JIS G 3444: Carbon steel tubes for general structure.

It specifies requirements for carbon steel pipes used in civil engineering and construction, such as steel towers, scaffolding, foundation piles, foundation piles, and anti-slip piles.

STK 400 steel pipe is one of the most common grades, with mechanical properties of a minimum tensile strength of 400 MPa and a minimum yield strength of 235 MPa. Its good structural strength and durability make it suitable for many different applications.

According to the minimum tensile strength of the steel pipe is divided into 5 classes, which are:

STK 290, STK 400, STK 490, STK 500, STK 540.

General purpose Outer diameter: 21.7-1016.0mm;

Foundation piles and piles for landslide suppression OD: below 318.5mm.

| Symbol of grade | Symbol of the manufacturing process | |

| Pipe manufacturing process | Finishing method | |

| STK 290 | Seamless: S Electric resistance welded: E Butt welded: B Automatic arc welded: A |

Hot-finished: H Cold-finished: C As electric resistance welded: G |

| STK 400 | ||

| STK 490 | ||

| STK 500 | ||

| STK 540 | ||

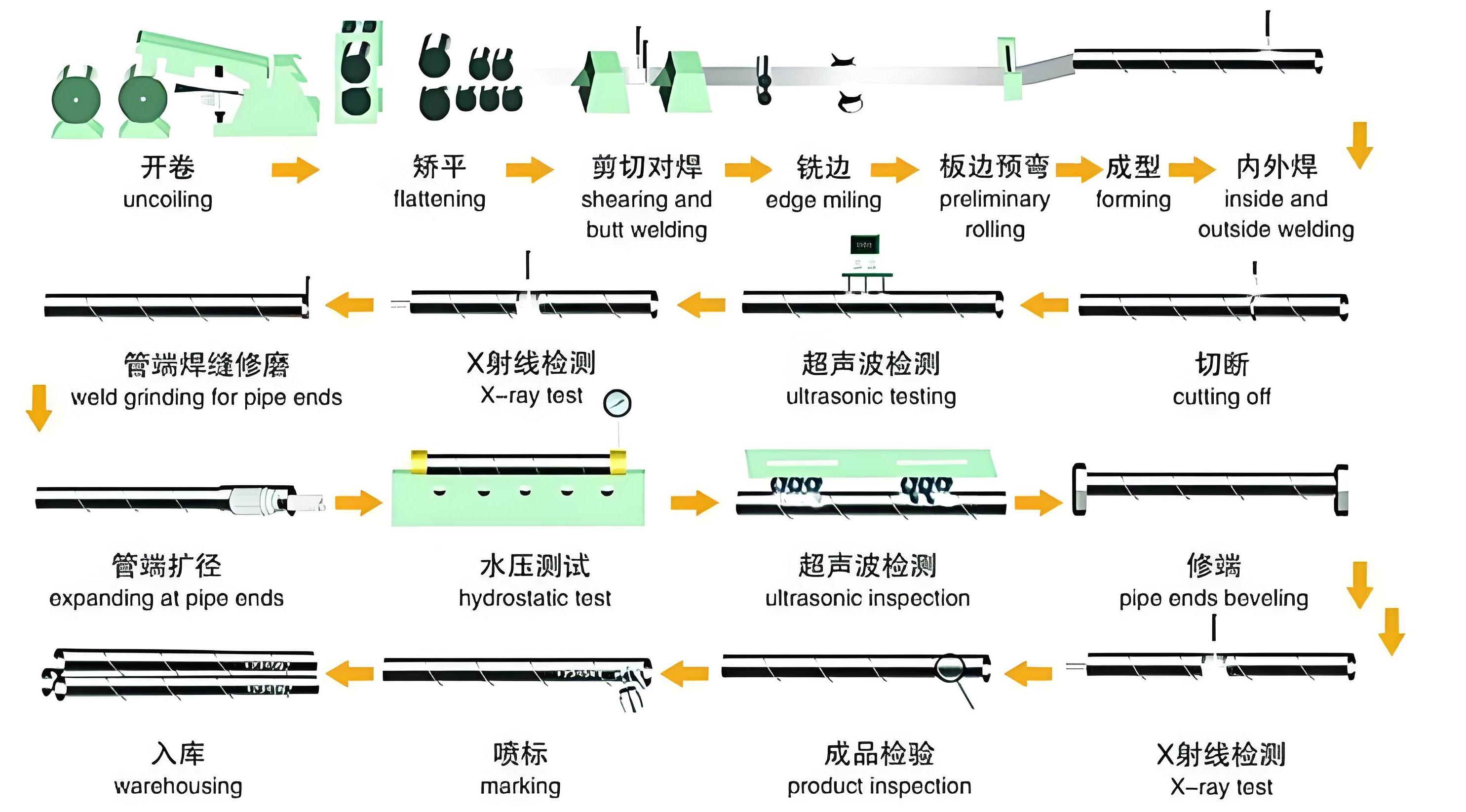

The tubes shall be manufactured by a combination of the tube manufacturing method and the finishing method which are indicated.

Specifically, they can be categorized into the following seven types, so choose the appropriate type according to different needs:

1) Hot-finished seamless steel tube: -S-H

2) Cold-finished seamless steel tube: -S-C

3) As electric resistance welded steel tube: -E-G

4) Hot-finished electric resistance welded steel tube: -E-H

5) Cold-finished electric resistance welded steel tube: -E-C

6) Butt-welded steel tubes: -B

7) Automatic arc welded steel tubes: -A

| Chemical Composition a % | |||||

| Symbol of grade | C (Carbon ) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | max | ||

| STK 400 | 0.25 | — | — | 0.040 | 0.040 |

| a Alloy elements not included in this table and elements indicated with “—” may be added as necessary. | |||||

STK 400 is low-carbon steel with good weldability and workability for structural applications requiring welding. Phosphorus and sulfur are controlled at low levels to help maintain the overall toughness and workability of the material. Although specific values for silicon and manganese are not given, they may be adjusted within permissible limits to optimize the properties of the steel further.

Tensile Strength and Yield Point or Proof Stress

The tensile strength of the weld is applicable to automatic arc welded tubes. It's the SAW welding process.

| Symbol of grade | Tensile strength | Yield point or proof stress | Tensile strength in weld |

| N/mm² (MPA) | N/mm² (MPA) | N/mm² (MPA) | |

| min | min | min | |

| STK 400 | 400 | 235 | 400 |

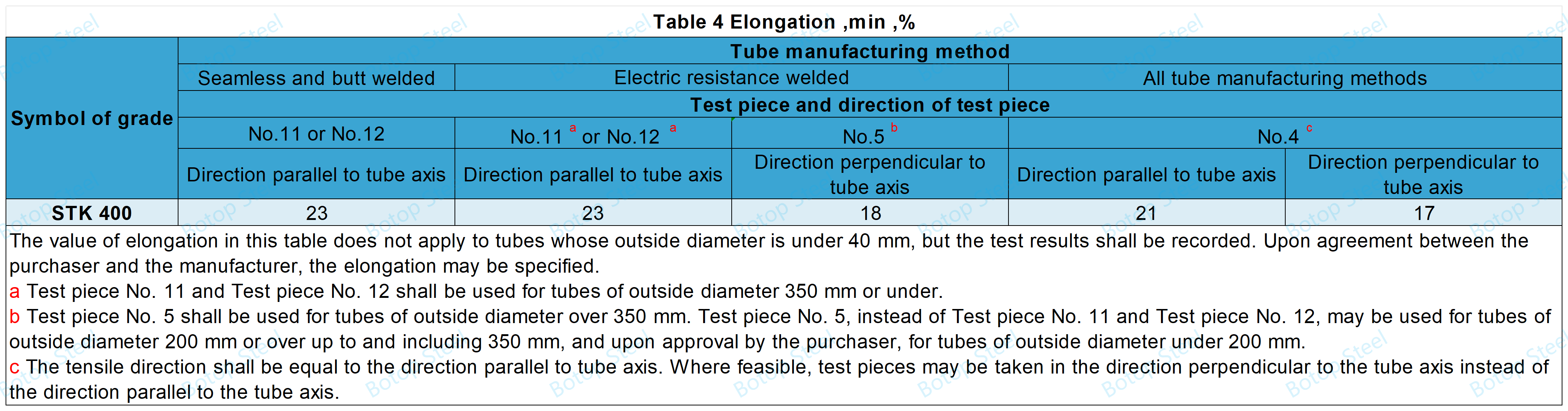

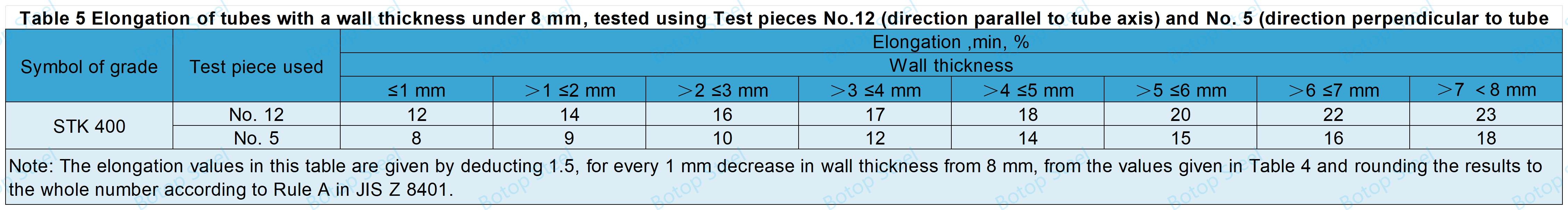

Elongation of JIS G 3444

The elongation corresponding to the tube manufacturing method is shown in Table 4.

However, when the tensile test is performed on Test Piece No. 12 or Test Piece No.5 taken from the tube under 8 mm in wall thickness, the elongation shall be in accordance with Table 5.

At room temperature (5 °C to 35 °C), place the specimen between two flat plates and press firmly to flatten them until the distance H ≤ 2/3D between the plates, then check for cracks in the specimen.

At room temperature (5 °C to 35 °C), bend the specimen around a cylinder at a minimum bending angle of 90° and a maximum internal radius of not more than 6D and check the specimen for cracks.

Hydrostatic tests, non-destructive tests of welds, or other tests shall be agreed in advance on the relevant requirements.

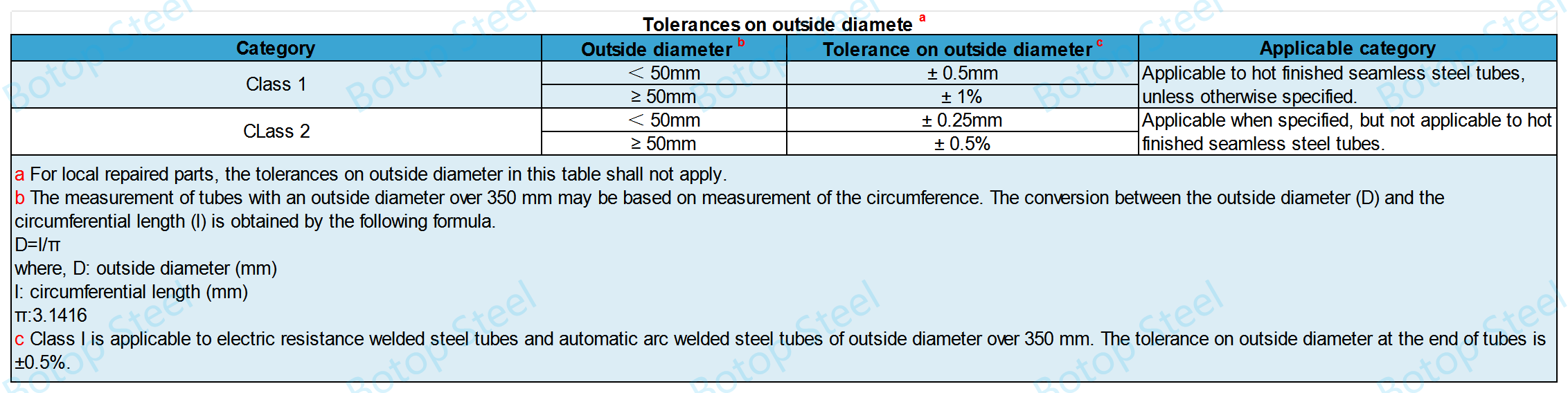

Outside Diameter Tolerance

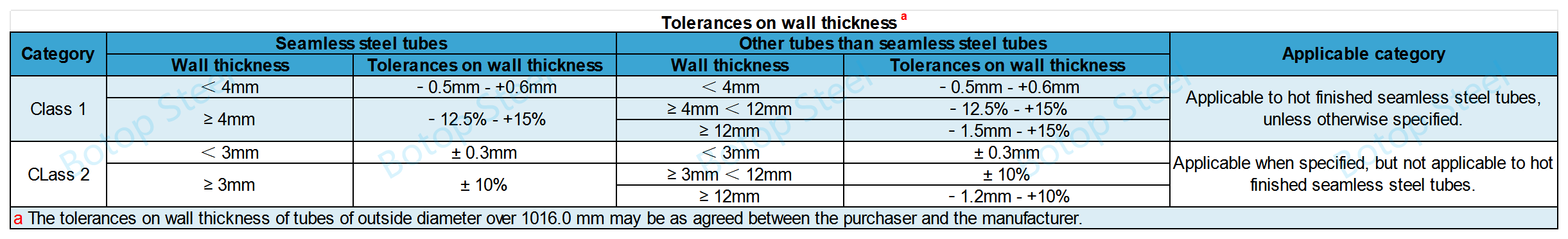

Wall Thickness Tolerance

Length Tolerance

Length ≥ specified length

The internal and external surfaces of the steel pipe shall be smooth and free from defects unfavorable to ues.

Each steel pipe shall be labeled with the following information.

a) Symbol of grade.

b) Symbol for manufacturing method.

c) Dimensions. The outside diameter and wall thickness shall be marked.

d) Manufacturer's name or abbreviation.

When the marking on a tube is difficult because its outside diameter is small or when so requested by the purchaser, the marking may be given on each bundle of tubes by a suitable means.

Anti-corrosion coatings such as zinc-rich coatings, epoxy coatings, paint coatings, etc. can be applied to the external or internal surfaces.

STK 400 offers a good balance of strength and economy, making it ideal for many engineering and construction projects.

STK 400 steel tubes are commonly used in the construction industry and are particularly suitable for use as structural elements such as columns, beams, or frames in commercial and residential buildings.

It is also suitable for bridges, support structures, and other projects that require medium strength and durability.

It can also be used to construct road guardrails, traffic sign frames, and other public facilities.

In manufacturing, STK 400 can be used to produce frames and support structures for machinery and equipment due to its good load-bearing capacity and workability.

Please note that while these standards are similar in application and performance, there may be minor differences in specific chemical composition and certain mechanical property parameters.

When substituting materials, the specific requirements of the standards should be compared in detail to ensure that the materials selected will meet the specific technical and safety standards of the project.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.