JIS G 3454 is the Japanese industrial standard for carbon steel pipes for pressure systems with a maximum operating temperature of 350°C. The standard includes two grades: STPG 370 and STPG 410. It applies to electric resistance welded (ERW) or seamless pipes with a nominal diameter of 10.5 mm to 660.4 mm (i.e. 6A to 650A, or 1/8B to 26B).

JIS G 3454 Steel pipes shall be manufactured using the appropriate combination of steel pipe manufacturing methods and finishing methods in the table below.

| Symbol of grade | Symbol of the manufacturing process | ||

| Pipe manufacturing process | Finishing method | Classification of zinc-coating | |

| STPG370 STPG410 |

Seamless: S Electric resistance welded: E |

Hot-finished: H Cold-finished: C As electric resistance welded: G |

Black pipes: pipes not given zinc-coating White pipes: pipes given zinc-coating |

Specifically, there are five manufacturing methods:

S-H: Hot-finished seamless steel pipe;

S-C: Cold-finished seamless steel pipe;

E-H: Hot-finished electric resistance welded steel pipe;

E-C: Cold-finished electric resistance welded steel pipe;

E-G: Electric resistance welded steel pipe other than hot-finished and cold-finished ones.

Botop Steel is a manufacturer and supplier of high-quality welded carbon steel pipes from China, as well as a stockist of seamless steel pipes. If you have any needs, please feel free to contact us and we will provide you with free professional technical support.

| Symbol of grade | C | Si | Mn | P | S |

| max | max | — | max | max | |

| STPG 370 | 0.25% | 0.35 % | 0.30-0.90% | 0.040 % | 0.040% |

| STPG 410 | 0.30% | 0.35 % | 0.30-1.00% | 0.040 % | 0.040% |

Allows the addition of other alloying elements.

Tensile Strength, Yield Point or Proof Stress, and Elongation

| Symbol of grade |

Tensile strength | Yield point or proof stress |

Elongation min, % |

|||

| Tensile test piece | ||||||

| No.11 or No.12 | No.5 | No.4 |

||||

| N/mm² (MPA) | N/mm² (MPA) | Tensile test direction | ||||

| min | min | Parallel to the pipe axis | Perpendicular to pipe axis | Parallel to the pipe axis | Perpendicular to pipe axis | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Flattening Test

When the distance between the two plates reaches the specified distance H, there shall be no defects or cracks on the surface of the steel pipe.

For seamless steel tubes: H = (1+e)t/(e + t/D);

For ERW steel pipes: H = 1/3 D (for weld) or H = 2/3 D (for the portion without weld);

H: distance between flattening plates (mm);

е: constant individually defined for each grade of pipe, 0.08 for STPG 370, 0.07 for STPG 410;

t: wall thickness of pipe (mm);

D: outside diameter of pipe (mm);

Flattening Test is applicable to steel pipes with a nominal diameter greater than 40A (48.6mm).

Bendability

Bendability applies to pipes with a nominal diameter of 40 A (48.6) or smaller.

The pipe should be bent 90° at a radius of 6 times its outer diameter. The pipe wall must be free of defects or cracks.

Each steel pipe must undergo a hydrostatic pressure test or a non-destructive test.

Hydrostatic Test

Maintain a certain pressure for at least 5 seconds without leakage.

The pressure value is related to the schedule No. of the steel pipe.

| Nominal wall thickness | Schedule number: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Minimum hydraulic test pressure, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Non-destructive Test

If ultrasonic inspection is used, it should be based on a stricter standard than the UD class signal in JIS G 0582.

If eddy current testing is used, it should be based on a standard that is more stringent than the EY class signal in JIS G 0583.

| Nominal diameter | Outside diameter | Wall thickness | Unit mass | Schedule number (Sch No.) |

|

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

JIS G 3454 includes schedule 10, schedule 20, schedule 30, schedule 40, schedule 60, and schedule 80.

You can click on the schedule No. you wish to view; we have organized the corresponding PDF versions for your convenience.

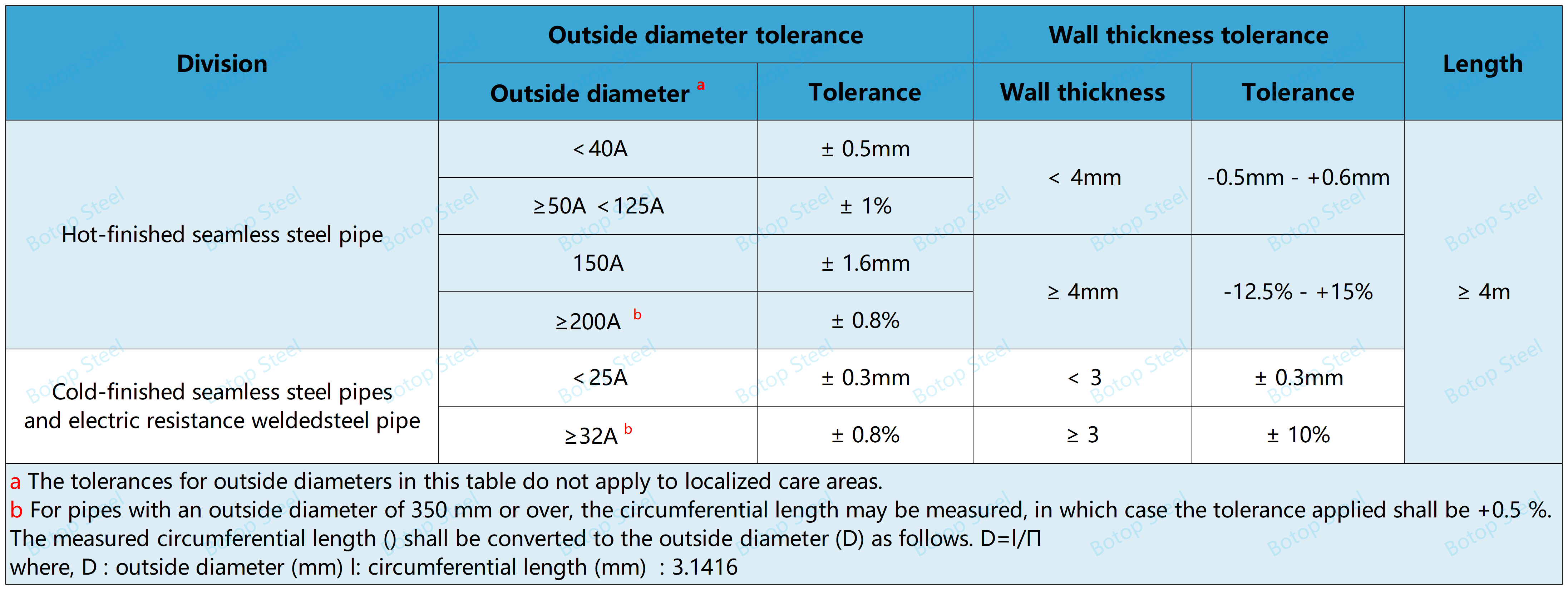

JIS G 3454 The tolerances for outer diameter, wall thickness, eccentricity, and length shall meet the following requirements.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.

Please contact us, we will provide you with high-quality, standard steel pipes with professional and efficient service. Botop looks forward to serving you.