JIS G 3455 is a Japanese Industrial Standard (JIS) for high-pressure service at temperatures of 350 °C or lower, mainly for mechanical parts.

STS370 steel pipe is a steel pipe with a minimum tensile strength of 370 MPa and a minimum yield strength of 215 MPa, with a carbon content of no more than 0.25% and a silicon content between 0.10% and 0.35%, and is mainly used in applications requiring high strength and good weldability, such as building structures, bridges, pressure vessels, and ship components.

JIS G 3455 has three grades. STS370, STS410, STA480.

Outside diameter of 10.5-660.4mm (6-650A) (1/8-26B).

Tubes shall be manufactured from the killed steel.

Killed steel is steel that has been completely deoxidized before being cast into ingots or other forms. The process consists of adding a deoxidizing agent such as silicon, aluminum, or manganese to the steel before it solidifies. The term "killed" indicates that no oxygen reaction occurs in the steel during the solidification process.

By eliminating oxygen, killed steel prevents the formation of air bubbles in the molten steel, thus avoiding porosity and air bubbles in the final product. This results in a more homogeneous and dense steel with superior mechanical properties and structural integrity.

Killed steel is particularly suitable for applications requiring high quality and durability, such as pressure vessels, large structures, and pipelines with high-quality requirements.

By using killed steel to produce tubes, you can be sure of better performance and longer service life, especially in environments subject to heavy loads and pressures.

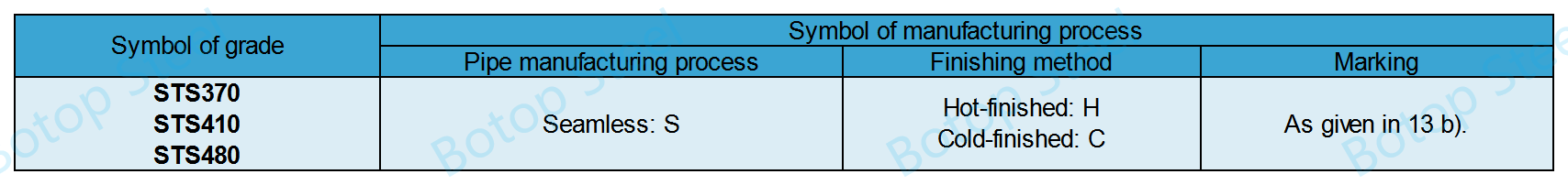

Produced using a seamless manufacturing process combined with a finishing method.

Hot-finished seamless steel pipe: S-H;

Cold-finished seamless steel pipe: S-C.

For the seamless manufacturing process, it can be roughly divided into seamless steel pipes with an outside diameter of more than 30mm using hot finish production, and 30mm using cold finish production.

Here is the production flow of the Hot-finished seamless.

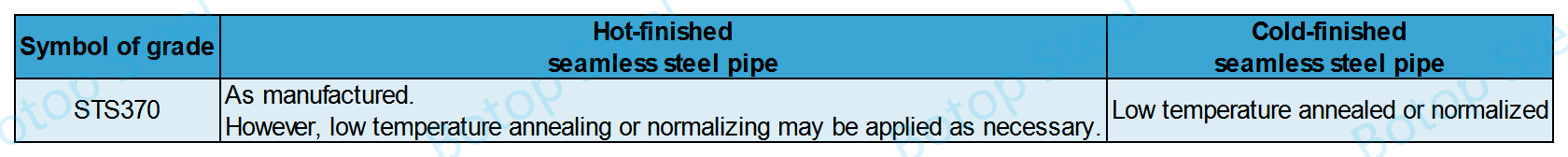

Low-temperature annealing is mainly used to improve the workability of materials, reduce hardness, and improve toughness, and is suitable for cold-worked steel.

Normalizing is used to improve the strength and toughness of the material, so that the steel is more suitable to withstand mechanical stress and fatigue, often used to improve the performance of cold-worked steel.

Through these heat treatment processes, the internal structure of the steel is optimized and its properties are improved, making it more suitable for use in demanding industrial applications.

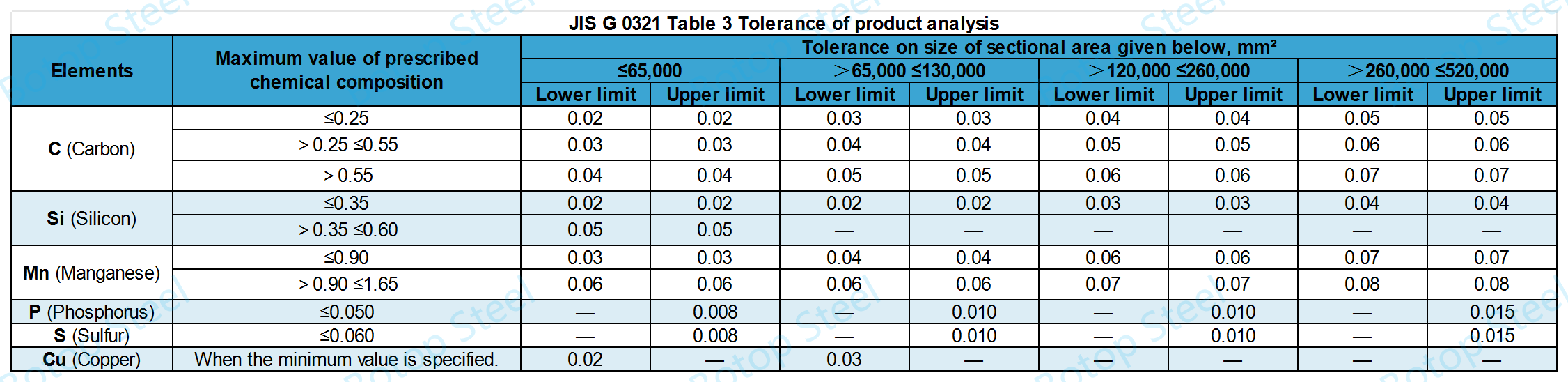

The heat analysis shall be in accordance with JIS G 0320. The product analysis shall be in accordance with JIS G 0321.

| grade | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| STS370 | 0.25% max | 0.10-0.35% | 0.30-1.10% | 0.35% max | 0.35% max |

Heat analysis is mainly aimed at testing the chemical composition of raw materials.

By analyzing the chemical composition of raw materials, it is possible to predict and adjust the processing steps and conditions that may be required in the production process, such as heat treatment parameters and the addition of alloying elements.

Product analysis analyzes the chemical composition of finished products to verify compliance and quality of the final product.

Product analysis ensures that all changes, additions or any possible impurities in the product during the manufacturing process are under control and that the final product meets the technical specifications and application requirements.

JIS G 3455 the values of the product analysis shall not only comply with the requirements of the elements in the above table, but also the tolerance range shall comply with the requirements of JIS G 3021 Table 3.

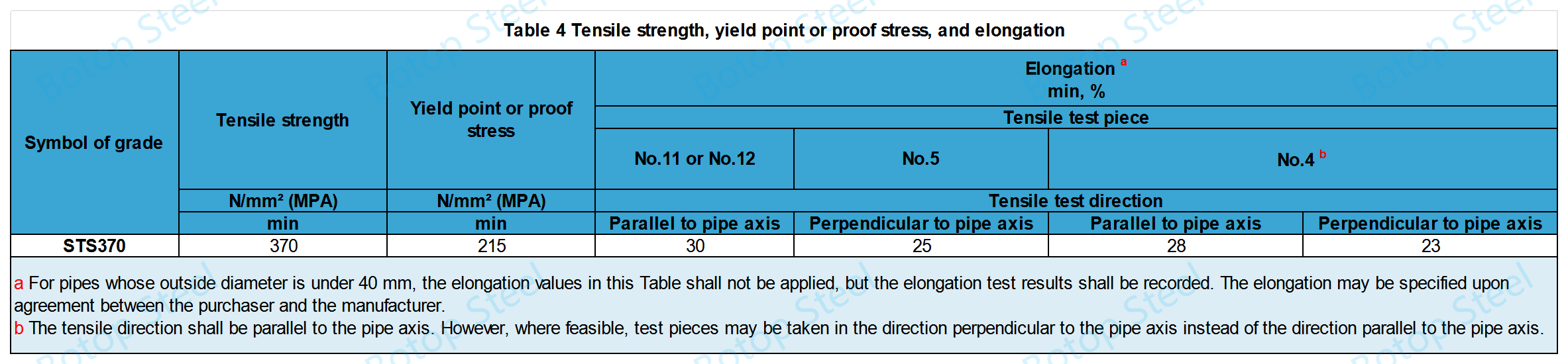

Elongation values for Test piece No. 12 (parallel to pipe axis) and Test piece No. 5 (perpendicular to pipe axis) taken from pipes under 8 mm in wall thickness.

| Symbol of grade | Test piece used | Elongation min, % |

||||||

| Wall thickness | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| STS370 | No. 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| No. 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| The elongation values in this table are obtained by subtracting 1.5 % from the elongation value given in Table 4 for each 1 mm decrease in wall thickness from 8 mm, and by rounding the result to an integer according to Rule A of JIS Z 8401. | ||||||||

The flattening test may be omitted unless otherwise specified by the purchaser.

Place the specimen in the machine and flatten it until the distance between the two platforms reaches the specified value H. Then check the specimen for cracks.

When testing critical resistance welded pipe, the line between the weld and the center of the pipe is perpendicular to the compression direction.

H=(1+e)t/(e+t/D)

H: distance between platens (mm)

t: wall thickness of tube (mm)

D: outside diameter of the tube (mm)

е: constant defined for each grade of the tube. 0.08 for STS370: 0.07 for STS410 and STS480.

Suitable for pipes with an outside diameter of ≤ 50 mm.

The specimen shall be free of cracks when bent at 90° with an inside diameter 6 times the outside diameter of the pipe.

The bending angle shall be measured at the beginning of the bend.

Every steel pipe needs to be hydrostatically or non-destructively tested to ensure the quality and safety of the pipe and to meet the standards of use.

Hydraulic Test

If no test pressure is specified, the minimum hydro test pressure shall be determined in accordance with the Pipe Schedule.

| Nominal wall thickness | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Minimum hydraulic test pressure, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

When the wall thickness of the outer diameter of the steel pipe is not a standard value in the table of weight of the steel pipe, it is necessary to use the formula to calculate the pressure value.

P=2st/D

P: test pressure (MPa)

t: wall thickness of pipe (mm)

D: outside diameter of pipe (mm)

s: 60 % of the minimum value of yield point or proof stress given.

When the minimum hydrostatic test pressure of the selected plan number exceeds the test pressure P obtained by the formula, the pressure P shall be used as the minimum hydrostatic test pressure instead of selecting the minimum hydrostatic test pressure in the table above.

Non-destructive Test

Non-destructive testing of steel tubes should be performed by ultrasonic or eddy current testing.

For ultrasonic inspection characteristics, the signal from a reference sample containing a reference standard of class UD as specified in JIS G 0582 shall be considered as an alarm level and shall have a basic signal equal to or greater than the alarm level.

The standard detection sensitivity for the eddy current examination shall be category EU, EV, EW, or EX specified in JIS G 0583, and there shall be no signals equivalent to or greater than the signals from the reference sample containing the reference standard of the said category.

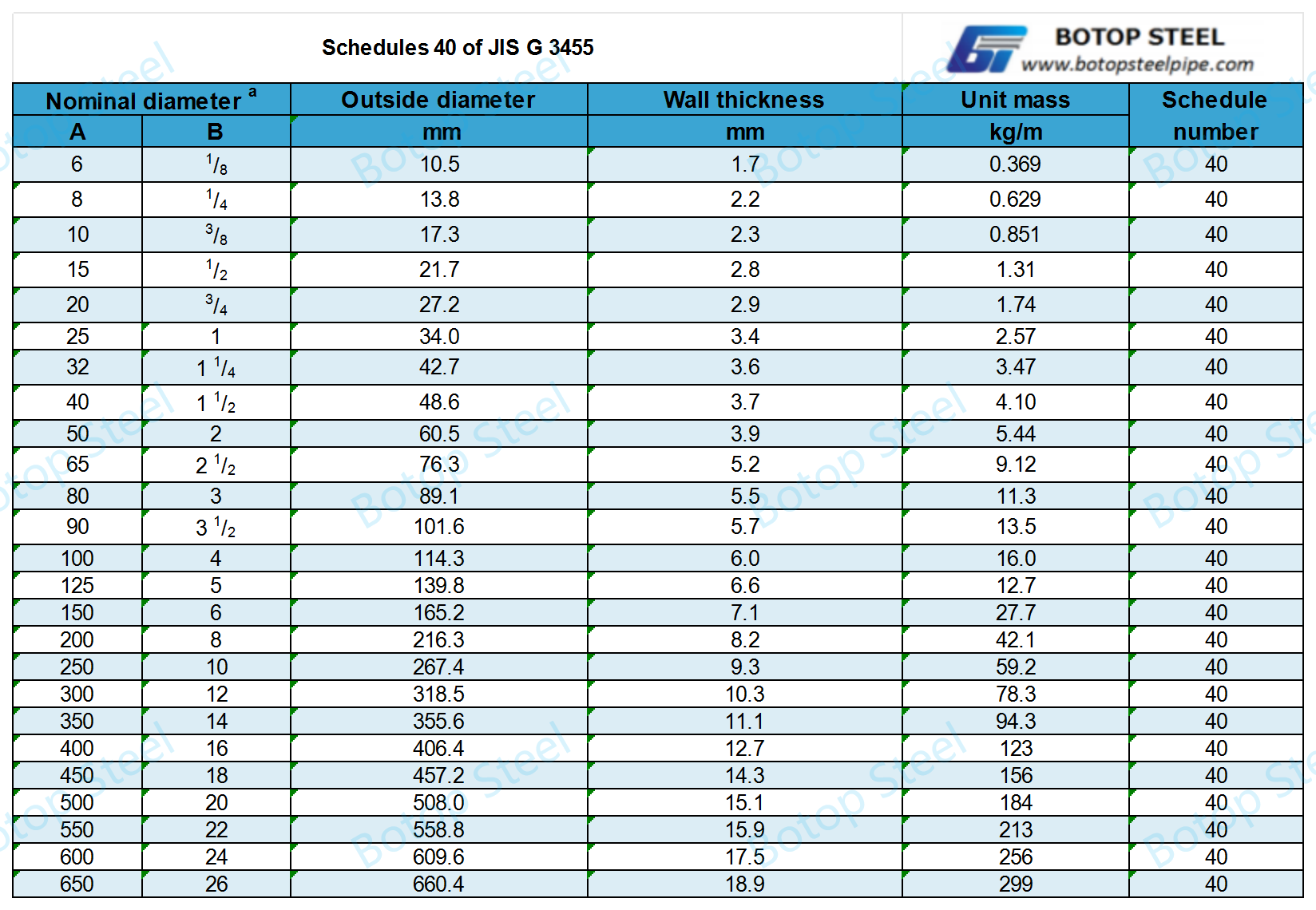

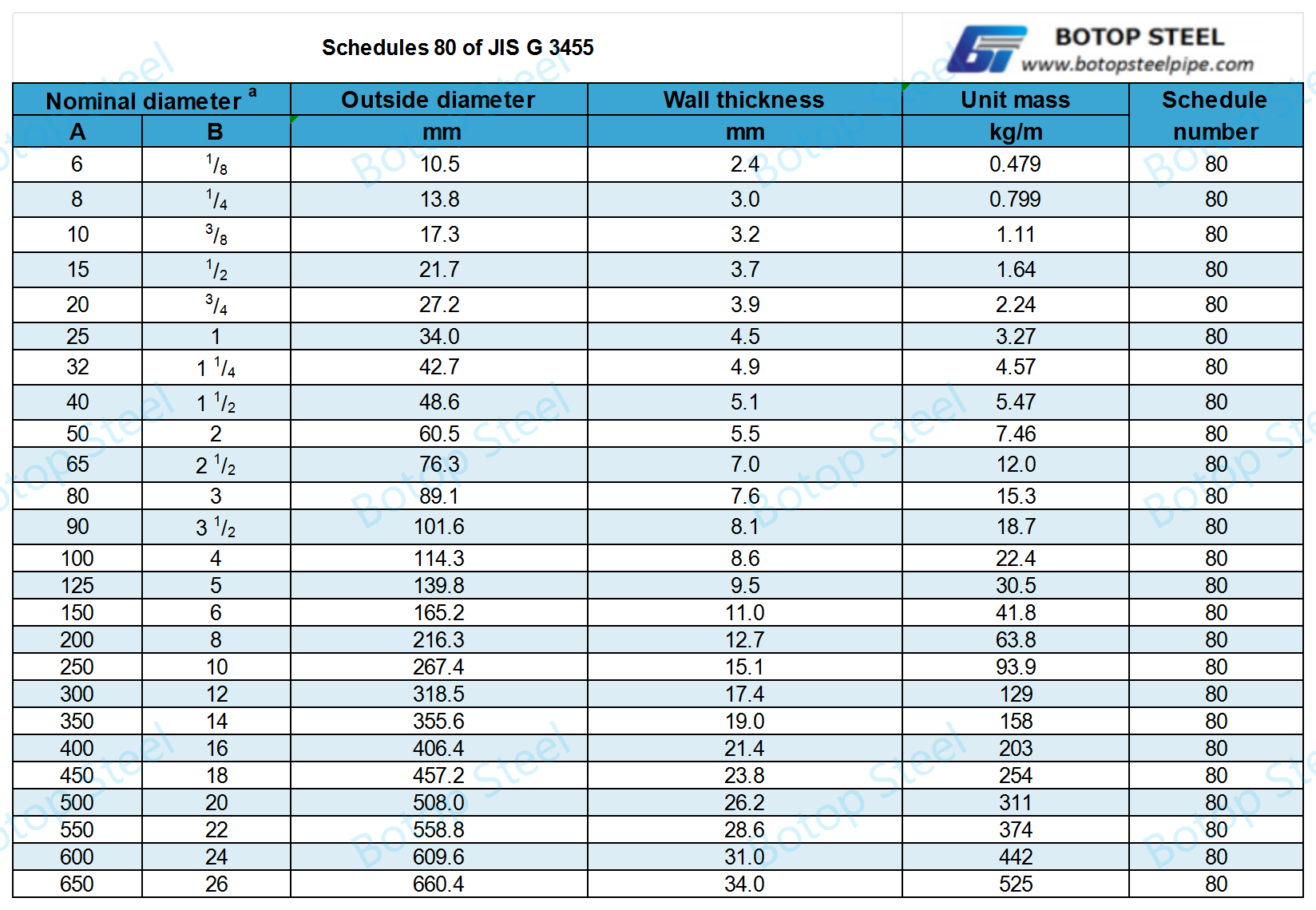

For more Pipe Weight Charts and Pipe Schedules within the standard, you can click through.

Schedule 40 pipe is ideally suited for low to medium-pressure applications because it offers a moderate wall thickness that avoids excessive weight and cost while ensuring adequate strength.

Schedule 80 piping is widely used in industrial environments that require high-pressure handling, such as chemical processing systems and oil and gas transmission piping, due to its ability to withstand higher pressures and stronger mechanical impacts due to its thicker wall thickness, providing additional safety, security, and durability.

Each tube shall be labeled with the following information.

a) Symbol of grade;

b) Symbol of the manufacturing method;

c) Dimensions Example 50AxSch80 or 60.5x5.5;

d) Manufacturer's name or identifying brand.

When the outside diameter of each tube is small and it is difficult to mark each tube, or when the purchaser requires that each bundle of tubes is marked, each bundle may be marked by an appropriate method.

STS370 is suitable for low-pressure but relatively high-temperature fluid transfer systems.

Heating systems: In city heating or large building heating systems, STS370 can be used to transport hot water or steam because it can withstand the pressure and temperature changes in the system.

Power plants: In the production of electricity, a large number of high-pressure steam pipes are required, and STS370 is the ideal material for manufacturing these pipes because it can withstand long periods of high temperature and high-pressure working environments.

Compressed air systems: In manufacturing and automated production lines, compressed air is an important source of power, and STS370 steel pipe is used to build piping for these systems to ensure safe and efficient air delivery.

Structural use and general machinery: Due to its good mechanical properties, STS370 can also be used in the manufacture of various structural and mechanical components, especially in applications where a certain compressive strength is required.

JIS G 3455 STS370 is a carbon steel material used in high-pressure service. The following materials may be considered equivalent or nearly equivalent:

1. ASTM A53 Grade B: Suitable for general structural and mechanical applications and for fluid transportation.

2. API 5L Grade B: For high-pressure oil and gas transportation pipelines.

3. DIN 1629 St37.0: For general mechanical engineering and vessel construction.

4. EN 10216-1 P235TR1: Seamless steel pipe for high temperature and high pressure environment.

5. ASTM A106 Grade B: Seamless carbon steel pipe for high-temperature service.

6. ASTM A179: Seamless cold-drawn mild steel tubes and pipes for low-temperature service.

7. DIN 17175 St35.8: Seamless tube materials for boilers and pressure vessels.

8. EN 10216-2 P235GH: Seamless tubes and pipes of non-alloy and alloy steel for high-temperature and high-pressure environments.

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions. The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels, tailored to meet the demands of various pipeline projects.