the partner you are looking for. Contact us today and we will be happy to help you!

Suitable for outer diameters 10.5 mm - 660.4 mm (6A - 650A) (1/8B - 26B).

A and B are two ways to express the nominal diameter in the Japanese standard. Specifically, A corresponds to DN, while B corresponds to NPS.

JIS G 3456 STPT 370 can be produced using the seamless manufacturing process or the electric resistance welding (ERW) process.

The manufacturing process also corresponds to different finishing methods to cope with different use environments.

| Symbol of grade | Symbol of the manufacturing process | |

| Pipe manufacturing process | Finishing method | |

| JIS G 3456 STPT370 | Seamless: S | Hot-finished: H Cold-finished: C |

| Electric resistance welded: E Butt welded: B |

Hot-finished: H Cold-finished: C As electric resistance welded: G |

|

STPT 370 must be heat-treated.

1. Hot-finished seamless steel pipe: As manufactured Low-temperature annealing or normalizing may be applied as required;

2. Cold-finished seamless steel pipe: Low-temperature annealing or normalizing;

3. Hot-finished electric resistance welded steel pipe: As manufactured Low-temperature annealing or normalizing may be applied as required;

4. Cold-finished electric resistance welded and As electric resistance welded steel pipe: Low-temperature annealing or normalizing.

| Symbol of grade | C | Si | Mn | P | S |

| JIS G 3456 STPT370 | 0.25% max | 0.10 - 0.35% | 0.30 - 0.90% | 0.035% max | 0.035% max |

If necessary, additional elements can be added.

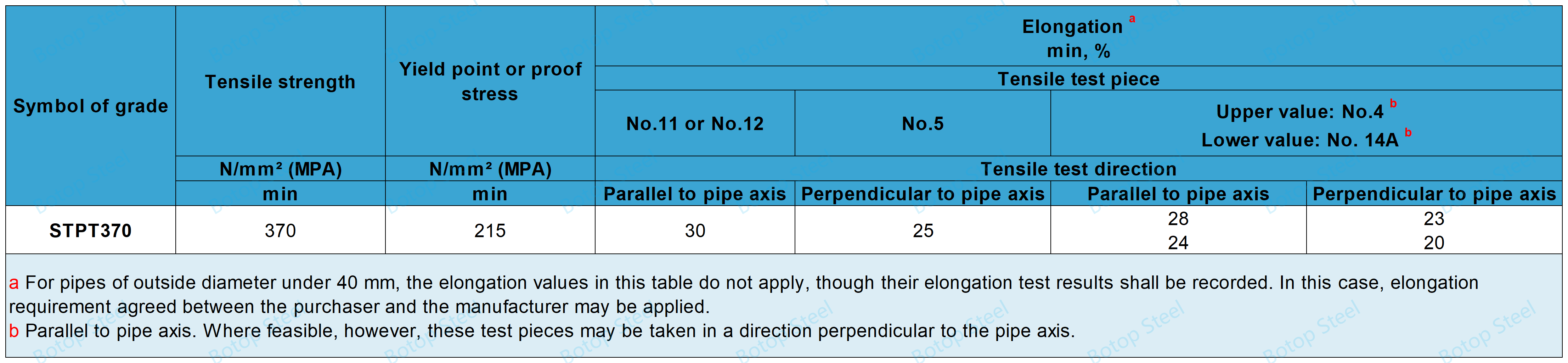

Tensile Strength, Yield Point or Proof Stress, and Elongation

Flattening Property

Suitable for pipes with an outer diameter of more than 60.5 mm.

The specimen is placed between the two platforms and flattened. When the distance between the two plates reaches H, there are no cracks on the surface of the steel pipe specimen.

H = 1.08t/(0.08+ t/D)

н: distance between platens (mm);

t: wall thickness of pipe (mm);

D: outside diameter of pipe (mm);

Bendability

Suitable for steel pipes with an outer diameter of 60.5 mm or less.

When the specimen is bent around the mandrel to an inner radius of 6 times the outer diameter of the pipe, the specimen is inspected and no cracks are found.

| Nominal wall thickness | Schedule number : Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Minimum hydraulic test pressure, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

When the outside diameter and wall thickness of the steel pipe are not standard sizes, the following methods can be used to determine the appropriate specification grade:

First, select the standard schedule grade that is closest to the non-standard size; second, determine the specification grade by calculating the P value.

In both methods, the smaller value should be selected as the final specification grade.

P = 2st/D

P: test pressure (MPa);

t: wall thickness of pipe (mm);

D: outside diameter of pipe (mm);

s: 60% of the specified minimum value of yield point or proof stress;

Common non-destructive testing methods include ultrasonic testing (UT) and eddy current testing (ET).

When performing ultrasonic inspection, reference should be made to JIS G 0582, and when the inspection result is equal to or exceeds the reference standard for the UD class, it is considered to be a failure.

When performing an eddy current inspection, reference should be made to JIS G 0583. When the inspection result is equal to or exceeds the reference standard for the EY class, it is considered to be unqualified.

The standard dimensions and wall thicknesses in the range of 10.5 mm to 660.4 mm are listed in JIS G 3456, which is the steel pipe weight table and the corresponding schedule No.

Schedule 10, Schedule 20, Schedule 30, Schedule 40, Schedule 60, Schedule 80, Schedule 100, Schedule 120, Schedule 140, Schedule 160.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Please feel free to contact us and we will be happy to answer your questions.