JIS G 3461 steel pipe is a seamless (SMLS) or electric-resistance-welded (ERW) carbon steel pipe, mainly used in boilers and heat exchangers for applications such as realizing heat exchange between inside and outside the tube.

STB340 is a carbon steel pipe grade in the JIS G 3461 standard. It has a minimum tensile strength of 340 MPa and a minimum yield strength of 175 MPa.

It is the material of choice for many industrial applications because of its high strength, good thermal stability, adaptability, relative corrosion resistance, cost-effectiveness, and good processability.

JIS G 3461 has three grades. STB340, STB410, STB510.

STB340: Minimum tensile strength: 340 MPa; Minimum yield strength: 175 MPa.

STB410: Minimum Tensile Strength: 410 MPa; Minimum Yield Strength: 255 MPa.

STB510: Minimum Tensile Strength: 510 MPa; Minimum Yield Strength: 295 MPa.

In fact, it is not difficult to find out that the JIS G 3461 grade is classified according to the minimum tensile strength of the steel pipe.

As the grade of the material increases, its tensile and yield strengths increase accordingly, allowing the material to withstand higher loads and pressures for more demanding work environments.

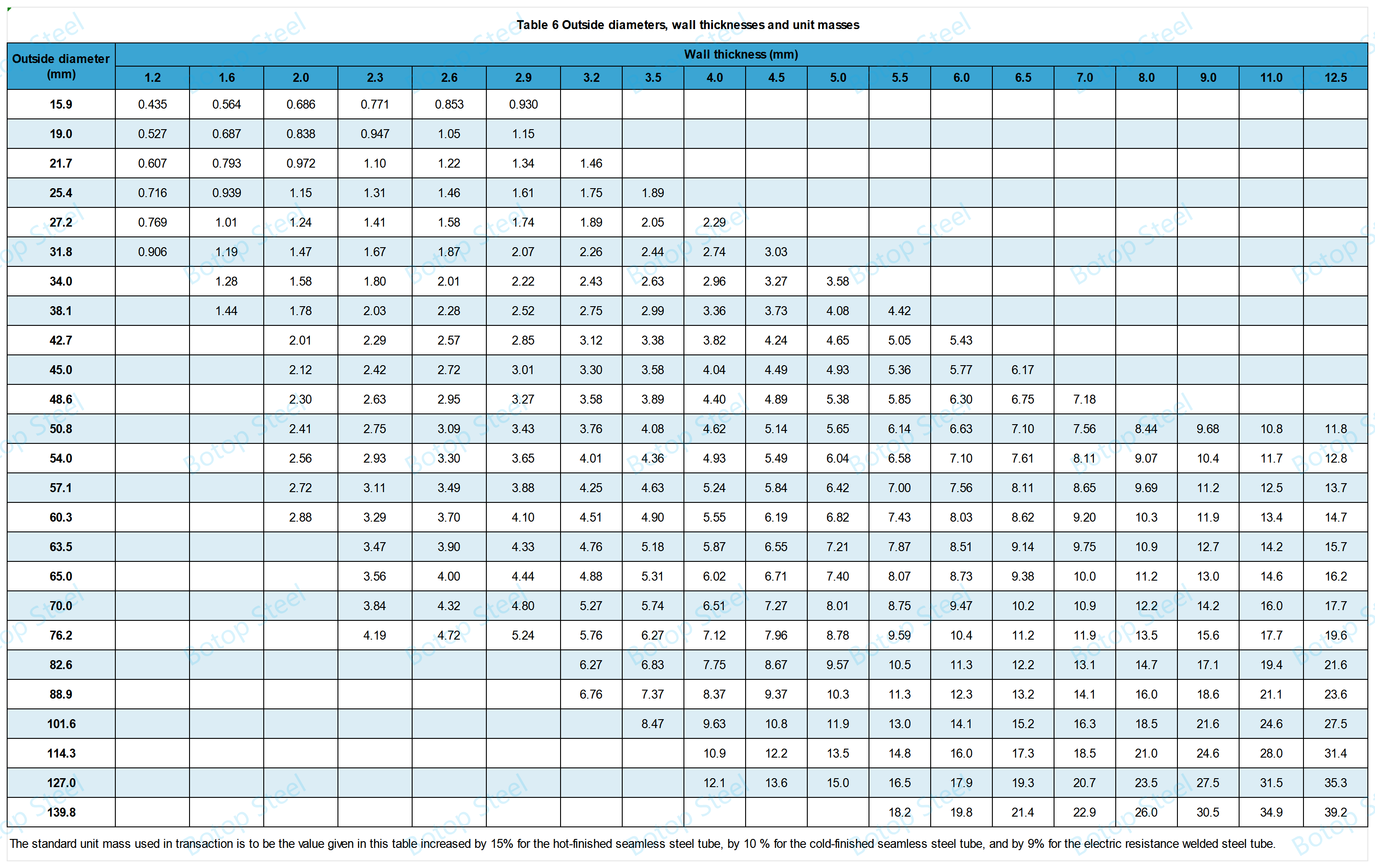

Outside diameter of 15.9-139.8mm.

Applications in boilers and heat exchangers usually do not require very large tube diameters. Smaller tube diameters increase thermal efficiency because the surface area to volume ratio for heat transfer is higher. This helps to transfer heat energy faster and more efficiently.

Tubes shall be manufactured from the killed steel.

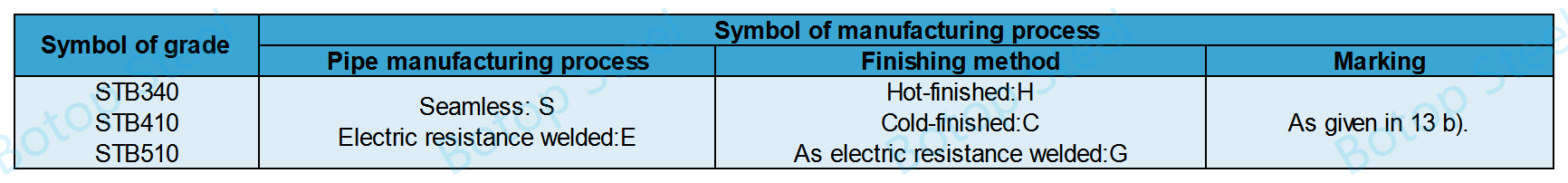

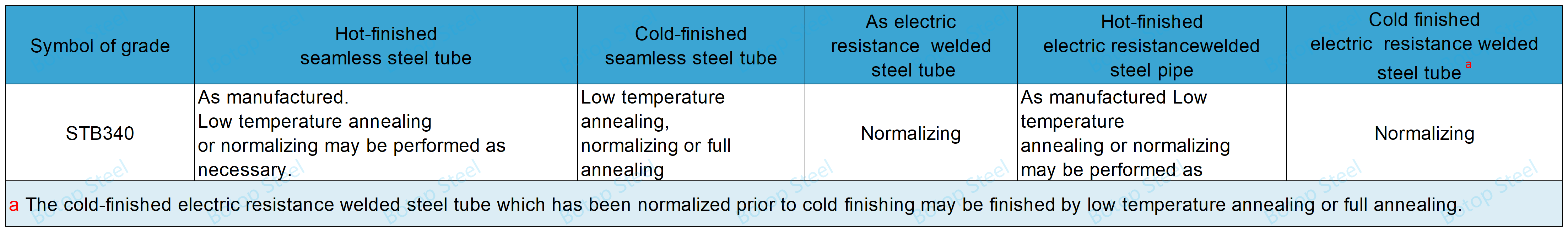

Combination of pipe manufacturing methods and finishing methods.

In detail, they can be categorized as follows:

Hot-finished seamless steel tube: S-H

Cold-finished seamless steel tube: S-C

As electric resistance welded steel tube: E-G

Hot-finished electric resistance welded steel tube: E-H

Cold-finished electric resistance welded steel tube: E-C

Here is the production flow of the Hot-finished seamless.

For the seamless manufacturing process, it can be roughly divided into seamless steel pipes with an outside diameter of more than 30mm using hot finish production, and 30mm using cold finish production.

Thermal analysis methods shall be in accordance with the standards in JIS G 0320.

Alloying elements other than those may be added to obtain specific properties.

When the product is analyzed, the deviation values of the chemical composition of the pipe shall meet the requirements of Table 3 of JIS G 0321 for seamless steel pipes and Table 2 of JIS G 0321 for resistance-welded steel pipes.

| Symbol of grade | C (Carbon ) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | max | ||

| STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| The purchaser may specify the amount of Si to be in the range of 0.10 % to 0.35%. | |||||

The chemical composition of STB340 is designed to ensure adequate mechanical properties and machinability while making the material suitable for welding and applications in high-temperature environments.

| Symbol of grade | Tensile strength a | Yield point or proof stress | Elongation min, % | ||

| Outside diameter | |||||

| <10mm | ≥10mm <20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Test piece | |||

| No.11 | No.11 | No.11/No.12 | |||

| min | min | Tensile test direction | |||

| Parallel to tube axis | Parallel to tube axis | Parallel to tube axis | |||

| STB340 | 340 | 175 | 27 | 30 | 35 |

Note: exclusively for the heat exchanger tubes, the purchaser may, where necessary, specify the maximum value of tensile strength. In this case, the maximum tensile strength value shall be the value obtained by adding 120 N/mm² to the value in this table.

When the tensile test is carried out on Test piece No. 12 for the tube under 8 mm in wall thickness.

| Symbol of grade | Test piece used | Elongation min, % |

||||||

| Wall thickness | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| STB340 | No. 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

The elongation values in this table are calculated by subtracting 1.5 % from the elongation value given in Table 4 for each 1 mm decrease in tube wall thickness from 8 mm, and by rounding the result to an integer according to Rule A of JIS Z 8401.

The test method shall be in accordance with JIS Z 2245. The hardness of the test piece shall be measured on its cross-section or internal surface at three positions per test piece.

| Symbol of grade | Rockwell hardness (mean value of three positions) HRBW |

| STB340 | 77 max. |

| STB410 | 79 max. |

| STB510 | 92 max. |

This test shall not be performed on tubes of wall thickness 2 mm or under. For electric resistance welded steel tubes, the test shall be performed in the portion other than the weld or the heat-affected zones.

It does not apply to seamless steel tubes.

Test Method Place the specimen in the machine and flatten it until the distance between the two platforms reaches the specified value H. Then check the specimen for cracks.

When testing critical resistance welded pipe, the line between the weld and the center of the pipe is perpendicular to the compression direction.

H=(1+e)t/(e+t/D)

H: distance between platens (mm)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

е: constant defined for each grade of the tube. STB340: 0.09; STB410: 0.08; STB510: 0.07.

It does not apply to seamless steel tubes.

One end of the specimen is flared at room temperature (5°C to 35°C) with a conical tool at an angle of 60° until the outside diameter is enlarged by a factor of 1.2 and inspected for cracks.

This requirement also applies to tubes with an outside diameter of more than 101.6 mm.

The reverse flattening test may be omitted when performing the flaring test.

Cut a 100 mm length of test piece from one end of the pipe and cut the test piece in half 90° from the weld line on both sides of the circumference, taking the half containing the weld as the test piece.

At room temperature (5 °C to 35 °C) flatten the specimen into a plate with the weld at the top and inspect the specimen for cracks in the weld.

Every steel pipe needs to be hydrostatically or non-destructively tested to ensure the quality and safety of the pipe and to meet the standards of use.

Hydraulic Test

Hold the inside of the pipe at minimum or higher pressure P (P max 10 MPa) for at least 5 seconds, then check that the pipe can withstand the pressure without leaks.

P=2st/D

P: test pressure (MPa)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

s: 60 % of the specified minimum value of yield point or proof stress.

Non-destructive Test

Non-destructive testing of steel tubes should be performed by ultrasonic or eddy current testing.

For ultrasonic inspection characteristics, the signal from a reference sample containing a reference standard of class UD as specified in JIS G 0582 shall be considered as an alarm level and shall have a basic signal equal to or greater than the alarm level.

The standard detection sensitivity for the eddy current examination shall be category EU, EV, EW, or EX specified in JIS G 0583, and there shall be no signals equivalent to or greater than the signals from the reference sample containing the reference standard of the said category.

For more Pipe Weight Charts and Pipe Schedules within the standard, you can click through.

Take an appropriate approach to labeling the following information.

a) Symbol of grade;

b) Symbol for the manufacturing method;

c) Dimensions: outside diameter and wall thickness;

d) Manufacturer's name or identifying brand.

When the marking on each tube is difficult due to its small outside diameter or when so requested by the purchaser, the marking may be given on each bundle of tubes by a suitable means.

STB340 is commonly used in the manufacture of water pipes and flue pipes for various industrial boilers, especially in environments where resistance to high temperatures and pressures is required.

Due to its good heat conduction properties, it is also suitable for the manufacture of pipes for heat exchangers, helping to transfer heat efficiently between different media.

It can also be used to transport high-temperature or high-pressure fluids, such as steam or hot water, and is widely used in chemical, electric power, and machinery manufacturing industries.

ASTM A106 Grade A

DIN 17175 St35.8

DIN 1629 St37.0

BS 3059-1 Grade 320

EN 10216-1 P235GH

GB 3087 20#

GB 5310 20G

Although these materials may be similar in terms of chemical composition and basic properties, specific heat treatment processes and machining may affect the properties of the final product.

Therefore, detailed comparisons and appropriate testing should be performed when selecting equivalent materials for practical applications.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.