JIS G 3452 is a Japanese standard that specifies welded carbon steel pipe for the transportation of steam, water, oil, gas, air, etc. at relatively low working pressures. JIS G 3452 consists of only one grade, SGP, which can be fabricated by either resistance welding (ERW) or butt welding.

JIS G 3452 Steel pipes shall be fabricated using a suitable combination of pipe manufacturing methods and finishing methods.

| Symbol of grade |

Symbol of manufacturing process | Classification of zinc-coating | |

| Pipe manufacturing process | Finishing method | ||

| SGP | Electric resistance welded: E Butt welded: B |

Hot-finished: H Cold-finished: C As electric resistance welded: G |

Black pipes: pipes not given zinc-coating White pipes: pipes given zinc-coating |

The pipes shall normally be delivered as manufactured. Cold-finished pipes shall be annealed after manufacturing.

If the pipe is made by ERW, the welds on the inside and outside surfaces of the pipe shall be removed to obtain a smooth weld along the contour of the pipe.

If limited due to pipe diameter or equipment, etc., the weld on the inner surface may not be removed.

Prep: Before hot-dip galvanizing, the surface of the steel pipe must be thoroughly cleaned by sandblasting, pickling, etc.

Thickness: For zinc-coating, the distilled zinc ingot Class 1 specified in JIS H 2107 or zinc with at least equivalent quality to this shall be used.

Other: Other general requirements for galvanizing are in accordance with JIS H 8641.

Test: Measurement of the uniformity of the galvanized coating according to JIS H 0401 Article 6.

In addition to the given elements, other alloying elements can be added as required.

| Symbol of grade | P (Phosphorus) | S (Sulfur) |

| SGP | max 0.040 % | max 0.040 % |

JIS G 3452 has fewer restrictions on chemical composition because JIS G 3452 is mainly used for general-purpose applications such as transportation of steam, water, oil, and natural gas. The chemical composition of the material is not the most important factor, but rather the mechanical properties of the pipe to withstand the working pressure.

Tensile Properties

| Symbol of grade | Tensile strength | Elongation, min, % | ||||||

| Test piece | Test direction |

Wall thickness, mm | ||||||

| N/mm² (MPA) | >3 ≤ 4 |

>4 ≤ 5 |

>5 ≤ 6 |

>6 ≤ 7 |

>7 | |||

| SGP | 290 min | No.11 | Parallel to the pipe axis | 30 | 30 | 30 | 30 | 30 |

| No.12 | Parallel to the pipe axis | 24 | 26 | 27 | 28 | 30 | ||

| No.5 | Perpendicular to pipe axis | 19 | 20 | 22 | 24 | 25 | ||

For pipes of nominal diameter 32A or under, the elongation values in this table do not apply, though their elongation test results shall be recorded. In this case, the elongation requirement agreed between the purchaser and the manufacturer may be applied.

Flattening Property

Scope: For tubes with a nominal diameter greater than 50A (2B).

No cracks when the tube is flattened to 2/3 of the outside diameter of the tube.

Bendability

Scope: For steel tubes with a nominal diameter ≤ 50A (2B).

Bend the specimen to 90° with an inside radius of six times the outside diameter of the pipe without producing any cracks.

Each steel pipe should have a hydrostatic pressure test or a non-destructive test.

Hydrostatic Test

Pressure: 2.5 MPa;

Time: Hold for at least 5 seconds;

Judgment: steel pipe under pressure without leakage.

Non-destructive Test

The ultrasonic examination specified in JIS G 0582 shall apply. The test level may be more severe than Category UE.

The eddy current examination specified in JIS G 0583 shall apply. The test level may be more severe than Category EZ.

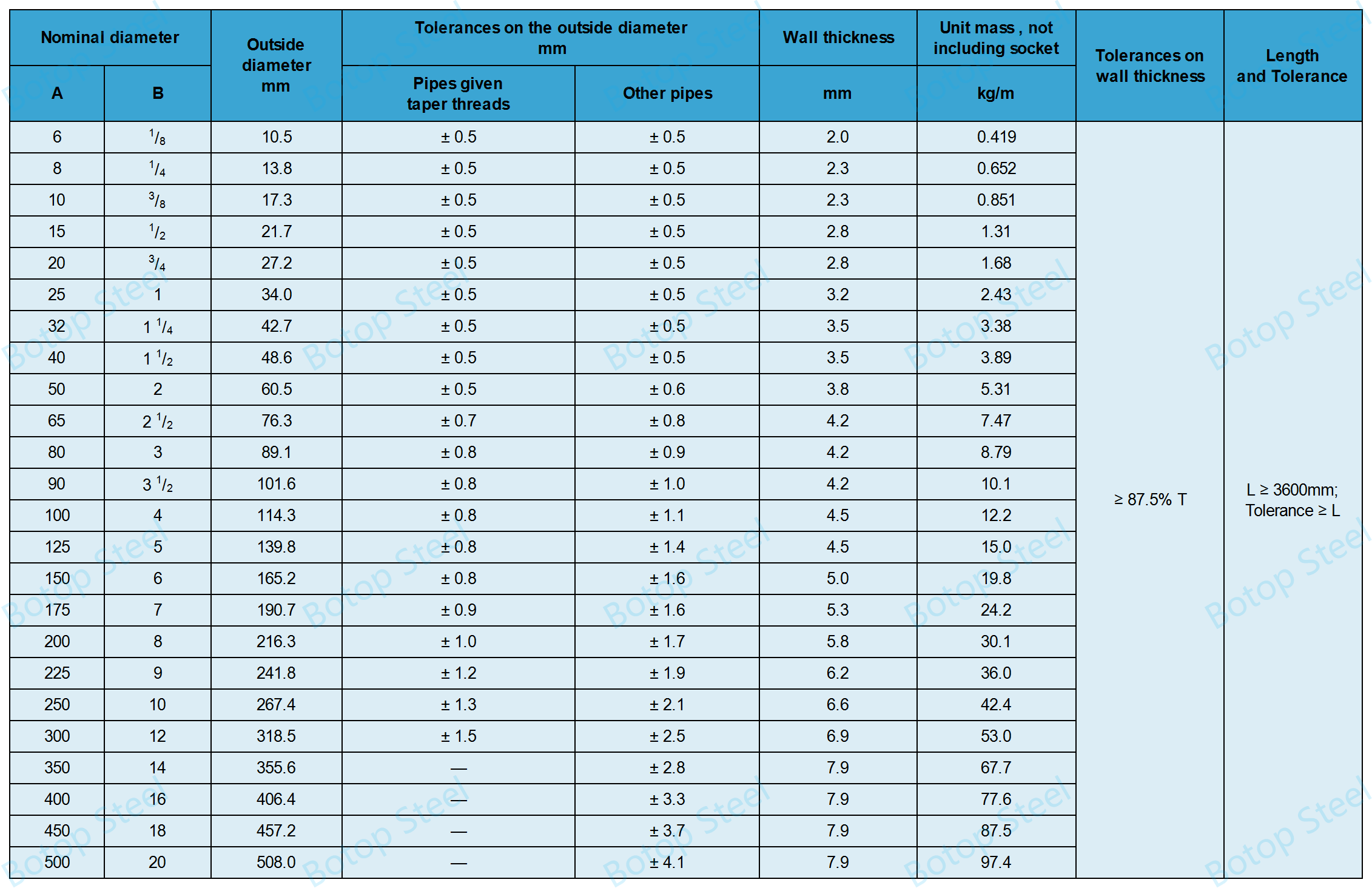

For pipes with nominal diameters ≥ 350A (14B), calculate the diameter by measuring the circumference, in which case the tolerance is ± 0.5%.

Type of pipe end for DN≤300A/12B: threaded or flat end.

Type of pipe end for DN≤350A/14B: flat end.

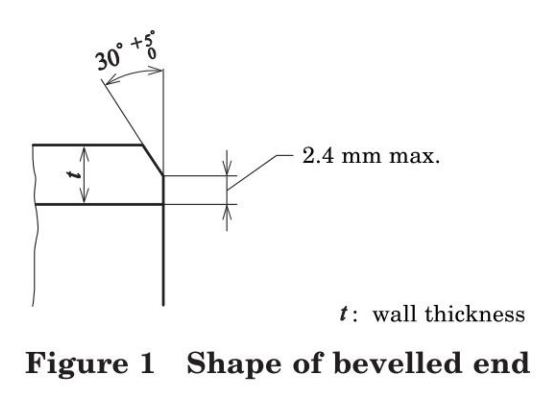

If the buyer requires a beveled end, the angle of the bevel is 30-35°, bevel width of the steel pipe edge: max 2.4mm.

JIS G 3452 has equivalents in ASTM A53 and GB/T 3091, and the pipe materials specified in these standards can be considered equivalent to each other in terms of performance and application.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges. Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Contact us, the professional team is ready to provide you with quality services and solutions, looking forward to reaching a pleasant cooperation with you, and jointly opening a new chapter of success.