API 5L X65 PSL1/PSL2Pipa Baja Karbon LSAWdiprodhuksi dening mbentuk piring baja X65 menyang wangun bunder banjur welding lapisan liwat proses welding busur otomatis. Ing produksi sakaAPI 5L X65 PSL1&PSL2Pipa Baja Karbon LSAW, piring kelas X65 dibentuk dening mesin cetakan dadi bentuk bunder banjur dilas liwat welding busur submerged dobel.Proses produksi pipa baja jahitan lurus dilas busur submerged kalebu teknologi JCOE forming, teknologi pengelasan busur submerged coil lan teknologi UOE forming.

Proses pembuatan Longitudinal Submerged-arc Welded (LSAW) Pipa minangka nderek:

Ultrasonik plate probing → pinggiran panggilingan → wis mlengkung → mbentuk → Pra-welding → Internal welding → External welding → Ultrasonik inspeksi → X-ray inspeksi → Expanding → hydraulic test → l. Chamfering → Inspeksi ultrasonik → inspeksi sinar-X → inspeksi partikel magnetik ing ujung tabung

| Jeneng produk | Pipa Baja LSAW |

| Proses | LSAW-UO(UOE), RB (RBE), JCO(JCOE) |

| Standar | API 5L, API 5CT, ASTM 53, EN10219, GB/T3091, GB/T9711 |

| Sertifikat | ISO9001 ISO45001 IS014001 BV BC1 EN10219 EN10210 ASTM A500/501 JIS G3466 EPD PHD |

| Diameter metu | 406mm-1500mm |

| Kekandelan tembok | 8-50 mm |

| dawa | 1-12M utawa minangka panyuwunan |

| sasmita | API X42 X52 X60 X65 X70 GR.A GR.B GR.C,S275JOH,S355JR,S355JOH,S355J2H,S355S235, S420, S460 |

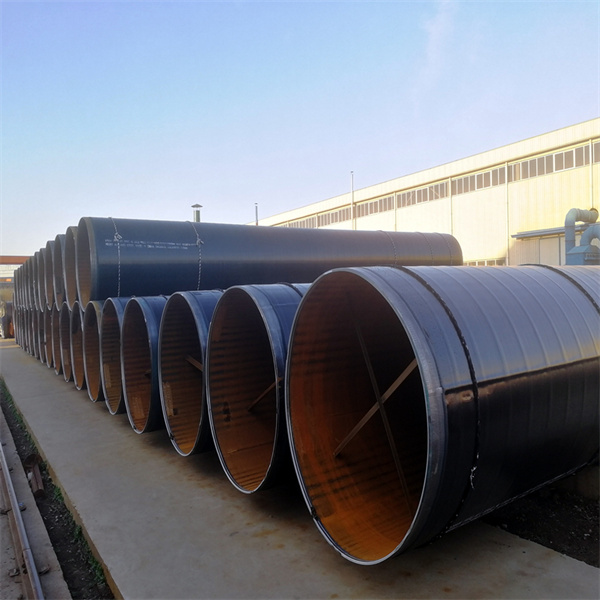

| lumahing | Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating sesuai kebutuhan pelanggan |

| Tes | Analisis Komponen Kimia, Sifat Mekanik (Kekuatan tarik akhir, Hasilkekuatan, Elongation), Sifat Teknis (Tes Flattening, Tes Mlengkung, Tes Blow, Tes Dampak), Inspeksi Ukuran Eksterior, HidrostatikTes, Tes X-ray. |

| MOQ | 5 ton |

| END | Biasa, Bevel |

| Paket | Ing bundel, potongan longgar. |

API 5L X65 PSL1/PSL2Pipa Baja Karbon LSAWbiasane digunakake ing proyek pipa lenga lan gas, pipa submarine, lan pipa liwat zona dhuwur lan wilayah kutha sing padhet.

Kasus Teknik Hong Kong

Kasus Teknik Qatar

Kasus Teknik Iran

Properti Mekanik API 5L GR.B X65 (PSL1) / API 5L X70 (PSL1):

| sasmita | Kekuwatan Ngasilake(MPa) | Kekuwatan Tensile(MPa) | Elongation A% | ||

|

| psi | MPa | psi | MPa | Elongation (Min) |

| X65 | 65.000 | 448 | 77.000 | 531 | 18 |

| X70 | 70.000 | 483 | 82.000 | 565 | 18 |

Sifat Mekanik KabAPI 5LX65 PSL1/PSL 2(PSL2) / API 5L Grade X70 (PSL 2):

| sasmita | Kekuwatan Ngasilake(MPa) | Kekuwatan Tensile(MPa) | Elongation A% | Dampak (J) | ||

|

| psi | MPa | psi | MPa | Elongation (Min) | Min |

| X65 | 65.000 | 448 | 87.000 | 600 | 18 | 40 |

| X70 | 70.000 | 483 | 90.000 | 621 | 18 | 40 |

Pengujian RT

Pengujian Hidrostatik

Pengujian UT

Komposisi Kelas lan Kimia (%)Kanggo API 5LX65PSL1 / API 5L X70 PSL1

| Standar |

sasmita | Komposisi kimia(%) | |||

| C | Mn | P | S | ||

| API 5L | X65 | ≤0,26 | ≤1.45 | ≤0,030 | ≤0,030 |

| API 5L | X70 | ≤0,26 | ≤1,65 | ≤0,030 | ≤0,030 |

| Ukuran | Typeof Pipa | Ttoleransi1(Persen Kekandelan Tembok Ditemtokake} | |

| Grade B utawa Lower | Kelas X42 utawa luwih dhuwur | ||

| <2 7/8 | Kabeh | +20.- 12.5 | + 15.0.-12.5 |

| >2 7/8lan<20 | Kabeh | + 15,0,-12,5 | + 15-I2.5 |

| > 20 | Dilas | + 17.5.-12.5 | + 19.5.-8.0 |

| > 20 | mulus | + 15.0.-12.5 | + 17.5.-10.0 |

Yen toleransi negatif sing luwih cilik tinimbang sing kadhaptar ditemtokake dening panuku, toleransi positif kudu ditambah menyang kisaran toleransi total sing ditrapake ing persen kurang saka toleransi negatif kekandelan tembok.

Lukisan Ireng

3 LPE Coating

FBE Coating

Pipa Baja API 5L X70 LSAW

Pipa Baja API 5L X65 LSAW

Pipa Baja Karbon LSAW

LSAW STEEL PIPE KARO COATING 3PE

DN1400 DIAMETER BESAR LSAW STEEL PIPE